ISO 15569:1998

(Main)Practice for dosimetry in an electron-beam facility for radiation processing at energies between 300 keV and 25 MeV

Practice for dosimetry in an electron-beam facility for radiation processing at energies between 300 keV and 25 MeV

Pratique de la dosimétrie utilisant des faisceaux d'énergie comprise entre 300 keV et 25 MeV

General Information

- Status

- Withdrawn

- Publication Date

- 19-Dec-1998

- Withdrawal Date

- 19-Dec-1998

- Drafting Committee

- ISO/TC 85/WG 3 - Dosimetry for radiation processing

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 18-Apr-2002

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 15-Apr-2008

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

ISO 15569:1998 is a standard published by the International Organization for Standardization (ISO). Its full title is "Practice for dosimetry in an electron-beam facility for radiation processing at energies between 300 keV and 25 MeV". This standard covers: Practice for dosimetry in an electron-beam facility for radiation processing at energies between 300 keV and 25 MeV

Practice for dosimetry in an electron-beam facility for radiation processing at energies between 300 keV and 25 MeV

ISO 15569:1998 is classified under the following ICS (International Classification for Standards) categories: 17.240 - Radiation measurements. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 15569:1998 has the following relationships with other standards: It is inter standard links to ISO/ASTM 51649:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 15569:1998 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IS0

INTERNATIONAL

STANDARD

First edition

Practice for dosimetry in an electron-beam

facility for radiation processing at energies

between 300 keV and 25 MeV

Pratique de la dosim&e utill ’sant des faisceaux d ’hergie comprise entre

300keVet25MeV

Reference number

IS0 15569: 1998(E)

IS0 15569:1998(E)

Foreword

IS0 (the International Organization for Standardization) is a worldwide federation of national standards bodies

(IS0 member bodies). The work of preparing International Standards is normally carried out through IS0 technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. IS0 collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

re circul ated to the member bodi es for votin .

Draft International Standards adopted by the technical committees a

g

Publication as an lnternationa I Standard requires approval by at least 75 % of the me mber bodies casti a vote.

International Standard IS0 15569 was prepared by the American Society for Testing and Materials (ASTM)

Subcommittee E1O.O1 (as E 1649-94) and was adopted, under a special “fast-track procedure ”, by Technical

Committee lSO/TC 85, Nuclear energy, in parallel with its approval by the IS0 member bodies.

A new lSO/TC 85 Working Group WG 3, High-level dosimetry for radiation processing, was formed to review the

voting comments from the IS0 “Fast-track procedure” and to maintain these standards. The USA holds the

convenership of this working group.

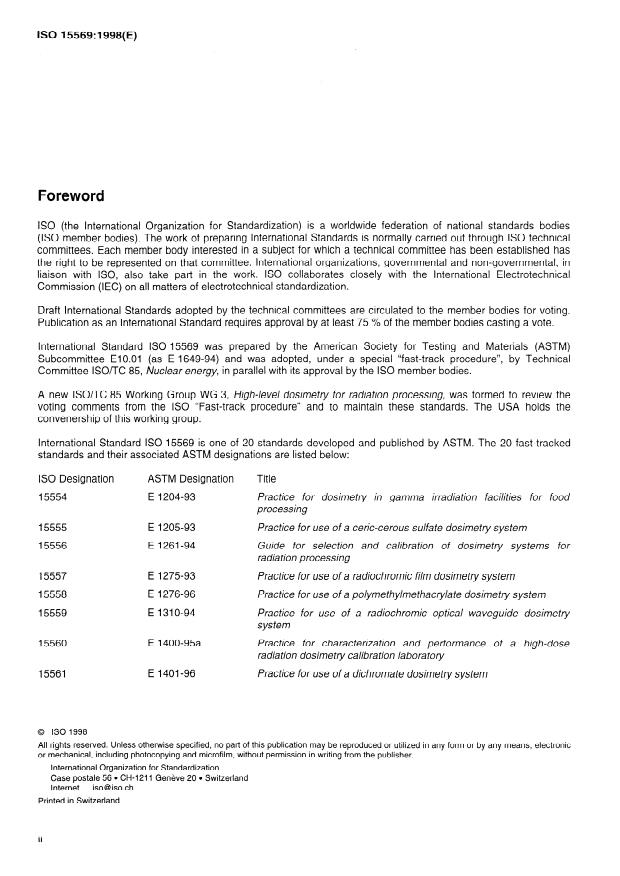

International Standard IS0 15569 is one of 20 standards developed and published by ASTM. The 20 fast-tracked

standards and their associated ASTM designations are listed below:

IS0 Designation ASTM Designation Title

E 1204-93 Practice for dosimetry in gamma irradiation facilities for food

processing

E 1205-93 Practice for use of a ceric-cerous sulfate dosimetry system

15556 E 1261-94 Guide for selection and calibration of dosimetry systems for

radiation processing

15557 E 1275-93 Practice for use of a radiochromic film dosimetry system

E 1276-96 Practice for use of a polymethylmethacrylate dosimetry system

15559 E 1310-94 Practice for use of a radiochromic optical waveguide dosimetry

sys tern

E 1400-95a Practice for characterization and performance of a high-dose

radiation dosime try calibra Con labora tory

E 1401-96 Practice for use of a dichromate dosimetry system

0 IS0 1998

All rights reserved. Unless otherwise specified, no pa .rt of this publication may be reproduced or utilized in any form or by any means, electronic

mechanical, including photocopying and mic rofilm, without permission in writing from the publisher.

or

International Organization for Standardization

Case postale 56 l CH-1211 Geneve 20 l Switzerland

Internet iso @ isoch

Printed in Switzerland

ii

IS0 15569:1998(E)

@ IS0

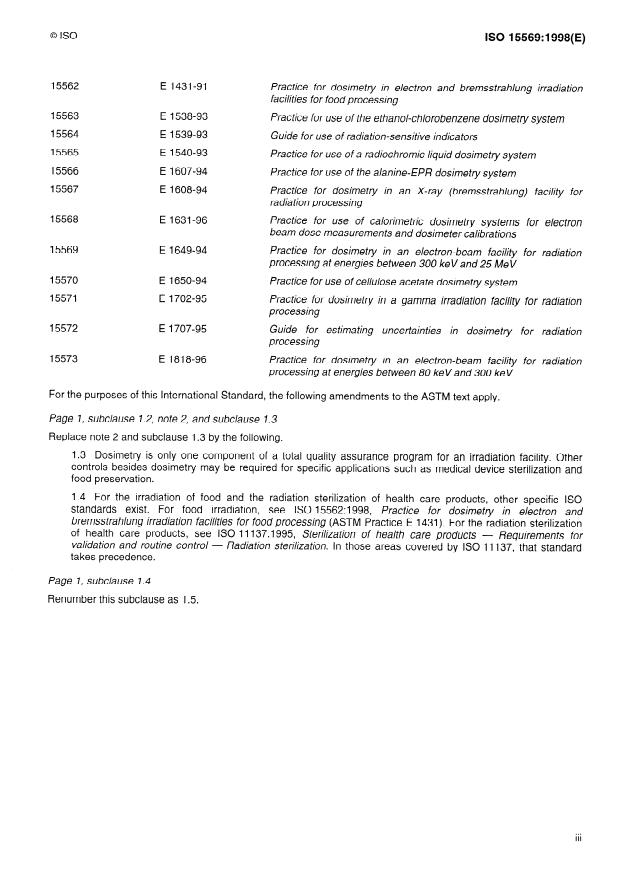

15562 E 1431-91 Practice for dosimetry in electron and bremsstrahlung irradiation

facilities for food processing

15563 E 1538-93 Practice for use of the ethanol-chlorobenzene dosimetry system

15564 E 1539-93 Guide for use of radiation-sensitive indicators

E 1540-93

15565 Practice for use of a radiochromic liquid dosimetry system

15566 E 1607-94 Practice for use of the alanine-EPR dosimetry system

Practice for dosimetry in an X-ray (bremsstrahlung) facility for

15567 E 1608-94

radiation processing

Practice for use of calorimetric dosimetry systems for electron

15568 E 1631-96

beam dose measurements and dosimeter calibrations

Practice for dosimetty in an electron-beam facility for radiation

15569 E 1649-94

processing at energies between 300 keV and 25 MeV

15570 E 1650-94 Practice for use of cellulose acetate dosimetry system

15571 E 1702-95 Practice for dosimetry in a gamma irradiation facility for radiation

processing

15572 E 1707-95 Guide for estimating uncertainties in dosimetry for radiation

processing

E 1818-96 Practice for dosimetry in an electron-beam facility for radiation

processing at energies between 80 keV and 300 keV

For the purposes of this International Standard, the following amendments to the ASTM text apply.

Page 1, subclause 1.2, note 2, and subclause 1.3

Replace note 2 and subclause 1.3 by the following.

1.3 Dosimetry is only one component of a total quality assurance program for an irradiation facility. Other

controls besides dosimetry may be required for specific applications such as medical device sterilization and

food preservation.

I .4 For the irradiation of food and the radiation sterilization of health care products, other specific IS0

standards exist. For food irradiation, see IS0 15562:1998, Practice for dosimetry in electron and

bremsstrahlung irradiation facilities for food processing (ASTM Practice E 1431). For the radiation sterilization

of health care products, see IS0 11137:1995, Sterilization of health care products - Requirements for

validation and routine control - Radiation sterilization. In those areas covered by IS0 11137, that standard

takes precedence.

Page I, subclause 1.4

Renumber this subclause as 1.5.

. . .

Ill

0 IS0 IS0 15569: 1998(E)

AMERICAN SOCIETY FOR TESJlNG AND MATERIALS

Designation: E 1649 - 94

1916 Race St Philadelphia, Pa 19103

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

If not listed in the current combined index, will appear in the next edition.

Standard Practice for

Dosimetry in an Electron Beam Facility for Radiation

Processing at Energies Between 300 keV and 25 IVleV’

This standard is issued under the fixed designation E 1649; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (c) indicates an editorial change since the last revision or reapproval.

Absorbed Dose in Radiation-Hardness Testing of Elec-

1. Scope

tronic Devices2

1.1 This practice covers dosimetric procedures to be

E 1026 Practice for Using the Fricke Reference Standard

followed in facility characterization, process qualification,

Dosimetry System2

and routine processing using electron beam radiation to

E 1205 Practice for Use of a Ceric-Cerous Sulfate

ensure that the entire product has been treated with an

Dosimetry System2

acceptable range of absorbed doses. Other procedures related

E 126 1 Guide for Selection and Calibration of Dosimetry

to facility characterization (including equipment documen-

Systems for Radiation Processing2

tation), process qualification, and routine product processing

E 1275 Practice for Use of a Radiochromic Film

that may influence and may be used to monitor absorbed

Dosimetry System2

dose in the product are also discussed.

E 1276 Practice for Use of a Polymethylmethacrylate

NOTE I-For guidance in the selection and calibration of dosimeters,

Dosimetry System2

see Guide E 126 I. For further guidance in the selection, calibration, and

E 140 1 Practice for Use of a Dichromate Dosimetry

use of specific dosimeters, and interpretation of absorbed dose in the

System2

product from dosimetry, also see Practices E 668, E 1275, E 1276,

E 143 1 Practice for Dosimetry in Electron and Brems-

E 143 1, E 1607, E 163 1, and E 1650. For use with electron energies

above 5 MeV, see Practices E 1026, E 1205, E 1401, E 1538, and E 1540

strahlung Irradiation Facilities for Food Processing2

for discussions of specific large volume dosimeters. For discussion of

E

1538 Practice for Use of an Ethanol-Chlorobenzene

radiation dosimetry for pulsed radiation, see ICRU Report 34. When

Dosimetry System2.

considering a dosimeter type, be cautious of influences from dose rates

E 1539 Guide for the Use of Radiation-Sensitive Indi-

and accelerator pulse rates and widths (if applicable).

cators2

1.2 The electron energy range covered in this practice is

E 1540 Practice for Use of a Radiochromic Liquid Solu-

between 300 keV and 25 MeV, although there are some

tion Dosimetry System2

discussions for other energies.

E 1607 Practice for Use of the Alanine-EPR Dosimetry

NOTE 2-For application of dosimetry in the characterization and System2

operation of electron beam and X-ray (bremsstrahlung) irradiation E 1608 Practice for Dosimetry in an X-Ray (Brems-

facilities for food processing, see Practice E 143 1. For application of

strahlung) Irradiation Facility for Radiation Processing2

dosimetry in the characterization and operation of irradiation facilities

E 163 1 Practice for Use of Calorimetric Dosimetry Sys-

using X-ray radiation (bremsstrahlung), see Practice E 1608.

tems for Electron Beam Measurements and Dosimeter

1.3 Dosimetry is one component of a total quality assur-

Calibrations2

ance program for adherence to good manufacturing prac-

E

1650 Practice for Use of a Cellulose Acetate Dosimetry

tices. Specific applications of electron beam radiation pro-

System2

cessing may require additional controls.

2.2 International Commission on Radiation Units and

1.4 This standard does not purport to address all of the

Measurements (ICR V” Reports:

safety concerns, ZJ! any, associated with its use. It is the

ICRU Report 33 Radiation Quantities and Units3

responsibility of the user of this standard to establish appro-

ICRU Report 34 The Dosimetry of Pulsed Radiation3

priate safety and health practices and determine the applica-

ICRU Report 35 Radiation Dosimetry: Electron Beams

bility of regulatory limitations prior to use.

with Energies Between 1 and 50 MeV3

ICRU Report 37 Stopping Powers for Electrons and

2. Referenced Documents

Positrons3

2.1 ASTM Standards:

E 170 Terminology Relating to Radiation Measurements 3. Terminology

and Dosimetry2

3.1 Definitions -Other terms used in this practice may be

E 668 Practice for the Application of Thermolumi-

found in Terminology E 170 and ICRU Report 33.

nescence-Dosimetry (TLD) Systems for Determining

3.2 Descriptions of Terms Speci$c to This Standard.

3.2.1 absorbed dose, D-the quotient of dZ by dm, where

d? is the mean energy imparted by ionizing radiation to the

I This practice is under the jurisdiction of ASTM Committee E-IO on Nuclear

Technology and Applications and is the direct responsibility of Subcommittee

E1O.O1 on Dosimetry for Radiation Processing.

3 Available from International Commission on Radiation Units and Measurc-

Current edition approved Nov. i 5, 1994. Published February 1995.

mcnts, 79 10 Woodmont Ave., Suite 800, Bcthcsda, MD 208 14.

2 Anntrui Book o/ASTM S~~r~hrds, Vol 12.02.

I

@ IS0

IS0 15569:1998(E)

beam current; for a puked machine, the averaging shalE be

done over a large number of pulses.

3.2,3 beam length--dimension of the irradiation zone

perpendicular to the beam width and direction of the

electron beam specified at a specified distance from the

accelerator window.

DscusstoN-See Fig. 1 0

3.2.4 beam power-product of the average electron en-

ergy and the average beam current.

3.2.5 beam width-dimension of the irradiation zone

perpendicular to the beam length and direction of the

electron beam specified at a specific distance from where the

beam exits the accelerator.

~lscussroN--For a radiation processing facility with a conveyor

system, the beam width is usually perpendicular to the flow of motion of

the conveyor (see Fig. 1). Beam width is the distance between the points

CONVEYOR-

along the dose profile which are at a defined level from the maximum

dose region in the profile (see Fig. 2). Various techniques may be

LENGTH

employed to produce an electron beam width adequate to cover the

FIG. 1 Diagram Showing Beam Length and Width for a Scanned processing zone, for example, use of electromagnetic scanning of pencil

Beam Using a Conveyor Material Handling System

beam (in which case beam width is also referred to as scan width),

defocussing elements, and scattering foils.

3.2.6 compensating dummy-simulated product used

matter of mass dm (see ICRU Report 33).

L

during routine production runs with irradiation units con-

de

=-

D

taining less product than specified in the product loading

dm

configuration or at the beginning and end of a production

The special name of the unit for absorbed dose is the gray

run to compensate for the absence of product.

(GYh 3.2.7 depth-dose distribution-variation of absorbed dose

with depth from the incident surface of a material exposed to

1 Gy = 1 J-kg-’

radiation.

Formerly, the special unit for absorbed dose was the rad:

DISCUWON-A typical distribution in homogeneous material pro-

1 rad = 1O-2 Jekg-’ = 1O-2 Gy

duced by an electron beam along the beam axis is shown in Fig. 3. See

and:

1 Mrad = 10 kGy

4 McKeown, J., AECL Accelerators, private communication, 1993. Example of

a beam width profile of an AECL lmpela accelerator.

beam current-time-averaged electron

3.2.2 average

0.16

0.15

-0

0.14 max

- fD

0.13 max

0.12

0.11

s 0.1

(3

s 0.09

W

g 0.08

0 0.07

0.06

0.05

0.04

0.03

0.02

0.01

I 1 1 I 1 I I 1 I 1

-50 -30 -10 10 30 50

DISTANCE (cm)

FIG. 2 Example of Electron-beam Dose Distribution Along the Beam Width4 with the Width Noted at Some Defined Fractional Level f of

the Average Maximum Dose D,,,

IS0 15569:1998(E)

at the surface where the electron beam enters.

DIscussloN-See Fig. 3.

3.2.19 practical range @,)-distance from the surface of

De homogeneous material where the electron beam enters to the

ii

point where the tangent at the steepest point (the inflection

point) on the almost straight descending portion of the

depth-dose distribution curve meets the depth axis.

DrscussIoN-See Fig. 3.

3.2.20 production run- series of irradiation units con-

taining the same product, and irradiated sequentially to the

same absorbed dose.

FQopt R50 40, Rp 3.2.21 pulse beam current -for a pulsed accelerator, the

beam current averaged over the top ripples (aberrations) of

DEPTH (ARBITRAFIY UNfTS)

the pulse current waveform; this is equal to &/wl; where

Iavs is the average beam current, w is the pulse width, andfis

FIG. 3 A Typical Depth-Dose Distribution for an Electron Beam

the pulse rate.

Appendix X 1.

DIscussrON-See Fig. 4.

3.2.8 dose unz@mity ratio-ratio of the maximum to the

3.2.22 pulse rate-for a pulsed accelerator, the pulse

minimum absorbed dose within the irradiation unit; it is a

current repetition frequency in hertz, or pulses per second;

measure of the degree of uniformity of the absorbed dose; the

concept is also referred to as the max/min dose ratio. this is also referred to as the repetition (rep) rate.

3.2.23 pulse width-for a pulsed accelerator, the time

3.2.9 dosimetry system- a system used for determining

interval between the half peak beam current amplitude

absorbed dose, consisting of dosimeters, measurement in-

points on the leading and falling edges of the pulse beam

struments and their associated reference standards, and

procedures for the system ’s use. current waveform.

3.2.10 duty cycle-for a pulsed accelerator, the fraction of

DrscussloN-See Fig. 4,

time the beam is effectively on; it is the product of the pulse

width in seconds and the pulse rate in pulses per second.

3.2.24 reference material-homogeneous material of

3.2.11 electron beam facility-an establishment that uses

known radiation absorption and scattering properties used to

energetic electrons produced by particle accelerators to

establish characteristics of the irradiation process, such as

irradiate product.

scan uniformity, depth-dose distribution, throughput rate,

3.2.12 electron energy-kinetic energy of electron (unit:

and reproducibility.

electron volt (eV))

3.2.25 refirence plane-a selected plane in the radiation

3.2.13 electron energy spectrum-frequency or energy

zone that is perpendicular to the electron beam axis.

distribution of electrons as a function of energy; the energy

3.2.26 scanned beam-an electron beam which is swept

spectrum of the electron beam impinging on the product

back and forth with a varying magnetic field.

depends on the type of the accelerator and the conditions of

the irradiation process.

DIscussroN-This is most commonly done along one dimension

3.2.14 electron range-penetration distance along the

(beam width), although two dimensional scanning (beam width and

beam axis of electrons within homogeneous material. length) may be used with high-current electron beams to avoid

overheating the beam exit window of the accelerator.

DrsCus%ON-Several range parameters may be defined to describe

the characteristics of the electron beam. For more information, refer to

ICRU Report 35.

~ PULSE ~

I

WIDTH

3.2.15 hapentrance depth (R&-depth in homogeneous

I

I

material at which the absorbed dose has decreased 50 % of

the absorbed dose at the surface of the material.

DrscussroN-See Fig. 3.

3.2.16 ha@alue depth &J--depth in homogeneous

material at which the absorbed dose has decreased 50 % of its

maximum value.

DISCussloN-See Fig. 3.

3.2.17 irradiation unit-a volume of product with a

specified loading configuration processed as a single entity;

TlME

this term is not relevant to bulk-flow processing.

3.2.18 optimum thickness (R&-depth in homogeneous

FIG. 4 Typical Pulse Current Waveform with Pulse Current and

Pulse Width Noted

material at which the absorbed dose equals the absorbed dose

IS0 15569:1998(E) @ IS0

4.5 Before a radiation process can be used, the facility

3.2.27 scan unijbrmity-the degree of uniformity of the

must be qualified to demonstrate its ability to deliver known,

dose measured along the scan direction.

controllable doses in a reproducible manner. This involves

3.2.28 simulated product-a mass of material with atten-

uation and scattering properties similar to those of a partic- testing the process equipment, calibrating the equipment and

ular material or combination of materials; this material is dosimetry system, and characterizing the magnitude, distri-

sometimes referred to as dummy product or phantom. bution, and reproducibility of the dose absorbed by a

.

reference material.

4. Significance and Use

4.6 To ensure that products are irradiated with reproduc-

ible doses, routine process control requires hocumented

4.1 Various products and materials are routinely irradi-

product handling procedures before, during, and after the

ated at pre-determined doses at electron beam facilities to

irradiation, consistent orientation of the products during

preserve or modify their characteristics. Dosimetry require-

irradiation, monitoring of critical process parameters, rou-

ments may vary depending upon the radiation process and

tine product dosimetry, and documentation of the required

end use of the product. For example, a partial list of

activities and functions.

processes where dosimetry may be used is:

4.1.1 Cross-linking or degradation of polymers and

5. Radiation Source Characteristics

elastomers,

4.1.2 Polymerization of monomers and grafting of mono-

5.1 Radiation sources for electrons with energies greater

mers onto polymers,

than 300 keV considered in this practice are either direct-

4.1.3 Sterilization of medical devices,

action (potential-drop) or indirect-action (microwave-

4.1.4 Disinfection of consumer products,

powered) accelerators. These are further discussed in Ap-

4.1.5 Food irradiation (parasite and pathogen control,

pendix X2.

insect disinfestation, and shelf-life extension),

4.1.6 Control of pathogens in liquid or solid waste,

6. Types of Irradiation Facility

4.1.7 Modification of characteristics of semiconductor

6.1 An electron beam facility includes the electron beam

devices,

accelerator system; material handling systems; a radiation

4.1.8 Color enhancement of gemstones and other mate-

shield with personnel safety system; product staging, loading,

rials, and

and storage areas; auxiliary equipment for power, cooling,

4.1.9 Research on materials effects.

ventilation, etc.; equipment control room; a laboratory for

NOTE 3-Dosimetry is required for regulated radiation processes

dosimetry and product testing; and personnel ofices. The

such as the sterilization of medical devices (I,%, 3)s and the preservation

electron beam accelerator system consists of the radiation

of food. It may be less important for other processes, such as polymer

source (see Appendix X2), equipment to disperse the beam

modification, which may be evaluated by changes in the physical and

on product, and associated equipment (4).

chemical properties of the irradiated materials. Nevertheless, routine

6.2 Process Parameters:

dosimetry may be used to monitor the reproducibility of the treatment

6.2.1 There are various process parameters that play

process.

essential roles in determining and controlling the absorbed

4.2 As a means of (quality) control of the radiation

dose in radiation processing at an irradiation facility. They

process, dosimeters are used to relate the calibrated response

should, therefore, be considered when performing the ab-

to radiation to the absorbed dose in the material or product

sorbed-dose measurements required in Sections 8, 9, and 10.

being irradiated.

6.2.2 Process parameters include irradiation unit charac-

NOTE 4-Measured dose is often characterized as absorbed dose in

teristics (for example, size, bulk density, and heterogeneity),

water because materials commonly found in disposable medical devices

irradiation conditions (for example, processing geometry,

and food are approximately equivalent to water in the absorption of

multi-sided exposure, and number of passes through the

ionizing radiation. Absorbed dose in materials other than water may be

beam), and operating parameters.

determined by applying conversion factors in accordance with Guide

6.2.3 Operating parameters include beam characteristics

E 1261.

(controlled by accelerator parameters: for example, energy,

4.3 A beneficial irradiation process is usually specified by

average beam current, and pulse rate), performance charac-

a minimum absorbed dose to achieve the desired effect and a

teristics of material handling (see 6.3), and beam dispersion

maximum dose limit that the product can tolerate and still

parameters (for example, beam width and frequency at

be functional. Since it is used to determine these limits,

which scanned beam is swept across product). Operating

dosimetry is essential in the evaluation and control of the

parameters are measurable, and their values depend on the

radiation process.

facility controlling parameters. During irradiation facility

4.4 The dose distribution within the product depends on

qualification (see Section 8), absorbed dose characteristics

irradiation unit characteristics, irradiation conditions, and

over the expected range of the operating parameters are

operating parameters. The operating parameters consist of

established for a reference material.

beam characteristics (such as energy and beam current),

6.2.4 Process parameters for a radiation process are estab-

beam dispersion parameters, and product material handling,

lished during process qualification (see Section 9) to achieve

These critical parameters must be controlled to obtain

the absorbed dose within the specified limits.

reproducible results.

6.2.5 During routine product processing (see Section lo),

the facility operating parameters are controlled and moni-

tored to maintain all values that were set during process

3 The boldface numbers in parentheses refer to a list of references at the end of

this practice. qualification.

0 IS0

IS0 15569:1998(E)

operating within specified limits, will consistently produce an

6.2.6 Different product types may require different oper-

absorbed-dose distribution in a given product to prerequisite

ating and process parameters.

6.3 Configuration of A4ateriaI Handling-The absorbed specification. Such documentation shall be retained for the

dose distributions within product may be affected by the life of the irradiator, and include: -

8.2.1 The irradiator specifications and characteristics,

material handling system. Examples of systems commonly

8.2.2 A description of the location of the irradiator within

used are:

6.3.1 Conveyors or Carriers-Material is placed upon the operator ’s premises in relation to the means ’provided for

carriers or conveyors for passage through the electron beam. the segregation of non-irradiated products from irradiated

The speed of the conveyor or carriers is controlled in products, if required,

conjunction with the electron beam current and beam width 8.2.3 A description of the construction and the operation

so that the required dose is applied. of any associated material handling equipment,

8.2.4 The dimensions and the description of the materials

6.3.2 Roll-to-Roil Feed System-Roll-to-roll (also referred

to as reel-to-reel) feed systems are used for tubing, wire, and the construction of containers used to hold products

during irradiation, if used,

cable, and continuous web products. The speed of the system

is controlled in conjunction with the electron beam current 8.2.5 A description of the manner of operating the irradi-

and beam width so that the required dose is applied. ator, and

6.3.3 Bulk-flow System- For irradiation of liquids or 8.2.6 Any modifications made during and after installa-

particulate materials like grain or plastic pellets, bulk-flow tion.

transport through the irradiation zone may be used. Because 8.3 Equipment Testing and Calibration-The absorbed

the flow velocity of the individual pieces of the product dose within an irradiation unit depends in part on the

cannot be controlled, the average velocity of the product in operating parameters: beam characteristics, material han-

dling, beam dispersion parameters, and their inter-relation-

conjunction with the beam characteristics and beam disper-

sion parameters determines the average absorbed dose. ships. It also depends on irradiation unit characteristics and

6.3.4 Stationary-For high dose processes, the material irradiation conditions. These operating parameters are con-

may be placed under the beam and not moved. Cooling may trolled by various accelerator and other facility parameters.

be required to dissipate the heat accumulated by the product 8.3.1 Beam Characteristics:

8.3.1.1 The three principal beam characteristics that affect

during processing. The amount of irradiation time is con-

trolled in conjunction with the electron beam current, beam dosimetry are the electron energy spectrum, average beam

length, and beam width to achieve the required dose. current, and pulse beam current. The electron energy spec-

trum affects the depth-dose distribution within the product

7. Dosimetry Systems (see Appendix Xl). The average and pulse beam currents, in

addition to several other operating parameters, affect the

7.1 Dosimetry systems are used to determine absorbed

average and peak dose rates, respectively.

dose and consist of the dosimeter, the calibration curve or

function, reference standards, appropriate instrumentation,

NOTE S-Indirect-action (microwave-powered) accelerators may de-

and procedures for the system ’s use.

liver higher dose rates while the beam current is actually on compared to

direct-action (potential-drop) accelerators with the same average beam

7.2 It is important that the dosimeter be evaluated for

current. These higher dose rates in a pulsed mode may affect the

those parameters which may influence the dosimeter ’s re-

dosimeter response.

sponse; for example, electron energy, average and peak

NOTE 6-The electron energy spectrum of the accelerated electron

absorbed dose rate (particularly for pulsed accelerators), and

beam may be characterized by the average electron energy (E,) and the

environmental conditions (for example, temperature, hu-

most probable electron energy (E,) (see Appendix X3). An energy

midity, and light). Guidance as to desirable characteristics

analyzing magnet may be used for more detailed analysis.

and selection criteria for dosimetry systems can be found in

8.3.2 Material Handling:

Guide E 126 1, Practices E 1026, E 1205, E 1275, E 1276,

8.3.2.1 For facilities utilizing continuously-moving con-

E 1401, E 1538, E 1540, E 1607, E 1631, and E 1650.

veyors (including, for example, roll-to-roll feed systems for

7.3 The dosimetry system should be properly calibrated

tubing, wire, cable, and continuous web products) to trans-

using a calibration service traceable to national standards.

port product through the irradiation zone, conveyor speed

Guidance for calibration can be found in Guide E 126 1.

determines the irradiation time. Therefore, when other

operating parameters are held constant, conveyor speed

8. Irradiation Facility Qualification

governs the absorbed dose in the product.

8.1 Objeclive-The purpose of qualifying an electron

NOTE 7-The conveyor speed and the beam current may be linked

beam facility is to establish baseline data for evaluating the

for some types of accelerators so that a variation in one causes a

ability of the facility to accurately and reproducibly deliver

corresponding change in the other to maintain a constant value of the

doses over the range of conditions at which the facility will

absorbed dose (also see Note 8).

operate (4). For example, dosimetry can be used (I) to

establish relationships between measured absorbed dose 8.3.2.2 For those facilities that irradiate products while

distributions in reference materials in given geometries and they are stationary in the irradiation zone, irradiation time

operating parameters of the facility, and (2) to characterize governs the absorbed dose in the product when other

dose variations when these conditions fluctuate statistically operating parameters are held constant.

and through normal operations (5). 8.3.3 Beam Dispersion Parameters:

8.3.3.1 Dispersion of the electron beam to produce a

8.2 Equipment Documentation-Document the irradiator

qualification program that demonstrates that the irradiator, beam width adequate to cover the processing zone may be

IS0 15569: 1998(E) 0 IS0

width, irradiation unit characteristics and irradiation condi-

achieved by various techniques. These include electromag-

tions necessary to achieve the absorbed dose for the set

netic scanning of a pencil beam or use of defocussing

requirements (see, for example, Refs 4, 7, and 8).

elements or scattering foils.

8.3.3.2 The beam width, in addition to several other

NOTE g-In conjunction with dose distribution measurements, it is

operating parameters, affects the dose rate. Scanning of a

usually necessary to do testing of the product to ensure compatibility

with the electron beam treatment. It is recommended that this testing be

pencil beam can produce pulsed dose at points along the

done at doses higher than the maximum absorbed dose attained during

beam width. This can influence the dosimeters’ performance

routine processing.

when they are sensitive to dose rate variations.

8.3.3.3 See Appendix X4 for determination of beam

9.2 Determination of Product Loading Pattern-A load-

width and dose uniformity across the beam width.

ing pattern for irradiation shall be established for each

8.4 Irradiator Characterization:

product type. The specification for this loading pattern shall

8.4. I The dose on the surface of the product facing the

document the following:

beam is primarily related to the beam characteristics, the

9.2.1 Description of the product with specifications that

beam dispersion, electron scatter conditions at the surface,

influence the absorbed dose distribution (such as dimensions

and material handling (see 8.3). Over the expected range of

and composition) and, if applicable, description of the

these operating parameters, establish the absorbed dose

orientation of the product within its package, and

characteristics in a reference material using appropriate

9.2.2 Orientation of the product with respect to the

dosimetry.

material handling. This may include a further description of

the orientation of the product within another container used

NOTE 8-Electron beam irradiators generally utilize continuously-

during irradiation.

moving conveyors. Dose uniformity in a reference plane is strongly

9.3 Irradiation Unit Absorbed-Dose Mapping (9):

influenced by the coordination of the beam spot dimensions, conveyor

speed, beam width, and scan frequency (for those irradiators that

NOTE lo-The irradiation of tubing, wire, cable, and continuous

employ beam scanning). For a pulsed-beam accelerator, all these

web products may not require absorbed dose mapping studies. Desired

parameters must also be coordinated with the pulse width and repetition

effects from absorbed dose may be attained through control of the

rate. Improper coordination of these parameters can cause unacceptable

operating parameters and monitoring the desired effects themselves.

dose variation in the reference plane.

9.3.1 Establish the locations of absorbed dose extremes for

8.4.2 Using appropriate dosimetry, establish the depth-

the selected product loading pattern. This can be accom-

dose distribution within a reference material (see Appendixes

plished by placing dosimeters throughout the volume of

X1 and X3). The exact shape of the distribution will be

interest for several irradiation units. Select placement pat-

different for different facilities since it depends on the energy

terns that can most probably identify the locations of the

spectrum of the electron beam and the irradiation geometry

dose extremes; concentrate dosimeters in those areas, with

(6). The depth of penetration depends on electron energy.

fewer dosimeters placed in areas likely to receive interme-

Increasing the electron energy increases the half-value depth

diate absorbed dose. Dosimeters used for dose mapping must

(R,,), the practical range (R,), and the optimum thickness

be selected to be able to detect doses and dose gradients likely

to occur within irradiated products. For electron irradiation,

8L4.3 Establish the capability of the facility to deliver a

dosimeter films in sheets or strips may be most useful for

reproducible constant dose in a reference geometry. Measure

obtaining this information. Because of variations in pack-

the fluctuations in the values of the operating parameters

aging geometry or product distribution, dosimeters placed in

that may cause variation in absorbed dose. Estimate the

similar locations in several irradiation units may produce a

magnitude of these dose variations, for example, by passing

range of absorbed dose measurements. Select a sufficient

dosimeters in the reference geometry through the irradiation

number of irradiation units for mapping to determine the

zone on the product conveyor at time intervals appropriate

variability of the distributions among irradiation units.

to the frequency of the parameter fluctuations. The reference

9.3.2 Ensure that values of the process parameters that

geometry for the irradiated material is selected so that the

affect the absorbed dose in the product are the same during

placement of the dosimeters on and within the material will

both mapping and routine production runs. This require-

not affect the reproducibility of the measurements.

ment is necessary to avoid altering the magnitudes (and

perhaps locations) of absorbed dose extremes because a

9. Process Qualification

change in process parameters might cause the doses to lie

9.1 Objective- Absorbed dose requirements vary de- outside the prescribed absorbed dose requirements. Dose

pending upon the process and type of product being irradi- mapping may need to be repeated whenever one or more of

ated. A radiation process is usually associated with a min- the process parameters are changed.

imum absorbed dose requirement and sometimes a 9.3.3 If process parameters are changed that could affect

maximum absorbed dose requirement. For a given process, the magnitudes or locations of absorbed dose extremes,

one or both of these limits may be prescribed by regulations. repeat the dose mapping to the extent necessary to establish

Therefore, the objective of process qualification is to ensure the effects.

that absorbed dose requirements are satisfied. This is accom- 9.3.4 If the locations of absorbed dose extremes identified

plished by mapping the dose distribution throughout the

during the dose mapping procedure of 9.3.1 are not readily

irradiation unit for a specific product loading pattern. This

accessible during production runs, alternative external or

procedure also establishes all the process parameters, for internal positions may be used for routine product pro-

example, electron energy, beam current, material handling cessing dosimetry. The relationships between the absorbed

parameters (conveyor speed or irradiation time), beam doses at these alternative reference positions and the ab-

0 IS0 IS0 15569:1998(E)

food irradiation). For these situations, dosimetry is required during

sorbed dose extremes shall be established, shown to be

routine product processing.

reproducible, and documented.

9.3.5 Results from the dose mapping measurements will

10.2 Routine Production Dosimetry-Ensure that the

govern the dose to be delivered to the product to ensure that

product receives the absorbed dose within prescribed limits

prescribed dose requirements within the product are

by employing proper dosimetry procedures, with appropriate

achieved. The uncertainties of the dosimetry system, . the statistical controls and documentation. These procedures

uncertainties from the measurement of the dose distribution,

involve the use of routine in-plant dosimetric measurements

and the variations of the radiation process lead to an overall

performed as follows:

uncertainty of the minimum and maximum doses within the

NOTE 12-Some processes, such as the modification of material

product. This uncertainty must be taken into account when

properties, may not require routine dosimetry (see Notes 3 and 11).

the process parameters are chosen. Generally, the parameters

10.2.1 Dosimeter Location-Place dosimeters either

must be chosen so that the probability of irradiating the

within or on the selected irradiation units at predetermined

product or part of the product with doses lower than the

locations of the minimum (and maximum, if a prescribed

required minimum or higher than the allowed maximum is

limit) absorbed dose (see 9.3. l), or at the reference positions

known and documented (7, 8).

determined in 9.3.4.

9.3.6 For irradiators being used in a bulk flow mode,

10.2.2 Placement Frequency-Place dosimeters at loca-

absorbed-dose mapping as described in 9.3.1 may not be

tions described in 10.2.1. Always place dosimeters at the start

feasible. In this case, absorbed dose extremes may be

of the run. For long production runs, place dosimeters at or

estimated by using an appropriate number of dosimeters

near the middle of the run, at the end of the run, and at other

mixed with and carried by the product through the irradia-

intervals as appropriate.

tion zone. Enough dosimeters should be used to obtain

NOTE 13-More frequent placement of dosimeters during the pro-

statistically significant results (10, 11). Calculation of the

duction run could result in less product rejection should some opera-

absorbed dose extremes may be an appropriate alternative

tional uncertainty or failure arise.

(8)

9.3.7 If the dose mapping procedure of 9.3.1 reveals that 10.2.3 Partial Loading-If processing partially-loaded ir-

radiation units is necessary, follow the same process qualifi-

the measured dose extremes are unacceptable, it may be

cation requirements as for fully-loaded irradiation units.

possible to alter these values by changing the operating

parameters. Alternatively, it may be necessary to change the Perform the dose mapping procedures of 9.3 to ensure that

product within the irradiation unit or the shape, size, or flow the absorbed-dose distributions are adequately characterized

pattern of the irradiation unit itself. and are acceptable. Variations to the dose distribution from a

9.3.7.1 Changing the beam characteristics, for example, partial loading may in some cases be minimized by the use of

by optimizing the electron energy, can change the dose compensating dummy material placed at appropriate loca-

extremes. Other means to change the dose extremes may be tions within the irradiation unit.

employed, such as use of attenuators, scatterers and reflec- 10.2.4 Buf/L--ow-For some types of bulk-flow irradiators

tors. (for example, where fluids or grains continuously flow during

9.3.7.2 Depending upon the density, thickness, and irradiation), where it may not be feasible during routine

inhomogeneity of an irradiation unit and beam energy of the production to place dosimeters at the locations of minimum

irradiator, many processes require double-sided irradiation and maximum absorbed dose, add several dosimeters to the

to achieve an acceptable dose distribution. For double-sided product stream at the beginning, the middle, and near the

irradiation, the magnitudes and locations of dose extremes end of the production run. Each set of absorbed-dose

measurements requires several dosimeters to ensure, within a

are usually quite different from those for single-sided irradi-

ation. Slight fluctuations in density or thickness of product specified level of confidence, that the minimum (and max-

within the irradiation unit may cause much more pro- imum, if a prescribed limit) absorbed dose is known. This

nounced changes in absorbed dose within the product for procedure requires that the total irradiation time and rate of

double-sided irradiation as compared to single-sided irradia- flow of the dosimeters are the same as those of the product.

tion.

NOTE 14-In case it is not feasible to utilize dosimeters during the

routine processing of bulk materials, it may be acceptable to rely on

10. Routine Product Processing (Ref 4) process parameter control or product end point analysis. For some

processes, it may be sufficient to determine the average dose and the

10.1 Process Parameters:

maximum and minimum doses in process experiments using samples of

10.1.1 For routine product processing, set the operating

the material to be irradiated or dummy products. Calculation of dose

parameters as established during process qualification.

extremes may also be acceptable. The consistency of the dose distribu-

10.1.2 Control, monitor and document the operating

tion can be ensured by monitoring all of the critical process parameters

parameters to ensure that each irradiation unit that passes and by repeating the process qualification procedure at appropriate

intervals.

through the irradiator is processed in accordance with

specifications.

10.2.5 Environmental Changes-A change in the environ-

10.1.3 If these parameters deviate outside the processing

ment (for example, temperature or humidity) of a dosimeter

limits prescribed from process qualification, take appropriate

during the irradiation process may affect its response. If

actions, for example, immediate interruption of the process

required, correct the dosimeter response for any such effect

to evaluate and correct the cause of the deviations.

(see Guide E 126 1).

10.3 Radiation-Sensitive Indicators-For some dose

NOTE 1 l-Monitoring of operating parameters alone may not be

levels, radiation-sensitive indicators may be available that

adequate for some radiation processes (for example, sterilization and

IS0 15569:1998(E) 0 IS0

with an established quality assurance program, the delivery

can be used for process control and for inventory purposes.

of the dose to the product. Certification shall be performed

A radiation-sensitive indicator may be affixed on

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...