ISO 4020:2001

(Main)Road vehicles — Fuel filters for diesel engines — Test methods

Road vehicles — Fuel filters for diesel engines — Test methods

ISO 4020 specifies the types of test for fuel filters in accordance with their application. It applies to fuel filters provided for road vehicles with diesel engines and for test installations for fuel injection equipment and is intended for filters having a rated flow of up to 200 l .h-1. By agreement, the tests, with some modifications, may be used for filters with higher rates of flow. The test described may be used for fuel filters located either on the pressure side or on the suction side of the fuel supply pump.

Véhicules routiers — Filtres à combustible pour moteurs diesels — Méthodes d'essai

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 4020

First edition

2001-12-15

Road vehicles — Fuel filters for diesel

engines — Test methods

Véhicules routiers — Filtres à combustible pour moteurs diesels —

Méthodes d'essai

Reference number

©

ISO 2001

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2001

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2001 – All rights reserved

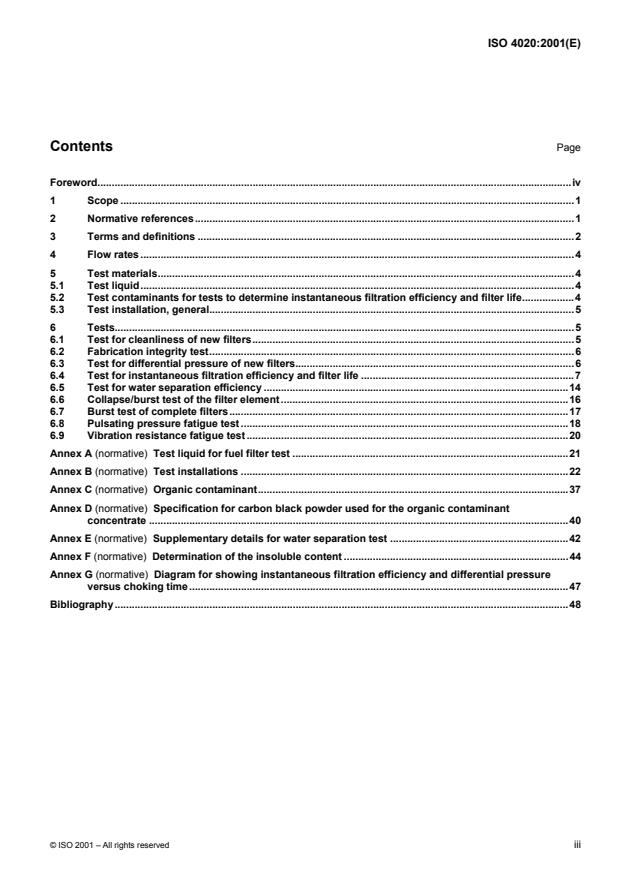

Contents Page

Foreword.iv

1 Scope .1

2 Normative references.1

3 Terms and definitions .2

4 Flow rates .4

5 Test materials.4

5.1 Test liquid.4

5.2 Test contaminants for tests to determine instantaneous filtration efficiency and filter life.4

5.3 Test installation, general.5

6 Tests.5

6.1 Test for cleanliness of new filters.5

6.2 Fabrication integrity test.6

6.3 Test for differential pressure of new filters.6

6.4 Test for instantaneous filtration efficiency and filter life .7

6.5 Test for water separation efficiency .14

6.6 Collapse/burst test of the filter element.16

6.7 Burst test of complete filters.17

6.8 Pulsating pressure fatigue test .18

6.9 Vibration resistance fatigue test .20

Annex A (normative) Test liquid for fuel filter test .21

Annex B (normative) Test installations .22

Annex C (normative) Organic contaminant.37

Annex D (normative) Specification for carbon black powder used for the organic contaminant

concentrate .40

Annex E (normative) Supplementary details for water separation test .42

Annex F (normative) Determination of the insoluble content .44

Annex G (normative) Diagram for showing instantaneous filtration efficiency and differential pressure

versus choking time.47

Bibliography.48

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 4020 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee

SC 7, Injection equipment and filters for use on road vehicles.

This first edition cancels and replaces ISO 4020-1:1979, which has been technically revised. The former Part 2 has

been withdrawn.

Annexes A to G form a normative part of this International Standard.

iv © ISO 2001 – All rights reserved

INTERNATIONAL STANDARD ISO 4020:2001(E)

Road vehicles — Fuel filters for diesel engines — Test methods

1 Scope

This International Standard specifies the types of test for fuel filters in accordance with their application.

This International Standard applies to fuel filters provided for road vehicles with diesel engines and for test

installations for fuel injection equipment.

The test described may be used for fuel filters located either on the pressure side or on the suction side of the fuel

supply pump.

−1

This International Standard is intended for filters having a rated flow of up to 200 l⋅h .

By agreement, the tests, with some modifications, may be used for filters with higher rates of flow.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this International Standard. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this International Standard are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO 565:1990, Test sieves — Metal wire cloth, perforated metal plate and electroformed sheet — Nominal sizes of

openings

ISO 760:1978, Determination of water — Karl Fischer method (General method)

1)

ISO 2719:— , Determination of flash point — Pensky-Martens closed cup method

ISO 2942:1994, Hydraulic fluid power — Filter elements — Verification of fabrication integrity and determination of

the first bubble point

ISO 3016:1994, Petroleum products — Determination of pour point

ISO 3104:1994, Petroleum products — Transparent and opaque liquids — Determination of kinematic viscosity and

calculation of dynamic viscosity

ISO 3405:2000, Petroleum products — Determination of distillation characteristics at atmospheric pressure

ISO 3675:1998, Crude petroleum and liquid petroleum products — Laboratory determination of density —

Hydrometer method

1) To be published. (Revision of ISO 2719:1988)

ISO 4548-7:1990, Methods of test for full-flow lubricating oil filters for internal combustion engines — Part 7:

Vibration fatigue test

ISO 8213:1986, Chemical products for industrial use — Sampling techniques — Solid chemical products in the

form of particles varying from powders to coarse lumps

ISO 11841-1:2000, Road vehicles and internal combustion engines — Filter vocabulary — Part 1: Definitions of

filters and filter components

ISO 11841-2:2000, Road vehicles and internal combustion engines — Filter vocabulary — Part 2: Definitions of

characteristics of filters and their components

ISO 12103-2:1997, Road vehicles — Test dust for filter evaluation — Part 2: Aluminium oxide test dust

ASTM-D 971-99a, Standard Test Method for Interfacial Tension of Oil Against Water by the Ring Method

ASTM-D 2784-98, Standard Test Method for Sulfur in Liquefied Petroleum Gases (Oxy-Hydrogen Burner or Lamp)

3 Terms and definitions

For the purposes of this International Standard the terms and definitions given in ISO 11841-1, ISO 11841-2 and

the following apply.

NOTE Pressures are indicated in kPa (instead of bar) or in Pa (instead of mbar); to obtain them in bar or mbar, divide them

by 10 ⋅(100 kPa = 1 bar; 100 Pa = 1 mbar)

3.1

sedimentor

separator in which contaminant is removed by density difference

3.2

instantaneous filtration efficiency

h

ratio between the test contaminant retained versus that added, expressed as a percentage

dd-

h = 100

d

where

d is the concentration of test contaminant at filter inlet;

d is the concentration of test contaminant at filter outlet.

3.3

filter life

t or V

service interval of a filter or filter element until maintenance or replacement, expressed in minutes or until final

differential pressure is reached, expressed in litres

3.4

pressure difference

p

stat

difference in static pressure between upstream and downstream of a filter, expressed in pascals

2 © ISO 2001 – All rights reserved

3.5

rated flow

q

v

normal operating flow at which liquid is passed through a filter, expressed in litres per hour or litres per minute

NOTE The flow can be that specified by the manufacturer or as agreed between manufacturer and user.

3.6

contaminant, organic

suspension of finely divided carbon black in test liquid, formulated to provide similar filter choking characteristics to

those of normal diesel fuel

3.7

contaminant, inorganic

fused aluminium oxide dust of closely controlled particle size

NOTE It is the incombustible constituent that is added to the organic contaminant for the purpose of revealing the

instantaneous filtration efficiency property of a filter.

3.8

collapse/burst pressure of filter element

p

diff

differential pressure at which a choked filter element suffers structural failure, expressed in kilopascals

3.9

burst pressure of complete filter

p

internal pressure at which the filter housing suffers structural failure, expressed in kilopascals

3.10

fabrication integrity test

test to indicate quality standard of filter element by measurement of volume of air escaping through filter medium or

joints in unit time, when immersed in liquid at specified depth and internal pressure

NOTE The volume is measured in millilitres per minute and is given the symbol V .

B

3.11

test of cleanliness

test to enables the degree of cleanliness of new filters to be determined and reveal the amount of impurities flushed

from the clean side of the filter under specified test conditions

NOTE The amount is measured in milligrams and is given the symbol W.

3.12

test flow rate

q

t

rate at which test liquid flows through the filter during a specific test, expressed in litres per hour or litres per minute

NOTE It may be different from the rated flow q .

v

3.13

undissolved water

water dispersed in test liquid

NOTE This means diesel fuel containing water which can be separated by physical means, e. g. by centrifuging.

4 Flow rates

The test flow rate shall reflect service conditions and shall be one of the following values:

−1 −1 −1 −1 −1 −1 −1 −1 −1

10 l⋅h , 25 l⋅h , 50 l⋅h , 75 l⋅h , 100 l⋅h , 125 l⋅h , 150 l⋅h , 175 l⋅h , 200 l⋅h

or as agreed between filter manufacturer and user.

5 Test materials

5.1 Test liquid

The test liquid used for all tests, except the water separation test (see 6.5) and collapse/burst test of the filter

2)

element (see 6.6), shall be a straight mineral oil with properties as shown in annex A.

Except in tests 6.1 and 6.2, this liquid shall be used at such a temperature that the kinematic viscosity of the liquid

2 2

lies between 4 mm /s and 6 mm /s. Alternatively, the liquid shall be blended with refined spindle oil or premium

grade kerosene to give a viscosity that is between these limits at the test temperature. All test liquids shall be free

from additives apart from colouring dyes. Provision shall be made to ensure that the test liquid is free from

undissolved water. The liquid for each test shall be drawn from its storage container at a point above the zone of

sedimentation.

Before use, and if needed, all liquids shall be passed through a highly efficient filter medium, the latter being

adequately supported and suitably clamped at the edges; see the following items from B.3 (2nd, 3rd and 4th items

under Other equipment), e.g.:

vacuum pump: 85 kPa below atmospheric pressure;

filtration apparatus: filter paper disc holder;

filter paper disc or membrane: diameter 140 mm, mean pore size between 0,4 µm and 1,1 µm.

The differential pressure across the filter paper shall not exceed 85 kPa.

Providing the test liquid is suitably cleaned, it may be reused up to a maximum of 20 times.

5.2 Test contaminants for tests to determine instantaneous filtration efficiency and filter life

5.2.1 Organic contaminant concentrate

The concentrate (see note) shall consist of a dispersion in a ratio of 1 g of carbon black to a mixture of 90 ml of test

liquid and 10 ml of dispersant additive.

For the method of preparation, see annex C.

The specification of the carbon black can be found in annex D.

NOTE This concentrate is difficult to prepare and when prepared requires to be tested for suitability as described in

annex C.

2) Suitable products are available commercially. Details (product list) may be obtained from the Secretariat of Technical

Committee ISO/TC 22 or from the ISO Central Secretariat.

4 © ISO 2001 – All rights reserved

5.2.2 Inorganic contaminant

The contaminant shall be fused aluminium oxide dust. The particle size distribution shall conform to grades M1 and

M2 of ISO 12103-2. Normally, grade M2 dust shall be used, however, for filters manufactured from fine paper the

finer M1 grade dust shall be used as an alternative contaminant.

5.3 Test installation, general

There shall be no sudden changes in tube or hose bore throughout the test rigs.

6 Tests

6.1 Test for cleanliness of new filters

6.1.1 Purpose of the test

This test shall be carried out first to ascertain whether the clean side of the filter to be tested is free from dirt and of

other loose particles which may result from production, storage and transport.

6.1.2 Test installation

See B.1.

The test liquid temperature shall be 23 °C ± 5 °C.

6.1.3 Other equipment

See B.1.

6.1.4 Procedure

a) Clean and dry the test sieve for 30 min in a drying cabinet at approximately 20 °C above the final boiling point

of the petroleum ether employed in accordance with 6.1.4 d) and allow to cool for 30 min to ambient

temperature.

b) Weigh the test sieve to the nearest 0,1 mg on a laboratory balance and insert the test sieve in a horizontal

position in the measuring device (B.1.7).

c) Pump the test liquid through the circuit for 1 h at twice the rated flow of the filter under test.

d) Spray approximately 10 ml of petroleum ether through the cleaning hole on to the inner walls of the measuring

device in order to wash down particles from the wall and to gather them on the sieve.

e) Remove the test sieve with tweezers, place it on filter paper and allow to dry.

f) Place the test sieve in a clean, dry Petri dish, cover it with a lid, dry and allow to cool as before the first

weighing.

g) Weigh the test sieve to the nearest 0,1 mg. The mass of dirt released by the filter is equal to the difference

between the results of the two weighings of the sieve.

6.1.5 Test report

The test report shall indicate at least the following:

a) the filter make and model;

b) a description of the filter tested and internal diameter of connections;

c) the rated flow, in litres per hour;

d) the type or blend of test liquid.

Indicate the mass, in milligrams, of dirt released.

6.2 Fabrication integrity test

This test shows whether the filter element is “tight”; i.e. whether it does not contain pores larger than the unused

filter medium. The test shall be conducted in accordance with ISO 2942. However, test liquid in accordance with

annex E shall be used instead of isopropanol, as specified in ISO 2942. If this test is made, it should be carried out

prior to the other tests specified, but it may be carried out after the cleanliness test.

6.3 Test for differential pressure of new filters

6.3.1 Purpose and application of the test

The purpose of this test is to measure the differential pressure across the filter at the filter manufacturer’s rated

flow. This test shall be carried out prior to the tests for instantaneous filtration efficiency and filter life and for water

separation efficiency, but may be carried out after the cleanliness and fabrication integrity tests.

NOTE This method is equally applicable for the measurement of the pressure drop in a filter which has been in use for a

determined period, or at a flow rate different from the nominal rate.

6.3.2 Test installation

See B.2.

The test liquid temperature shall be 23 °C ± 5 °C.

6.3.3 Other equipment

See B.2.

6.3.4 Procedure

a) Connect the filter to be tested to the test rig, start up the system and prime and vent the filter to ensure

removal of air from the filter and pressure gauges, inverting the filter if necessary.

b) Close the control valve (B.2.10) and adjust the pressure by means of the by-pass valve (B.2.12) to that used in

practice. Adjust the zero of the differential manometer (B.2.14).

c) Open the control valve to re-establish the pressure reading on the upstream pressure gauge (B.2.8) to that

used in practice, and partially close the by-pass valve. Thus adjust the flow rate, indicated by the flowmeter

(B.2.6), to the desired value.

d) Record the value shown on the differential manometer.

6.3.5 Test report

The test report shall indicate at least the following:

a) the filter make and model;

b) a description of the filter; whether it is new or used; in the latter case, the approximate period of service;

6 © ISO 2001 – All rights reserved

c) the rated flow and the test flow rate, in litres per hour;

d) the type of blend of test liquid;

e) its viscosity at the test temperature, in square millimetres per second;

f) the test temperature, in degrees Celsius;

g) the internal diameter, d, actually used for the pipes itemized in B.2.

Indicate the differential pressure in Pa.

6.4 Test for instantaneous filtration efficiency and filter life

6.4.1 Purpose and application of the test

The purpose of this test is to measure the percentage retention of specific particles by a filter under defined test

conditions and at the filter manufacturer’s rated flow.

It is useful to conduct the test with filters which have already been tested by the cleanliness test, the fabrication

integrity test or the differential pressure test.

6.4.2 Test installation

See B.3.

The test liquid temperature shall be 23 °C ± 5 °C.

6.4.3 Other equipment

See B.3.

6.4.4 Procedure

6.4.4.1 Description

The filter test shall be carried out as a continuous process during which the contamination concentration of the test

liquid being fed to the filter is constant. The effectiveness of the filter under test (B.3.8) is determined by measuring

the amount of inorganic test dust remaining in the effluent samples initially and during the process of choking.

Clean test liquid is pumped from the tank (B.3.1b) by means of the main delivery pump (B.3.6) through the filter

under test into the collection tank (B.3.12). This enables the filter to be primed and vented. The organic and

inorganic contaminants are added as follows:

a) either as shown in diagram B.3: manually into the tanks (B.3.1a and B.1.3b) with the contaminants held in

suspension with stirrers (B.3.2);

b) or as shown in Figure B.4: with the injection pump (B.3.21) the organic contaminant is fed into the tank (B.3.1a

or B.3.1b) and with the injection pump (B.3.24) the inorganic contaminant is fed via the injection nozzle

(B.3.25) before the main delivery pump. The contaminants are held in suspension in the injection tanks by

recirculating pumps (B.3.19 and B.3.23).

The main delivery pump transfers this suspension to the filter under test, from which the filtered liquid flows via the

flow-measuring device [head tube (B.3.10)] and the orifice (B.3.11) into the collection tank. Samples of the effluent

are taken 2 min after the addition of the contaminants and at 4 min intervals thereafter for the determination of the

inorganic concentration. The continuity of the process is ensured by having a second tank (B.3.1b) prepared and

ready for use in the event that the whole of the contaminated test liquid contained in the first tank (B.3.1a) has

been used up.

The test for instantaneous filtration efficiency and filter life ends when the end pressure or any other agreed value is

attained.

To determine the instantaneous filtration efficiency of felt filters, terminate the instantaneous filtration efficiency test

after 20 min and analyse the samples taken during that time period.

6.4.4.2 Preparation of contaminants

6.4.4.2.1 Organic contaminant

See 5.2.1 and annexes C and D.

Before use ensure that the organic contaminant is thoroughly mixed; an example of the mixing procedure is as

follows.

a) The contaminant shall be supplied in a container which is not more than 75 % full. It shall be agitated by hand

shaking for approximately 5 min. To do this, the container shall be turned upside down and back again a

number of times.

b) Immediately following this, the container shall be placed on its side on a laboratory shaker and agitated at a

frequency of approximately 250 cycles per minute (approx. 4,2 Hz) at approximately 25 mm amplitude for 2 h.

c) The container shall then be taken from the shaker and the cap removed. A laboratory stirrer shall be lowered

into the container to a position as near as possible to the bottom and stirring shall be maintained for 3 h at a

-1

rotational frequency of approximately 1 000 min .

d) Immediately after stirring, a sample shall be removed and the solid content determined (see annex F) to

ensure that it is within (1 ± 0,1) % mass/volume.

6.4.4.2.2 Inorganic contaminant

See 5.2.2.

a) To obtain the test dust samples from the bulk supply, the appropriate standard sampling method, e.g. as

specified in ISO 8213, shall be used.

b) Immediately before use, each small quantity of inorganic contaminant shall be dried at a temperature between

110 °C and 150 °C (see B.3, Other equipment) for not less than 1 h.

c) The inorganic contaminant shall be allowed to cool in a desiccator and shall be stored in same.

6.4.4.3 Test rig and contaminents

6.4.4.3.1 Preparation of test rig

a) Prepare the test liquid as described in 5.1.

b) Flush the test rig by pouring 5 l of clean test liquid into the main tanks and and recirculating for 15 min. This is

achieved by attaching a separate flexible hose to the flexible transparent hose and suspending the other end

in either of the tanks.

c) After this flushing operation, pump out and discard the test liquid; refill the rig with 10 l.

8 © ISO 2001 – All rights reserved

d) Clean the test rig with an arrangement in accordance with Figure B.3 or Figure B.4.

This test shall be carried out prior to the tests for instantaneous filtration efficiency and filter life and for water

separation efficiency, but may be carried out after the cleanliness and fabrication integrity tests.

e) After approximately 30 min and before discarding the test liquid, take a sample at the orifice and determine the

level of contamination using the method specified in 6.4.4.5.

f) If the level of contamination exceeds 0,004 g/l (i.e. 1 % of the inorganic contaminant concentration), the

cleaning shall be repeated until this or a lower level is reached.

g) Prime the system by partially filling the tank (B.3.1a) with clean test liquid, and starting the pump to transfer

test liquid through the filter under test into the collection tank. During this process, vent air from the filter by

opening bleed orifices normally located on the filter head.

h) When priming is complete, close the bleed orifices and continue pumping test liquid through the filter until the

collection tank is almost full but before the level of the test liquid reaches the outlet opening of the main tank

(B.3.1a).

6.4.4.3.2 Preparation of contaminants

a) For manual feeding, a mixture of organic contaminant concentrate and clean test liquid shall be produced with

a volume ratio of 1:99 in the tanks. The concentrate shall be thoroughly mixed, as described in 6.4.4.2.1. A

quantity of inorganic test dust shall be weighed out that will give a concentration of 0,4 g/l in the test liquid

contained in the tanks. The inorganic contaminant shall be added to a volume of 500 ml from the contents of

-1

the tank, and then stirred for 15 min at about 1 000 min . The suspension of the inorganic contaminant shall

then be added to the whole amount of test liquid which contains the organic contaminant in the tanks. The

prepared test liquid, to which the organic and the inorganic contaminants have now been added, shallt be

stirred for at least 30 min with the stirrer before the start of the test.

b) For separate contaminant injection, the organic contaminant concentrate – prepared as described in

6.4.4.2.1 – is added to the injection tank (B.3.22). The solids are held in suspension with the recirculating

pump. The contaminant is injected in the as-delivered state.

A quantity of 80 g of the inorganic contaminant – prepared as described in 6.4.4.2.2 – is weighed out and manually

wetted with a rubber scraper in 950 ml of clean test liquid. Then 5 ml of an anti-static agent are added. This is

made up to 1 000 ml with clean test liquid and placed in an ultrasonic bath for 3 min to 5 min. The contaminant

prepared in this way is placed in the injection tank – always in a quantity of 1 000 ml – and kept in suspension with

the recirculating pump.

6.4.4.3.3 Preparation of injection device for separate injection of contaminant

If the injection pumps are not in operation, the intake tubes (B.3.26) shall be removed from the injection tanks and

the whole injection line shall be flushed with clean test liquid. During this cleaning process the whole test rig is in

operation as in 6.4.4.3.1, g) though without a test filter in place; i.e., a connector pipe instead of the test filter. When

the effluent entering the collector vessel is visually clean, preparation of the injection device is completed. The test

filter is fitted and the test system is evacuated.

6.4.4.3.4 Setting of injected quantity/calibration

Calibration or setting of the quantity injected takes place before the final arrangement of the injection lines.

The volume flow is set with the aid of the orifices [standard graduated tubes (B.3.20)].

The contents of the individual injection tanks are circulated during this time and the injected quantities are returned

to the relevant injection tanks.

After the target value has been set the injected samples are evaluated gravimetrically; e.g., with a test volume flow

rate of q = 75 l/h and the appropriately prepared proportions of contaminant – as described in 6.4.4.3.2 and

t

6.4.4.3.3 – the following target values are obtained for the injected quantities:

organic contaminant constituent: 12,5 ml/min;

inorganic contaminant constituent: 6,25 ml/min;

inorganic solids element: 80 mg/ml.

6.4.4.4 Test procedure

6.4.4.4.1 Feeding of contaminant/oil mixture

a) Open the stopcock (B.3.4) at the bottom of the main tank (B.3.1a).

b) Start the main delivery pump (B.3.6) and allow the test liquid to flow through the filter under test (B.3.8) and

adjust the flow to the required rate (see clause 4) by controlling the speed of the pump.

c) Record the differential pressure indicated by the differential pressure gauge (B.3.9).

d) After 1 min, take a 300 ml sample of test liquid from the sampling pipe (B.3.14).

e) After 2 min, 4 min and at intervals of 4 min thereafter, take 300 ml samples of effluent at the orifice (B.3.11)

and record the differential pressure. Throughout the test the speed of rotation of the stirrer in the main tanks

containing test liquid (see B.3) should be carefully controlled to prevent aeration.

f) When the end pressure or any agreed value is reached, take a final sample from the orifice and a final sample

from the sampling pipe.

g) Shut off the pump and close the stopcock at the bottom of the main tank.

h) Should the test liquid from main tank become exhausted during the test, open the stopcock at the bottom of

the reserve tank (B.3.1b), close the stopcock at the bottom of the main tank and continue the test. Care shall

be taken that the test liquid level does not drop so low as to allow air to be entrained.

i) Care shall be taken that there is no interruption or variation of flow in the course of the test.

j) Care shall be taken that the filter is not subjected to vibration or shock during the test.

k) Care shall be taken that pulsation amplitude is less than 1/10 of average inlet pressure.

6.4.4.4.2 Separate contaminant feeding

a) Replace intake tubes (B.3.26) in the injection tanks (B.3.18) and (B.3.22).

b) Open the stopcock at the base of either tank.

c) The pump is switched on and the test liquid is passed through the filter under test; the flow rate is set by

regulating the speed of the pump to the required value.

d) The differential pressure indicated at the differential pressure gauge is noted.

e) Actuated the injection pumps (B.3.21) and (B.3.24) and operate briefly (max. 15 s) at max. output – to reduce

start-up time – and then set the desired flow rate on the standard graduated tubes (20) by means of the pump

controller. The start of the test time is determined by the start of discoloration of the test liquid at the outlet into

the collection tank (B.3.12).

10 © ISO 2001 – All rights reserved

f) After 1 min, take a 300 ml sample of test liquid from the sampling pipe.

g) After 2 min, after 4 min, and subsequently at intervals of 4 min, 300 ml samples of the effluent are to be taken

at the orifice and the differential pressure noted.

h) Either tank shall always be replenished with clean test fluid.

i) When the end pressure or any agreed value is reached, one final sample shall be taken at the orifice and from

the sampling pipe.

j) The injection pumps and main delivery pump are switched off and the relevant stopcock closed.

k) The intake pipes shall be removed from the injection tanks and the injection pipes shall be cleaned as in

6.4.4.3.3.

l) Care shall be taken to ensure that the test liquid level does not fall so much that air is entrained.

m) Care shall be taken to ensure that no interruption or variation in flow occurs during the test.

n) Care shall be taken to ensure that the filter is not subjected to vibration or shock during the test.

6.4.4.5 Determination of the mass of incombustible (inorganic) particles in the test liquid samples

6.4.4.5.1 Preparation of the sample

Each sample shall be passed through the filtration apparatus specified in B.3 (2nd, 3rd and 4th items under Other

equipment) or an equivalent apparatus. After filtration, wash the filter medium and the collected solids and the

walls of the filter holder with a suitable solvent, such as petroleum ether of analytical quality, to remove all traces of

the test liquid (150 ml to 200 ml is usually sufficient).

6.4.4.5.2 Weighing of the residue

Ignite the filter medium and weigh the residue as specified in 6.4.4.5.3, making a correction for the ash content of

the filter medium and any change in mass of the inorganic contaminant due to the incineration.

6.4.4.5.3 Ashing and weighing procedure

a) Wash a crucible (see B.3) in water to which a little detergent has been added.

b) Dry the crucible and, using tongs, place it in a muffle furnace controlled at 800 °C ± 50 °C for 1 h. The crucible

shall be handled with tongs from this stage onwards.

c) Remove the crucible and place it in a desiccator until cool (i.e. for at least 1 h); weigh to the nearest 0,1 mg.

d) Remove the filter medium from the filter holder with care, keeping it horizontal so that no insolubles are lost.

e) If a membrane is used, roll it into a cylindrical form, holding the lower end of the filter medium above the

crucible, and carefully squeeze with thumb and forefinger of both hands to form a “flat tube”.

NOTE The membrane may be moistened to avoid cracking. Moistening may be achieved by carefully holding the

membrane in contact with the flat surface of a clean sponge dampened with distilled water.

f) Fold the filter medium in half until small enough to go into the crucible.

g) Place the crucible and its contents on a hot-plate to incinerate the larger portion of combustible material; care

shall be taken to avoid open conflagration of the contents.

h) When all the filter material has been incinerated on the hotplate, place the crucible in the muffle furnace

controlled at 800 °C ± 50 °C.

i) After 2 h, remove the crucible and place it in a desiccator to cool for at least 1 h before re-weighing to the

nearest 0,1 mg.

j) Subtract the initial mass of the crucible from the final mass to obtain the mass of the residue; i.e. of the

incombustible (inorganic) material.

k) The results shall be corrected by the subtraction of the mass of ash obtained from an unused filter medium.

6.4.4.5.4 Calculation of instantaneous filtration efficiency

The mass of inorganic material in each effluent sample shall be related to the average mass of inorganic material in

the initial and final applied influx samples.

The percentage instantaneous filtration efficiency is given by the formula:

mm-

¥ 100

m

where

m is the average mass, in grams, of inorganic material in the applied influent;

m is the mass, in grams, of inorganic material in the effluent.

This formula applies to each test; i.e. with and without water saturation of the element.

6.4.5 Test to determine the effect of water (optional)

Immerse an unused filter element in the test liquid for 10 min, remove and drain for 10 min. Then immerse it in

water for 30 min, after which remove it and allow it to drain for 10 min before installation in the test rig. Then carry

out the test for instantaneous filtration efficiency and filter life in accordance with the procedure specified in 6.4.4.

6.4.6 Test report

The test report shall indicate at least the following:

a) procedure used (6.4.4.4.1 or 6.4.4.4.2);

b) the filter make and model;

c) a description of the filter; whether it is new or used; in the latter case, the approximate period of service;

d) the rated flow and the test flow rate, in litres per hour;

e) the type or blend of test liquid;

f) its viscosity at the test temperature, in square millimetres per second;

g) the test temperature, in degrees Celsius;

h) the organic contaminant (see 5.2.1):

supplier;

batch No.;

12 © ISO 2001 – All rights reserved

volume, V , in millilitres, of test liquid to choke reference paper 633/9, should be near to the standard

volume V of 25 ml.

NOTE A choking volume range of 25 ml is permitted for reference paper 633/9 as a check on quality.

i) inorganic contaminant (see 5.2.2):

supplier;

grade;

batch No.;

50 % mean particle size, in micrometres.

6.4.7 Test results

6.4.7.1 Presentation of test results

6.4.7.1.1 Instantaneous filtration efficiency

Efficiency Dp

Stage

% kPa

Initial (2 min)

4 min

8 min

12 min and at 4 min intervals until the end

pressure is reached

Figure 1 — Presentation of filtration efficiencies

6.4.7.1.2 Filter life

In terms of time:

measured time (t ) to choke test filter to 70 kPa or any other agreed value: . min;

The measured time (t ) shall be corrected to make allowances for variations in the choking ratios of different

batches of organic contaminants, using the equation:

V

tt=

V

where

t is the corrected time;

V is the standard volume (25 ml) to choke the reference paper 633/9;

V is the average volume to choke the reference paper 633/9 with the batch of contaminant used in the test.

NOTE This correction to the measured time enables more accurate comparisons to be made between filter tests, using

different batches of contaminant, over a period of time. See also C.3 when changes have been made to the reference papers

used to determine V .

6.4.7.1.3 Diagram

The diagram showing instantaneous filtration efficiency and differential pressure versus choking time is shown in

annex G.

6.5 Test for water separation efficiency

6.5.1 Purpose and application of the test

With this test, it is possible to determine the quantity of water separated by the filter from a water-oil dispersion. This

test only applies to filters which are claimed to separate water. The test may be conducted with new or used filters.

NOTE The main pump (B.4.8), as specified in B.4, limits the use of the test to filters with rated flows up to 50 l/h. Filters

with higher rated flows require the use of two or more pumps operating in parallel. If two or more pumps are used, the rated flow

value is to be multiplied by the number of pumps.

6.5.2 Test installation

See B.4 and annex E.

The test liquid temperature shall be 23 °C ± 5 °C.

NOTE 1 The test installation is designed for filters downstream of the fuel supply pump (pressure side), but it is suitable for

filters upstream of the fuel supply pump (suction side) as well.

For this test, ordinary diesel fuel oil, free from anti-smoke additives and undissolved water shall be used.

The test liquid shall be treated with Fuller’s Earth (see B.5), followed by the addition of cetane number improver.

NOTE 2 This treatment of test liquid will tend to eliminate differences in testing fuel/water separators at different laboratories

in different geographic locations.

6.5.3 Other equipment

See B.4.

6.5.4 Procedure

6.5.4.1 Preparation and calibration

a) All equipment shall be clean and free from water. Fit a new element in the absorbent filter (B.4.24), if

necessary.

b) Fill the main tank (B.4.1) with test liquid free from undissolved water. Open by-pass valve (B.4.11) and check

that the stopcock (B.4.13) is shut. Start the main pump(s) (B.4.8) and adjust by-pass valve, so that the flow

through the pump is 50 l/h. If two or more pumps are used, this value shall be multiplied by their number.

c) If a recirculation system is used, allow the collection tank (B.4.20) to fill partly and refill the main tank. Start the

transfer pump (B.4.21), flush the coalescer (B.4.23) and absorbent filter (B.4.24) then adjust valve (B.4.25) to

balance the main flow.

d) Fill the water tank (B.4.3) with distilled or deionized water. Open valve (B.4.6) and adjust it to give a flow of

1 l/h. If two or more pumps are used, this value shall be multiplied by their number. The percentage water

content in the test liquid will then be approximately 2 % and the water will be dispersed by the action of the

14 © ISO 2001 – All rights reserved

main pump(s). It is essential to keep the level in the water tank reasonably constant, otherwise frequent

adjustment of valve (B.4.6) will be necessary. For this purpose, it is recommended that a constant-level device

(B.4.4) be fitted.

e) Stop the water feed by shutting valve (B.4.6).

NOTE The overflow valve should be made non-operative during these operations.

6.5.4.2 Test to determine the separation of undissolved water

a) Fit the filter to be tested (B.4.15) into the circuit. Open valve (B.4.17) [plus, if necessary, valve (B.4.19)] and

the stopcock. Flush the filter under test to remove air locks. Set the flow to the rated value of the filter under

test or to any other required value by adjusting valves (B.4.17) and (B.4.19) and at the same time adjusting the

by-pass valve so that the flow through the main pump is 50 l/h ± 2,5 l/h (see note). If two or more pumps are

used, this value shall be multiplied by their number. Note and maintain constant the level in the head tube

(B.4.18).

NOTE The reason for maintaining this flow through the main pump, regardless of the rated flow of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...