ISO 24698-2:2008

(Main)Rubber, raw — Determination of bound acrylonitrile content in acrylonitrile-butadiene rubber (NBR) — Part 2: Kjeldahl method

Rubber, raw — Determination of bound acrylonitrile content in acrylonitrile-butadiene rubber (NBR) — Part 2: Kjeldahl method

ISO 24698-2:2008 specifies a method for the determination of the bound acrylonitrile content in NBR by an automatic analyser which uses the Kjeldahl method.

Caoutchouc brut — Détermination du contenu en acrylonitrile lié dans le caoutchouc acrylonitrile-butadiène (NBR) — Partie 2: Méthode Kjeldahl

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 24698-2

First edition

2008-05-15

Rubber, raw — Determination of bound

acrylonitrile content in acrylonitrile-

butadiene rubber (NBR) —

Part 2:

Kjeldahl method

Caoutchouc brut — Détermination du contenu en acrylonitrile lié dans le

caoutchouc acrylonitrile-butadiène (NBR) —

Partie 2: Méthode Kjeldahl

Reference number

ISO 24698-2:2008(E)

©

ISO 2008

---------------------- Page: 1 ----------------------

ISO 24698-2:2008(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

©

ii ISO 2008 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 24698-2:2008(E)

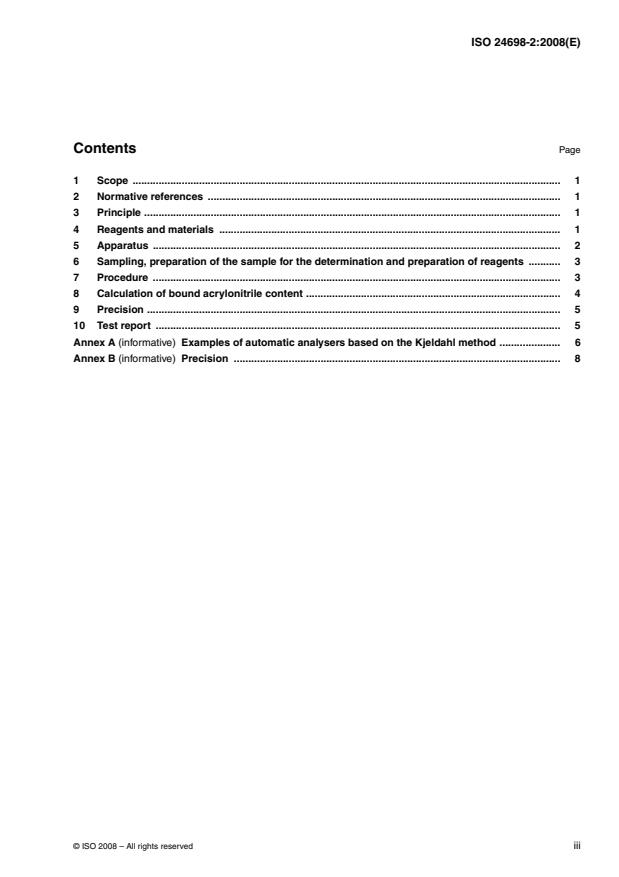

Contents Page

1 Scope . 1

2 Normative references . 1

3 Principle . 1

4 Reagents and materials . 1

5 Apparatus . 2

6 Sampling, preparation of the sample for the determination and preparation of reagents . 3

7 Procedure . 3

8 Calculation of bound acrylonitrile content . 4

9 Precision . 5

10 Test report . 5

Annex A (informative) Examples of automatic analysers based on the Kjeldahl method . 6

Annex B (informative) Precision . 8

©

ISO 2008 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 24698-2:2008(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the International

Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 24698-2 was prepared by Technical Committee ISO/TC 45, Rubber and rubber products, Subcommittee

SC 2, Testing and analysis.

ISO 24698 consists of the following parts, under the general title Rubber, raw — Determination of bound

acrylonitrile content in acrylonitrile-butadiene rubber (NBR):

— Part 1: Combustion (Dumas) method

— Part 2: Kjeldahl method

©

iv ISO 2008 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 24698-2:2008(E)

Rubber, raw — Determination of bound acrylonitrile content in

acrylonitrile-butadiene rubber (NBR) —

Part 2:

Kjeldahl method

WARNING — Persons using this part of ISO 24698 should be familiar with normal laboratory practice.

This part of ISO 24698 does not purport to address all of the safety problems, if any, associated with its

use. It is the responsibility of the user to establish appropriate safety and health practices and to

ensure compliance with any national regulatory conditions.

CAUTION — Certain procedures specified in this part of ISO 24698 may involve the use or generation of

substances, or the generation of waste, that could constitute a local environmental hazard. Reference

should be made to appropriate documentation on safe handling and disposal after use.

1Scope

This part of ISO 24698 specifies a method for the determination of the bound acrylonitrile content in NBR by an

automatic analyser which uses the Kjeldahl method.

NOTE Parts 1 and 2 of this International Standard may not necessarily give the same result for any given rubber sample.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced document

(including any amendments) applies.

ISO 1407:1992, Rubber — Determination of solvent extract

ISO 1795, Rubber, raw natural and raw synthetic — Sampling and further preparative procedures

3 Principle

The nitrogen in a sample of raw rubber is converted into an ammonium salt by digestion with potassium sulfate,

sulfuric acid and a copper sulfate catalyst. Ammonia is then released by the addition of strong alkali and steam-

distilled into boric acid solution and titrated with standard volumetric acid solution.

4 Reagents and materials

4.1 Reference material: ammonium sulfate, purity � 99,5 %.

4.2 Standard volumetric acid solutions:

3

— sulfuric acid solution, 0,05 mol/dm ;

3

— hydrochloric acid solution, 0,05 mol/dm .

3

4.3 Sulfuric acid, .ρ = 1,84 g/cm

©

ISO 2008 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 24698-2:2008(E)

3

4.4 Sodium hydroxide solution, .10 mol/dm

4.5 Potassium sulfate (K SO ).

2 4

4.6 Copper sulfate (CuSO ·5H O).

4 2

4.7 Indicators, in accordance with the analyser manufacturer's instructions:

— methyl red;

— methylene blue;

— bromophenol blue.

4.8 Boric acid solution, in accordance with the analyser manufacturer's instructions (commonly, 3% or 4%

solution).

4.9 Ethanol, purity � 95 % by volume.

4.10 Methanol, purity � 99,8 % by volume.

5 Apparatus

5.1 Automatic analyser.

5.1.1 General

The automatic analyser consists of the following components:

a) a digestion unit, capable of maintaining a minimum operating temperature in accordance with the

manufacturer's instructions for digestion of the sample;

b) a digestion tube, capable of being used for both digestion and distillation;

c) a distillation unit, capable of introducing a fixed volume of sodium hydroxide into the digestion tube when it

is placed in the unit and of steam-distilling, for a fixed time, the liberated NH and condensing it into a fixed

3

volume of ammonia-absorbing boric acid solution in a titration vessel;

d) a titration unit, capable of introducing the boric acid solution into the titration vessel before distillation and of

titrating the distillate with standard volumetric acid solution photometrically using a photo-cell or

potentiometrically;

e) a microprocessor, capable of calibrating the instrument with a reference material and of converting the

titration result into mass % of nitrogen in the sample.

5.1.2 Performance requirements

The accuracy of the system shall be demonstrated by performing ten successive determinations using a

reference material such as ammonium sulfate. The mean of the ten determinations with the reference material

± 0,2

shall be within percentage points of the theoretical value. The relative standard deviation shall be within

0,5 % by mass of nitrogen for the reference material.

s

NOTE Relative standard deviation (%) = × 100

w

N

where

s is the standard deviation;

w is the mean nitrogen content, in mass %.

N

5.2 Balance, weighing to the nearest 0,1 mg.

5.3 Extraction apparatus, as specified for method B in ISO 1407:1992.

©

2 ISO 2008 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 24698-2:2008(E)

3

5.4 Beaker, capacity 300 cm .

5.5 Stirrer.

5.6 Sieve, aperture 150µm.

5.7 Absorbent tissue.

◦ ◦

5.8 Drying oven, capable of maintaining a temperature of 100 C± 2 C.

◦ ◦

5.9 Roll mill, the temperature of whose rolls can be maintained at 100 C± 5 C.

6 Sampling, preparation of the sample for the determination and preparation of

reagents

6.1 Sampling and preparation of the sample for the determination

Take a sample of 10 g to 50 g in accordance with the method specified in ISO 1795, and pass the sample

between the surfaces of the mill rolls with the nip set at 0,2 mm± 0,05 mm and with the surface temperature of

◦ ◦

the rolls maintained at 100 C± 5 C.

Take a portion of about 3g to 5g from the sample prepared as specified above.

Extract this portion with ethanol by method B in ISO 1407:1992 and rinse the extracted material twice with a

small amount of fresh ethanol. Pour the contents of the flask onto a clean 150µm sieve to recover the extracted

material. Gently blot the extracted material with absorbent tissue to remove excess solvent, and dry the pieces

◦ ◦

of extracted rubber, separated from each other, in the oven at 100 C± 2 C until the mass does not change by

more than 0,1 mg over a period of 10 min.

6.2 Preparation of reag

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.