ISO 19904-1:2019

(Main)Petroleum and natural gas industries — Floating offshore structures — Part 1: Ship-shaped, semi-submersible, spar and shallow-draught cylindrical structures

Petroleum and natural gas industries — Floating offshore structures — Part 1: Ship-shaped, semi-submersible, spar and shallow-draught cylindrical structures

This document provides requirements and guidance for the structural design and/or assessment of floating offshore platforms used by the petroleum and natural gas industries to support the following functions: — production; — storage and/or offloading; — drilling and production; — production, storage and offloading; — drilling, production, storage and offloading. NOTE 1 Floating offshore platforms are often referred to using a variety of abbreviations, e.g. FPS, FSU, FPSO (see Clauses 3 and 4), in accordance with their intended mission. NOTE 2 In this document, the term "floating structure", sometimes shortened to "structure", is used as a generic term to indicate the structural systems of any member of the classes of platforms defined above. NOTE 3 In some cases, floating platforms are designated as "early production platforms". This term relates merely to an asset development strategy. For the purposes of this document, the term "production" includes "early production". This document is not applicable to the structural systems of mobile offshore units (MOUs). These include, among others, the following: — floating structures intended primarily to perform drilling and/or well intervention operations (often referred to as MODUs), even when used for extended well test operations; — floating structures used for offshore construction operations (e.g. crane barges or pipelay barges), for temporary or permanent offshore living quarters (floatels), or for transport of equipment or products (e.g. transportation barges, cargo barges), for which structures reference is made to relevant recognized classification society (RCS) rules. This document is applicable to all possible life-cycle stages of the structures defined above, such as: — design, construction and installation of new structures, including requirements for inspection, integrity management and future removal, — structural integrity management covering inspection and assessment of structures in-service, and — conversion of structures for different use (e.g. a tanker converted to a production platform) or re‑use at different locations. The following types of floating structure are explicitly considered within the context of this document: a) ship-shaped structures and barges; b) semi-submersibles; c) spars; d) shallow-draught cylindrical structures. In addition to the structural types listed above, this document covers other floating platforms intended to perform the above functions, consisting of partially submerged buoyant hulls made up of any combination of plated and space frame components. These other structures can have a great range of variability in geometry and structural forms (e.g. tension leg platforms) and, therefore, can be only partly covered by the requirements of this document. In other cases, specific requirements stated in this document can be found not to apply to all or part of a structure under consideration. NOTE 4 Requirements for topsides structures are presented in ISO 19901-3. In the above cases, conformity with this document requires the design to be based upon its underpinning principles and to achieve a level of safety equivalent, or superior, to the level implicit in it. NOTE 5 The speed of evolution of offshore technology often far exceeds the pace at which the industry achieves substantial agreement on innovation in structural concepts, structural shapes or forms, structural components and associated analysis and design practices, which are continuously refined and enhanced. On the other hand, International Standards can only capture explicit industry consensus, which requires maturation and acceptance of new ideas. Consequently, advanced structural concepts can, in some cases, only be partly covered by the requirements of this document. This document is applicable to steel floating structures. The principles documented herein are, however, considered to be generally applicable to structures fabricated in materials other

Industries du pétrole et du gaz naturel — Structures en mer flottantes — Partie 1: Structures en forme de navire, structures semi-submersibles, plates-formes spar et structures cylindriques à faible tirant d’eau

Le présent document spécifie des exigences et des recommandations pour la conception et/ou l'évaluation de la structure de plates-formes en mer flottantes utilisées par les industries du pétrole et du gaz naturel pour supporter les fonctions suivantes : — production ; — stockage et/ou déchargement ; — forage et production ; — production, stockage et déchargement ; — forage, production, stockage et déchargement. NOTE 1 Les plates-formes en mer flottantes sont souvent citées au moyen de différentes abréviations, par exemple FPS, FSU, FPSO (voir les Articles 3 et 4), conformément à leur mission prévue. NOTE 2 Dans le présent document, le terme « structure flottante », parfois abrégé en « structure » est utilisé comme terme générique pour indiquer les systèmes structurels de tous éléments de classes de plates-formes définies ci-dessus. NOTE 3 Dans certains cas, les plates-formes flottantes sont désignées comme étant des « plates-formes de production précoce ». Ce terme se rapporte simplement à une stratégie de développement d'immobilisation. Pour les besoins du présent document, le terme « production » inclut « production précoce ». Le présent document ne s'applique pas aux systèmes structurels d'unités en mer mobiles (MOU). Cela comprend notamment : — des structures flottantes prévues principalement pour exécuter des opérations de forage et/ou d'interventions sur les puits (souvent appelées MODU), même lorsqu'elles sont utilisées pour des opérations étendues d'essais de puits ; — des structures flottantes utilisées pour des opérations de construction en mer (par exemple des barges grues ou des barges de pose), pour des quartiers de vie en mer temporaires ou permanents (hôtels flottants), ou pour le transport d'équipements ou de produits (par exemple barges de transport, des barges cargo), pour lesquelles la référence des structures est établie par rapport à des règles de société de classification reconnues (RCS). Le présent document est applicable à tous les stades possibles du cycle de vie des structures définies ci‑dessus, tels que : — la conception, la construction et l'installation de nouvelles structures, y compris les exigences d'inspection, de gestion de l'intégrité et d'enlèvement futur ; — la gestion de l'intégrité structurelle couvrant l'inspection et l'évaluation des structures en service ; et — la conversion de structures pour une utilisation différente (par exemple un pétrolier converti en une plate-forme de production) ou la réutilisation à des endroits différents. Les types suivants de structures flottantes sont explicitement considérés dans le contexte du présent document : a) structures en forme de navires et barges ; b) unités semi-submersibles ; c) plates-formes spars ; d) structures cylindriques à faible tirant d'eau. En plus des types de structures répertoriés ci-dessus, le présent document couvre d'autres plates-formes flottantes prévues pour exécuter les fonctions ci-dessus, constituées de coques flottantes partiellement submergées constituées de toute combinaison de composants de structures plaqués et d'espace. Ces autres structures peuvent avoir une géométrie et des formes structurelles très différentes (par exemple plates-formes à ancrage tendu) et, en conséquence, ne peuvent être que partiellement couvertes par les exigences du présent document. Dans d'autres cas, il se peut que les exigences spécifiques mentionnées dans le présent document ne s'appliquent pas à tout ou partie des structures à l'étude. NOTE 4 Les exigences relatives aux structures Top Sides sont présentées dans l'ISO 19901-3. Dans tous les cas ci-dessus, la conformité au présent document exige que la conception soit fondée sur ses principes de base et atteigne un niveau de sécurité équivalent, ou supérieur, au niveau implicite de celle-ci. NOTE 5 La vitesse d'évolution de la technologie des structures en mer dépasse souvent de loin le rythme auquel l'industrie arrive à un accord substantiel sur l'innovation dans

General Information

- Status

- Published

- Publication Date

- 09-May-2019

- Technical Committee

- ISO/TC 67/SC 7 - Offshore structures

- Drafting Committee

- ISO/TC 67/SC 7/WG 5 - Floating systems

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 05-Dec-2025

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 12-Feb-2026

- Effective Date

- 06-Jun-2022

- Effective Date

- 13-Apr-2013

Overview

ISO 19904-1:2019 - "Petroleum and natural gas industries - Floating offshore structures - Part 1" provides requirements and guidance for the structural design and assessment of floating offshore platforms used in petroleum and natural gas operations. It covers ship-shaped units, barges, semi-submersibles, spars and shallow-draught cylindrical structures, and other partially submerged buoyant hull forms used for production, storage/offloading, drilling and combinations thereof (e.g., FPS, FSU, FPSO). The standard is primarily aimed at steel floating structures but its design principles are generally applicable to other materials.

Key topics and technical requirements

- Scope and applicability: Life‑cycle coverage including design, construction, installation, in‑service inspection, integrity management, conversion and re‑use. Explicit exclusions include mobile offshore units (MODUs), construction barges, floatels and transport barges where recognized classification society (RCS) rules apply.

- Design philosophy: Safety requirements, functional requirements, and a documented basis of design with planning, inspection and maintenance philosophies.

- Limit states and design situations: Definitions and treatment of Ultimate (ULS), Serviceability (SLS), Fatigue (FLS) and Accidental (ALS) limit states across operating and temporary phases.

- Actions and environmental loads: Treatment of permanent, variable and environmental actions - wind, current, waves, vortex‑induced vibrations, ice, tidal and geotechnical hazards - and action combinations.

- Global analysis: Static and dynamic global response, frequency and time‑domain analyses, coupled/uncoupled models, platform motions, air‑gap and wave crest assessments, and stationkeeping considerations.

- Materials and structural integrity: Material selection, weight control, hydrostatic stability, compartmentation, topsides safety interface (see ISO 19901‑3), inspection, integrity management and life‑extension assessment.

- Verification and tools: Independent verification, analytical tools and model testing guidance; recognition that advanced or novel concepts may require bespoke assessment to achieve equivalent safety.

Applications and users

Who uses ISO 19904-1:

- Offshore structural engineers and naval architects designing FPS, FPSO, FSU, semi‑submersible and spar platforms

- Project managers, owners and operators responsible for structural integrity management and life‑extension decisions

- Classification societies, certifiers and inspection teams applying structural assessments

- Contractors and conversion yards undertaking tanker-to-FPSO conversions or platform re‑use

Practical uses:

- Establishing a design basis for new floating production/storage/offloading units

- Performing structural assessments for in‑service inspection and life‑extension

- Guiding conversions, relocations and integrity management programs

Related standards

- ISO 19901-3 - topsides structures and layout considerations

- Recognized classification society (RCS) rules for MOUs and specialized floating units

Keywords: ISO 19904-1, floating offshore structures, FPSO, semi-submersible, spar, ship-shaped structures, structural design, petroleum and natural gas, structural integrity management.

Buy Documents

ISO 19904-1:2019 - Petroleum and natural gas industries -- Floating offshore structures

ISO 19904-1:2019 - Petroleum and natural gas industries — Floating offshore structures — Part 1: Ship-shaped, semi-submersible, spar and shallow-draught cylindrical structures Released:5/10/2019

ISO 19904-1:2019 - Industries du pétrole et du gaz naturel — Structures en mer flottantes — Partie 1: Structures en forme de navire, structures semi-submersibles, plates-formes spar et structures cylindriques a faible tirant d’eau Released:15. 12. 2025

REDLINE ISO 19904-1:2019 - Industries du pétrole et du gaz naturel — Structures en mer flottantes — Partie 1: Structures en forme de navire, structures semi-submersibles, plates-formes spar et structures cylindriques a faible tirant d’eau Released:15. 12. 2025

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

ISO 19904-1:2019 is a standard published by the International Organization for Standardization (ISO). Its full title is "Petroleum and natural gas industries — Floating offshore structures — Part 1: Ship-shaped, semi-submersible, spar and shallow-draught cylindrical structures". This standard covers: This document provides requirements and guidance for the structural design and/or assessment of floating offshore platforms used by the petroleum and natural gas industries to support the following functions: — production; — storage and/or offloading; — drilling and production; — production, storage and offloading; — drilling, production, storage and offloading. NOTE 1 Floating offshore platforms are often referred to using a variety of abbreviations, e.g. FPS, FSU, FPSO (see Clauses 3 and 4), in accordance with their intended mission. NOTE 2 In this document, the term "floating structure", sometimes shortened to "structure", is used as a generic term to indicate the structural systems of any member of the classes of platforms defined above. NOTE 3 In some cases, floating platforms are designated as "early production platforms". This term relates merely to an asset development strategy. For the purposes of this document, the term "production" includes "early production". This document is not applicable to the structural systems of mobile offshore units (MOUs). These include, among others, the following: — floating structures intended primarily to perform drilling and/or well intervention operations (often referred to as MODUs), even when used for extended well test operations; — floating structures used for offshore construction operations (e.g. crane barges or pipelay barges), for temporary or permanent offshore living quarters (floatels), or for transport of equipment or products (e.g. transportation barges, cargo barges), for which structures reference is made to relevant recognized classification society (RCS) rules. This document is applicable to all possible life-cycle stages of the structures defined above, such as: — design, construction and installation of new structures, including requirements for inspection, integrity management and future removal, — structural integrity management covering inspection and assessment of structures in-service, and — conversion of structures for different use (e.g. a tanker converted to a production platform) or re‑use at different locations. The following types of floating structure are explicitly considered within the context of this document: a) ship-shaped structures and barges; b) semi-submersibles; c) spars; d) shallow-draught cylindrical structures. In addition to the structural types listed above, this document covers other floating platforms intended to perform the above functions, consisting of partially submerged buoyant hulls made up of any combination of plated and space frame components. These other structures can have a great range of variability in geometry and structural forms (e.g. tension leg platforms) and, therefore, can be only partly covered by the requirements of this document. In other cases, specific requirements stated in this document can be found not to apply to all or part of a structure under consideration. NOTE 4 Requirements for topsides structures are presented in ISO 19901-3. In the above cases, conformity with this document requires the design to be based upon its underpinning principles and to achieve a level of safety equivalent, or superior, to the level implicit in it. NOTE 5 The speed of evolution of offshore technology often far exceeds the pace at which the industry achieves substantial agreement on innovation in structural concepts, structural shapes or forms, structural components and associated analysis and design practices, which are continuously refined and enhanced. On the other hand, International Standards can only capture explicit industry consensus, which requires maturation and acceptance of new ideas. Consequently, advanced structural concepts can, in some cases, only be partly covered by the requirements of this document. This document is applicable to steel floating structures. The principles documented herein are, however, considered to be generally applicable to structures fabricated in materials other

This document provides requirements and guidance for the structural design and/or assessment of floating offshore platforms used by the petroleum and natural gas industries to support the following functions: — production; — storage and/or offloading; — drilling and production; — production, storage and offloading; — drilling, production, storage and offloading. NOTE 1 Floating offshore platforms are often referred to using a variety of abbreviations, e.g. FPS, FSU, FPSO (see Clauses 3 and 4), in accordance with their intended mission. NOTE 2 In this document, the term "floating structure", sometimes shortened to "structure", is used as a generic term to indicate the structural systems of any member of the classes of platforms defined above. NOTE 3 In some cases, floating platforms are designated as "early production platforms". This term relates merely to an asset development strategy. For the purposes of this document, the term "production" includes "early production". This document is not applicable to the structural systems of mobile offshore units (MOUs). These include, among others, the following: — floating structures intended primarily to perform drilling and/or well intervention operations (often referred to as MODUs), even when used for extended well test operations; — floating structures used for offshore construction operations (e.g. crane barges or pipelay barges), for temporary or permanent offshore living quarters (floatels), or for transport of equipment or products (e.g. transportation barges, cargo barges), for which structures reference is made to relevant recognized classification society (RCS) rules. This document is applicable to all possible life-cycle stages of the structures defined above, such as: — design, construction and installation of new structures, including requirements for inspection, integrity management and future removal, — structural integrity management covering inspection and assessment of structures in-service, and — conversion of structures for different use (e.g. a tanker converted to a production platform) or re‑use at different locations. The following types of floating structure are explicitly considered within the context of this document: a) ship-shaped structures and barges; b) semi-submersibles; c) spars; d) shallow-draught cylindrical structures. In addition to the structural types listed above, this document covers other floating platforms intended to perform the above functions, consisting of partially submerged buoyant hulls made up of any combination of plated and space frame components. These other structures can have a great range of variability in geometry and structural forms (e.g. tension leg platforms) and, therefore, can be only partly covered by the requirements of this document. In other cases, specific requirements stated in this document can be found not to apply to all or part of a structure under consideration. NOTE 4 Requirements for topsides structures are presented in ISO 19901-3. In the above cases, conformity with this document requires the design to be based upon its underpinning principles and to achieve a level of safety equivalent, or superior, to the level implicit in it. NOTE 5 The speed of evolution of offshore technology often far exceeds the pace at which the industry achieves substantial agreement on innovation in structural concepts, structural shapes or forms, structural components and associated analysis and design practices, which are continuously refined and enhanced. On the other hand, International Standards can only capture explicit industry consensus, which requires maturation and acceptance of new ideas. Consequently, advanced structural concepts can, in some cases, only be partly covered by the requirements of this document. This document is applicable to steel floating structures. The principles documented herein are, however, considered to be generally applicable to structures fabricated in materials other

ISO 19904-1:2019 is classified under the following ICS (International Classification for Standards) categories: 75.180.10 - Exploratory, drilling and extraction equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 19904-1:2019 has the following relationships with other standards: It is inter standard links to EN ISO 19904-1:2019, ISO 14696:2009, ISO 19904-1:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 19904-1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 19904-1

Second edition

2019-05

Petroleum and natural gas

industries — Floating offshore

structures —

Part 1:

Ship-shaped, semi-submersible,

spar and shallow-draught cylindrical

structures

Industries du pétrole et du gaz naturel — Structures en mer

flottantes —

Partie 1: Unités monocoques, unités semi-submersibles et unités spars

Reference number

©

ISO 2019

© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2019 – All rights reserved

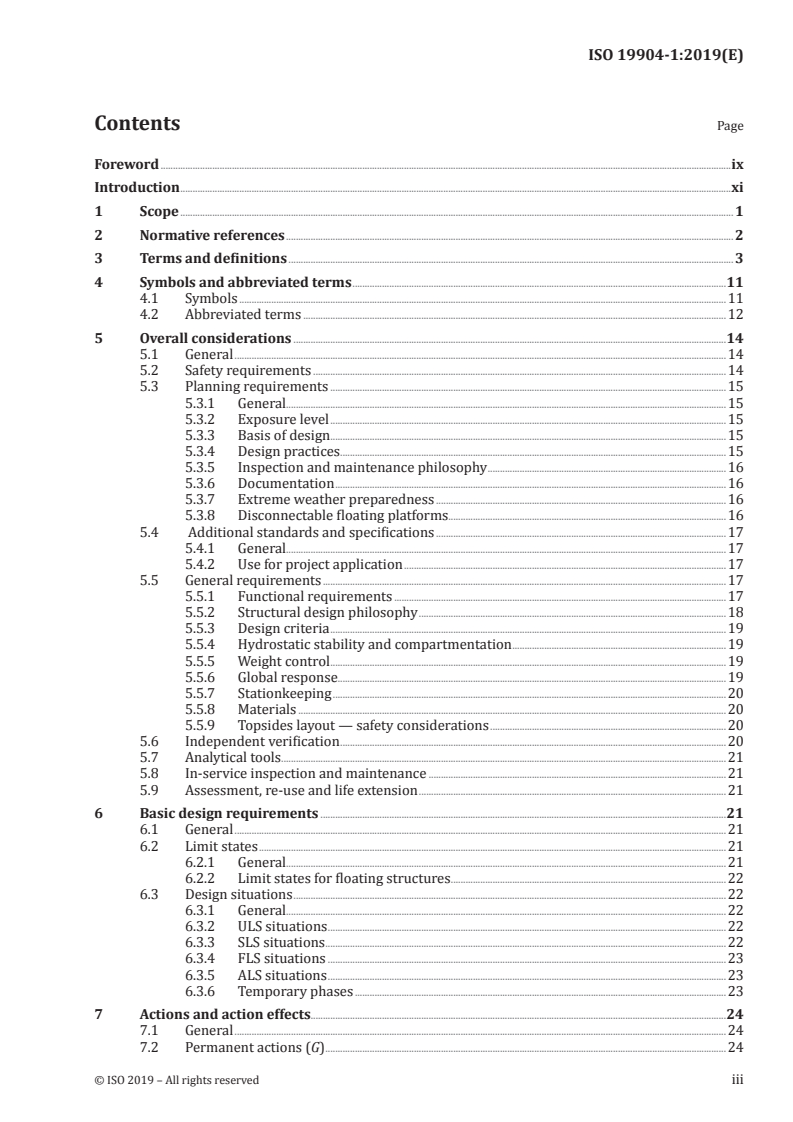

Contents Page

Foreword .ix

Introduction .xi

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 3

4 Symbols and abbreviated terms .11

4.1 Symbols .11

4.2 Abbreviated terms .12

5 Overall considerations .14

5.1 General .14

5.2 Safety requirements .14

5.3 Planning requirements .15

5.3.1 General.15

5.3.2 Exposure level .15

5.3.3 Basis of design . .15

5.3.4 Design practices . . .15

5.3.5 Inspection and maintenance philosophy .16

5.3.6 Documentation .16

5.3.7 Extreme weather preparedness .16

5.3.8 Disconnectable floating platforms.16

5.4 Additional standards and specifications .17

5.4.1 General.17

5.4.2 Use for project application .17

5.5 General requirements .17

5.5.1 Functional requirements .17

5.5.2 Structural design philosophy .18

5.5.3 Design criteria .19

5.5.4 Hydrostatic stability and compartmentation .19

5.5.5 Weight control .19

5.5.6 Global response.19

5.5.7 Stationkeeping .20

5.5.8 Materials .20

5.5.9 Topsides layout — safety considerations .20

5.6 Independent verification .20

5.7 Analytical tools .21

5.8 In-service inspection and maintenance .21

5.9 Assessment, re-use and life extension .21

6 Basic design requirements .21

6.1 General .21

6.2 Limit states .21

6.2.1 General.21

6.2.2 Limit states for floating structures .22

6.3 Design situations .22

6.3.1 General.22

6.3.2 ULS situations .22

6.3.3 SLS situations .22

6.3.4 FLS situations .23

6.3.5 ALS situations .23

6.3.6 Temporary phases .23

7 Actions and action effects.24

7.1 General .24

7.2 Permanent actions (G) .24

7.3 Variable actions (Q) .24

7.4 Environmental actions (E ) .25

e

7.4.1 General.25

7.4.2 Environmental site-specific data .25

7.4.3 Wind actions .26

7.4.4 Current actions .28

7.4.5 Wave actions .28

7.4.6 Vortex-induced vibrations and motions .31

7.4.7 Direct ice action .32

7.4.8 Temperature effects .32

7.4.9 Tidal effects .33

7.4.10 Geotechnical hazards .33

7.5 Accidental actions (A) .33

7.5.1 General.33

7.5.2 Collision .33

7.5.3 Dropped objects .34

7.5.4 Fire and blast.34

7.6 Other actions.34

7.6.1 Stationkeeping actions .34

7.6.2 Sloshing actions .34

7.7 Repetitive actions .35

7.8 Action combinations .35

8 Global analysis .35

8.1 General .35

8.2 Static and mean response analyses .35

8.2.1 General.35

8.2.2 Static equilibrium in still-water condition .36

8.2.3 Mean response analysis .36

8.3 Global dynamic behaviour .36

8.3.1 General.36

8.3.2 Analysis models .37

8.3.3 Mass .37

8.3.4 Damping .38

8.3.5 Stiffness .38

8.3.6 Action classification .38

8.3.7 Turret moored systems .38

8.4 Frequency domain analysis .38

8.5 Time domain analysis .39

8.6 Uncoupled analysis .39

8.7 Coupled analysis .39

8.8 Resonant excitation and response .39

8.9 Platform offset .40

8.10 Air gap and wave crest assessment .40

8.10.1 Air gap .40

8.10.2 Wave crest effects .40

8.11 Platform motions and accelerations.41

8.12 Model tests.41

8.13 Structural analysis .42

8.13.1 General.42

8.13.2 Short-term response analysis .42

8.13.3 Long-term response analysis .42

8.13.4 Design wave analysis .42

9 Structural modelling, analysis and design.42

9.1 General .42

9.2 Representative values of actions .43

9.2.1 General.43

9.2.2 Representative values of actions for operating phases .43

iv © ISO 2019 – All rights reserved

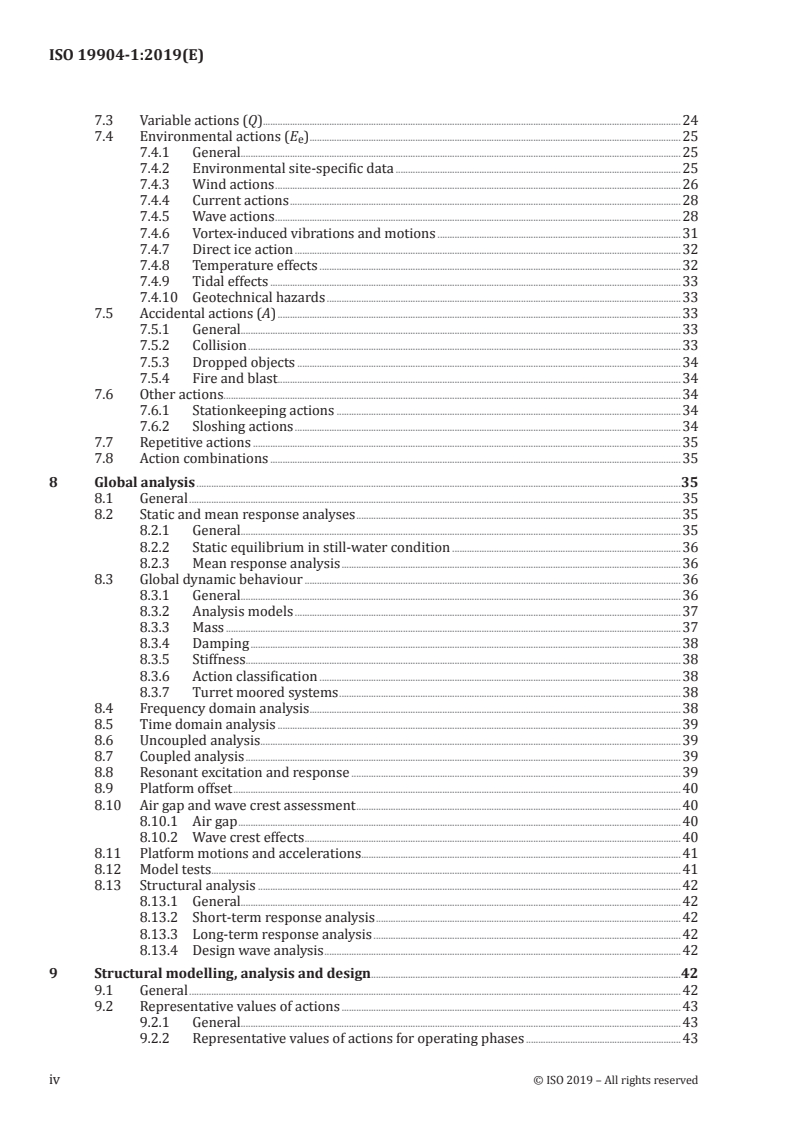

9.2.3 Representative values of actions for temporary phases .43

9.2.4 Actions at interfaces . . .44

9.3 Scantlings .44

9.4 Modelling .45

9.4.1 General.45

9.4.2 Global models .45

9.4.3 Local models .45

9.4.4 Response evaluation .46

9.4.5 Model verification .46

9.5 Structural analysis .47

9.5.1 General principles .47

9.5.2 Linear analysis .47

9.5.3 Non-linear analysis .48

9.5.4 Vibration analysis . .48

9.6 Structural strength .49

9.6.1 Representative strength values .49

9.6.2 Yield strength . . .49

9.6.3 Buckling strength .49

9.7 Design verification .49

9.7.1 General.49

9.7.2 SLS deflection limits .50

9.7.3 Partial factor design format .50

9.7.4 Working stress design format.52

9.7.5 Reliability-based methods .53

9.8 Special design issues .53

9.8.1 General.53

9.8.2 Slamming .54

9.8.3 Green water .54

9.8.4 Sloshing .54

9.8.5 Wave impact on deck.54

9.8.6 Local structure and components .54

9.9 Materials .55

9.9.1 General.55

9.9.2 Material selection .56

9.9.3 Through-thickness tension .56

9.9.4 Aluminium substructures .57

9.9.5 Cement grout .57

9.9.6 Elastomeric material .57

9.10 Corrosion protection of steel .57

9.10.1 General.57

9.10.2 Electrical bonding and isolation .58

9.11 Fabrication and construction .58

9.11.1 General.58

9.11.2 Inspection and testing during fabrication and construction .58

9.11.3 Fabrication details .59

9.11.4 Welding .59

9.12 Marine operations .59

9.13 Topsides/hull interface .59

10 Fatigue analysis and design .60

10.1 General .60

10.2 Fatigue damage factors .61

10.3 Outline of approach .62

10.4 Metocean data for fatigue .63

10.5 Structural modelling .63

10.6 Hydrostatic analyses .63

10.7 Response amplitude operators and combinations of actions .63

10.8 Stresses and SCFs .64

10.9 Stress range counting and distribution .64

10.10 Fatigue resistance .64

10.11 Damage accumulation .65

10.12 Fracture mechanics methods .65

10.13 Fatigue-sensitive components and connections .65

11 Ship-shaped structures .66

11.1 General .66

11.2 General design criteria .67

11.2.1 Collision protection .67

11.2.2 Deckhouse requirements.67

11.2.3 Sloshing .68

11.2.4 Green water .68

11.3 Structural strength .68

11.3.1 General.68

11.3.2 Scantlings .69

11.3.3 ULS-a and ULS-b longitudinal strength design verification .69

11.3.4 Local strength and details .71

11.3.5 Topsides structural support .72

11.3.6 Load monitoring .73

12 Semi-submersibles .73

12.1 General .73

12.2 General design criteria .73

12.2.1 General.73

12.2.2 Limitations .74

12.2.3 Damage tolerance.74

12.3 Structural strength .74

12.3.1 Critical connections .74

12.3.2 Structural detailing .74

13 Spars .74

13.1 General .74

13.2 General design requirements .75

13.2.1 Model testing .75

13.2.2 Static equilibrium position.75

13.2.3 Global action effects .75

13.2.4 Local action effects .76

13.3 Structural strength .76

13.3.1 Critical interfaces.76

13.3.2 Fatigue .76

13.3.3 Structural details .76

14 Shallow-draught cylindrical structures .76

14.1 General .76

14.2 General design criteria .77

14.2.1 Collision protection .77

14.2.2 Deckhouse requirements.77

14.2.3 Global response.77

14.2.4 Local action effects .77

14.2.5 Model testing .78

14.2.6 Temporary phases .78

14.2.7 In-service conditions .78

14.3 Structural strength .79

14.3.1 Global strength .79

14.3.2 Local strength .79

14.3.3 Capacity verification .79

14.3.4 Fatigue .79

14.4 Damage stability .80

15 Conversion and re-use .80

15.1 General .80

vi © ISO 2019 – All rights reserved

15.2 Minimum design, construction and maintenance standards .80

15.3 Pre-conversion structural survey .81

15.4 Effects of prior service.81

15.4.1 General.81

15.4.2 Ship-shaped structures .81

15.4.3 Semi-submersibles .82

15.4.4 Fatigue damage from prior service .82

15.4.5 Repair of defects, dents, pitting, grooving and cracks .82

15.5 Corrosion protection and material suitability .82

15.5.1 Corrosion protection .

...

INTERNATIONAL ISO

STANDARD 19904-1

Second edition

2019-05

Petroleum and natural gas

industries — Floating offshore

structures —

Part 1:

Ship-shaped, semi-submersible,

spar and shallow-draught cylindrical

structures

Industries du pétrole et du gaz naturel — Structures en mer

flottantes —

Partie 1: Unités monocoques, unités semi-submersibles et unités spars

Reference number

©

ISO 2019

© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2019 – All rights reserved

Contents Page

Foreword .ix

Introduction .xi

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 3

4 Symbols and abbreviated terms .11

4.1 Symbols .11

4.2 Abbreviated terms .12

5 Overall considerations .14

5.1 General .14

5.2 Safety requirements .14

5.3 Planning requirements .15

5.3.1 General.15

5.3.2 Exposure level .15

5.3.3 Basis of design . .15

5.3.4 Design practices . . .15

5.3.5 Inspection and maintenance philosophy .16

5.3.6 Documentation .16

5.3.7 Extreme weather preparedness .16

5.3.8 Disconnectable floating platforms.16

5.4 Additional standards and specifications .17

5.4.1 General.17

5.4.2 Use for project application .17

5.5 General requirements .17

5.5.1 Functional requirements .17

5.5.2 Structural design philosophy .18

5.5.3 Design criteria .19

5.5.4 Hydrostatic stability and compartmentation .19

5.5.5 Weight control .19

5.5.6 Global response.19

5.5.7 Stationkeeping .20

5.5.8 Materials .20

5.5.9 Topsides layout — safety considerations .20

5.6 Independent verification .20

5.7 Analytical tools .21

5.8 In-service inspection and maintenance .21

5.9 Assessment, re-use and life extension .21

6 Basic design requirements .21

6.1 General .21

6.2 Limit states .21

6.2.1 General.21

6.2.2 Limit states for floating structures .22

6.3 Design situations .22

6.3.1 General.22

6.3.2 ULS situations .22

6.3.3 SLS situations .22

6.3.4 FLS situations .23

6.3.5 ALS situations .23

6.3.6 Temporary phases .23

7 Actions and action effects.24

7.1 General .24

7.2 Permanent actions (G) .24

7.3 Variable actions (Q) .24

7.4 Environmental actions (E ) .25

e

7.4.1 General.25

7.4.2 Environmental site-specific data .25

7.4.3 Wind actions .26

7.4.4 Current actions .28

7.4.5 Wave actions .28

7.4.6 Vortex-induced vibrations and motions .31

7.4.7 Direct ice action .32

7.4.8 Temperature effects .32

7.4.9 Tidal effects .33

7.4.10 Geotechnical hazards .33

7.5 Accidental actions (A) .33

7.5.1 General.33

7.5.2 Collision .33

7.5.3 Dropped objects .34

7.5.4 Fire and blast.34

7.6 Other actions.34

7.6.1 Stationkeeping actions .34

7.6.2 Sloshing actions .34

7.7 Repetitive actions .35

7.8 Action combinations .35

8 Global analysis .35

8.1 General .35

8.2 Static and mean response analyses .35

8.2.1 General.35

8.2.2 Static equilibrium in still-water condition .36

8.2.3 Mean response analysis .36

8.3 Global dynamic behaviour .36

8.3.1 General.36

8.3.2 Analysis models .37

8.3.3 Mass .37

8.3.4 Damping .38

8.3.5 Stiffness .38

8.3.6 Action classification .38

8.3.7 Turret moored systems .38

8.4 Frequency domain analysis .38

8.5 Time domain analysis .39

8.6 Uncoupled analysis .39

8.7 Coupled analysis .39

8.8 Resonant excitation and response .39

8.9 Platform offset .40

8.10 Air gap and wave crest assessment .40

8.10.1 Air gap .40

8.10.2 Wave crest effects .40

8.11 Platform motions and accelerations.41

8.12 Model tests.41

8.13 Structural analysis .42

8.13.1 General.42

8.13.2 Short-term response analysis .42

8.13.3 Long-term response analysis .42

8.13.4 Design wave analysis .42

9 Structural modelling, analysis and design.42

9.1 General .42

9.2 Representative values of actions .43

9.2.1 General.43

9.2.2 Representative values of actions for operating phases .43

iv © ISO 2019 – All rights reserved

9.2.3 Representative values of actions for temporary phases .43

9.2.4 Actions at interfaces . . .44

9.3 Scantlings .44

9.4 Modelling .45

9.4.1 General.45

9.4.2 Global models .45

9.4.3 Local models .45

9.4.4 Response evaluation .46

9.4.5 Model verification .46

9.5 Structural analysis .47

9.5.1 General principles .47

9.5.2 Linear analysis .47

9.5.3 Non-linear analysis .48

9.5.4 Vibration analysis . .48

9.6 Structural strength .49

9.6.1 Representative strength values .49

9.6.2 Yield strength . . .49

9.6.3 Buckling strength .49

9.7 Design verification .49

9.7.1 General.49

9.7.2 SLS deflection limits .50

9.7.3 Partial factor design format .50

9.7.4 Working stress design format.52

9.7.5 Reliability-based methods .53

9.8 Special design issues .53

9.8.1 General.53

9.8.2 Slamming .54

9.8.3 Green water .54

9.8.4 Sloshing .54

9.8.5 Wave impact on deck.54

9.8.6 Local structure and components .54

9.9 Materials .55

9.9.1 General.55

9.9.2 Material selection .56

9.9.3 Through-thickness tension .56

9.9.4 Aluminium substructures .57

9.9.5 Cement grout .57

9.9.6 Elastomeric material .57

9.10 Corrosion protection of steel .57

9.10.1 General.57

9.10.2 Electrical bonding and isolation .58

9.11 Fabrication and construction .58

9.11.1 General.58

9.11.2 Inspection and testing during fabrication and construction .58

9.11.3 Fabrication details .59

9.11.4 Welding .59

9.12 Marine operations .59

9.13 Topsides/hull interface .59

10 Fatigue analysis and design .60

10.1 General .60

10.2 Fatigue damage factors .61

10.3 Outline of approach .62

10.4 Metocean data for fatigue .63

10.5 Structural modelling .63

10.6 Hydrostatic analyses .63

10.7 Response amplitude operators and combinations of actions .63

10.8 Stresses and SCFs .64

10.9 Stress range counting and distribution .64

10.10 Fatigue resistance .64

10.11 Damage accumulation .65

10.12 Fracture mechanics methods .65

10.13 Fatigue-sensitive components and connections .65

11 Ship-shaped structures .66

11.1 General .66

11.2 General design criteria .67

11.2.1 Collision protection .67

11.2.2 Deckhouse requirements.67

11.2.3 Sloshing .68

11.2.4 Green water .68

11.3 Structural strength .68

11.3.1 General.68

11.3.2 Scantlings .69

11.3.3 ULS-a and ULS-b longitudinal strength design verification .69

11.3.4 Local strength and details .71

11.3.5 Topsides structural support .72

11.3.6 Load monitoring .73

12 Semi-submersibles .73

12.1 General .73

12.2 General design criteria .73

12.2.1 General.73

12.2.2 Limitations .74

12.2.3 Damage tolerance.74

12.3 Structural strength .74

12.3.1 Critical connections .74

12.3.2 Structural detailing .74

13 Spars .74

13.1 General .74

13.2 General design requirements .75

13.2.1 Model testing .75

13.2.2 Static equilibrium position.75

13.2.3 Global action effects .75

13.2.4 Local action effects .76

13.3 Structural strength .76

13.3.1 Critical interfaces.76

13.3.2 Fatigue .76

13.3.3 Structural details .76

14 Shallow-draught cylindrical structures .76

14.1 General .76

14.2 General design criteria .77

14.2.1 Collision protection .77

14.2.2 Deckhouse requirements.77

14.2.3 Global response.77

14.2.4 Local action effects .77

14.2.5 Model testing .78

14.2.6 Temporary phases .78

14.2.7 In-service conditions .78

14.3 Structural strength .79

14.3.1 Global strength .79

14.3.2 Local strength .79

14.3.3 Capacity verification .79

14.3.4 Fatigue .79

14.4 Damage stability .80

15 Conversion and re-use .80

15.1 General .80

vi © ISO 2019 – All rights reserved

15.2 Minimum design, construction and maintenance standards .80

15.3 Pre-conversion structural survey .81

15.4 Effects of prior service.81

15.4.1 General.81

15.4.2 Ship-shaped structures .81

15.4.3 Semi-submersibles .82

15.4.4 Fatigue damage from prior service .82

15.4.5 Repair of defects, dents, pitting, grooving and cracks .82

15.5 Corrosion protection and material suitability .82

15.5.1 Corrosion protection .

...

Norme

internationale

ISO 19904-1

Deuxième édition

Industries du pétrole et du gaz

2019-05

naturel — Structures en mer

flottantes —

Partie 1:

Structures en forme de navire,

structures semi-submersibles,

plates-formes spar et structures

cylindriques à faible tirant d’eau

Petroleum and natural gas industries — Floating offshore

structures —

Part 1: Ship-shaped, semi-submersible, spar and shallow-draught

cylindrical structures

Numéro de référence

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2019

Tous droits réservés. Sauf prescription différente ou nécessité dans le contexte de sa mise en œuvre, aucune partie de cette

publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique,

y compris la photocopie, ou la diffusion sur l’internet ou sur un intranet, sans autorisation écrite préalable. Une autorisation peut

être demandée à l’ISO à l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Case postale 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Genève

Tél.: +41 22 749 01 11

E-mail: copyright@iso.org

Web: www.iso.org

Publié en Suisse

ii

Sommaire Page

Avant-propos .ix

Introduction .xi

1 Domaine d'application . 1

2 Références normatives . 2

3 Termes et définitions . 3

4 Symboles et abréviations .12

4.1 Symboles . 12

4.2 Abréviations. 13

5 Considérations générales .15

5.1 Généralités . 15

5.2 Exigences de sécurité . 15

5.3 Exigences de planification .16

5.3.1 Généralités .16

5.3.2 Niveau d'exposition .16

5.3.3 Base de conception .16

5.3.4 Pratiques de conception.16

5.3.5 Philosophie d'inspection et de maintenance .16

5.3.6 Documentation.17

5.3.7 Préparation aux conditions météorologiques extrêmes.17

5.3.8 Plates-formes flottantes déconnectables .17

5.4 Normes et spécifications supplémentaires .18

5.4.1 Généralités .18

5.4.2 Utilisation pour une application de projet.18

5.5 Exigences générales .18

5.5.1 Exigences fonctionnelles .18

5.5.2 Philosophie de la conception structurelle .19

5.5.3 Critères de conception . . 20

5.5.4 Stabilité hydrostatique et compartimentage . 20

5.5.5 Contrôle des poids . 20

5.5.6 Réponse globale . 20

5.5.7 Maintien de position.21

5.5.8 Matériaux .21

5.5.9 Implantation des superstructures : considérations de sécurité .21

5.6 Vérification indépendante . 22

5.7 Outils analytiques . 22

5.8 Inspection et maintenance en service . 22

5.9 Évaluation, réutilisation et prolongation de la durée de vie . . 22

6 Exigences de conception de base .22

6.1 Généralités . 22

6.2 États limites . 23

6.2.1 Généralités . 23

6.2.2 États limites pour les structures flottantes . 23

6.3 Situations conceptuelles . 23

6.3.1 Généralités . 23

6.3.2 Situations ULS . 23

6.3.3 Situations SLS .24

6.3.4 Situations FLS .24

6.3.5 Situations ALS .24

6.3.6 Phases temporaires . 25

7 Actions et effets des actions .25

7.1 Généralités . 25

7.2 Actions permanentes (G) . 25

iii

7.3 Actions variables (Q) . 26

7.4 Actions dues à l'environnement (E ) . 26

e

7.4.1 Généralités . 26

7.4.2 Données environnementales spécifiques au site . . 26

7.4.3 Actions du vent. 28

7.4.4 Actions liées aux courants . 29

7.4.5 Actions des vagues . 30

7.4.6 Vibrations et mouvements induits par des vortex . 34

7.4.7 Action directe de la glace . 35

7.4.8 Effets de la température . 35

7.4.9 Effets de la marée . 35

7.4.10 Dangers géotechniques . 35

7.5 Actions accidentelles (A) . . 36

7.5.1 Généralités . 36

7.5.2 Collision . 36

7.5.3 Chutes d'objets . 36

7.5.4 Incendie et explosion . 36

7.6 Autres actions.37

7.6.1 Actions de maintien de la position .37

7.6.2 Actions de mouvements de liquides dans des citernes .37

7.7 Actions répétitives .37

7.8 Combinaison d'actions . 38

8 Analyse globale . .38

8.1 Généralités . 38

8.2 Analyses des réponses statique et moyenne . 38

8.2.1 Généralités . 38

8.2.2 Équilibre statique dans des conditions d'eau tranquille . 38

8.2.3 Analyse de la réponse moyenne . . 39

8.3 Comportement dynamique global . 39

8.3.1 Généralités . 39

8.3.2 Modèles d'analyse . 40

8.3.3 Masse . 40

8.3.4 Amortissement . . . 40

8.3.5 Rigidité .41

8.3.6 Classification des actions .41

8.3.7 Systèmes ancrés par tourelle .41

8.4 Analyse dans le domaine fréquentiel .41

8.5 Analyse dans le domaine temporel .42

8.6 Analyse sans couplage .42

8.7 Analyse avec couplage .42

8.8 Excitation résonante et réponse .42

8.9 Décalage de la plate-forme .43

8.10 Évaluation de la garde d'air et des crêtes de vagues .43

8.10.1 Garde d'air .43

8.10.2 Effets des crêtes de vagues .43

8.11 Mouvements et accélérations de la plate-forme . 44

8.12 Essais sur maquettes . 44

8.13 Analyse structurelle .45

8.13.1 Généralités .45

8.13.2 Analyse de la réponse à court terme .45

8.13.3 Analyse de la réaction à long terme .45

8.13.4 Analyse pour la vague de conception .45

9 Modélisation, analyse et conception structurelles .46

9.1 Généralités . 46

9.2 Valeurs représentatives des actions . 46

9.2.1 Généralités . 46

9.2.2 Valeurs représentatives d'actions pour les phases d'exploitation . 46

9.2.3 Valeurs représentatives d'actions pour les phases temporaires .47

iv

9.2.4 Actions au niveau des interfaces . 48

9.3 Échantillonnages . 48

9.4 Modélisation . 48

9.4.1 Généralités . 48

9.4.2 Modèles globaux . 49

9.4.3 Modèles locaux . 49

9.4.4 Évaluation de la réponse . 50

9.4.5 Vérification du modèle . 50

9.5 Analyse structurelle .51

9.5.1 Principes généraux .51

9.5.2 Analyse linéaire .51

9.5.3 Analyse non linéaire . . .52

9.5.4 Analyse des vibrations . 53

9.6 Résistance structurelle . 53

9.6.1 Valeurs de résistance représentatives . 53

9.6.2 Limite d'élasticité . 53

9.6.3 Résistance au flambement . 53

9.7 Vérification de la conception . 54

9.7.1 Généralités . 54

9.7.2 Limites de flexion d'états SLS . 54

9.7.3 Format de conception à coefficients partiels . 54

9.7.4 Format de conception à contrainte de travail . 56

9.7.5 Méthodes fondées sur la fiabilité .57

9.8 Problèmes de conception spéciaux . 58

9.8.1 Généralités . 58

9.8.2 Tossage . 58

9.8.3 Embarquement d'eau . 58

9.8.4 Effets dus aux mouvements de liquides dans des citernes . 58

9.8.5 Impact de vagues sur le pont . 58

9.8.6 Structure et composants locaux . 58

9.9 Matériaux . 60

9.9.1 Généralités . 60

9.9.2 Choix des matériaux . 60

9.9.3 Traction sur l'épaisseur .61

9.9.4 Sous-structures en aluminium .61

9.9.5 Coulis de ciment .61

9.9.6 Élastomère .61

9.10 Protection contre la corrosion de l'acier .61

9.10.1 Généralités .61

9.10.2 Métallisation et isolation électrique .62

9.11 Fabrication et construction .62

9.11.1 Généralités .62

9.11.2 Inspection et essais au cours de la fabrication et de la construction . 63

9.11.3 Détails de fabrication . 63

9.11.4 Soudage . 63

9.12 Opérations marines . 63

9.13 Interface superstructures/coque . 64

10 Analyse de la fatigue et conception en fatigue .64

10.1 Généralités . 64

10.2 Coefficients pour l'endommagement dû à la fatigue . 66

10.3 Description de l'approche . 66

10.4 Données océano-météorologiques pour la fatigue . 68

10.5 Modélisation de la structure . 68

10.6 Analyses hydrostatiques . 68

10.7 Exploitants d'amplitude de réponse et combinaisons d'actions . 68

10.8 Contraintes et facteurs SCF . 69

10.9 Comptage et distribution de la plage de contraintes . 69

10.10 Résistance à la fatigue .70

v

10.11 Cumul de l'endommagement .70

10.12 Méthodes par la mécanique de la rupture .70

10.13 Composants et connexions sensibles à la fatigue .70

11 Structures en forme de navire .71

11.1 Généralités .71

11.2 Critères de conception généraux . 73

11.2.1 Protection contre les collisions . 73

11.2.2 Exigences concernant la superstructure . 73

11.2.3 Effets dus aux mouvements de liquides dans des citernes . 73

11.2.4 Embarquement d'eau .74

11.3 Résistance structurelle .74

11.3.1 Généralités .74

11.3.2 Échantillonnages . 75

11.3.3 Vérification de conception pour la résistance longitudinale aux états ULS-a et

ULS-b . 75

11.3.4 Résistance et détails locaux . 77

11.3.5 Support structurel des structures Top Sides . 78

11.3.6 Surveillance de la charge . 79

12 Unités semi-submersibles .79

12.1 Généralités . 79

12.2 Critères de conception généraux . 79

12.2.1 Généralités . 79

12.2.2 Limitations . 80

12.2.3 Tolérance vis-à-vis des dommages . 80

12.3 Résistance structurelle . 80

12.3.1 Connexions critiques . 80

12.3.2 Description en détail de la structure . 80

13 Plates-formes spars .81

13.1 Généralités . 81

13.2 Exigences conceptuelles générales . 81

13.2.1 Évaluation de la maquette . 81

13.2.2 Position d'équilibre statique . 81

13.2.3 Effets d'actions globales . 81

13.2.4 Effets d'actions locales . 82

13.3 Résistance structurelle . 82

13.3.1 Interfaces critiques . 82

13.3.2 Fatigue . 83

13.3.3 Détails structurels . 83

14 Structures cylindriques à faible tirant d'eau .83

14.1 Généralités . 83

14.2 Critères de conception généraux . 83

14.2.1 Protection contre les collisions . 83

14.2.2 Exigences concernant la superstructure . 84

14.2.3 Réponse globale . 84

14.2.4 Effets d'actions locales . 84

14.2.5 Évaluation de la maquette . 84

14.2.6 Phases temporaires . 84

14.2.7 Conditions en service . 85

14.3 Résistance structurelle . 86

14.3.1 Résistance globale . . 86

14.3.2 Résistance locale . 86

14.3.3 Vérification de la capacité . 86

14.3.4 Fatigue . 86

14.4 Stabilité en cas de dommage . 86

15 Conversion et réutilisation .87

15.1 Généralités . 87

vi

15.2 Normes minimales de conception, de construction et de maintenance . 87

15.3 Examen structurel avant la conversion.

...

ISO /TC 67/SC 7

Date : 2019-05

Deuxième édition

2019-05

ISO/TC 67/SC 7

Secrétariat : BSI

Industries du pétrole et du gaz naturel — Structures en mer

flottantes —

Partie 1 : :

Structures en forme de navire, structures semi -submersibles,

plates-formes spar et structures cylindriques à faible tirant d’eau

Petroleum and natural gas industries — Floating offshore structures — Part 1: Ship-shaped,

semi-submersible, spar and shallow-draught cylindrical structures

ICS : 75.180.10

Type du document: Norme internationale

Sous-type du document:

Stade du document: (60) Publication

Langue du document: F

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© Part 1: Ship-shaped, semi-submersible, spar and shallow-draught cylindrical structures

Type du document: Norme internationale

Sous-type du document:

Stade du document: (60) Publication

Langue du document: F

Tous droits réservés. Sauf prescription différente ou nécessité dans le contexte de sa mise en œuvreoeuvre, aucune partie

de cette publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique

ou mécanique, y compris la photocopie, ou la diffusion sur l'internetl’internet ou sur un intranet, sans autorisation écrite

préalable. Une autorisation peut être demandée à l’ISO à l’adresse ci-après ou au comité membre de l’ISO dans le pays du

demandeur.

ISO Copyright Officecopyright office

Case PostaleCP 401 • • Ch. de Blandonnet 8

CH-1214 Vernier, GenèveGeneva

Tél. : Phone: + 41 22 749 01 11

E-mail : : copyright@iso.org

Web : Website: www.iso.org

Publié en Suisse

iii

iii

Sommaire

Avant-propos . vii

Introduction . x

1 Domaine d'application . 1

2 Références normatives . 3

3 Termes et définitions . 3

4 Symboles et abréviations . 14

4.1 Symboles . 14

4.2 Abréviations . 15

5 Considérations générales . 17

5.1 Généralités . 17

5.2 Exigences de sécurité . 17

5.3 Exigences de planification . 18

5.4 Normes et spécifications supplémentaires . 20

5.5 Exigences générales . 21

5.6 Vérification indépendante . 25

5.7 Outils analytiques . 25

5.8 Inspection et maintenance en service . 25

5.9 Évaluation, réutilisation et prolongation de la durée de vie . 26

6 Exigences de conception de base . 26

6.1 Généralités . 26

6.2 États limites . 26

6.3 Situations conceptuelles . 27

7 Actions et effets des actions . 29

7.1 Généralités . 29

7.2 Actions permanentes (G) . 29

7.3 Actions variables (Q) . 30

7.4 Actions dues à l'environnement (E ) . 30

e

7.5 Actions accidentelles (A) . 41

7.6 Autres actions . 42

7.7 Actions répétitives . 43

7.8 Combinaison d'actions . 43

8 Analyse globale . 44

8.1 Généralités . 44

8.2 Analyses des réponses statique et moyenne. 44

8.3 Comportement dynamique global . 45

8.4 Analyse dans le domaine fréquentiel . 48

8.5 Analyse dans le domaine temporel . 48

8.6 Analyse sans couplage . 49

8.7 Analyse avec couplage . 49

8.8 Excitation résonante et réponse . 49

8.9 Décalage de la plate-forme . 49

8.10 Évaluation de la garde d'air et des crêtes de vagues . 49

8.11 Mouvements et accélérations de la plate-forme . 51

8.12 Essais sur maquettes . 51

iv © ISO 2019 – Tous droits réservés

iv

8.13 Analyse structurelle . 52

9 Modélisation, analyse et conception structurelles . 53

9.1 Généralités . 53

9.2 Valeurs représentatives des actions . 53

9.3 Échantillonnages . 56

9.4 Modélisation . 56

9.5 Analyse structurelle . 59

9.6 Résistance structurelle . 61

9.7 Vérification de la conception . 62

9.8 Problèmes de conception spéciaux . 67

9.9 Matériaux . 70

9.10 Protection contre la corrosion de l'acier . 72

9.11 Fabrication et construction . 73

9.12 Opérations marines . 74

9.13 Interface superstructures/coque . 74

10 Analyse de la fatigue et conception en fatigue . 75

10.1 Généralités . 75

10.2 Coefficients pour l'endommagement dû à la fatigue . 77

10.3 Description de l'approche. 78

10.4 Données océano-météorologiques pour la fatigue . 79

10.5 Modélisation de la structure . 79

10.6 Analyses hydrostatiques . 80

10.7 Exploitants d'amplitude de réponse et combinaisons d'actions . 80

10.8 Contraintes et facteurs SCF . 81

10.9 Comptage et distribution de la plage de contraintes . 81

10.10 Résistance à la fatigue . 82

10.11 Cumul de l'endommagement . 82

10.12 Méthodes par la mécanique de la rupture . 83

10.13 Composants et connexions sensibles à la fatigue . 83

11 Structures en forme de navire . 84

11.1 Généralités . 84

11.2 Critères de conception généraux . 85

11.3 Résistance structurelle . 87

12 Unités semi-submersibles . 93

12.1 Généralités . 93

12.2 Critères de conception généraux . 93

12.3 Résistance structurelle . 94

13 Plates-formes spars . 95

13.1 Généralités . 95

13.2 Exigences conceptuelles générales . 95

13.3 Résistance structurelle . 97

14 Structures cylindriques à faible tirant d'eau . 98

14.1 Généralités . 98

14.2 Critères de conception généraux . 98

14.3 Résistance structurelle . 101

14.4 Stabilité en cas de dommage . 102

v

v

15 Conversion et réutilisation . 102

15.1 Généralités . 102

15.2 Normes minimales de conception, de construction et de maintenance . 102

15.3 Examen structurel avant la conversion . 103

15.4 Effets du service antérieur . 103

15.5 Protection contre la corrosion et aptitude des matériaux . 105

15.6 Ajout de nouveaux composants . 106

15.7 Inspection et maintenance . 106

16 Stabilité, étanchéité à l'eau et compartimentage . 106

16.1 Généralités . 106

16.2 Essai d'inclinaison . 107

16.3 Compartimentage . 107

16.4 Étanchéité aux intempéries et équipements étanches à l'eau . 107

16.5 Stabilité en cas de dommage . 108

17 Systèmes mécaniques . 108

17.1 Généralités . 108

17.2 Systèmes de coque . 109

17.3 Systèmes d'import et d'export . 120

17.4 Systèmes de protection contre les incendies . 126

18 Systèmes de maintien en position . 128

18.1 Généralités . 128

18.2 Équipement d'ancrage . 128

18.3 Tourelle . 129

18.4 Structures déconnectables . 132

19 Inspection, surveillance et maintenance en service . 134

19.1 Généralités . 134

19.2 Philosophies des systèmes de gestion de l'intégrité structurelle . 135

19.3 Considérations sur le planning . 140

19.4 Problèmes concernant la réalisation . 142

19.5 Exigences minimales . 145

20 Évaluation de structures flottantes existantes . 151

20.1 Généralités . 151

20.2 Procédures d'évaluation . 151

20.3 Mesures d'atténuation . 153

21 Autres coques . 155

21.1 Généralités . 155

21.2 Conception des structures en acier de construction . 155

21.3 Intégrité de la stabilité et de l'étanchéité à l'eau . 155

Annexe A (informative) Additional information and guidance. 156

Bibliographie . 244

vi © ISO 2019 – Tous droits réservés

vi

PageAvant-propos

L'ISO (Organisation internationale de normalisation) est une fédération mondiale d'organismes nationaux de

normalisation (comités membres de l'ISO). L'élaboration des Normes internationales est en général confiée

aux comités techniques de l'ISO. Chaque comité membre intéressé par une étude a le droit de faire partie du

comité technique créé à cet effet. Les organisations internationales, gouvernementales et non

gouvernementales, en liaison avec l'ISO participent également aux travaux. L'ISO collabore étroitement avec

la Commission électrotechnique internationale (IEC) en ce qui concerne la normalisation électrotechnique.

Les procédures utilisées pour élaborer le présent document et celles destinées à sa mise à jour sont décrites

dans les Directives ISO/IEC, Partie 1. Il convient, en particulier, de prendre note des différents critères

d'approbation requis pour les différents types de documents ISO. Le présent document a été rédigé

conformément aux règles de rédaction données dans les Directives ISO/IEC, Partie 2

(voir www.iso.org/directiveswww.iso.org/directives).).

L'attention est attirée sur le fait que certains des éléments du présent document peuvent faire l'objet de droits

de propriété intellectuelle ou de droits analogues. L'ISO ne saurait être tenue pour responsable de ne pas avoir

identifié de tels droits de propriété et averti de leur existence. Les détails concernant les références aux droits

de propriété intellectuelle ou autres droits analogues identifiés lors de l'élaboration du document sont

indiqués dans l'Introduction et/ou dans la liste des déclarations de brevets reçues par l'ISO

www.iso.org/brevets).).

(voir www.iso.org/brevets

Les appellations commerciales éventuellement mentionnées dans le présent document sont données pour

information, par souci de commodité, à l'intention des utilisateurs et ne sauraient constituer un engagement.

Pour une explication de la nature volontaire des normes, la signification des termes et expressions spécifiques

de l'ISO liés à l'évaluation de la conformité, ou pour toute information au sujet de l'adhésion de l'ISO aux

principes de l'Organisation mondiale du commerce (OMC) concernant les obstacles techniques au

commerce (OTC), voir www.iso.org/iso/avant-proposwww.iso.org/iso/avant-propos.

Le présent document a été élaboré par le comité technique ISO/TC 67, Matériel, équipement et structures en

mer pour les industries pétrolière, pétrochimique et du gaz naturel, sous-comité SC 7, Structures en mer.

Cette deuxième édition annule et remplace la première édition (ISO 19904-1:2006), qui a fait l'objet d'une

révision technique. Les principales modifications par rapport à l'édition précédente sont les suivantes :

— — le titre a été modifié en remplaçant « monocoques » par « structures en forme de navire » et en

ajoutant « structures cylindriques à faible tirant d'eau » ;

— — la liste des références normatives (Article 2(Article 2)) a été élargie ;

— — certaines définitions ont été modifiées et de nouveaux termes et définitions (Article 3(Article 3)) ont

été ajoutés ;

— — le paragraphe relatif aux exigences de planification (5.3(5.3)) a été développé en traitant de la

philosophie d'inspection et de maintenance (5.3.5(5.3.5),), de la documentation (5.3.6(5.3.6),), de la

préparation aux conditions météorologiques extrêmes (5.3.7(5.3.7)) et des plates-formes flottantes

déconnectables (5.3.8(5.3.8)) ;

vii

vii

— — le paragraphe relatif à l'utilisation pour une application de projet (5.4.2(5.4.2)) a été complété par un

alinéa traitant de la documentation applicable aux plates-formes flottantes déconnectables ;

— — un nouveau paragraphe relatif à l'agencement des superstructures (5.5.9(5.5.9)) a été ajouté ;

— — le paragraphe relatif à la garde d'air (8.10(8.10)) a été renommé « Évaluation de la garde d'air et des

crêtes de vagues », et un nouveau paragraphe traitant des effets des crêtes des vagues (8.10.2(8.10.2)) a

été ajouté ;

— — le paragraphe relatif aux matériaux (9.9(9.9)) a été élargi au coulis de ciment (9.9.5(9.9.5)) et aux

matériaux élastomères (9.9.6(9.9.6)) ;

— — le paragraphe relatif à la protection contre la corrosion de l'acier (9.10(9.10)) a été remanié de

manière substantielle ;

— — le paragraphe relatif à la fabrication et aux constructions (9.11(9.11)) a été élargi pour traiter des

détails de fabrication (9.11.3(9.11.3)) et du soudage (9.11.4(9.11.4)) ;

— — le paragraphe relatif aux aspects généraux de l'analyse de la fatigue et de la conception en

fatigue (10.1(10.1)) a été complété par l'ajout d'une discussion sur la résistance à la fatigue et les actions

de fatigue ;

— — le paragraphe relatif aux aspects généraux des structures en forme de navire (11.1(11.1)) a été élargi ;

— — le paragraphe relatif à l'effet du mouvement d'un liquide dans une citerne (11.2.3(11.2.3)) a été élargi

pour traiter de la configuration générale des citernes et de la résonance due au mouvement d'un liquide

dans une citerne ;

— — le paragraphe relatif à l'embarquement d'eau (11.2.4(11.2.4)) a été élargi ;

— — le paragraphe relatif à la résistance structurelle (11.3(11.3)) a été élargi pour traiter de l'évaluation

de la résistance des hiloires de coque (11.3.1(11.3.1)) et de la résistance et des détails locaux

(11.3.4(11.3.4)) ;

— — le paragraphe relatif aux critères de conception généraux pour les unités semi-submersibles

(12.2(12.2)) a été élargi ;

— — un nouvel article traitant des structures cylindriques à faible tirant d'eau (Article 14(Article 14)) a été

ajouté ;

— — le paragraphe relatif à l'étanchéité aux intempéries et aux équipements étanches à l'eau (16.4(16.4))

a été élargi ;

— — le paragraphe relatif aux systèmes de coques (17.2(17.2)) a été élargi pour traiter des citernes

atmosphériques (17.2.5.2(17.2.5.2)) et des citernes avec système de déplacement d'eau

(17.2.5.3(17.2.5.3),), avec une description des systèmes de gaz inerte (17.2.6(17.2.6)) et une prise en

compte des systèmes d'évent/torchère de production (17.2.8(17.2.8)) et des systèmes électriques

(17.2.9(17.2.9)) ;

viii © ISO 2019 – Tous droits réservés

viii

— — le paragraphe relatif aux systèmes d'import et d'export (17.3(17.3)) a été complété par une discussion

sur les aspects généraux (17.3.1(17.3.1),), le transfert le long du bord (17.3.3.3.3(17.3.3.3.3),), le transfert

en tandem (17.3.3.3.4(17.3.3.3.4)) et le transfert direct (17.3.3.3.5(17.3.3.3.5)) ;

— — l'article relatif aux systèmes de maintien en position (Article 18(Article 18)) a été élargi aux structures

déconnectables (18.4(18.4)) ;

— — le paragraphe relatif aux philosophies des systèmes de gestion de l'intégrité structurelle (19.2(19.2))

a été développé en approfondissant les aspects généraux, avec l'ajout d'une figure (19.2.1(19.2.1)) ;

— — un nouvel article traitant de l'évaluation des structures flottantes existantes (Article 20(Article 20)) a

été ajouté ;

— — les informations et recommandations supplémentaires (Annexe A(Annexe A)) ont été modifiées, avec

des ajouts et des modifications alignés sur les modifications apportées au corps du texte ;

— — la liste des références informatives (Bibliographie) a été mise à jour et élargie au besoin.

Une liste de toutes les parties de la série ISO 19904 se trouve sur le site web de l'ISO.

Il convient que l'utilisateur adresse tout retour d'information ou toute question concernant le présent

document à l'organisme national de normalisation de son pays. Une liste exhaustive desdits organismes se

trouve à l'adresse www.iso.org/fr/members.htmlwww.iso.org/fr/members.html.

ix

ix

Introduction

Les Normes internationales pour les structures en mer élaborées par le TC 67 (c'est-à-dire l'ISO 19900, la série

ISO 19901, l'ISO 19902, l'ISO 19903, la série ISO 19905 et l'ISO 19906) constituent une base commune qui

couvre les aspects traitant des exigences de conception et des évaluations de toutes les structures en mer

utilisées par les industries du pétrole et du gaz naturel dans le monde. Par leur application, l’objectif est

d’obtenir des niveaux de fiabilité adaptés aux structures en mer habitées et non habitées, quels que soient le

type de structure et la nature ou la combinaison de matériaux utilisés.

Il est important de savoir que l’intégrité de la construction est un concept global qui comprend la modélisation

des actions, les analyses structurales, les règles conceptuelles, les aspects liés à la sécurité, les méthodes de

fabrication, les méthodes de contrôle de la qualité et les réglementations nationales, tous ces éléments étant

interdépendants. La modification d'un aspect isolé des bases conceptuelles peut avoir, en termes de fiabilité,

une incidence sur la conception globale ou sur les performances de la structure dans son ensemble. Par

conséquent, il est nécessaire que les implications des modifications soient considérées par rapport à la fiabilité

globale de l'ensemble des systèmes de structures en mer.

Les Normes internationales pour les structures en mer élaborées par le TC sont élaborées pour permettre un

choix étendu de configurations structurelles, de matériaux et de techniques sans entraver l'innovation.

L'utilisation de ces documents nécessite donc une bonne appréciation en matière d'ingénierie.

Le présent document a été élaboré en réponse à la demande exprimée par l'industrie offshore d'une définition

cohérente des méthodologies de conception, d'analyse et d'appréciation des structures en mer relevant de la

classe décrite à l'Article 1l'Article 1. D'autres exigences applicables figurent dans les codes et normes

nationaux et internationaux, ainsi que dans les règles de la RCS.

L'Annexe AL'Annexe A (informative) fournit un contexte et des recommandations pour l'utilisation du présent

document. La numérotation des paragraphes de l'Annexe Al'Annexe A est identique à celle du texte normatif

afin de faciliter le repérage.

x © ISO 2019 – Tous droits réservés

x

NORME INTERNATIONALE ISO 19904-1:2019(F)

Industries du pétrole et du gaz naturel — Structures en mer

flottantes —

Partie 1 : :

Structures en forme de navire, structures semi -submersibles, plates-

formes spar et structures cylindriques à faible tirant d’eau

1 Domaine d'application

Le présent document spécifie des exigences et des recommandations pour la conception et/ou l'évaluation de

la structure de plates-formes en mer flottantes utilisées par les industries du pétrole et du gaz naturel pour

supporter les fonctions suivantes :

— — production ;

— — stockage et/ou déchargement ;

— — forage et production ;

— — production, stockage et déchargement ;

— — forage, production, stockage et déchargement.

NOTE 1 Les plates-formes en mer flottantes sont souvent citées au moyen de différentes abréviations, par exemple

FPS, FSU, FPSO (voir les Articles 3Articles 3 et 44),), conformément à leur mission prévue.

NOTE 2 Dans le présent document, le terme « structure flottante », parfois abrégé en « structure » est utilisé comme

terme générique pour indiquer les systèmes structurels de tous éléments de classes de plates-formes définies ci-dessus.

NOTE 3 Dans certains cas, les plates-formes flottantes sont désignées comme étant des « plates-formes de production

précoce ». Ce terme se rapporte simplement à une stratégie de développement d'immobilisation. Pour les besoins du

présent document, le terme « production » inclut « production précoce ».

Le présent document ne s'applique pas aux systèmes structurels d'unités en mer mobiles (MOU). Cela

comprend notamment :

— — des structures flottantes prévues principalement pour exécuter des opérations de forage et/ou

d'interventions sur les puits (souvent appelées MODU), même lorsqu'elles sont utilisées pour des

opérations étendues d'essais de puits ;

— — des structures flottantes utilisées pour des opérations de construction en mer (par exemple des barges

grues ou des barges de pose), pour des quartiers de vie en mer temporaires ou permanents (hôtels

Type du document: Norme internationale

Sous-type du document:

Stade du document: (60) Publication

Langue du document: F

flottants), ou pour le transport d'équipements ou de produits (par exemple barges de transport, des barges

cargo), pour lesquelles la référence des structures est établie par rapport à des règles de société de

classification reconnues (RCS).

Le présent document est applicable à tous les stades possibles du cycle de vie des structures définies

ci--dessus, tels que :

— — la conception, la construction et l'installation de nouvelles structures, y compris les exigences

d'inspection, de gestion de l'intégrité et d'enlèvement futur ;

— — la gestion de l'intégrité structurelle couvrant l'inspection et l'évaluation des structures en service ; et

— — la conversion de structures pour une utilisation différente (par exemple un pétrolier converti en une

plate-forme de production) ou la réutilisation à des endroits différents.

Les types suivants de structures flottantes sont explicitement considérés dans le contexte du présent

document :

a) a) structures en forme de navires et barges ;

b) b) unités semi-submersibles ;

c) c) plates-formes spars ;

d) d) structures cylindriques à faible tirant d'eau.

En plus des types de structures répertoriés ci-dessus, le présent document couvre d'autres plates-formes

flottantes prévues pour exécuter les fonctions ci-dessus, constituées de coques flottantes partiellement

submergées constituées de toute combinaison de composants de structures plaqués et d'espace. Ces autres

structures peuvent avoir une géométrie et des formes structurelles très différentes (par exemple plates-

formes à ancrage tendu) et, en conséquence, ne peuvent être que partiellement couvertes par les exigences du

présent document. Dans d'autres cas, il se peut que les exigences spécifiques mentionnées dans le présent

document ne s'appliquent pas à tout ou partie des structures à l'étude.

NOTE 4 Les exigences relatives aux structures Top Sides sont présentées dans l'ISO 19901-3.

Dans tous les cas ci-dessus, la conformité au présent document exige que la conception soit fondée sur ses

principes de base et atteigne un niveau de sécurité équivalent, ou supérieur, au niveau implicite de celle-ci.

NOTE 5 La vitesse d'évolution de la technologie des structures en mer dépasse souvent de loin le rythme auquel

l'industrie arrive à un accord substantiel sur l'innovation dans les concepts structurels, les formes ou les dessins

structurels, les composants structurels et les pratiques d'analyse et de conception associées, qui sont constamment

affinés et améliorés. Par ailleurs, les présentes Normes internationales ne peuvent que parvenir à un consensus explicite

de l'industrie, lequel nécessite la maturation et l'acceptation de nouvelles idées. En conséquence, des concepts de

structures évolués ne peuvent, dans certains cas, qu'être partiellement couverts par les exigences du présent document.

Le présent document est applicable aux structures flottantes en acier. Les principes exposés ici sont cependant

considérés comme étant généralement applicables à des structures fabriquées dans des matériaux autres que

l'acier.

2 © ISO 2019 – Tous droits réservés

2 Références normatives

Les documents suivants sont cités dans le texte de sorte qu'ils constituent, pour tout ou partie de leur contenu,

des exigences du présent document. Pour les références datées, seule l'édition citée s'applique. Pour les

références non datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

ISO 13702, Industries du pétrole et du gaz — Contrôle et atténuation des feux et des explosions dans les

installations en mer — Exigences et lignes directrices

ISO 19900, Industries du pétrole et du gaz naturel — Exigences générales relatives aux structures en mer

ISO 19901--1, Industries du pétrole et du gaz naturel — Exigences spécifiques relatives aux structures en mer —

Partie 1 : Dispositions océano-météorologiques pour la conception et l'exploitationl’exploitation

ISO 19901--3, Industries du pétrole et du gaz naturel — Exigences spécifiques relatives aux structures, y compris

les énergies à faible teneur en mer carbone — Exigences spécifiques relatives aux structures en mer — Partie 3 :

Superstructures: Structures Top Sides

ISO 19901--6, Industries du pétrole et du gaz naturel — Exigences spécifiques relatives aux structures en mer —

Partie 6: Opérations marines

ISO 19901--7, Industries du pétrole et du gaz naturel — Exigences spécifiques relatives aux structures en mer —

Partie 7 : Systèmes de maintien en position des structures en mer flottantes et des unités marines mobiles en mer

ISO 19902, Industries du pétrole et du gaz naturel — Structures en mer fixes en acier

ISO 19906, Industries du pétrole et du gaz naturel — Structures arctiques en mer de l'Arctique

ORGANISATION mARITIME iNTERNATIONALE. Convention MARPOL de l'OMI, Convention internationale pour la

prévention de la pollution par les navires

Organisation maritime internationale. Code international de l'OMI sur la stabilité à l'état intact

ORGANISATION mARITIME iNTERNATIONALE. Convention internationale de l'OMI sur les lignes de charge

Organisation maritime internationale. OMI, Systèmes de lavage au pétrole brut

IMO MEPC/Circ.406, Guidelines for application of MARPOL Annex 1 requirements to FPSOs and FSUs as

modified by Resolutions MEPC.139(53) and MEPC.142(54)

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivants s'appliquent.

L'ISO et l'IEC tiennent à jour des bases de données terminologiques destinées à être utilisées en normalisation,

consultables aux adresses suivantes :