ISO 15558:1998

(Main)Practice for use of a polymethylmethacrylate dosimetry system

Practice for use of a polymethylmethacrylate dosimetry system

Pratique de l'utilisation d'un système dosimétrique au polyméthylméthacrylate

General Information

- Status

- Withdrawn

- Publication Date

- 19-Dec-1998

- Withdrawal Date

- 19-Dec-1998

- Drafting Committee

- ISO/TC 85/WG 3 - Dosimetry for radiation processing

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 18-Apr-2002

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 15-Apr-2008

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

ISO 15558:1998 is a standard published by the International Organization for Standardization (ISO). Its full title is "Practice for use of a polymethylmethacrylate dosimetry system". This standard covers: Practice for use of a polymethylmethacrylate dosimetry system

Practice for use of a polymethylmethacrylate dosimetry system

ISO 15558:1998 is classified under the following ICS (International Classification for Standards) categories: 17.240 - Radiation measurements. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 15558:1998 has the following relationships with other standards: It is inter standard links to ISO/ASTM 51276:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 15558:1998 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IS0

INTERNATIONAL

STANDARD

First edition

Practice for use of a

polymethylmethacrylate dosimetry system

Pratique de I’utilisation d ’un systeme dosimktrique au

polym&hylm6thacryla te

Reference number

IS0 15558: 1998(E)

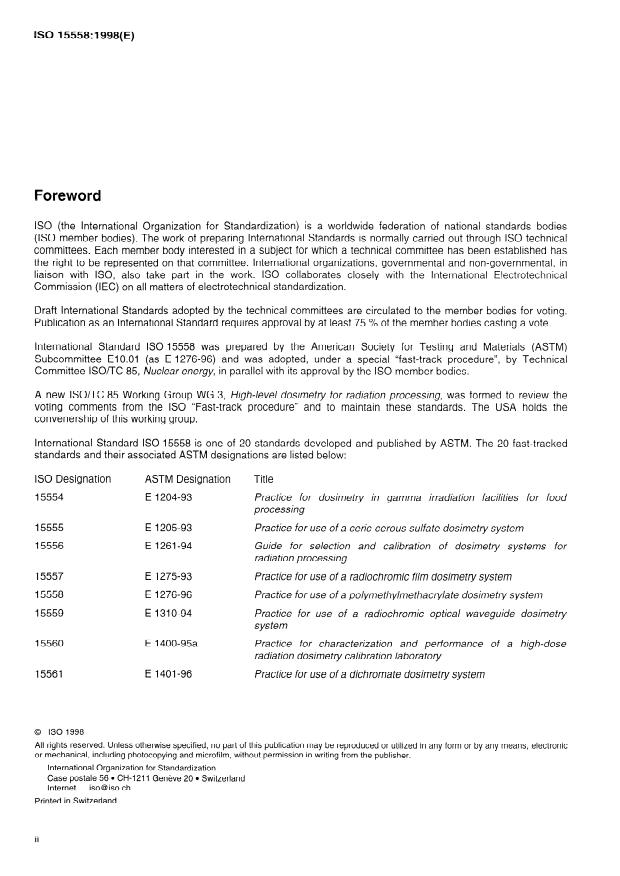

Foreword

IS0 (the International Organization for Standardization) is a worldwide federation of national standards bodies

(IS0 member bodies). The work of preparing International Standards is normally carried out through IS0 technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. IS0 collaborates closely with the International Ejectrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the tee hnical committees a re circulated to the member bodies for votin .

cl

Publi cation as an lnternationa I Standard requires approval by at least 75 % of the membe r bodies casting a vote.

International Standard IS0 15558 was prepared by the American Society for Testing and Materials (ASTM)

Subcommittee E1O.O1 (as E 1276-96) and was adopted, under a special “fast-track procedure ”, by Technical

Committee ISOmC 85, Nuclear energy, in parallel with its approval by the IS0 member bodies.

A new ISOTTC 85 Working Group WG 3, High-level dosimetry for radiation processing, was formed to review the

voting comments from the IS0 “Fast-track procedure” and to maintain these standards. The USA holds the

convenership of this working group.

International Standard IS0 15558 is one of 20 standards developed and published by ASTM. The 20 fast-tracked

standards and their associated ASTM designations are listed below:

IS0 Designation ASTM Designation Title

15554 E 1204-93 Practice for dosimetry in gamma irradiation facilities for food

processing

15555 E 1205-93 Practice for use of a ceric-cerous sulfate dosimetry system

15556 E 1261-94 Guide for selection and calibration of dosimetty systems for

radia Con processing

15557 E 1275-93 Practice for use of a radiochromic film dosimetty system

15558 E 1276-96 Practice for use of a polymethylmethacrylate dosimetry system

15559 E 1310-94 Practice for use of a radiochromic optical waveguide dosimetry

sys tern

E 1400-95a

15560 Practice for characterization and performance of a high-dose

radiation dosimetry calibration laboratory

15561 .E 1401-96 Practice for use of a dichromate dosimetry system

0 IS0 1998

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case postale 56 l CH-1211 Geneve 20 l Switzerland

Internet iso @ isoch

Printed in Switzerland

ii

IS0 15558: 1998(E)

@IS0

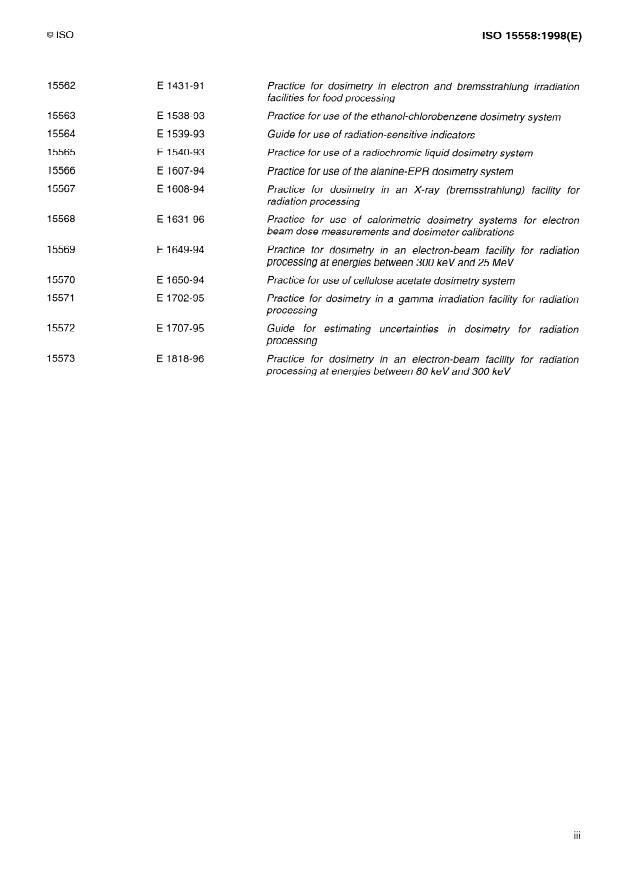

Practice for dosimetty in electron and bremsstrahlung irradiation

15562 E1431-91

facilities for food processing

Practice for use of the ethanol-chlorobenzene dosimetry system

15563 E 1538-93

E 1539-93 Guide for use of radiation-sensitive indicators

Practice for use of a radiochromic liquid dosimetry system

15565 E 1540-93

E 1607-94 Practice for use of the alanine-EPR dosimetry system

15567 E 1608-94 Practice for dosimetry in an X-ray (bremsstrahlung) facility for

radiation processing

E 1631-96 Practice for use of calorimetric dosimetry systems for electron

beam dose measurements and dosimeter calibrations

Practice for dosimetry in an electron-beam facility for radiation

E 1649-94

processing at energies between 300 keV and 25 MeV

E 1650-94 Practice for use of cellulose acetate dosimetry system

Practice for dosimetry in a gamma irradiation facility for radiation

15571 E 1702-95

processing

Guide for estimating uncertainties in dosimetty for radiation

15572 E 1707-95

processing

Practice for dosimetry in an electron-beam facility for radiation

15573 E 1818-96

processing at energies between 80 keV and 300 keV

. . .

III

0 IS0 IS0 15558: 1998(E)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

Designation: E 1276 - 96

An American National Standard

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

If not listed in the current combined index, will appear in the next edition.

Standard Practice for

Use of a Polymethylmethacrylate Dosimetry System’

This standard is issued under the fixed designation E 1276; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (c) indicates an editorial change since the last revision or reapproval.

1. Scope E 140 1 Practice for Use of a Dichromate Dosimetry

System

1.1 This practice covers procedures for using hermeti-

E 1607 Practice for Use of the Alanine-EPR Dosimetry

cally-sealed polymethylmethacrylate (PMMA) dosimeters for

System*

measuring absorbed dose in materials irradiated by photons

E 163 1 Practice for Use of Calorimetric Dosimetry Sys-

or electrons in terms of absorbed dose in water.

tems for Electron Beam Dose Measurements and Do-

1.2 This practice covers systems that permit absorbed

simeter Calibrations*

dose measurements under the following conditions:

E 1707 Guide for Estimating Uncertainties in Dosimetry

1.2.1 The absorbed dose range is 0.1 to 100 kGy.

for Radiation Processing*

1.2.2 The absorbed dose rate is 1 x lo-* to 1 X lo7

2.2 International Commission on Radiation Units and

Gys ’.

Measurements (ICR U” Reports:

1.2.3 The radiation energy range for photons is 0.1 to 50

ICRU Report 14-Radiation Dosimetry: X Rays and

MeV, and for electrons 3 to 50 MeV.

Gamma Rays with Maximum Photon Energies Between

1.2.4 The irradiation temperature is -78 to +5O ”C.

0.6 and 50 MeV5

1.3 This standard does not purport to address all of the

ICRU Report 17-Radiation Dosimetry: X Rays Gener-

safety concerns, if any, associated with its use. It is the

ated at Potentials of 5 to 150 kV5

responsibility of the user of this standard to establish appro-

ICRU Report 33-Radiation Quantities and Units5

priate safety and health practices and determine the applica-

ICRU Report 34-The Dosimetry of Pulsed Radiation5

bility of regulatory limitations prior to use.

ICRU Report 35-Radiation Dosimetry: Electron Beams

with Energies Between 1 and 50 MeVS

2. Referenced Documents

2.1 ASTM Standards:

3. Terminology

E 170 Terminology Relating to Radiation Measurements

3.1 Definitions

and Dosimetry*

3.1.1 absorbed dose (D), n-quantity of ionizing radiation

E 178 Practice for Dealing with Outlying Observations3

energy imparted per unit mass of a specified material. The SI

E 275 Practice for Describing and Measuring Performance

unit of absorbed dose is the gray (Gy), where 1 gray is

of Ultraviolet, Visible, and Near Infrared Spectro-

equivalent to the absorption of 1 joule per kilogram of the

photometers4

specified material (1 Gy = 1 J/kg). The mathematical

E 668 Practice for Application of Thermoluminescence-

relationship is the quotient of & by dm, where CZT is the

Dosimetry (TLD) Systems for Determining Absorbed

mean incremental energy imparted by ionizing radiation to

Dose in Radiation-Hardness Testing of Electronic

matter of incremental mass dm (see ICRU Report 33).

Devices*

ZI

E 1026 Practice for Using the Fricke Reference Standard

D d

(1)

=zi

Dosimetry System*

3.1.1.1 Discussion-The discontinued unit for absorbed

E 1204 Practice for Dosimetry in Gamma Irradiation

dose is the rad (1 rad = 100 erg per gram = 0.0 1 Gy).

Facilities for Food Processing*

Absorbed dose is sometimes referred to simply as dose.

E 1205 Practice for Use of a Ceric-Cerous Sulfate

3.1.2 absorbed-dose rate (I), n-the absorbed dose in a

Dosimetry System*

material per incremental time interval, that is, the quotient

E 126 1 Guide for Selection and Calibration of Dosimetry

of dD by dt (see ICRU Report 33).

Systems for Radiation Processing*

E 1400 Practice for Characterization and Performance of a =-

D dD

dt

High-Dose Radiation Dosimetry Calibration Labora-

tory* Unit: Gys-I.

3.1.2.1 Discussion-The absorbed-dose rate is often spec-

ified in terms of average value of I) over long-time intervals,

i This practice is under the jurisdiction of ASTM Committee E- 10 on Nuclear

Technology and Applications and is the direct responsibility of Subcommittee

for example, in units of Gy l min-l or Gy l h- ‘.

E 10.0 1 on Dosimetry for Radiation Processing.

3.1.3 analysis

wavelength, n-wavelength used a

Current edition approved June 10, 1996. Published July 1996. Originahy

published as E 1276 - 88. Last previous edition E 1276 - 93.

2 Annual Book ofASTM Standards, Vol 12.02.

3 Annual Book of AST. Standards, Vol 14.02. 3 Available from International Commission on Radiation Units and Measure-

4 Annual Book of ASTM Standards, Vol 14.0 1. ments, 79 10 Woodmoat Ave., Suite 800, Bethesda, MD 208 14.

IS0 15558:1998(E)

3.1.15 reference standard dosimeter, n-a dosimeter of

spectrophotometric instrument for the measurement of op-

tical absorbance. high metrological quality, used as a standard to provide

3.1.4 cafibrati~~ cunte, n-graphical representation of the measurements traceable to and consistent with measure-

dosimetry system ’s response function. ments made using primary standard dosimeters (see Guide

3.1.5 calibration facility, n-combination of an ionizing E 1261).

3.1. f 6 response, n-

radiation source and its associated instrumentation that see dosimeter response.

provides a uniform and reproducible absorbed dose or 3.1.17 response funct ion, n -mathematical representation

of the relationship between dosimeter response and absorbed

absorbed-dose rate traceable to national or international

standards, at a specified location and within a specific dose for a given dosimetry system.

material, and that may be used to derive the dosimetry 3.1.18 routine dosimeter, n-dosimeter calibrated against

system ’s response function or calibration curve. a primary-, reference-, or transfer-standard dosimeter and

3.1.6 dosimeter, n-a device that, when irradiated, ex- used for routine absorbed-dose measurement (see Guide

hibits a quantifiable change in some property of the device E 1261).

which can be related to absorbed dose in a given material 3.1.19 simulated product, n-a mass of material with

using appropriate analytical instrumentation and techniques. attenuation and scattering properties similar to those of the

3.1.7 d&meter batch, n-quantity of dosimeters made product, material, or substance to be irradiated.

from a specific mass of material with uniform composition, 3.1.19.1 Discussion-Simulated product is used during

fabricated in a single production run under controlled, irradiator characterization as a substitute for the actual

consistent conditions, and having a unique identification product, material, or substance to be irradiated. When used

in routine production runs, it is sometimes referred to as

code.

3.1.8 dosimeter response, n-the reproducible, quantifi- compensating dummy, When used for absorbed-dose map-

able radiation effect produced by a given absorbed dose. ping, simulated product is sometimes referred to as phantom

3.1.9 dosimeter stock, n-part of a dosimeter batch held material.

by the user. 3.1.20 specific absorbance (k), n-absorbance, A, at a

3.1.10 dosimetry system, n-a system used for deter- selected wavelength divided by the optical path length, d,

mining absorbed dose, consisting of dosimeters, measure- through the dosimeter, as follows:

ment instruments and their associated reference standards,

k = A/d

(4)

and procedures for the system ’s use.

3.1.1 1 electron equilibrium, n-a condition that exists in 3.1.20. I Discussion --In this practice (Practice E 1276), d

material under irradiation if the kinetic energies, number, is equated to dosimeter thickness (t). If t is virtually constant

and direction of electrons induced by the radiation are (within t 1 %), calculation of specific absorbance is unneces-

uniform throughout the measurement volume of interest.

sary, and absorbance A may be taken as the dose-related

Thus, the sum of the kinetic energies of the electrons quantity.

entering the volume equals the sum of the kinetic energies of 3.1.2 I traceability, n-the documentation demonstrating

the electrons leaving the volume (see ICRU Report 33). by means of an unbroken chain of comparisons that a

3.1.11.1 Discussion-Electron equilibrium is often re-

measurement is in agreement within acceptable limits of

ferred to as charged particle equilibrium (see Terminology uncertainty with comparable nationally or internationally

E 170 and ICRU Report 33). recognized standards.

3.1.12 measurement quality assurance plan, n-a docu- 3.1.22 transfir standard dosimeter, n-a dosimeter, often

mented program for the measurement process that assures a reference standard dosimeter, suitable for transport be-

on a continuing basis that the overall uncertainty meets the

tween different locations, used to compare absorbed-dose

requirements of the specific application. This plan requires measurements (see Guide E 126 1).

traceability to, and consistency with, nationally or interna- 3.1.23 uncertainty, n -a parameter associated with the

tionally recognized standards. result of a measurement, that characterizes the dispersion of

3.1.13 mean spec$c absorbance (I;i, n-average value of the values that could reasonably be attributed to the

k for a set of dosimeters irradiated to the same absorbed measurand or derived quantity.

dose, under the same conditions. 3.1.23.1 Discussion-The parameter may be, for ex-

ample, a standard deviation (or a given multiple of it), or the

1 n

E

=n c ki half-width of an interval having a stated confidence.

(3

i-l

3.1.23.2 Discussion-Uncertainty of measurement com-

prises, in general, many components. Some of these compo-

where:

nents may be evaluated from the statistical distribution of

n = number of dosimeters, and

.

the results of series of measurements and can be character-

k = individual dosimeter specific absorbance.

’ 3.1.14 polymethylmethacrylate (PUMA) dosimeter, n- ized by experimental standard deviations. The other compo-

piece of specially selected or specially developed PMMA nents, which also can be characterized by standard devia-

material that exhibits characterizable ionizing radiation-

tions, are evaluated from assumed probability distributions

induced.changes in specific optical absorbance as a function

based on experience or other information.

of absorbed doses, individually sealed by the manufacturer in 3.1.23.3 Discussion-It is understood that the result of

a hermetically sealed pouch. the measurement is the best estimate of the value of the

3.1.14.1 Discussion-The PMMA piece, when removed measurand, and that all components of uncertainty, in-

from the pouch, is still referred to as the dosimeter. cluding those arising from systematic effects, such as compo-

IS0 15558:1998(E)

@ IS0

5.1.4 Calibrated ‘Thickness Gage.

nents associated with corrections and reference standards,

5 1.5 Calibrated thickness gage blocks covering the range

contribute to the dispersion.

3.2 Other appropriate terms may be found in Termi- of thicknesses encountered.

nology E 170.

NOTE 2-For constant thickness dosimeters (see 3.1.20. I) documen-

tation provided by the manufacturer of the PMMA dosimeter with

4. Significance and Use

regard to the thickness and its uniformity must first be verified by the

user for a representative sample, and may then be substituted for direci,

4.1 Polymethylmethacrylate dosimetry systems are com-

measurement by the user.

monly applied in industrial radiation processing, for ex-

ample, in the sterilization of medical devices and the

5.1.6 Calibration curve on response function see 75.6.

processing of foods. In these applications, doses fall mostly

within the 0.1 to 100 kGy working range of the family of

6. Performance Check of Instrumentation

PMMA dosimeters.

6.1 Check and document the uncertainties of the wave-

4.2 Properly selected PMMA dosimeter materials provide

length and absorbance scales of the spectrophotometer at or

a means of directly estimating absorbed doses in near

near the analysis wavelength at documented time intervals

water-equivalent substances, such as plastics, cotton, paper,

during periods of use, or whenever there are indications of

gut, and rubber. The doses are normally expressed in terms

poor performance. Compare and document this information

of dose in water (see 4.7). Under the influence of ionizing

with the original instrument specifications to verify adequate

radiation, chemical reactions take place in the material,

performance. (See Practices E 275 and E 1026.)

creating and/or enhancing absorption bands in the visible

6.2 Check the thickness gage before, during, and after use

and/or ultraviolet regions of the spectrum. Absorbance is

to assure reproducibility and lack of zero drift. Check and

determined at selected wavelengths within these radiation-

document the calibration of the gage at documented time

induced absorption bands. Examples of appropriate wave-

intervals. Use gage blocks traceable to national standards for

lengths used for analysis of specific dosimeters are provided

this purpose.

in Table X1.1.

4.3 In the application of a specific dosimetry system,

7. Calibration of Dosimeters

absorbed dose is determined by using an experimentally

7.1 Calibration of PMMA dosimeters can be accom-

derived calibration curve. The calibration curve is deter-

plished by irradiating the dosimeters in a calibration facility,

mined by measuring sets of dosimeters irradiated to known

or by irradiating the dosimeters, along with reference or

absorbed doses that adequately span the range of utilization

transfer standard dosimeters in a production irradiator (see

of the system (see 7.5.2).

Guide E 126 1).

4.4 Polymethylmethacrylate dosimetry systems require

7.2 The gamma- or electron-beam facility used may be an

calibration traceable to national or international standards.

accredited calibration facility that provides an absorbed-dose

See Guide E 1261.

rate measured by reference or transfer standard dosimeters,

4.5 During calibration and use, possible effects of condi-

or it may be a production irradiator. If a production

tions such as temperature, light exposure, energy spectrum,

irradiator is used, the absorbed doses delivered to the

and absorbed dose rate are taken into account.

calibration dosimeters shall be determined by means of

,

4.6 Unprotected PMMA dosimeter material is sensitive to

reference or transfer standard dosimeters irradiated together

changes in humidity, and cut pieces are therefore individu-

with the dosimeters to be calibrated, under conditions that

ally sealed in water impermeable pouches at the manufac-

ensure that the calibration- and corresponding reference- or

turing stage. They must be kept in these sealed pouches

transfer-standard dosimeter sets receive the same dose, under

during irradiation.

the same envircnmental conditions.

4.7 Absorbed dose in materials other than water may be

determined by applying conversion factors in accordance

NOTE 3-The radiation response of PMMA dosimeters may be

with Cuide E 1261. affected by extremes of environmental or seasonal conditions, such as

absorbed dose rate and temperature found in some production irradip

NOTE l-For a comprehensive discussion of various dosimetry

tors (see Refs l-10, 17-19, and 25)? In these circumstances the use of

methods applicable to the radiation types and energies discussed in this

dosimeter calibrations performed at fixed dose rates and fixed tempera-

practice, see ICRU Reports 14, 17, 34, and 35.

tures could result in unacceptably large increases in dosimetric uncer-

tainty. If prior experience, manufacturer ’s recommendations, or scien-

5. Apparatus

tific literature suggest that the range of environmental conditions met by

the dosimeters in the production facility arc likely to significantly

5.1 Components of the PMMA Dosimetry System--The

increase the uncertainties, then the PMMA dosimeters should be

following shall be used to determine absorbed dose with

calibrated in an environment that encompasses these conditions. This

PMMA dosimetry systems:

type of calibration may, for example, be carried out using the produc-

5.1.1 Polymethylmethacrylate Dosimeters.

tion irradiator, under the conditions identified, using reference- or

5.1.2 Spectrophotometer (or an equivalent instrument), transfer-standard dosimeters to determine the calibration doses given.

capable of determining optical absorbance at the analysis

7.3 Absorbed doses shall be specified in terms of absorbed

wavelength and having documentation covering analysis

dose in water, or in another specified material appropriate

wavelength range, accuracy of wavelength selection and

for the particular application.

absorbance determination, spectral bandwidth, and stray

light rejection.

5.1.3 Holder, to position the dosimeter reproducibly in,

6 The boldface numbers in parentheses refer to the list of references at the end

and perpendicular to, the analyzing light beam. of this practice.

IS0 15558: 1998(E) 0 IS0

dsTE, E 1276

If Q is less than 1, use a minimum

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...