ISO 3605:1987

(Main)Textile glass — Rovings — Determination of compressive strength of rod composites

Textile glass — Rovings — Determination of compressive strength of rod composites

Verre textile — Stratifils — Détermination de la résistance à la compression sur joncs

General Information

Relations

Standards Content (Sample)

IS0

INTERNATIONAL STANDARD

3605

Second edition

1987-05-01

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION

ORGANISATION INTERNATIONALE DE NORMALISATION

MEXaYHAPOAHAR OPrAHMSAI#lR fl0 CTAHflAPTMSAL(i4M

Textile glass - Rovings - Determination of

compressive strength of rod composites

Verre textile - Stratifils - Détermination de la résistance à la Compression sur joncs

Reference number

IS0 3605 : 1987 (E)

---------------------- Page: 1 ----------------------

Foreword

IS0 (the international Organization fôr Standardization) is a worldwide federation of

national standards bodies (IS0 member bodies). The work of preparing International

Standards is normally carried out through IS0 technical committees. Each member

body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, govern-

mental and non-governmental, in liaison with ISO, also take part in the work.

Draft International Standards adopted by the technical committees are circulated to

the member bodies for approval before their acceptance as International Standards by

the IS0 Council. They are approved in accordance with IS0 procedures requiring at

least 75 % approval by the member bodies voting.

International Standard IS0 3605 was prepared by Technical Committee ISO/TC 61,

Plastics.

This second edition cancels and replaces the first edition (IS0 3605 : 19781, clauses 1,

3, 4 and 5 of which have been technically revised.

Users should note that all International Standards undergo revision from time to time

and that any reference made herein to any other International Standard implies its

latest edition, unless otherwise stated.

0 International Organization for Standardization, 1987 O

Printed in Switzerland

---------------------- Page: 2 ----------------------

INTERNATIONAL STANDARD IS0 3605 : 1987 (E)

Textile glass - Rovings - Determination of

compressive strength of rod composites

1 Scope and field of application 3.2 Resin.

This International Standard specifies a method foi' determining

Not all resin systems are necessarily suitable and the system to

the compressive strength of composite rods of circular cross- be used shall be at the discretion of the roving supplier. In the

section made from rovings.

event of dispute, the system used shall be declared and shall

form the basis for the test, subject to an agreement between

This test may be made on rods as moulded, or on rods that

the interested parties. The selected resin system shall be mixed

have been in boiling water for a specified time. in accordance with the resin manufacturer's detailed instruc-

tions. (See the annex.)

This test is intended for inspection testing and quality control of

rovings and the results obtained shall not be used for the

3.3 Metal wire, for pulling the roving through the mould

generation of design data.

(3.1).

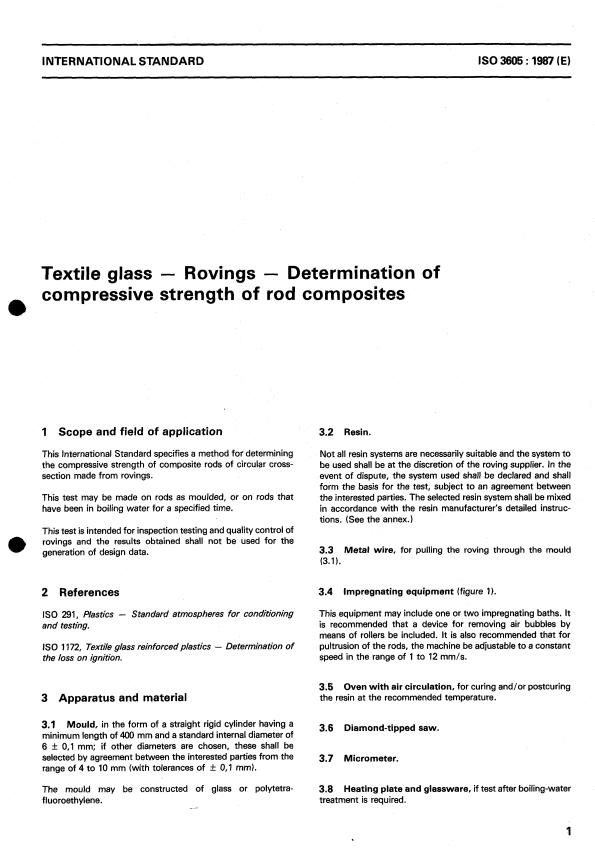

3.4 impregnating equipment (figure I).

2 References

This equipment may include one or two impregnating baths. It

IS0 291, Plastics - Standard atmospheres for conditioning

is recommended that a device for removing air bubbles by

and testing.

means of rollers be included. It is also recommended that for

pultrusion of the rods, the machine be adjustable to a constant

IS0 1172, Textile glass reinforced plastics - Determination of

speed in the range of 1 to 12 mm/s.

the loss on ignition.

Oven with air circulation, for curing and/or postcuring

3.5

3 Apparatus and material the resin at the recommended temperature.

3.1 Mould, in the form of a straight rigid cylinder having a

3.6 Diamond-tipped saw.

minimum length of 400 mm and a standard internal diameter of

6 f 0,l mm; if other diameters are chosen, these shall be

selected by agreement between the interested parties from the

3.7 Micrometer.

range of 4 to 10 mm (with tolerances of _+ 0,l mm).

The mould may be constructed of glass or polytetra-

3.8 Heating plate and glassware, if test after boiling-water

fluoroethylene. treatment is required.

_.

1

---------------------- Page: 3 ----------------------

IS0 3605 : 1987 (E)

'c

O

r

O

---------------------- Page: 4 ----------------------

IS0 3605 : 1987 (E)

5 Procedure

3.9 Compression testing machine, capable of maintaining

a constant speed of 1 mm/min.

5.1 Preparation of the rovings

3.10 Two test jigs, as shown, for example, in figure 2, each Take a parallel assembly of rovings, 1 m long (or more

consisting of

according to mould length) and of the correct mass (approxi-

mately 15 g for the rods of 6 mm diameter) to give a glass

a) a base plate X;

content in the moulded rod of 65 I 3 % (mim).

b) an elastic compressive pad Y (for example of

polyamide);

5.2 Preparation of reinforced rods

c) a support ring Z.

Fold the roving assembly about its midpoint and secure the

hank at this point to a length of the wire (3.3). Condition for at

least 16 h in one of the standard laboratory atmospheres

defined in IS0 291. Take care to minimize contamination of the

roving during handling.

Dimensions in millimetres

Impregnate the roving by immersion in a bath containing the

catalysed resin (3.2) or by any other suitable means. In order to

Test specimen

obtain a good impregnation, it is desirable to eliminate air

bubbles within the filaments. A good way to do this is to pull

di

the impregnated rovings under metallic rollers. Another

method is to pull the specimen vertically. When the roving is

completely impregnated, draw it into the mould (3.1) by means

of the wire. This drawing shall be done at a constant speed,

preferably using an adjustable-speed motor capable of pulling

the wire at a speed in the range of 1 to 10 mm/s.

2

Draw the lower end of the roving a few millimetres into the

inside of the mould and prevent flow-out of resin by sealing the

I

opening of the mould with a cork or plastic stopper, or by a

cellophane bag sealed over the opening of the mould with

. CI

cellulose tape.

Y (polyamide)

Prepare in this way a number of rods sufficient to run at least

15 compressive strength tests (or 30 if the compressive

strength is also to be determined after treatment with boiling

water).

QS a

lil-

5.3 Curing of the rods

Cu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.