ISO 15573:1998

(Main)Practice for dosimetry in an electron-beam facility for radiation processing at energies between 80 keV and 300 keV

Practice for dosimetry in an electron-beam facility for radiation processing at energies between 80 keV and 300 keV

Pratique de la dosimétrie de faisceaux d'électrons pour irradiations à des énergies comprises entre 80 keV et 300 keV

General Information

- Status

- Withdrawn

- Publication Date

- 19-Dec-1998

- Withdrawal Date

- 19-Dec-1998

- Drafting Committee

- ISO/TC 85/WG 3 - Dosimetry for radiation processing

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 18-Apr-2002

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 15-Apr-2008

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

ISO 15573:1998 is a standard published by the International Organization for Standardization (ISO). Its full title is "Practice for dosimetry in an electron-beam facility for radiation processing at energies between 80 keV and 300 keV". This standard covers: Practice for dosimetry in an electron-beam facility for radiation processing at energies between 80 keV and 300 keV

Practice for dosimetry in an electron-beam facility for radiation processing at energies between 80 keV and 300 keV

ISO 15573:1998 is classified under the following ICS (International Classification for Standards) categories: 17.240 - Radiation measurements. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 15573:1998 has the following relationships with other standards: It is inter standard links to ISO/ASTM 51818:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 15573:1998 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IS0

STANDARD

First edition

1998-12-15

Practice for dosimetry in an electron-beam

facility for radiation processing at energies

between 80 keV and 300 keV

Pratique de la dosimktrie de faisceaux d ’6lectrons pour irradiations ti des

bergies comprises entre 80 keV et 300 keV

Reference number

IS0 15573: 1998(E)

IS0 15573: 1998(E)

Foreword

IS0 (the International Organization for Standardization) is a worldwide federation of national standards bodies

(IS0 member bodies). The work of preparing International Standards is normally carried out through IS0 technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. IS0 collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

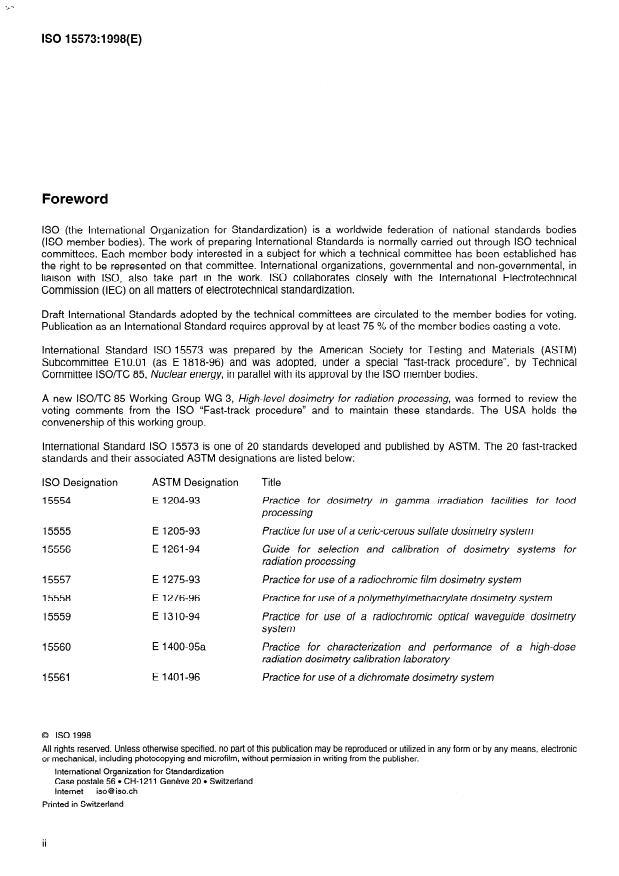

International Standard IS0 15573 was prepared by the American Society for Testing and Materials (ASTM)

Subcommittee E1O.O1 (as E 1818-96) and was adopted, under a special “fast-track procedure ”, by Technical

Committee ISOflC 85, Nuclear energy, in parallel with its approval by the IS0 member bodies.

A new ISOflC 85 Working Group WG 3, High-/eve/ dosimetry for radiation processing, was formed to review the

voting comments from the IS0 “Fast-track procedure” and to maintain these standards. The USA holds the

convenership of this working group.

International Standard IS0 15573 is one of 20 standards developed and published by ASTM. The 20 fast-tracked

standards and their associated ASTM designations are listed below:

IS0 Designation ASTM Designation Title

E 1204-93

15554 Practice for dosimetty in gamma irradiation facilities for food

processing

15555 E 1205-93 Practice for use of a ceric-cerous sulfate dosimetry system

15556 E 1261-94 Guide for selection and calibration of dosimetry systems for

radiation processing

15557 E 1275-93 Practice for use of a radiochromic film dosimetry system

15558 E 1276-96 Practice for use of a polymethylmethacry~ate dosimetry system

15559 E 1310-94 Practice for use of a radiochromic optical waveguide dosimetry

system

15560 E 1400-95a Practice for characterization and pen ’ormance of a high-dose

radiation dosimetry calibration labora tory

E 1401-96 Practice for use of a dichromate dosimetry system

0 IS0 1998

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case postale 56 l CH-1211 Geneve 20 l Switzerland

iso @ iso.ch

Internet

Printed in Switzerland

ii

IS0 15573:1998(E)

@ IS0

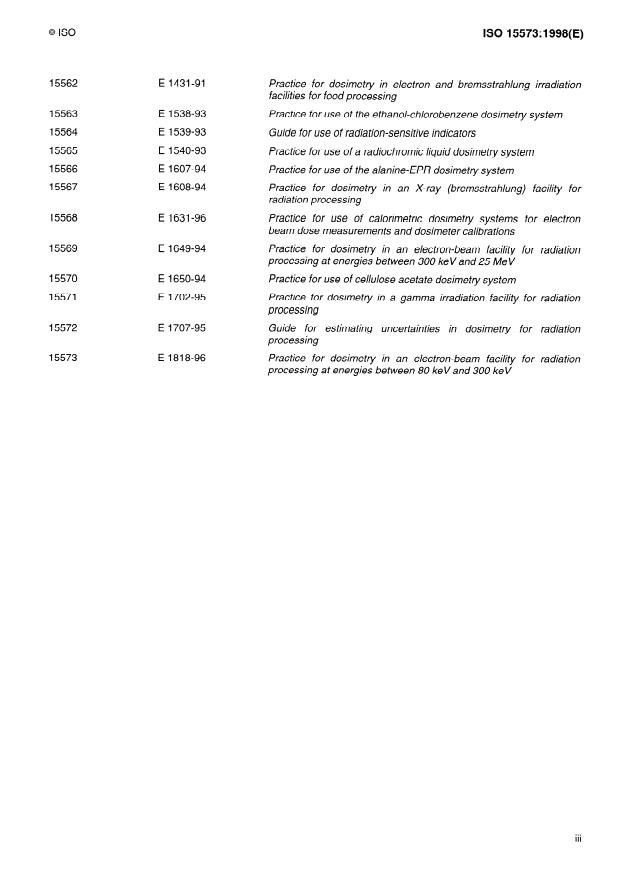

15562 E1431-91 Practice for dosimetry in electron and bremsstrahlung irradiation

facilities for food processing

15563 E 1538-93 Practice for use of the ethanol-chlorobenzene dosimetry system

E 1539-93 Guide for use of radiation-sensitive indicators

15565 E 1540-93 Practice for use of a radiochromic liquid dosimetry system

E 1607-94 Practice for use of the alanine-EPR dosimetry system

15567 E 1608-94 Practice for dosimetry in an X-ray (bremss tra hlung) facility

radiation processing

15568 E 1631-96 Practice for use of calorimetric dosimetry systems for electron

beam dose measurements and dosimeter calibrations

E 1649-94 Practice for dosimetry in an electron-beam facility for radiation

processing at energies between 300 keV and 25 MeV

Practice for use of cellulose acetate dosimetry system

15570 E 1650-94

dosimetry in a facility for radiation

15571 E 1702-95 Practice for gamma irradiation

processing

15572 E 1707-95 Guide for estimating uncertainties in dosimetry for radiation

processing

Practice for dosimetry in an electron-beam facility for radiation

15573 E 1818-96

processing at energies between 80 keV and 300 keV

@ IS0 IS0 15573: 1998(E)

Designation: E 1818 - 96

Standard Practice for

Dosimetry in an Electron Beam Facility for Radiation

Processing at Energies Between 80 and 300 keV1

This standard is issued under the fixed designation E 18 18; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (c) indicates an editorial change since the last revision or reapproval.

2.3 Methods for Calculating Absorbed Dose and Dose

1. Scope

Distribution?

1.1 This practice covers dosimetric procedures to be

ZTRAN Monte Carlo Code

followed to determine the performance of low energy (300

Integrated Tiger Series (ITS) Monte Carlo Codes

keV or less) single-gap electron beam radiation processing

Energy Deposition in Multiple Layers (EDMULT) Elec-

facilities. Other practices and procedures related to facility

tron Gamma Shower (EGS43) Monte Carlo Codes

characterization, product qualification, and routine pro-

cessing are also discussed.

3. Terminology

1.2 The electron energy range covered in this practice is

from 80 keV to 300 keV. Such electron beams can be

3.1 Dejnitions:

generated by single-gap self-contained thermal filament or

3.1.1 Definitions of terms used in this practice may be

plasma source accelerators.

found in Terminology E 170 and ICRU Report 33.

1.3 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, zf any, associated with its use. It is the

3.2.1 absorbed dose (D), n-quantity of ionizing radiation

responsibility of the user of this standard to establish appro-

energy imparted per unit mass of a specified material. The SI

priate safety and health practices and determine the applica-

unit of absorbed dose is the gray (Gy), where 1 gray is

bility of regulatory limitations prior to use.

equivalent to the absorption of 1 joule per kilogram of the

specified material (1 Gy = 1 J/kg). The mathematical

2. Referenced Documents

relationship is the quotient of dc by dm, where d ’7 is the

mean incremental energy imparted by ionizing radiation to

2.1 ASTM Standards:

matter of incremental mass dm (see ICRU Report 33).

170 Terminology Relating to Radiation Measurements

and Dosimetry2 dT

D=-&

(1)

177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods3

3.2.1.1 Discussion-The discontinued unit for absorbed

456 Terminology Relating to Quality and Statistics3

dose is the rad (1 rad = 100 erg/g = 0.0 1 Gy). Absorbed dose

126 1 Guide for Selection and Calibration of Dosimetry

is sometimes referred to simply as dose.

Systems for Radiation Processing2

3.2.2 air gap, n-the distance between the product plane

1275 Practice for Use of a Radiochromic Film

and the electron beam window.

Dosimetry System2

3.2.3 backscatter, n-the term used to describe additional

1276 Practice for Use of a Polymethylmethacrylate

absorbed dose caused by scatter of the primary electron

Dosimetry System2

beam from nearby material.

1607 Practice for Use of the Alanine-EPR Dosimetry

3.2.4 beam current, n-time-averaged electron beam cur-

System2

rent delivered from the accelerator.

1650 Practice for Use of a Cellulose Acetate Dosimetry

3.2.5 beam length, n-non-scanned electron beam, the

System2

active length of the cathode assembly in vacuum parallel to

1707 Guide for Estimating Uncertainties in Dosimetry

the product flow and perpendicular to the beam width.

for Radiation Processing2

3.2.6 beam power, n-the product of the average electron

2.2 International Commission on Radiation Units and

beam energy and the average beam current (unit kVV).

Measurements (ICR U) Reports?

3.2.7 beam width, n-non-scanned electron beam, the

ICRU Report 33 Radiation Quantities and Units

active width of the cathode assembly in vacuum perpendic-

ICRU Report 37 Stopping Powers for Electrons and

ular to the product flow and beam length.

Positrons

3.2.8 b&processing rate, n-mass throughput rate based

on the output power in watts of the electron beam, the mass

of the irradiated material and the dose. Expressed in kilogray

1 This practice is under the jurisdiction of ASTM Committee E-10 on Nuclear

Technology and Applications and is the direct responsibility of Subcommittee

kilograms per kilowatt hour or Megarad pounds per kilowatt

E 10.01 on Dosimetry for Radiation Processing

hour.

Current edition approved June 10, 1996. Published August 1996.

2 Annual Book of ASTM Standards, Vol 12.02.

3 Annual Book ofASTM Standards, Vol 14.02.

4Availablc from the International Commission on Radiation Units and s Available from the Radiation Shielding Information Center (RSIC), Oak

Ridge National Laboratory (ORNL), P.O. Box 2008, Oak Ridge, TN 37831.

Measurements, 7910 Woodmont Ave., Suite 800, Bethesda, MD 208 14.

@ IS0

IS0 15573: 1998(E)

3.2.18 product plane, n-the plane corresponding to the

3.2.9 depth-dose distribution, n-variation of absorbed

top surface of the product being irradiated.

dose with depth from the incident surface of a material

3.2.19 self-shielded accelerator, n-an electron beam

exposed to a given radiation (see Fig. 1 for calculated values).

source that is integrally designed with radiation shielding,

3.2.10 dose uniformity ratio, n-ratio of the maximum to

product transport system, and irradiation chamber.

the minimum absorbed dose within the process load. The

3.2.20 single-gap accelerator, n-an electron beam source

concept is also referred to as the max/min dose ratio.

consisting of a vacuum tube and a high voltage power supply

3.2.11 dosimeter, n-a device that, when irradiated, ex-

that can accelerate a dispersed beam of electrons from a high

hibits a quantifiable change in some property of the device

voltage potential to ground potential in one stage.

which can be related to absorbed dose in a given material

3.2.21 surface area rate coeficient (K), n-a quantity

using appropriate analytical instrumentation and techniques.

relating area irradiated per unit time to beam current and

3.2.12 dosimetry system, n-a system used for deter-

absorbed dose. Typically this value is expressed in kGy

mining’ absorbed dose, consisting of dosimeters, measure-

meters2 per milliampere minute, or Megarad feet2 per

ment instruments, and their associated reference standards

milliampere minute. Calculated values using Monte Carlo

and procedures for the system ’s use.

simulation are shown in Table 1. In the literature, this

3.2.13 electron energy, n- kinetic energy of the acceler-

processing rate concept is sometimes called the processing

ated electron beam (units-ev (electron volts)). Often,

coefficient.

acceleration voltage in kV is used to characterize beam

3.2.22 uncertainty, n-a parameter associated with the

energy in keV. The maximum energy of the beam inside the

result of a measurement that characterizes the dispersion of

accelerator is equal to the acceleration voltage but expressed

the values that could reasonably be attributed to the

in keV units. The beam energy at the product surface is less

measurand or derived quantity (see Guide E 1707).

than the maximum energy inside the accelerator due to

losses in the beam path, such as the window and the air gap.

4. Significance and Use

3.2.14 traceability, n-the documentation demonstrating

by means of an unbroken chain of comparisons that a 4.1 A variety of processes use low energy electron beam

measurement is in agreement within acceptable limits of accelerators to modify product characteristics. Dosimetry

uncertainty with comparable nationally or internationally requirements, the number and frequency of measurements,

recognized standards. and record keeping requirements will vary depending on the

3.2.15 practical electron range, n-distance from the inci- type and end use of the products being processed. In many

dent surface of a homogeneous material where the electron cases dosimetry may be used in conjunction with physical,

beam enters to the point where the tangent at the steepest

chemical, or biological testing of the product. In many cases

point (the inflection point) on the almost straight descending reference standards may be developed, comparing dosimetry

portion of the depth dose distribution curve meets the depth results with other quantitative product testing; for example,

axis. sterility, gel fraction, melt flow, modulus, molecular weight

3.2.16 process load, n-a volume of material with a distribution, or cure analysis tests can be used to determine

specified loading configuration irradiated as a single entity. radiation dose in specific relevant materials, Wherever pos-

3.2.17 production run, n-continuous-jlow irradiation, a

sible, the results of quantitative physical testing should be

series of process loads, consisting of materials or products used in conjunction with dosimetry in commercial radiation

having similar radiation-absorption characteristics, that are processing applications.

irradiated sequentially to a specified range of absorbed dose. 4.2 Radiation processing specifications usually include a

bmpthlQeQ6 Ptoflls Okrough FWT fidylm DoslmfIat@r

Pasod on Moata~ Carlo Codrs

tog\

125 kV\

150 kV’

175 kV’

160 kV f

0 IS0 IS0 15573:1998(E)

@ ‘i’ El818

TABLE 1 Calculated K Values at the Product Surface 6.1.3 An extended demonstration of system performance

at specified ratings,

Electron Beam Kbgray Metres2/ Megarad Feet2/Milliampere

Acceleration Voltage Milliampere Minute (K)A Minute (K)A

6.1.4 Operation of the system over the full range cf

-u__

100 kV 6.0 6.5 voltage and beam current,

125 kV 14.9 16.0

6.1.5 Radiation survey at maximum operating voltage

150 kV 24.3 25.1

and current,

23.4

175 kV 25.2

23.3 6.1.6 Mechanical inspection of the system,

200 kV 25.1

225 kV 22.7 24.4

6.1.7 Electrical inspection of the system,

250 kV 21.4 23.0

6.1.8 Performance of the inert gas system, if applicable,

275 kV 10.7 20.1

6.1.9 Performance of the ozone exhaust system, if appli-

300 kV 18.5 19.9

cable, and

A Based on Monte Carlo Integrated Tiger Series simulation, assuming Far West

6.1.10 Testing and calibration of product handling system

(FWT 60-00) film doslmeters and 12.7 mm (0.5 In.) air gap.

over the full performance range.

6.2 The second phase of qualifying an irradiation facility

minimum or maximum absorbed dose limit, or both. For a

is to characterize the performance of the equipment using

given application these limits may be set by government

dosimetry. The purpose of these measurements is to qualify

regulation or by limits inherent to the product itself.

the dose delivering characteristics of the equipment for

4.3 Critical process parameters must be controlled to

performance acceptance and for titure reference. The pro-

obtain reproducible dose distribution in processed materials.

cess should include, but not be limited to, the following:

The electron beam energy (in ev), beam current (in mA),

6.2.1 Surface Area Rate Measurements-minimum of

spatial distribution of the beam, and exposure time or

five measurements over the voltage range of interest with at

process line speed all affect absorbed dose (see Section 5). In

least five dosimeters equally spaced across the width of the

some liquid-to-solid polymerization applications (often re-

beam at the product plane at a nominal dose level. The

ferred to as radiation curing), the residual oxygen level

surface area rate measurement should be repeated at a

during irradiation must be controlled to achieve consistent

typical operating voltage level at several Merent beam

results. A high level of residual oxygen can affect product

current levels to establish and test the linearity between beam

performance in these curing applications, but it will not

current and surface dose (see Appendix Xl).

affect the absorbed dose.

6.2.2 Beam Uniformity Measurements-minimum of one

4.4 Before any radiation process can be utilized, it must

dosimeter per 2.5 cm over full width. Three measurements

be validated to determine its effectiveness. This involves

should be made at the product plane (see Appendix Xl).

testing of the process equipment, calibrating the measuring

6.2.3 Depth-dose Measurements-A minimum of three

instruments, and demonstrating the ability to deliver the

measurements should be made at each voltage covering the

desired dose within the desired dose range in a reliable and

voltage range of interest measured with the dosimetry stack

reproducible manner. The desired improvements, as well as

at the product plane (see Appendix Xl).

any undesirable effects due to radiation damage to a specific

product, should be understood.

7. Frequency of Dosimetric Measurements

7.1 Initial facility performance evaluation dosimetry

5. Dosimetry System

should be conducted in accordance with Section 6.

7.2 Product Validation-Surface area rate measurements

5.1 The documents listed in Section 2 provide detailed

should be made during product validation to compare with

information on the selection and use of appropriate

the results of product testing.

dosimetry systems for gamma-ray and electron beam imadi-

ation. Due to the limited depth of penetration of low energy

NOTE l-Absorbed dose distribution measurements may be required

electron beams and the narrOw air gaps that are inherent in for regulated processing applications.

self-shielded equipment, thin film dosimeters are usually

7.3 After Routine Maintenance-After routine mainte-

preferred over thicker systems (see Refs 1, 2, and 3,6

nance such as window changes, a minimum number of three

Practices E 1275 and E 1650, and Guide E 126 1).

surface area rate measurements should be made.

7.4 Aster Major System Maintenance-After major

system maintenance such as cathode or insulator bushing

6. Installation Qualification and Testing

replacement, a minimum number of three surface area rate

6.1 Equipment Testing-The first phase of qualifying an

and beam uniformity measurements should be made.

irradiation facility is to determine that the processing equip

7.5 Routine Process Control-Surface area rate measure-

ment performs in accordance with design specifications. The

ments can be made during a production run. In some

process should include mechanical and electrical testing of

applications process control dosimetry may be required by

the electron beam accelerator and related processin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...