ISO 25841:2014

(Main)Female condoms — Requirements and test methods

Female condoms — Requirements and test methods

ISO 25841:2014 specifies the minimum requirements and test methods for female condoms, which are supplied to consumers for contraceptive purposes, assisting in the prevention of sexually transmitted infections.

Préservatifs féminins — Exigences et méthodes d'essai

General Information

- Status

- Withdrawn

- Publication Date

- 13-Jan-2014

- Withdrawal Date

- 13-Jan-2014

- Technical Committee

- ISO/TC 157 - Non-systemic contraceptives and STI barrier prophylactics

- Drafting Committee

- ISO/TC 157 - Non-systemic contraceptives and STI barrier prophylactics

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 14-Aug-2017

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 31-May-2014

- Effective Date

- 29-Jun-2013

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

ISO 25841:2014 is a standard published by the International Organization for Standardization (ISO). Its full title is "Female condoms — Requirements and test methods". This standard covers: ISO 25841:2014 specifies the minimum requirements and test methods for female condoms, which are supplied to consumers for contraceptive purposes, assisting in the prevention of sexually transmitted infections.

ISO 25841:2014 specifies the minimum requirements and test methods for female condoms, which are supplied to consumers for contraceptive purposes, assisting in the prevention of sexually transmitted infections.

ISO 25841:2014 is classified under the following ICS (International Classification for Standards) categories: 11.200 - Birth control. Mechanical contraceptives. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 25841:2014 has the following relationships with other standards: It is inter standard links to ISO 25841:2017, ISO 25841:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 25841:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 25841

Second edition

2014-01-15

Female condoms — Requirements and

test methods

Préservatifs féminins — Exigences et méthodes d’essai

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

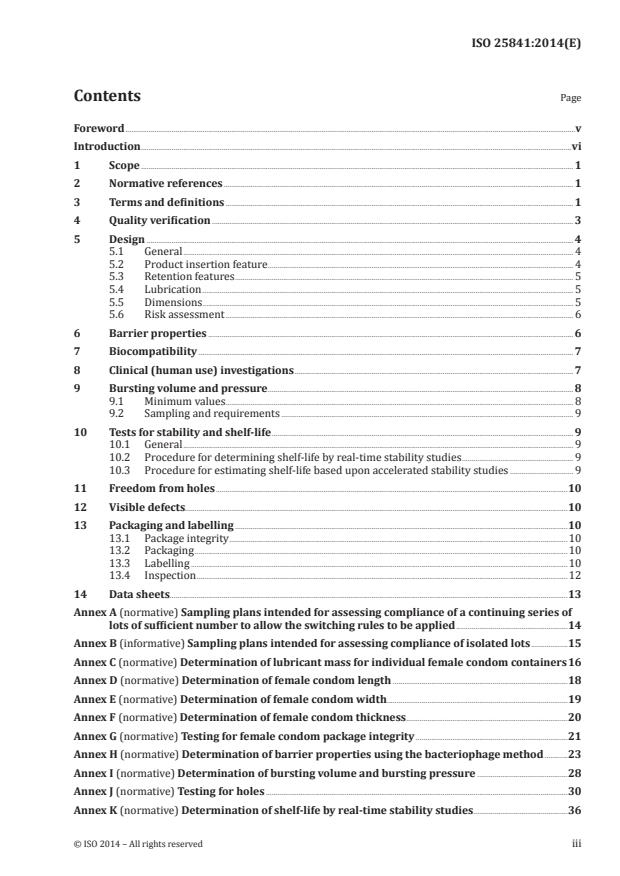

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Quality verification . 3

5 Design . 4

5.1 General . 4

5.2 Product insertion feature . 4

5.3 Retention features . 5

5.4 Lubrication . 5

5.5 Dimensions . 5

5.6 Risk assessment . 6

6 Barrier properties . 6

7 Biocompatibility . 7

8 Clinical (human use) investigations . 7

9 Bursting volume and pressure . 8

9.1 Minimum values. 8

9.2 Sampling and requirements . 9

10 Tests for stability and shelf-life . 9

10.1 General . 9

10.2 Procedure for determining shelf-life by real-time stability studies . 9

10.3 Procedure for estimating shelf-life based upon accelerated stability studies . 9

11 Freedom from holes .10

12 Visible defects.10

13 Packaging and labelling .10

13.1 Package integrity .10

13.2 Packaging .10

13.3 Labelling .10

13.4 Inspection .12

14 Data sheets.13

Annex A (normative) Sampling plans intended for assessing compliance of a continuing series of

lots of sufficient number to allow the switching rules to be applied .14

Annex B (informative) Sampling plans intended for assessing compliance of isolated lots .15

Annex C (normative) Determination of lubricant mass for individual female condom containers 16

Annex D (normative) Determination of female condom length .18

Annex E (normative) Determination of female condom width .19

Annex F (normative) Determination of female condom thickness .20

Annex G (normative) Testing for female condom package integrity .21

Annex H (normative) Determination of barrier properties using the bacteriophage method .23

Annex I (normative) Determination of bursting volume and bursting pressure .28

Annex J (normative) Testing for holes .30

Annex K (normative) Determination of shelf-life by real-time stability studies .36

Annex L (informative) Guidance on conducting and analysing accelerated ageing studies .38

Bibliography .41

iv © ISO 2014 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 157, Non-systemic contraceptives and STI barrier

prophylactics.

This second edition cancels and replaces the first edition (ISO 25841:2011), which has been technically

revised.

Introduction

A female condom is a sheath that completely lines the vaginal canal and is designated to be retained

in the vagina during sexual intercourse and after withdrawal of the penis to prevent pregnancy and

transmission of sexually transmitted infections (STIs).

A female condom is distinguished from a male condom in that it is retained in the vagina after withdrawal

of the penis. The external component of the device can provide some coverage to the external female

genitalia. Non-porous, intact, polymer films can be effective barriers to human immunodeficiency virus

(HIV), to other infectious agents responsible for the transmission of STls, and to spermatozoa. Female

condoms made from polymer films can be effective for contraceptive purposes and in the prevention of

STI transmission. To be effective, it is essential that female condoms completely line the vaginal canal,

be free from holes and defects, have adequate physical properties so as not to break during use, are

correctly packaged to protect them during storage, and are correctly labelled to facilitate their use.

To be safe, it is essential that the female condom and any lubricant, additive, dressing, individual

packaging material, or powder applied to it neither contain nor liberate substances in amounts that are

toxic, sensitizing, locally irritating, or otherwise harmful under normal conditions of storage or use.

Female condoms are non-sterile medical devices, but manufacturers are advised to take appropriate

precautions to minimize microbiological contamination of the product during manufacturing and

packaging. To ensure high quality products, it is essential that female condoms be designed and

produced under a good quality management system. Reference can be made, for example, to ISO 9000,

ISO 9001, ISO 9004, ISO 13485, and ISO 14971. To estimate the shelf-life of any new or modified female

condom, manufacturers conduct stability tests before the product is placed on the market. This ensures

that manufacturers have adequate data to support shelf-life claims and that these data are available

for review by regulatory authorities, test laboratories, and purchasers. They are also intended to limit

the need for third parties to conduct long-term stability studies. Real-time shelf-life studies are also

initiated, but not necessarily completed, prior to placing the product in the market.

Because female condoms are a relatively new class of devices and designs of female condoms vary

considerably, clinical investigations in humans are necessary to continue to build evidence of safety and

efficacy. These investigations enable an assessment of the overall performance of internal and external

retention features, failure modes, safety, and effectiveness of female condoms. This International

Standard represents minimal requirements and test methods and acknowledges that new designs can

require further due rigour of retention and other features as well as additional definition of specifications

and test methods by the manufacturer.

All these issues are addressed in this International Standard.

vi © ISO 2014 – All rights reserved

INTERNATIONAL STANDARD ISO 25841:2014(E)

Female condoms — Requirements and test methods

1 Scope

This International Standard specifies the minimum requirements and test methods for female condoms,

which are supplied to consumers for contraceptive purposes, assisting in the prevention of sexually

transmitted infections.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 2859-1:1999, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by

acceptance quality limit (AQL) for lot-by-lot inspection

ISO 4074, Natural rubber latex male condoms — Requirements and test methods

ISO 10993-1, Biological evaluation of medical devices — Part 1: Evaluation and testing within a risk

management process

ISO 10993-5, Biological evaluation of medical devices — Part 5: Tests for in vitro cytotoxicity

ISO 10993-10, Biological evaluation of medical devices — Part 10: Tests for irritation and skin sensitization

ISO 10993-11, Biological evaluation of medical devices — Part 11: Tests for systemic toxicity

ISO 13485, Medical devices — Quality management systems — Requirements for regulatory purposes

ISO 14155 (all parts), Clinical investigation of medical devices for human subjects

ISO 14971, Medical devices — Application of risk management to medical devices

ISO 15223 (all parts), Medical devices — Symbols to be used with medical device labels, labelling and

information to be supplied

3 Terms and definitions

For the purposes of this document, the terms and definitions in ISO 2859-1 and the following apply.

3.1

acceptance quality limit

AQL

quality level that is the worst tolerable process average when a continuing series of lots is submitted for

acceptance sampling

[SOURCE: ISO 2859-1:1999, 3.1.26]

3.2

consumer package

package intended for distribution to a consumer, containing one or more individual container(s) of

female condoms

3.3

date of manufacture

date of formation of the female condom sheath or the date the female condoms are packed in their

individual containers provided, in the latter case, a maximum period of bulk storage is specified and

shelf-life studies have been conducted on female condoms that have been subjected to the maximum

bulk storage period

3.4

expiry date

date at the end of the shelf-life

3.5

female condom

sheath that completely lines the vaginal canal and is designed to be retained in the vagina during sexual

intercourse to prevent pregnancy and STIs

3.6

identification number

number, or combination of numerals, symbols, or letters used by a manufacturer on consumer packages

to uniquely identify the lot numbers of individual female condoms contained in that package, and from

which it is possible to trace those lots through all stages of manufacturing, packaging, and distribution

Note 1 to entry: Whenever the consumer package contains only one kind of female condom, the identification

number can be the same as the lot number. However, if the consumer package contains several different types of

female condoms, for instance, female condoms of different shapes or colours, the identification number is different

from the lot number.

3.7

individual container

primary package containing a single female condom

3.8

inspection level

relationship between lot size and sample size

[SOURCE: ISO 2859-1:1999, 10.1]

3.9

lot

collection of female condoms of the same design, colour, shape, size, and formulation, manufactured at

essentially the same time, using the same process, raw materials of the same specifications, common

equipment, and packed with the same lubricant and any other additive or dressing in the same type of

individual container

Note 1 to entry: This International Standard does not specify the size of a lot; however, it is possible for a purchaser

to do so as part of the purchasing contract. Attention is drawn to the difficulties that can be associated with

the distribution and control of very large lots. The recommended maximum individual lot size for production is

500 000 female condoms.

3.10

lot number

number or combination of numerals, symbols, or letters used by the manufacturer to identify a lot of

individually packaged female condoms, and from which it is possible to trace that lot through all stages

of manufacture up to packaging

3.11

lot test

test to assess the conformity of a lot

Note 1 to entry: A lot test can be limited to include only those parameters that can change from lot to lot.

2 © ISO 2014 – All rights reserved

3.12

non-visible hole

hole in a female condom that is not visible under normal or corrected vision, but is detected by a suitable

water leak test

Note 1 to entry: Leakage during testing can be detected, for instance, by rolling a female condom on absorbent

paper.

Note 2 to entry: Suitable tests are specified in this International Standard.

3.13

sampling plan

specific plan that indicates the number of units of product from each lot which are to be inspected

(sample size or series of sample sizes) and the associated criteria for determining the acceptability of

the lot (acceptance and rejection numbers)

3.14

shelf-life

time from date of manufacture to the claimed expiry date during which condoms are required to conform

to specified requirements

3.15

total clinical failure

sum of female condoms that clinically break or slip, or are associated with misdirection, invagination, or

any additional failure mode(s) identified in the risk assessment which results in reduction of the female

condom protective function

Note 1 to entry: Total clinical failure rate is calculated by dividing the number of female condoms with a clinical

failure by the number of female condoms used during sexual intercourse.

3.16

visible hole

hole or tear in the female condom that is visible under normal or corrected vision

3.17

visible defect

other than a visible hole, broken, missing, or severely distorted retention feature, permanent crease

with adhesion of the film, or unintentional adhesion of the film to retention feature, including defect

particles from female condoms or other materials embedded in the female condom wall

4 Quality verification

Female condoms are produced in large quantities. Inevitably, there is some variation between individual

female condoms. A small proportion of female condoms in each production run might not meet the

requirements in this International Standard. Furthermore, the majority of the test methods described

in this International Standard is destructive. For these reasons, the only practicable method of assessing

conformity with this International Standard is by testing a representative sample from a lot or series of

lots. Basic sampling plans are identified in ISO 2859-1. See ISO/TR 8550 for guidance on the selection of

an acceptance sampling system, scheme, or plan for the inspection of discrete items in a lot. For testing

purposes, sampling shall be conducted by lot number, not by identification number. Handling and storage

conditions shall be documented before drawing the samples.

Sampling plans shall be selected to provide an acceptable level of consumer protection. Suitable sampling

plans are given in Annexes A and B.

Annex A describes sampling plans, based on ISO 2859-1, and is most applicable to manufacturers or

purchasers assessing the conformity of a continuing series of lots. The full level of consumer protection

available depends upon the switch to tightened inspection if deterioration in quality is detected. The

switching rules cannot offer full protection for the first two lots tested, but become progressively more

effective as the number of lots in a series increases. The sampling plans in Annex A are recommended

when five or more lots are being tested.

Annex B describes sampling plans, based on ISO 2859-1, which are recommended for the assessment of

isolated lots. It is recommended that these sampling plans be used for the assessment of fewer than five

lots, for example in cases of dispute, for referee purposes, for type testing, for qualification purposes, or

for short runs of continuing series of lots.

It is necessary to know the lot size in order to derive from ISO 2859-1 the number of female condoms to

be tested. The lot size varies among manufacturers and is regarded as part of the process and quality

controls used by the manufacturer.

Instead of concentrating solely on evaluation of the final product, the design and manufacture of

the female condoms shall conform to the appropriate requirements of ISO 13485, which include the

following:

a) controls in the work environment to ensure product safety;

b) focus on risk-management activities and design transfer activities during product development;

c) specific requirements for inspection and traceability for implantable devices;

d) specific requirements for documentation and validation of processes for sterile medical devices;

e) specific requirements for verification of the effectiveness of corrective and preventive actions.

5 Design

5.1 General

Female condoms shall be designed to prevent pregnancy and STIs during vaginal intercourse. A female

condom is distinguished from a male condom in that it is retained in the vagina after insertion. A female

condom can be made from natural rubber latex (NRL) or synthetic materials.

The design of a new female condom shall take into consideration the following design aspects:

a) product insertion into the vagina;

b) product retention during sexual intercourse or penile removal;

c) penile misdirection during sexual intercourse;

d) safe product removal after sexual intercourse.

5.2 Product insertion feature

Designs for female condoms shall include either a feature or tool to aid in the proper insertion and

deployment of the female condom or methods for insertion of the female condom without such additional

aids.

The insertion feature design, materials, and/or method shall be evaluated for function as part of design

validation and clinical evaluation of the finished female condom device described in Clause 8.

The insertion feature materials shall be evaluated for biocompatibility (irritation, sensitization,

cytotoxicity, and acute systemic cytotoxicity) as an integrated feature of the finished female condom

device in accordance with Clause 7.

Manufacturers shall identify specifications and test methods as appropriate to verify the design and

to ensure the quality and consistency of components and materials used for each insertion feature.

Examples of specifications the manufacturer should consider include critical dimensions, durometer,

stiffness, and density.

4 © ISO 2014 – All rights reserved

5.3 Retention features

Designs for female condoms shall incorporate intra-vaginal retention features to retain the female

condom within the vagina during sexual intercourse and permit safe withdrawal after use. Intra-vaginal

retention features can be affixed on or placed within the sheath. Examples of intra-vaginal retention

mechanisms include, but are not limited to, elastomeric rings and open or closed cell foam components.

Designs for female condoms shall incorporate external retention features to keep the open end of the

female condom open during sexual intercourse, prevent misdirection of penis, and prevent female

condom invagination. External retention features include, but are not limited to, annular, triangular, or

other-shaped components affixed to the open end of the female condom.

Retention feature designs, materials, and/or methods shall be evaluated for function as part of design

validation and clinical evaluation of the finished female condom device described in Clause 8. They shall

also be evaluated in this manner to ensure the features stay affixed to the sheath or are retained within

the sheath so that they remain intact during sexual intercourse and during product withdrawal, such

that the features are completely removed from the vagina when the female condom is removed from the

vagina.

Retention feature materials shall be evaluated for biocompatibility (irritation, sensitization, and

cytotoxicity) as an integrated feature of the finished female condom device in accordance with Clause 7.

Manufacturers shall identify specifications and test methods as appropriate to verify the design and

to ensure the quality and consistency of components and materials used for each retention feature.

Examples of specifications the manufacturer should consider include critical dimensions, durometer,

stiffness, and density.

5.4 Lubrication

The design of a female condom can include lubrication in any of the following manners:

a) lubricant pre-applied directly on the packaged female condom as supplied;

b) lubricant supplied in a separate container for application to the female condom by the user;

c) both pre-applied and as a separate container.

The type and amount of lubricant is unique to each female condom design. The manufacturer shall

specify the range for the mass of lubricant consistent with the mass of lubricant used in the clinical

trial described in Clause 8. When tested in accordance with the method given in Annex C, taking 13

female condoms from each lot, no female condom lubricant mass measurement shall be outside of the

manufacturer’s specified range.

Manufacturers shall identify specifications and test methods as appropriate to verify the design and to

ensure the quality and consistency of the lubricant. Examples of specifications the manufacturer should

consider include viscosity.

5.5 Dimensions

5.5.1 Length

The length of a female condom is unique to each design. The manufacturer shall specify a nominal value

and the range for the length of female condoms consistent with the length of the female condoms used

in the clinical trial described in Clause 8. When tested in accordance with the method given in Annex D,

taking 13 female condoms from each lot, no female condom length measurement shall be outside of the

manufacturer’s specified range.

5.5.2 Width

The width of a female condom is unique to each design. The manufacturer shall specify the range for the

width of the female condom consistent with the width of the female condoms used in the clinical trial

described in Clause 8. When tested in accordance with the method given in Annex E, taking 13 female

condoms from each lot, no female condom width measurement shall be outside of the manufacturer’s

specified range.

5.5.3 Thickness

The thickness of a female condom is unique to each design. The range for the thickness of the female

condom shall be specified by the manufacturer, based upon the female condoms that are used in the

clinical trials. When tested by the method given in Annex F, taking 13 female condoms from each lot, no

female condom thickness measurement shall be outside of the manufacturer’s specified range (from the

clinical trials).

5.6 Risk assessment

5.6.1 A risk assessment for the product shall be conducted in accordance with ISO 14971. The assessment

shall identify all potential failure modes for the device as well as any other safety and efficacy concerns.

Failure modes identified in the risk analysis shall be compared to those listed in 5.6.2. In addition to these

known failure modes, any new failure modes shall be assessed in the design and execution of any pre-

clinical or clinical investigations of the female condom. Manufacturers shall make the results of the risk

assessment available to regulatory authorities.

5.6.2 The following are definitions of known female condom failure modes.

a) Clinical breakage is defined as breakage during sexual intercourse or during withdrawal of the

female condom from the vagina. Clinical breakage is breakage with potential adverse clinical

consequences. The clinical breakage rate is calculated by dividing the number of female condoms

reported to have broken during sexual intercourse or during withdrawal by the number of female

condoms used during sexual intercourse.

NOTE Total breakage is defined as the sum of all female condom breakages at any time before, during, or

after sexual intercourse. It includes both clinical breakages and non-clinical breakages. The total breakage

rate is calculated by dividing the total number of female condoms that broke by the number of female condom

packages opened.

b) Slippage is defined as an instance when a female condom slips completely out of the vagina during

sexual intercourse. The slippage rate is calculated by dividing the number of female condoms that

slipped by the number of female condoms used during sexual intercourse.

c) Misdirection is defined as vaginal penetration whereby the penis is inserted between the female

condom and the vaginal wall. The misdirection rate is calculated by dividing the number of reported

events of misdirection by the number of female condoms used during sexual intercourse.

d) Invagination is defined as an instance when the external retention feature of the female condom

is partially or fully pushed into the vagina during sexual intercourse. The invagination rate is

calculated by dividing the number of events of invagination by the number of female condoms used

during sexual intercourse.

6 Barrier properties

The barrier properties of the female condom shall be established by viral penetration studies using

a suitable surrogate virus, for example bacteriophage phi-X 174. When tested in accordance with the

method given in Annex H, viral penetration properties shall be compared with those of a male latex

condom that meets the requirements of ISO 4074.

6 © ISO 2014 – All rights reserved

7 Biocompatibility

Biocompatibility for the finished product and its components shall be established. The female condom,

together with any lubricant, additive, dressing material, or powder applied to it, shall be tested as well

as all retention or insertion devices, whether affixed or removable. Accredited laboratories shall be used

for the testing.

Since the female condom is in repeated contact with surface mucosa and possibly compromised tissue

surfaces, the testing shall be conducted to demonstrate that the materials are neither cytotoxic nor

cause sensitization, mucosal irritation, or acute systemic cytotoxicity in accordance with the relevant

clauses of ISO 10993-1, ISO 10993-5, ISO 10993-10, and ISO 10993-11, respectively. If there is a likelihood

of systemic absorption of any components or residuals, mutagenicity testing shall be performed.

Regulatory bodies can require that the results be interpreted by a qualified toxicologist. The biological

assessment report shall justify that the product is safe under normal conditions of use. All data generated

in these evaluations shall be made available to regulatory authorities on request.

The manufacturer shall also obtain, and make available on request from regulatory authorities,

toxicity data on all the additives and residual monomers, solvents, and known impurities used in the

manufacture of the female condom subject to this International Standard. Suitable material safety data

sheets shall be supplied on request for materials used in the manufacture of products conforming with

this International Standard.

8 Clinical (human use) investigations

8.1 Clinical investigations of female condoms in humans shall be conducted in accordance with ISO 14155

(all parts), and are intended to be conducted with a future International Standard on functionality studies

of acute failure events based on self-reports.

NOTE Clinical investigations can also be subject to local regulatory requirements.

8.2 In order to assess the safety and effectiveness of a new female condom design, a contraceptive

effectiveness study shall be conducted. The study design shall be adequate to allow the 6-month

pregnancy rate to be computed using life table methods with at least 100 women years of data (e.g.

200 women completing 6 months). The 12-month pregnancy rate can be extrapolated from the 6-month

data providing it is made clear that the value obtained is an estimate and the method of extrapolation is

documented. The study should also measure all the rates of all failure modes identified in Clause 5.

8.3 New female condom designs that are sufficiently similar to a design that is already approved

and marketed can claim exemption from the requirement of 8.2. If a new female condom design and

specifications are sufficiently similar to those of a marketed device and that marketed device has a known

pregnancy rate established from a clinical effectiveness study, the manufacturer can refer to the estimated

pregnancy rate of the marketed device instead of conducting a contraceptive effectiveness study on the

new device. If there is no suitable control female condom available in the market with an established

pregnancy rate, then the manufacturer can use an alternative female condom that has been evaluated

directly against a device with an established pregnancy rate as the control.

To claim exemption from the requirements of 8.2, the following requirements shall be met:

a) The manufacturer shall conduct a risk analysis in accordance with 5.6.

b) The manufacturer shall establish that the new female condom design and specifications are

sufficiently similar to those of a marketed female condom, after assessing the impact of each

difference in dimension, material, insertion, and retention feature or method, on the incidence of

each failure mode described in 5.6.2, on the incidence of new failure modes, and on the efficacy of

the female condom in preventing pregnancy and STI transmission. To be considered sufficiently

similar to a marketed device, the risk analysis shall demonstrate that the new female condom can

be expected to have the same failure modes as the marketed device and no new failure modes or

other risk factors. Manufacturers shall make the results of this assessment available to regulatory

authorities.

c) The manufacturer shall conduct a randomized controlled clinical investigation comparing the new

female condom to a control female condom and the following.

1) The control female condom shall meet the bursting volume and pressure, freedom from holes,

and visible defects requirements of Clauses 9, 11, and 12, and shall have a known pregnancy

rate established from a clinical effectiveness study. If there is no suitable control female condom

available in the market with an established pregnancy rate, then the manufacturer can use an

alternative female condom that has been evaluated directly against a device with an established

pregnancy rate as the control.

2) The total clinical failure rate of the new female condom shall be shown to be non-inferior to the

total clinical failure rate of the control female condom.

3) The upper bound of the 95 % one-sided confidence interval for the new female condom total

clinical failure rate minus the control female condom total clinical failure rate shall be less than

or equal to 3 %.

4) The bound shall be calculated using a method that accounts for the unique characteristics of

data such as

i) each study participant can contribute data from more than one female condom use, and

ii) possibly low event rates.

5) The control female condom total clinical failure rates shall not be lower than 1 %.

9 Bursting volume and pressure

9.1 Minimum values

Manufacturers shall establish appropriate minimum pressure and volume limits for the specific female

condom based on the airburst properties of the lot or lots used for the clinical trial.

For products in the market prior to the publication of this International Standard, manufacturers shall

comply with the procedure in 9.1 or can use existing specifications as established by their regulatory

bodies for bursting properties. The specifications shall be consistent with the requirements in 9.1 based

on a representative sample of the product tested at the time of the clinical trial. Information regarding

the establishment of these values shall be made available to regulatory and governmental authorities

upon request.

The following procedure shall be used.

a) Determine the airburst properties of the lot or lots used in the clinical study using a sample size of

at least 2 000 female condoms. If more than one lot was used in the clinical study, the sample shall

be drawn across all the lots, each individual lot being sampled proportionally to its size.

b) Set the minimum airburst limits at 80 % of the 1,5 percentile values of the airburst volumes and

pressures determined above (see 9.1).

NOTE Based on the data supplied by the manufacturers for both synthetic and natural rubber male latex

condoms, taking 80 % of the 1,5 percentile values provides an adequate tolerance for the long-term lot-to-lot

variability seen in normal manufacture.

For the purposes of this International Standard, the relevant percentile, x, shall be determined by

ranking the N data values and taking the value of the n-th rank where n = Nx/100 + 1/2 rounded to the

nearest integer (e.g. for N = 2 000, the lower 1,5 percentile is the 31st lowest value).

8 © ISO 2014 – All rights reserved

9.2 Sampling and requirements

Whenever tested by the methods given in Annex I, the bursting volumes and bursting pressures shall not

be less than the minimum values established by the procedures described in 9.1. The compliance level

shall be an AQL of 1,5 for non-conforming female condoms. A non-conforming female condom is defined

as a female condom that fails the requirements for volume and/or pressure, or any female condom that

exhibits any leakage during airburst testing.

10 Tests for stability and shelf-life

10.1 General

Manufacturers shall verify that the female condoms conform to the airburst, freedom from holes, visible

defects, and labelling requirements of Clauses 9, 11, and 12 and 13.1 until the end of the labelled shelf-

life. Shelf-life claims shall not exceed 5 years.

Data supporting the shelf-life claims made by the manufacturer shall be made available to the appropriate

regulatory authorities and direct purchasers upon request.

Before a new or modified female condom design is placed in the market, the following requirements

shall be met.

a) A real-time stability study, as described in 10.2 to determine shelf-life, shall have commenced.

b) Pending completion of the real-time stability study, shelf-life shall be estimated as described in 10.3.

For existing designs on the market at the date of publication of this International Standard, real-time

+5

data in a form consistent with Annex K, at a temperature of (30 ) °C, shall be acceptable to verify the

−2

shelf-life claims.

10.2 Procedure for determining shelf-life by real-time stability studies

After testing in accordance with Annex K, the female condoms shall meet the requirements of Clauses 9,

11, and 12 and 13.1.

If the real-time data indicate a shorter shelf-life than that claimed on the basis of accelerated ageing

(see 10.3), the manufacturer shall notify the relevant regulatory authorities and direct purchasers. The

manufacturer shall change the shelf-life claim for the product to one based on the real-time stability

study. In no case shall shelf-life exceed 5 years. For female condoms placed on the market, real-time

stability studies shall be completed for the full period of the shelf-life claim.

10.3 Procedure for estimating shelf-life based upon accelerated stability studies

Pending the completion of real-time stability studies, accelerated stability studies shall be used to

+5

estimate the shelf-life. Shelf-life estimates shall be based on a mean kinetic temperature of (30 ) °C for

−2

all climatic conditions and can be carried out on female condoms from the same production lots as used

for real-time determination of shelf-life.

Several approaches to the analysis of accelerated-ageing data have been explored. However, at the

date of publication, no single method of analysis was sufficiently validated or widely used to justify its

designation as a standard method. The manufacturer can refer to ISO 11346 (Arrhenius testing) or use

other validated methods to conduct accelerated shelf-life studies. It is anticipated that as manufacturers

and regulatory agencies accumulate real-time data, a consensus method for the next revision of this

International Standard will be developed. Meanwhile, the results of accelerated-ageing data can be

analysed by a number of methods or as stipulated by the manufacturer’s regulatory authority.

NOTE Arrhenius testing cannot be applicable for some types of materials used for the manufacture of female

condoms.

Guidance on the conduct and analysis of accelerated ageing studies is provided in Annex L. Data generated

from such studies shall support the claim that the female condoms fulfil the requirements of Clauses 9,

+5

11, and 12 and 13.1 for the duration of the labelled shelf-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...