ISO/TR 18231:2016

(Main)Iron ores — Wavelength dispersive X-ray fluorescence spectrometers — Determination of precision

Iron ores — Wavelength dispersive X-ray fluorescence spectrometers — Determination of precision

ISO/TR 18231:2016 describes methods of test that can be applied to wavelength dispersive X-ray fluorescence (WD-XRF) spectrometers to ensure that the spectrometers are functioning in a manner that allows precise analyses to be made. The tests outlined are designed to measure the errors associated with the operation of certain parts of the spectrometer. They are not designed to check every part of the spectrometer but only those parts that may be the common sources of error. It is assumed that the performance of the instrument has been optimized according to the manufacturer's instructions. For all tests, the two-theta angle should be carefully set for the line being measured. The pulse height window should be set according to the manufacturer's instructions and should have a broad setting which may also include the escape peak for gas proportional counters. The instrument and detector gas environment should be as specified by the manufacturer, as should the power supply to the instrument. NOTE Where no distinction has been made, it is assumed that a test is applicable to both sequential and simultaneous spectrometers.

Minerais de fer — Spectromètres à fluorescence à rayons X à longueur d'onde dispersive — Détermination de la précision

General Information

- Status

- Published

- Publication Date

- 28-Apr-2016

- Technical Committee

- ISO/TC 102/SC 2 - Chemical analysis

- Drafting Committee

- ISO/TC 102/SC 2 - Chemical analysis

- Current Stage

- 6060 - International Standard published

- Start Date

- 29-Apr-2016

- Completion Date

- 08-Feb-2016

Relations

- Effective Date

- 06-Jun-2022

Overview

ISO/TR 18231:2016 - "Iron ores - Wavelength dispersive X‑ray fluorescence spectrometers - Determination of precision" provides a Technical Report of test methods to verify that wavelength dispersive X‑ray fluorescence (WD‑XRF) spectrometers deliver the precision required for iron‑ore chemical analysis. The document focuses on common sources of instrumental error and sets out procedures to measure and, where appropriate, help rectify those errors. It assumes instruments have already been optimized according to the manufacturer's instructions (two‑theta angle, pulse‑height window, detector gas environment and power supply).

Key topics and technical requirements

- Scope and assumptions: Tests target parts of WD‑XRF spectrometers likely to introduce error rather than every component; applicable to both sequential and simultaneous spectrometers unless stated otherwise.

- Frequency of testing: Suggested schedules include monthly, half‑yearly, and yearly checks depending on the test and instrument changes (see examples below).

- Counter tests:

- Counter resolution (gas‑flow proportional, scintillation, sealed gas counters), including theoretical and practical resolution calculations and acceptable performance guidance (e.g., theoretical Cu Kα resolution examples provided).

- Conductivity of gas‑flow proportional counter window and pulse‑height shift corrector operation.

- Spectrometer tests:

- Precision assessment and counting‑statistical error calculations.

- Test specimen selection and instrument operating conditions for sequential vs simultaneous spectrometers.

- Operational tests such as stability, specimen rotation, carousel reproducibility, mounting/loading reproducibility, sample holder and carousel position comparisons, angular reproducibility, collimator/detector/crystal changing reproducibility.

- Dead time and maximum usable count rate: Methods to determine detector dead time and recommend procedures for evaluating maximum count rates.

- Supporting material: Annexes include calculation methods such as coefficient of variation for duplicates.

Practical applications and users

- Laboratories performing chemical analysis of iron ores that rely on WD‑XRF for routine quality control and product specification.

- QC managers, laboratory technicians, calibration engineers, and instrument service teams who need documented test procedures for instrument validation and troubleshooting.

- Instrument manufacturers and third‑party service providers that develop maintenance, validation, and acceptance testing protocols.

- Use cases include verifying instrument readiness after maintenance, establishing routine quality assurance schedules, and confirming that measured precision meets internal or contractual limits.

Related standards and guidance

- ISO/TR 18231:2016 complements other ISO documents on chemical analysis and iron ores produced under ISO/TC 102 (Iron ore and direct reduced iron). Consult manufacturer manuals and ISO/TC 102 publications for harmonized test programs and conformity assessment guidance.

Keywords: ISO/TR 18231:2016, WD‑XRF, wavelength dispersive X‑ray fluorescence, iron ores, spectrometer precision, counter resolution, dead time, spectrometer testing, QC.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Chile

Bureau Veritas certification services in Chile.

Bureau Veritas Peru

Bureau Veritas certification services in Peru.

BVQI Peru

Bureau Veritas certification in Peru.

Sponsored listings

Frequently Asked Questions

ISO/TR 18231:2016 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Iron ores — Wavelength dispersive X-ray fluorescence spectrometers — Determination of precision". This standard covers: ISO/TR 18231:2016 describes methods of test that can be applied to wavelength dispersive X-ray fluorescence (WD-XRF) spectrometers to ensure that the spectrometers are functioning in a manner that allows precise analyses to be made. The tests outlined are designed to measure the errors associated with the operation of certain parts of the spectrometer. They are not designed to check every part of the spectrometer but only those parts that may be the common sources of error. It is assumed that the performance of the instrument has been optimized according to the manufacturer's instructions. For all tests, the two-theta angle should be carefully set for the line being measured. The pulse height window should be set according to the manufacturer's instructions and should have a broad setting which may also include the escape peak for gas proportional counters. The instrument and detector gas environment should be as specified by the manufacturer, as should the power supply to the instrument. NOTE Where no distinction has been made, it is assumed that a test is applicable to both sequential and simultaneous spectrometers.

ISO/TR 18231:2016 describes methods of test that can be applied to wavelength dispersive X-ray fluorescence (WD-XRF) spectrometers to ensure that the spectrometers are functioning in a manner that allows precise analyses to be made. The tests outlined are designed to measure the errors associated with the operation of certain parts of the spectrometer. They are not designed to check every part of the spectrometer but only those parts that may be the common sources of error. It is assumed that the performance of the instrument has been optimized according to the manufacturer's instructions. For all tests, the two-theta angle should be carefully set for the line being measured. The pulse height window should be set according to the manufacturer's instructions and should have a broad setting which may also include the escape peak for gas proportional counters. The instrument and detector gas environment should be as specified by the manufacturer, as should the power supply to the instrument. NOTE Where no distinction has been made, it is assumed that a test is applicable to both sequential and simultaneous spectrometers.

ISO/TR 18231:2016 is classified under the following ICS (International Classification for Standards) categories: 73.060.10 - Iron ores. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TR 18231:2016 has the following relationships with other standards: It is inter standard links to ISO 305:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/TR 18231:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 18231

First edition

2016-05-01

Iron ores — Wavelength dispersive

X-ray fluorescence spectrometers —

Determination of precision

Minerais de fer — Spectromètres à fluorescence à rayons X à longueur

d’onde dispersive — Détermination de la précision

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

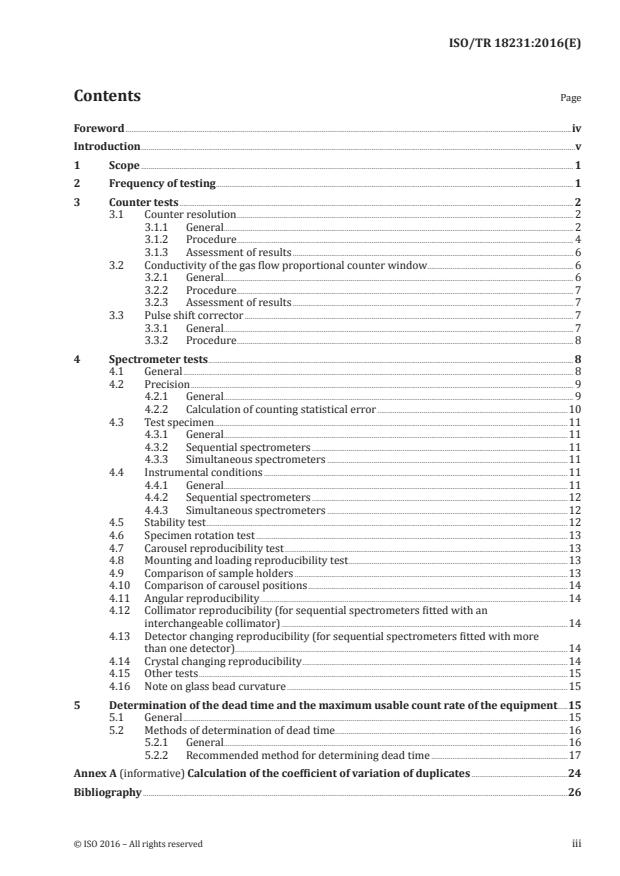

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Frequency of testing . 1

3 Counter tests . 2

3.1 Counter resolution . 2

3.1.1 General. 2

3.1.2 Procedure . 4

3.1.3 Assessment of results . 6

3.2 Conductivity of the gas flow proportional counter window . 6

3.2.1 General. 6

3.2.2 Procedure . 7

3.2.3 Assessment of results . 7

3.3 Pulse shift corrector . 7

3.3.1 General. 7

3.3.2 Procedure . 8

4 Spectrometer tests . 8

4.1 General . 8

4.2 Precision . 9

4.2.1 General. 9

4.2.2 Calculation of counting statistical error .10

4.3 Test specimen .11

4.3.1 General.11

4.3.2 Sequential spectrometers .11

4.3.3 Simultaneous spectrometers .11

4.4 Instrumental conditions .11

4.4.1 General.11

4.4.2 Sequential spectrometers .12

4.4.3 Simultaneous spectrometers .12

4.5 Stability test .12

4.6 Specimen rotation test .13

4.7 Carousel reproducibility test .13

4.8 Mounting and loading reproducibility test .13

4.9 Comparison of sample holders .13

4.10 Comparison of carousel positions .14

4.11 Angular reproducibility .14

4.12 Collimator reproducibility (for sequential spectrometers fitted with an

interchangeable collimator) .14

4.13 Detector changing reproducibility (for sequential spectrometers fitted with more

than one detector).14

4.14 Crystal changing reproducibility .14

4.15 Other tests .15

4.16 Note on glass bead curvature .15

5 Determination of the dead time and the maximum usable count rate of the equipment .15

5.1 General .15

5.2 Methods of determination of dead time .16

5.2.1 General.16

5.2.2 Recommended method for determining dead time .17

Annex A (informative) Calculation of the coefficient of variation of duplicates .24

Bibliography .26

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 102, Iron ore and direct reduced iron,

Subcommittee SC 2, Chemical analysis.

iv © ISO 2016 – All rights reserved

Introduction

If an X-ray fluorescence spectrometer is to be used for precise analyses, it needs to be functioning

correctly to specification, that is, the errors associated with the various functions of the instrument

have to be very small. It is important therefore that the spectrometer be tested to ensure that it is

indeed functioning to deliver the required precision. The objective of this Technical Report is to set

out tests that can be used to ascertain the extent of the errors and to suggest procedures for their

rectification. These tests are not used to ascertain whether the instrument is operating optimally but

to determine whether the instrument is capable of giving a preselected precision.

TECHNICAL REPORT ISO/TR 18231:2016(E)

Iron ores — Wavelength dispersive X-ray fluorescence

spectrometers — Determination of precision

1 Scope

This Technical Report describes methods of test that can be applied to wavelength dispersive X-ray

fluorescence (WD-XRF) spectrometers to ensure that the spectrometers are functioning in a manner

that allows precise analyses to be made.

The tests outlined are designed to measure the errors associated with the operation of certain parts of

the spectrometer. They are not designed to check every part of the spectrometer but only those parts

that may be the common sources of error.

It is assumed that the performance of the instrument has been optimized according to the

manufacturer’s instructions. For all tests, the two-theta angle should be carefully set for the line being

measured. The pulse height window should be set according to the manufacturer’s instructions and

should have a broad setting which may also include the escape peak for gas proportional counters. The

instrument and detector gas environment should be as specified by the manufacturer, as should the

power supply to the instrument.

NOTE Where no distinction has been made, it is assumed that a test is applicable to both sequential and

simultaneous spectrometers.

2 Frequency of testing

Testing is not required to be carried out with each batch of analyses. The frequency of testing varies

depending on the test involved. Table 1 lists the suggested frequency with which each test should be

carried out. Where specific problems are encountered, more frequent testing may be required and

remediation work performed.

Table 1 — Suggested frequency of precision tests

Frequency Test

Monthly Resolution of the gas-flow proportional counter

Resolution of the scintillation and sealed gas counters

a

Operation of the pulse height shift corrector

Half yearly Conductivity of gas-flow proportional counter window

General stability

Collimator reproducibility

Detector changing reproducibility

Crystal changing reproducibility

Angular reproducibility

Yearly Carousel reproducibility

Comparison of carousel positions

Comparison of sample holders

Sample loading and unloading

a

The position of the pulse height peak should also be checked after changing

a bottle of detector gas since a variation in the methane content of the gas will

change the position of the peak.

The frequencies with which the tests listed in Table 1 are carried out are suggested on the basis that

there have been no changes to the spectrometer. If mechanical or electronic maintenance of a major

nature is carried out, the appropriate tests should be made before the spectrometer is taken back into

routine service.

3 Counter tests

3.1 Counter resolution

3.1.1 General

3.1.1.1 Theoretical resolution

Impurities in the flow gas and contamination of the anode wire may cause gas flow proportional

counters to gradually deteriorate, which will result in both a shift and a broadening of the energy

distribution (pulse height) curve. Similarly, scintillation counters and sealed gas counters may, for

various reasons, exhibit the same gradual deterioration. This can, ultimately, adversely affect the

measurements. Impurities in detector gas can be minimized by the use of gas filters.

The resolution (RES) of a counter is related to its energy distribution curve, and is given by the measured

peak width at half height (W) expressed as a percentage of the maximum of the pulse amplitude

distribution (V), using Formula (1) where the values of W and V are in terms of arbitrary units (which

vary between instrument manufacturers) obtained from the X-axis (see Figure 1):

W

RES=×100 (1)

V

The theoretical resolution (RES ), using the full width at half height of a Gaussian distribution, can be

th

calculated using the following formulae:

RES =23, 6σ (2)

th

2 © ISO 2016 – All rights reserved

σ= n (3)

Expressed as a percentage relative to n, Formula (3) becomes:

σ = in% (4)

()

n

where

n is the number of primary electrons per incident photon (gas counters) or number of

photoelectrons collected by the first dynode of the photomultiplier tube (scintillation coun-

ters), calculated using Formula (5):

E

x

n= (5)

V

i

E is the energy of the incident radiation, in kilo electron volts (keV);

x

V is the effective ionization potential of Argon for a flow counter, in kilo electron volts (keV)

i

= 0,026 4.

Substituting Formula (5) into Formula (4), and Formula (4) into Formula (2) gives:

236× 0,026 4

38,4

RES = = (6)

th

EE

x x

Hence, for Cu Kα (E = 8,04 keV), the theoretical resolution of an Ar gas counter is 13,5 %.

3.1.1.2 Scintillation counter

For a scintillation counter:

RES = (7)

th

E

x

[1]

and for Cu Kα, the resolution should be approximately 45 %.

3.1.1.3 Practical resolution

In practice, however, the measured resolution achieved (RES ) is given in Formula (8):

m

RESk= R (8)

m

where

k is a factor that varies with the design of the counter, phosphor efficiency (scintillation

counters), diameter, cleanliness and composition of the anode wire (gas counters).

For a well-designed and clean gas-flow proportional counter, k should be less than 1,15. Hence, for such

a counter, RES should be less than 15,6 % for Cu Kα radiation. For the scintillation counter, this value

m

should be less than 52 %.

3.1.2 Procedure

This test should be carried out on all counters used in the spectrometer. Most modern instruments

provide the facility to measure pulse height distributions and to print out the counter resolution and

this facility should be used if available.

For sequential spectrometers, it is recommended that the test be carried out using either Cu Kα or Fe Kα

radiation for both detectors. However, if these lines are measured using only the scintillation counter

in actual analysis, measure an X-ray line of a major element analysed with the gas proportional counter

for testing.

If the spectrometer does not provide automatic functions to determine RES then the following

m

procedure should be used.

a) Select a sample containing the appropriate analyte and, using a lower level setting and the pulse

height analyser (PHA) window set to “threshold” (no upper level), adjust the X-ray tube power to

give a count rate of about 2 × 10 cps (counts per second).

b) Select a narrow pulse height window (2 % to 4 % of the peak voltage V of Figure 1) and decrease

the lower level setting until the count rate drops to essentially zero.

c) Increase the lower level stepwise, noting the count rate at each step, until the peak has been passed

and the count rate drops again to a very low value. Each step should be of the same width as the

pulse height window width, i.e. if the pulse height window width corresponds to 0,2 units, then

each step of the lower level should be 0,2 units.

d) Plot the count rate obtained at each step against the lower level values. An example is shown in

Figure 1.

4 © ISO 2016 – All rights reserved

W

AV B

Key

1 half peak height

2 peak width at half peak height

Figure 1 — Intensity as a function of lower level setting (arbitrary energy units) displayed for

Fe Kα radiation measured on a flow counter

The measured counter resolution RES (in %) is obtained from the plot as follows:

m

BA−

RES = ×100 (9)

m

V

where

B and A are the lower level settings at the half height positions on either side of the peak;

V is the lower level setting at the maximum of the pulse height distribution.

The pulse height distribution should be determined at a count rate indicated by the instrument

manufacturer, or just below 2 × 10 cps (see Figure 1).

When determining the pulse height distribution automatically, A, B, V and W are not usually displayed,

but the graph, peak position and detector resolution are shown together with instrument specific data.

3.1.3 Assessment of results

3.1.3.1 Gas flow proportional counter

Since the resolution of a proportional counter depends on design, an absolute resolution value cannot be

given but the value should be near to that given in Formula (6). The optimum resolution of a particular

counter may be specified by the manufacturer or it may be found with use. When RES increases by a

m

factor of 1,2 times that value, the counter should be serviced.

3.1.3.2 Scintillation and sealed gas counters

These counters usually do not exhibit significant changes in resolution unless the counter is beginning

to fail, which can be quite early for some sealed gas counters for light elements and where they have

been used at very high flux for extended periods. Their resolution can be calculated according to

Formula (9) but the k factor is instrument specific. Hence, it is sufficient to measure their resolution

experimentally on a regular basis. If a significant increase in resolution is noted or the pulse height

distribution extends outside the energy window when it did not on installation, then the counter should

be replaced.

Scintillation counters can fail due to leaks in the beryllium window, thereby admitting moisture to the

very hygroscopic NaI crystal. The effect of such moisture reduces count rates for the longer wavelengths,

e.g. ~2Å but may have relatively little effect on short wavelengths, ~0.6Å. As more moisture reacts with

the crystal, its sensitivity will be reduced for all wavelengths.

Similarly, the sensitivity of sealed counters will reduce due to leaks in the detector window. A leaking

sealed gas counter window will result in a loss of gas density and thus gas amplification.

Although a reduction in sensitivity of the scintillation and sealed gas counters does not affect counting

precision, the signal-to-noise ratio will be reduced and longer counting times will be required to achieve

a given precision. Furthermore, if the reduction in sensitivity is due to failure of the window, then this

reduction will be continuous and total detector failure will be imminent.

The best method of detecting deterioration of such counters is to set aside a stable specimen (such as an

instrument monitor) and to periodically measure the intensity of a reasonably long wavelength line (for

example, Fe Kα for the scintillation counter). Any pulse height shift or decrease of intensity over time

should be investigated to ascertain whether the scintillation (or sealed gas) counter requires replacing.

3.2 Conductivity of the gas flow proportional counter window

3.2.1 General

The gas-flow proportional counter window consists of a thin layer of plastic material (such as Mylar or

polypropylene) coated with a very thin electrically conductive layer (typically aluminium). For practical

considerations, the window material should be able to support atmospheric pressure without breakage.

Where air or helium paths are frequently used over a period of time, this material may stretch and cause

the aluminium coating to suffer from micro-cracks, resulting in the window becoming non-conducting.

A gas-flow proportional counter having a poorly conducting or non-conducting window appears to

function normally in most respects. However, measurements made with such a counter will be in error,

as the counter will give reduced count rates for samples which would normally give a high count rate.

This is especially noticeable when low and high count rates are measured consecutively.

Where 6 μm windows are used, loss of conductivity is seldom encountered, as the window usually has

a life of some years, requiring replacement only when the counter is serviced for other reasons. The

useful life of thinner windows (≤1 μm polypropylene windows are commonly used in most modern

spectrometers) varies from several months to more than a year. Where the spectrometer chamber

6 © ISO 2016 – All rights reserved

is continuously under vacuum, the window life is longer than for those where the spectrometer is let

down to normal air or Helium pressure frequently.

NOTE If the gas-flow proportional counter has a beryllium window, this test may be necessary to occasionally

check for the formation of hairline cracks.

3.2.2 Procedure

3.2.2.1 Sequential spectrometers

The procedure for sequential spectrometers is as follows.

a) Carry out the test using K Kα radiation.

b) Using low X-ray tube power (low kV and mA), select a sample that gives a count rate of between

1 000 cps and 5 000 cps.

c) Set the 2θ angle and pulse height analyser using this sample and then, using these settings, measure

the count rate for 10 s.

d) Replace the sample with one having a high potassium concentration (a briquette of potassium

chloride or potassium hydrogen phthalate is particularly suitable or a sample advised by the

instrument manufacturer); set the X-ray tube to such a power that the maximum count rate allowed

by the manufacturer is achieved. Maintain these conditions for 2 min.

e) Reduce the X-ray tube power to its starting value and measure the count rate for the original

sample again.

3.2.2.2 Simultaneous spectrometers

For simultaneous spectrometers, the test is made on those channels having gas-flow proportional

counters fitted with thin plastic windows. The test is carried out in a similar manner to the procedure

specified in 3.2.2.1, except that the radiation used is that specific to the selected channel.

NOTE Tests for simultaneous spectrometers are also applicable to fixed channels in a sequential

spectrometer.

3.2.3 Assessment of results

If the window is conducting properly, the initial count rate will be within 5 % of the final count rate

when the X-ray tube power is returned to the original settings. If the window is poorly conducting, a

reduced count rate will be observed. In such cases, the count rate should slowly return to the original

rate but for non-conducting windows, the time involved may be in excess of 12 h. The window should be

replaced if there is any evidence of poor conduction.

3.3 Pulse shift corrector

3.3.1 General

At high count rates, high detector gains will result in a shift to lower pulse amplitudes. In modern

spectrometers, the effects of pulse shift have been minimized by designing counters with a lower

dependence on gas density and composition and by the use of automatic pulse shift correction

electronics. Nevertheless, the effect of pulse shift errors on analytical accuracy can be significant.

All modern spectrometers are fitted with automatic pulse shift correction but the operation of

detectors should also be checked when the automatic shift correction is not operating at low count

rates. The threshold count rate at which the automatic shift correction operates can vary between each

detector type, instrument model and spectrometer manufacturer. This may even be programmable

with automatic pulse shift disabled or enabled in software or hardware.

For gas-flow detectors, since the pulse shift is dependent on the gas composition (proportion of argon

to methane and the level of contaminants) and gas density (temperature or pressure of the gas within

the detector), pulse shift should be checked whenever the flow gas supply cylinder has been replaced or

whenever the gas flow detector or gas density stabilizer has been repaired.

NOTE Leaks in the gas-flow circuitry may result in the erroneous entry of air, or helium in the case of liquid

measurements, which will alter the flow gas composition.

As modern spectrometers are fitted with gas density stabilizers of significant volume, detector gas lines

should be allowed to purge prior to checking pulse heights after any of the above work has been carried

out. As the volume of flow gas circuits may be up to 3 l, the purging of lines may take up to 3 h unless

the possibility exists for a higher purge rate for a short period of time. Advice from the manufacturer

should be taken here.

3.3.2 Procedure

a) For all XRF instruments, use a sample whose radiation wavelength is suitable for the detector and

crystal combination. Below are the recommended lines for each crystal:

1) TlAP – Al Kα or Mg Kα;

2) 2,5 nm to 5 nm 2d crystals (synthetic multilayer) — Al Kα, Na Kα or Mg Kα;

3) 0,18 nm to 0,41 nm 2d crystals (LiF , LiF & LiF ) — Fe Kα or Cu Kα;

200 220 420

4) Ge — S Kα;

5) PE — Al Kα, Si Kα or P Kα;

6) InSb — Si Kα.

b) Using high X-ray tube power (with high mA), select a sample, or samples, that give(s) a count rate

near to that specified by the manufacturer as the maximum for the counter.

c) Measure the pulse height using a small step size (1 % to 2 % of the peak voltage) and a step time of

not less than 1 s. Record the peak maximum position.

d) Check manufacturer instructions for the count rate at which the automatic pulse shift correction is

enabled. Reduce the X-ray tube mA setting so that a count rate below this level is obtained or use a

second sample.

e) Repeat the procedure c) and record the peak maximum position.

f) Repeat the whole procedure for each detector.

If the peak maximum positions at the low count rate and the high count rate differ by more than 5 %

then the high voltage gain of the detector requires adjusting. This adjustment may require the skills of

a qualified technician.

If the instrument uses pulse shift correction at all count rates, the test will check that the correction is

working.

4 Spectrometer tests

4.1 General

X-ray spectrometers are mainly used for quantitative analyses. The degree of precision required

in various applications varies considerably and the following tests are to determine whether the

spectrometer can deliver the required precision.

8 © ISO 2016 – All rights reserved

Determining the measurement error component of the total analytical error can be achieved by

measuring one sample 20 times (for example) and then processing the data to obtain the mean, standard

deviation and % coefficient of variation (%CoV) of the concentration or intensity values. The %CoV of

the concentration values will be that of the intensity values multiplied by the matrix correction term

for the element of interest. The standard deviation of the intensities should be close to the counting

statistical error.

If the measurement error is outside of the statistical error limits given in Table 2 and also outside of

the acceptable error for the analyses being carried out, then the following tests can be used to find the

instrumental variables which are causing the problem and they can then have their influence on the

total analytical error minimized.

For typical routine analyses, a %CoV of 0,1 % is generally satisfactory for analytical requirements.

If higher precision is required, then the instrument should be carefully maintained and the testing

frequency of parameters listed in Table 1 might need to be increased.

Testing of the spectrometer is carried out by making repeated measurements to determine the basic

instrument stability and then the repeatability as various instrumental parameters are changed, one

variable at a time, so that any error source can be found.

The statistical bounds of tests conducted present a probability distribution about the counting

statistical error (%CSE). For tests conducted at low levels of precision, it is frequently possible to obtain

results that are less than the %CSE. The probability of this occurring decreases when increasing the

number of counts accumulated per measurement and when increasing the number of measurements.

At higher levels of precision, residual instrumental errors will have an increased impact on results and

the %CoV will generally be greater than the %CSE.

Precision measurements are made on the major element of the material to be analysed using a sensitive

line. In the case below, the Fe Kα line is used.

Dead-time corrected intensities should be used for measurements since these intensity values are used

to convert intensity data into concentration values during the analytical procedure. Such intensities

are also used in calculating measuring times required to achieve the desired counting statistical error

when setting up an analytical method.

The %CSE should theoretically be based on the actual counts a detector registers. At high count rates

above about 1 000 000 cps, dead-time effects have an increasing effect on the calculated %CSE and this

value is better established using the non-dead-time corrected count rate.

At high count rates, where dead time and pulse pile up effects are high, the time interval distribution of

counts also varies from a Poisson distribution. However, such differences need not be considered when

simply trying to determine if a spectrometer is capable of obtaining a required degree of analytical

precision or if some component of the spectrometer needs to be fixed.

4.2 Precision

4.2.1 General

The precision of WD-XRF analytical methods is dependent on the error of sub-sampling the material

brought to the laboratory for analysis, the sample preparation error and the sample measurement error.

The total analytical error (T) is determined from contributing error components using Formula (10):

22 2

T= (subsampling error) +(preparationerror) +(measurementerrorr) (10)

Factors contributing to measurement precision errors are counting statistical errors, instrumental

stability errors, errors associated with moving instrumental parts and errors due to measurement

parameter settings. These error sources will be addressed in the subclauses below.

The above errors are based on 1 standard deviation (sd). Generally, the precision of an analytical

method is described using 2 sd, which corresponds to a 95 % probability that a result will be within

those bounds. The maximum counting statistical error required for an analytical procedure can be

calculated by rearranging Formula (10) and having minimized and knowing the sub sampling and

sample preparation errors. These can be obtained experimentally.

4.2.2 Calculation of counting statistical error

For an infinite number of measurements and assuming no instrumental errors:

100 N Standard deviation

%%CSEC==oV =×100 =×100 (11)

N Mean

N

where

N is the total counts accumulated per measurement.

For a finite number of measurements and assuming Poisson statistics apply:

Standard deviation

%CoV =×100 (12)

Mean

And the standard deviation = Mean , as shown in Formula (11).

If the number of measurements (n) is <20, then the sample standard deviation (based on n−1) is used

instead of the population standard deviation.

[2]

Where 20 measurements are made, the observed %CoV should not exceed 1,4 times (1 % probability )

the %CSE, as shown in Table 2.

Table 2 — %CSE and upper statistical limit for %CoV

Total counts

a a b b

%CSE 1,4 × %CSE %CSE 1,4 × %CSE

(N)

1 000 000 0,100 0,140 0,116 0,160

10 000 000 0,032 0,044 0,037 0,051

20 000 000 0,022 0,031 0,026 0,036

25 000 000 0,020 0,028 0,023 0,033

40 000 000 0,016 0,022 0,018 0,026

100 000 000 0,010 0,014 0,012 0,016

a

Using dead-time corrected counts at a count rate of 2 000 000 cps.

b

Using non-dead-time corrected counts at a count rate of 1 481 636 cps

Counting statistical errors should be calculated on the counts actually detected by the detectors and

not the dead-time corrected counts. At low count rates <1 000 000 cps, there will be little difference

in the dead-time corrected and non-dead-time corrected %CSE. At high count rates, the difference

becomes noticeable.

The non-dead-time corrected count rate can be calculated using the formula for extendable dead time

[Formula (14)]. A dead time of 0,15 μs was used in the calculation, with the value entered in seconds, i.e.

0,000 000 15 s and the count rate in counts per second.

b

The total counts (N) in Table 2 are the dead-time corrected counts accumulated. Calculation of %CSE

is based on the same counting time used to accumulate the dead-time corrected counts with a non-

dead-time corrected count rate of 1 481 636 cps.

10 © ISO 2016 – All rights reserved

a b

The difference between %CSE and %CSE will decrease with decreasing count rate and increase with

increasing count rate. There is little difference between the values below count rates of 1 million cps.

b

The %CSE values of Table 2 should be close approximations on the statistical limits obtained on flow

counters at 2 000 000 cps for most modern instruments.

Test measurements are always carried out using the dead time corrected counts. Only the counting

statistical limits are adjusted for dead-time effects.

If the %CoV for a precision test is larger than the values given in Table 2, which are limits based on

statistics alone, then the measurements should be repeated. If the measurements are outside the limits

again, then corrective measures should be taken to minimize the problem if the results do not satisfy

analytical requirements. If the spectrometer cannot meet the required precision for an analysis, tests

can be carried out at a lower count rate or its use should be limited to less precise work.

When testing spectrometers at the above levels of precision, it should be remembered that all

spectrometers have some residual instrument errors and, therefore, will not pass precision tests when

tested at some very high level of precision such as 100 million accumulated counts per measurement.

However, most spectrometers are expected to be within the statistical limits or plus 20 % of the

maximum limit when accumulating between 20 million to 40 million counts per measurement under

standard laboratory conditions since measurement errors should be and are generally small.

4.3 Test specimen

4.3.1 General

The test specimen should be robust and stable and should have a flat analytical surface. A metal alloy

or a glass disc into which the analyte(s) has/have been incorporated by fusion with a borate flux can

be used. The use of compacted powder pellets is to be actively discouraged as these are not stable over

long periods of time. The sample should be firmly fixed in the sample holder so that no movement is

possible during measurement.

4.3.2 Sequential spectrometers

Any analytical line that gives a high count rate can be used for the precision test and it is appropriate

to use the line of a major component of a typical sample. In the examples given below, Fe Kα is used

and the amount of iron in the test specimen should be such that, under normal conditions of X-ray tube

power, the maximum count rate stipulated by the manufacturer is not exceeded.

4.3.3 Simultaneous spectrometers

For simultaneous spectrometers, a test specimen that allows testing of several channels simultaneously

is desirable. Several samples may be required to cover all element channels. The test specimen should

be such that, under normal operating conditions of X-ray tube power, a count rate of around 10 cps

or higher is obtained in each of the channels under test. For channels measuring very light elements,

where such intensity may not be possible, use as high a count rate as is achievable. Very high count

rates should be avoided as there will then be significant errors in the recorded counting times used

unless three decimal places are available. Alternatively, use the fixed time method to collect sets of

counts which are very close to the target value (N) for all power settings.

4.4 Instrumental conditions

4.4.1 General

The X-ray tube should be operated at the normal working power. The sample spinner should be used, if

possible, unless otherwise stated in the specific test.

Where possible, measurements should be made using the pre-set count mode. The time, in seconds,

required to accumulate the counts should be recorded to at least three decimal places. If a pre-set count

facility is not available, or if the timer does not read to the required precision, the pre-set time mode

should be used and the measuring time should be adjusted so that approximately the same number

of counts is accumulated at each power setting. Alternatively, a pre-set counting statistical error

mode can be used for the desired level of precision. The actual number of counts accumulated for each

measurement should then be recorded for these alternate methods.

4.4.2 Sequential spectrometers

For sequential spectrometers, the collimator normally used for the major element being measured

should be used if there is more than one available. The detector should also be that normally used for

the element being measured.

A broad energy window should be used for the pulse height distribution (PHD) which may also include

the escape peak.

Setting an upper energy level at a position where the intensity is still significantly higher than zero will

lead to instability in a detector. This can be seen when comparing stability determinations between

Fe Kα to Zn Kα radiation on a scintillation detector at similar count rates, with the Zn Kα peak being

less broad, or when carrying out stability tests at high or lower intensity levels for a specific line.

4.4.3 Simultaneous spectrometers

A broad PHD window should be used with each channel under test. A trial measurement should be

made to ascertain the correct PHD window width.

4.5 Stability test

When an X-ray tube is turned on, or when total power settings are changed, it may take some time

for the output of the X-ray tube to stabilize. The period of instability, and its magnitude, varies even

between instruments of the same manufacture and it should be determined for each spectrometer.

Instability can be observed by taking repetitive counts and plotting the count rate against time.

Modern spectrometers often have this facility built into their software. The tests given below should

be carried out after the spectrometer has stabilized. The time to reach stability is likely to be longer

after an instrument is powered up after being turned off or set at low power overnight than when

power changes are made during analyses. It will also be longer when stabilizing for the higher levels of

precision.

The stability test should be carried out as follows.

a) Make 50 consecutive measurements on the test specimen in a static position. During this test, all

the spectrometer parameters should remain fixed and the sample spinner should not be used while

all measurements are made.

b) Calculate the %CoV.

The test should be performed using each of the detectors fitted to the spectrometer.

In this case, the calculated coefficient of variation should not exceed 1,23 times the counting statistical

[2]

error (%CSE) for 50 consecutive measurements. If the calculated value excee

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...