ISO 7503-1:2016

(Main)Measurement of radioactivity — Measurement and evaluation of surface contamination — Part 1: General principles

Measurement of radioactivity — Measurement and evaluation of surface contamination — Part 1: General principles

ISO 7503 (all parts) and ISO 8769 are addressed to the people responsible for determining the radioactivity present on solid surfaces. ISO 7503 is published in three parts and can be used jointly or separately according to needs. ISO 7503-1:2016 relates to the assessment of surface contamination by direct and indirect measurements and the calibration of the associated instrumentation. The standard applies to alpha-, beta- and photon emitters and is intended for use by hospitals, universities, police, or industrial establishments. The standard also can be used in the assessment of activity on trucks, containers, parcels, equipment and is applicable in any organization which handles radioactive materials. Generally, it is applicable to well defined flat surfaces where direct methods are applicable, however, it can also be used for surfaces which are not flat and where indirect wipe tests would be appropriate. These investigations may be carried out on containers, inaccessible areas, non-flat areas where wipe tests can be used. This part of ISO 7503 may be useful in emergency situations, i.e. in nuclear accidents where health physics professionals would be involved. ISO 7503-1:2016 does not apply to the evaluation of contamination of the skin, of clothing and of loose material such as gravel. NOTE The test method using wipe-test samples for the evaluation of radioactive surface contaminations is dealt with in ISO 7503-2. The calibration of instruments for the evaluation of radioactive surface contaminations is dealt with in ISO 7503-3.

Mesurage de la radioactivité — Mesurage et évaluation de la contamination de surface — Partie 1: Principes généraux

L'ISO 7503 (toutes les parties) et l'ISO 8769 s'adressent aux personnes chargées de déterminer la radioactivité présente sur des surfaces solides. L'ISO 7503 est publiée en trois parties qui peuvent être utilisées conjointement ou séparément, selon les besoins. L'ISO 7503-1:2016 porte sur l'évaluation de la contamination de surface par mesurages directs et indirects, ainsi que sur l'étalonnage de l'instrumentation associée. L'ISO 7503-1:2016 est applicable aux émetteurs alpha, bêta et photoniques et destinée aux établissements hospitaliers, universitaires, policiers ou industriels. Elle peut également servir à l'évaluation de l'activité des camions, conteneurs, colis ou équipements et est applicable à toute organisation qui manipule des matières radioactives. De manière générale, elle s'applique aux surfaces planes bien définies auxquelles les méthodes directes sont applicables, mais elle peut également être utilisée pour les surfaces non planes et lorsque des essais indirects par frottis seraient appropriés. Ces études peuvent être réalisées sur des conteneurs, des zones inaccessibles ou des surfaces non planes où des essais par frottis peuvent être réalisés. L'ISO 7503‑1:2016 peut s'avérer utile dans les situations d'urgence, telles que les accidents nucléaires, qui nécessiteraient l'intervention de spécialistes en radioprotection. L'ISO 7503-1:2016 ne s'applique pas à l'évaluation de la contamination de la peau, des vêtements et des matériaux en vrac (gravier, par exemple). NOTE La méthode d'essai par frottis qui utilise des échantillons pour l'évaluation de la contamination des surfaces radioactives est traitée dans l'ISO 7503‑2. L'étalonnage des instruments utilisés pour l'évaluation de la contamination des surfaces radioactives est traité dans l'ISO 7503‑3.

Merjenje radioaktivnosti - Merjenje in vrednotenje površinske kontaminacije - 1. del: Splošna načela

Standarda ISO 7503 (vsi deli) in ISO 8769 sta namenjena osebam, ki so odgovorne za določanje prisotnosti radioaktivnosti na trdnih površinah. Standard ISO 7503 je objavljen v treh delih, ki jih je mogoče uporabljati skupaj ali ločeno glede na potrebe.

Ta del standarda ISO 7503 se navezuje na ocenjevanje površinske kontaminacije z neposrednimi in posrednimi meritvami ter umerjanjem povezanih instrumentov.

Standard se uporablja za alfa in beta oddajnike ter fotonske oddajnike in je namenjen za uporabo v bolnišnicah, na univerzah, pri delu policije ali v industrijskih obratih. Uporabljati ga je mogoče tudi pri ocenjevanju dejavnosti na tovornjakih, vsebnikih, paketih in opremi ter se uporablja v kateri koli organizaciji, ki se ukvarja z radioaktivnimi snovmi. Na splošno se uporablja za natančno opredeljene ravne površine, kjer je primerna uporaba neposrednih metod, vendar ga je mogoče uporabljati tudi za površine, ki niso ravne in kjer bi bili primerni posredni preskusi z brisanjem. Te preiskave se lahko izvajajo na vsebnikih, nedostopnih območjih in neravnih območjih, kjer je mogoče uporabiti preskuse z brisanjem. Ta del standarda ISO 7503 je lahko uporaben v izrednih razmerah, tj. pri jedrskih nesrečah, kjer bi bili vključeni strokovnjaki za zdravstveno fiziko.

Ta del standarda ISO 7503 se ne uporablja za vrednotenje kontaminacije kože, oblačil in sipkega materiala, kot je gramoz.

OPOMBA: Preskusna metoda z uporabo vzorcev za brisanje za vrednotenje površinske radioaktivne kontaminacije je obravnavana v standardu ISO 7503-2. Umerjanje instrumentov za vrednotenje površinske radioaktivne kontaminacije je obravnavano v standardu ISO 7503-3.

General Information

Relations

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2025

Merjenje radioaktivnosti - Merjenje in vrednotenje površinske kontaminacije - 1.

del: Splošna načela

Measurement of radioactivity - Measurement and evaluation of surface contamination -

Part 1: General principles

Mesurage de la radioactivité — Mesurage et évaluation de la contamination de surface

— Partie 1: Principes généraux

Ta slovenski standard je istoveten z: ISO 7503-1:2016

ICS:

13.280 Varstvo pred sevanjem Radiation protection

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

INTERNATIONAL ISO

STANDARD 7503-1

Second edition

2016-01-15

Corrected version

2018-02-15

Measurement of radioactivity —

Measurement and evaluation of

surface contamination —

Part 1:

General principles

Mesurage de la radioactivité — Mesurage et évaluation de la

contamination de surface —

Partie 1: Principes généraux

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

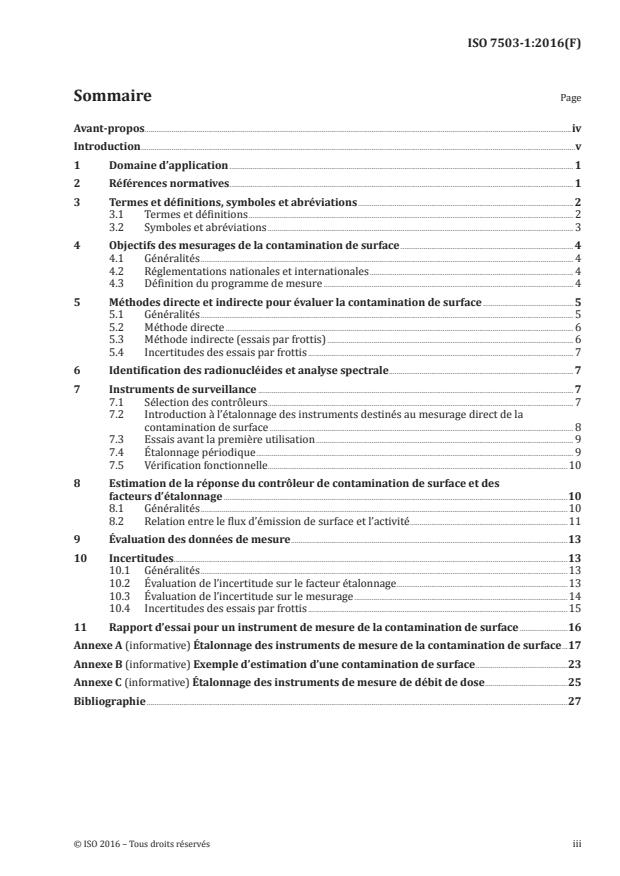

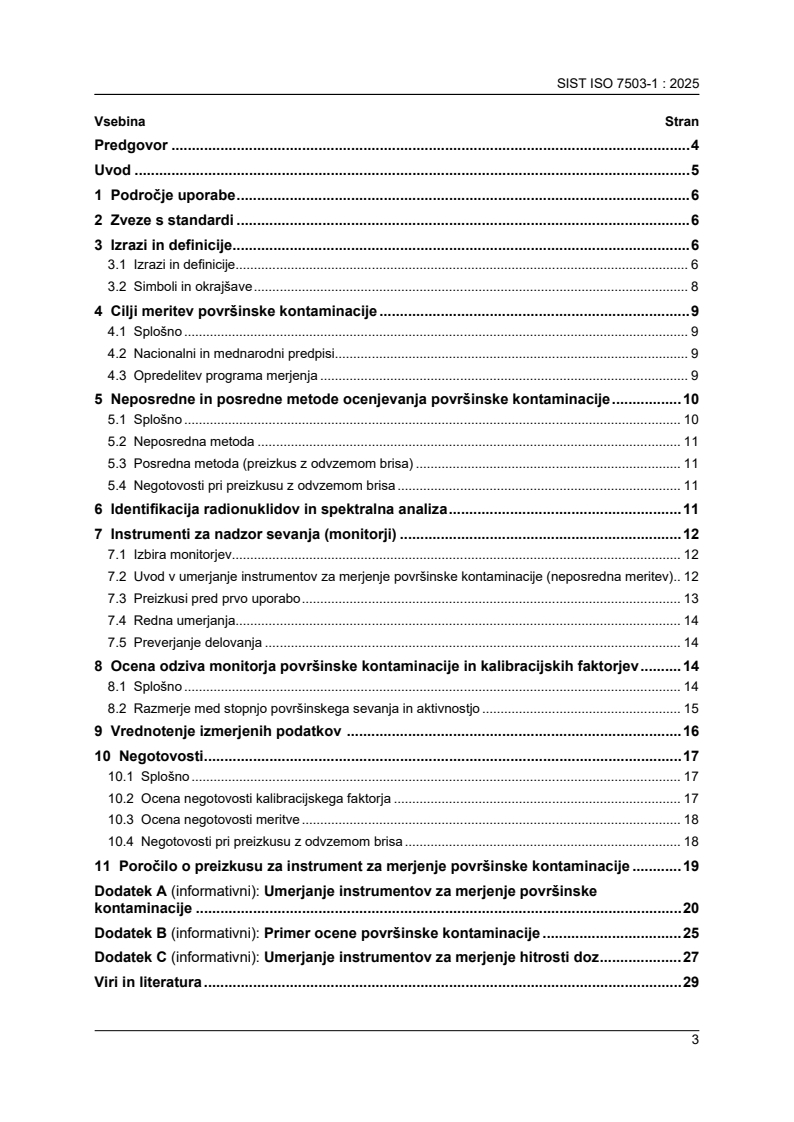

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions, symbols and abbreviations . 2

3.1 Terms and definitions . 2

3.2 Symbols and abbreviated terms. 3

4 Objectives of surface contamination measurements . 4

4.1 General . 4

4.2 National and international regulations. 4

4.3 Definition of the measuring programme . 4

5 Direct and indirect methods of assessing surface contamination . 5

5.1 General . 5

5.2 Direct method . 6

5.3 Indirect method (wipe tests) . 6

5.4 Wipe test uncertainties . 6

6 Radionuclide identification and spectral analysis . 6

7 Monitoring instruments . 7

7.1 Selection of monitors . 7

7.2 Introduction to the calibration of surface contamination instruments for

direct measurement . 7

7.3 Tests before first use (TBFU) . 8

7.4 Periodic calibration . 9

7.5 Function check . 9

8 Estimation of surface contamination monitor response and calibration factors.9

8.1 General . 9

8.2 Relationship between surface emission rate and activity .10

9 Evaluation of measurement data.12

10 Uncertainties .12

10.1 General .12

10.2 Assessment of uncertainty in the calibration factor .12

10.3 Assessment of uncertainty in the measurement .13

10.4 Wipe test uncertainties .14

11 Test report for a surface contamination instrument .14

Annex A (informative) Calibration of surface contamination instruments .16

Annex B (informative) Example of surface contamination estimation.21

Annex C (informative) Calibration of dose rate measuring instruments .23

Bibliography .25

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO's adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 85, Nuclear energy nuclear technologies and

radiological protection, Subcommittee SC 2, Radiation protection.

This second edition cancels and replaces the first edition (ISO 7503-1:1988), which has been technically

revised.

ISO 7503 consists of the following parts, under the general title Measurement of radioactivity —

Measurement and evaluation of surface contamination:

— Part 1: General principles

— Part 2: Test method using wipe-test samples

— Part 3: Apparatus calibration

This corrected version of ISO 7503-1:2016 incorporates the following corrections:

-2 -1 -1 -2

— In 3.2, for I(A), replace "(Bq·cm )/s " by "s /(Bq·cm )";

— In Clause 9, replace the first paragraph which has been rephrased.

iv © ISO 2016 – All rights reserved

Introduction

ISO 7503 gives guidance on the measurement of surface contamination. This International Standard is

applicable to many situations where radioactive contamination can occur. Contamination arises from

the release of radioactivity into the local environment. In most circumstances, the release is inadvertent

but, on occasion, may be deliberate. Although the purpose and scope of the investigation may differ, the

approaches taken to measure the levels and extent of the contamination are essentially similar.

Radioactive contamination can arise from a number of activities or events such as the following:

— routine laboratory use of radio-chemicals;

— medical treatments;

— industrial applications;

— transport accidents;

— equipment malfunctions;

— malevolent incidents;

— nuclear accidents.

Without process knowledge or documentation, it is not always possible to identify or distinguish the

different radionuclides constituting a surface contamination, and the evaluation of such a contamination

cannot be made on a quantitative basis. Instead of using instruments with nuclide specific calibrations,

it may be necessary to use other instruments which are fit for such a purpose.

However, there may be cases (e.g. a contaminated fuel material transport container) where the

radionuclide or the radionuclide mixture can be clearly characterized. A surface contamination

evaluation exceeding a pure qualitative assessment of fixed and removable surface contamination

may then be needed. Moreover, following requirements laid down in national regulations and in

international conventions, a measured surface contamination activity per unit area has to be compared

with surface contamination guideline values or surface contamination limits.

Surface contamination guideline values are radionuclide-specific and thus require complex

radionuclide-specific calibrations of measurement equipment. Calibration quality assurance is crucial

in order to avoid non-detection (i.e. type II decision errors) leading to incorrectly assuming compliance

with given surface contamination guideline values or limits. Evaluation of surfaces contaminated by a

mixture of radionuclides with known ratios requires respectively proportionated calibration factors.

ISO 7503 is concerned with the measurement and estimation of radioactivity levels. It does not provide

advice on decommissioning, planning and surveillance techniques.

Surface contamination is specified in terms of activity per unit area and the limits are based on the

recommendations by the International Commission on Radiological Protection (ICRP 103).

This part of ISO 7503 deals with the evaluation of surface contamination by direct measurement using

a surface contamination instrument, and in the case of the indirect method, using wipe tests. This

part of ISO 7503 is primarily concerned with direct monitoring, practical guidance on measurements,

it describes principles to keep an instrument in a fitness-for-purpose state. This part of ISO 7503

also presents instrument calibration principles and compiles the basic uncertainties of both surface

contamination evaluation methods.

INTERNATIONAL STANDARD ISO 7503-1:2016(E)

Measurement of radioactivity — Measurement and

evaluation of surface contamination —

Part 1:

General principles

1 Scope

ISO 7503 (all parts) and ISO 8769 are addressed to the people responsible for determining the

radioactivity present on solid surfaces. ISO 7503 is published in three parts and can be used jointly or

separately according to needs.

This part of ISO 7503 relates to the assessment of surface contamination by direct and indirect

measurements and the calibration of the associated instrumentation.

The standard applies to alpha-, beta- and photon emitters and is intended for use by hospitals,

universities, police, or industrial establishments. The standard also can be used in the assessment of

activity on trucks, containers, parcels, equipment and is applicable in any organization which handles

radioactive materials. Generally, it is applicable to well defined flat surfaces where direct methods are

applicable, however, it can also be used for surfaces which are not flat and where indirect wipe tests

would be appropriate. These investigations may be carried out on containers, inaccessible areas, non-

flat areas where wipe tests can be used. This part of ISO 7503 may be useful in emergency situations,

i.e. in nuclear accidents where health physics professionals would be involved.

This part of ISO 7503 does not apply to the evaluation of contamination of the skin, of clothing and of

loose material such as gravel.

NOTE The test method using wipe-test samples for the evaluation of radioactive surface contaminations is

dealt with in ISO 7503-2. The calibration of instruments for the evaluation of radioactive surface contaminations

is dealt with in ISO 7503-3.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 8769, Reference sources — Calibration of surface contamination monitors — Alpha-, beta- and photon

emitters

ISO 11929, Determination of the characteristic limits (decision threshold, detection limit, and limits of the

confidence interval) for measurements of ionizing radiation — Fundamentals and application

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

3 Terms and definitions, symbols and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

activity per unit area

ratio between the activity of the radionuclides present on a surface and the area of that surface,

expressed in becquerels per square centimetre

3.1.2

surface contamination

radioactive substances deposited on defined surfaces

3.1.3

fixed surface contamination

surface contamination which cannot be removed or transferred by non-destructive means

3.1.4

removable surface contamination

radioactive material that can be removed from surfaces by non-destructive means, including casual

contact, wiping, or washing

Note 1 to entry: It should be noted that under the influence of moisture, chemicals, etc., or as a result of corrosion

or diffusion, fixed contamination may become removable or vice versa without any human action. Furthermore,

surface contaminations may decrease due to evaporation and volatilization.

Note 2 to entry: It should be emphasized that the ratio between fixed and removable contamination can vary

over time, and that some decisions, such as those related to clearance, should be based on total activity with the

potential to become removable over time, not just the amount that is removable at the time of a survey.

3.1.5

direct measurement of surface contamination

measurement of surface contamination by means of a contamination meter or monitor

3.1.6

indirect evaluation of surface contamination

evaluation of the removable surface contamination by means of a wipe test

3.1.7

wipe test

test to determine if removable contamination is present through wiping the surface with a dry or wet

material, followed by evaluation of the wipe material for removable contamination

3.1.8

wiping efficiency

ratio of the activity of the radionuclides removed from the surface by one wipe sample to the activity of

the radionuclides of the removable surface contamination prior to this sampling

Note 1 to entry: In practice, it is almost impossible to measure the total amount of removable activity on the

surface, and in most cases, a value for the wiping efficiency cannot be assessed but can only be estimated.

3.1.9

surface emission rate of a source

number of particles of a given type above a given energy or of photons emerging from the front face of

the source per unit time

2 © ISO 2016 – All rights reserved

3.1.10

instrument efficiency

ratio between the instrument net reading and the surface emission rate of a source under given

geometrical conditions

3.1.11

emission instrument response

instrument efficiency times detector window area, equals the observed net count rate per surface

emission rate per unit area of a calibration source

3.1.12

activity instrument response

instrument efficiency times detector window area times the probability of a particle or photon leaving

the source surface, equals the observed net count rate per Bq per unit area of a calibration source

3.1.13

emission calibration factor

reciprocal of instrument efficiency times window area

3.1.14

activity calibration factor

reciprocal of instrument efficiency times window area times probability of a particle leaving the

source surface

3.1.15

calibration

operation that, under specified conditions, in a first step, establishes a relation between the quantity

values with measurement uncertainties provided by measurement standards and corresponding

indications with associated measurement uncertainties and, in a second step, uses this information to

establish a relation for obtaining a measurement result from an indication

3.1.16

guideline value

value which corresponds to scientific, legal or other requirements for which the measuring procedure

is intended to assess

3.2 Symbols and abbreviated terms

For the purposes of this part of ISO 7503, the following symbols apply:

−1 −1 −2

I(E) emission instrument response in s /(s ·cm )

−1

ρ observed count rate from the calibration source in s

c

−1

ρ background count rate in s

−1

R emission rate of the calibration source in s

c

S area of the calibration source in cm

c

−1 −2

I(A) activity instrument response in s /(Bq·cm )

A activity of the calibration source in Bq

c

P inverse of probability of a particle emerging from the surface, equal ratio of the particle or photon

−1 −1

generation rate (activity) and the emission rate from the surface in Bq /s

S effective detector or probe area in cm

p

−1 −2 −1

C(E) emission calibration factor in (s ·cm )/s

−2 −1

C(A) activity calibration factor in (Bq·cm )/s

−1 −1

ε instrument efficiency in s /s

−2

A activity per unit area of fixed and removable contamination in Bq·cm

s

−1

ρ measured total (gross) count rate in s

g

4 Objectives of surface contamination measurements

4.1 General

Initial investigations into possible surface contamination need to assume a worst case scenario. The

area, environment or premises need to be approached assuming that there may be significant dose-

rates. If the initial investigation establishes that the dose rates do not present a radiological hazard

where shielding may be necessary, the issue of contamination needs to be addressed.

If the investigation is routine, then the initial investigation into possible high dose rates does not need

to be undertaken. The investigation only needs to proceed into possible surface contamination.

Having established the presence of surface contamination, the question of contamination

instrumentation needs to be considered. Factors such as the instrument response to the likely

radionuclide contamination and other aspects shall be assessed. The area to be monitored may

determine the size of the most suitable detectors.

The bibliography contains publications which provide guidance on suitable instrumentation.

4.2 National and international regulations

It is necessary to comply with current national and international regulations or existing standards and

guidance in addition to the customer requirements. National and international regulations provide

guidance on averaging areas. In particular, it is essential to establish the areas over which measurements

may be averaged for the purposes of demarcating areas on the basis of contamination levels.

4.3 Definition of the measuring programme

The objectives of a surface contamination measurement programme are

— the detection of ionizing particles or photons emitted from a surface contaminated with radioactive

material, and

— the evaluation of the instrument readings which can be used to provide an estimate of the quantities

and characteristics radioactive contaminants.

In order to achieve these objectives with a reasonable degree of confidence, it is necessary to plan the

monitoring procedure. In many organizations, there are standard procedures that state how routine

radiation protection monitoring should be done. The monitoring takes place in familiar areas, carried

out by an organization‘s own staff, using its own monitoring equipment and reporting system.

In some circumstances, there may be no standard procedures in place to develop a suitable

measurement programme. In these circumstances, information needs to be gathered, which might

include the collection and documentation of the following details:

a) identification of the operator;

b) defining the areas or items to be monitored;

c) history of the areas to be monitored to include

1) radionuclides used in the area and at what times and in what quantities,

4 © ISO 2016 – All rights reserved

2) refurbishment, repair and maintenance histories, and

3) previous survey results and possibly trend analysis;

d) the level of detail and levels of accuracy required by the operator;

e) the sampling strategy;

f) the need to distinguish between fixed and removable contamination;

g) the need for any direct or indirect measurements;

h) types and quantities of equipment required for specific measurements and available including

status of calibration;

i) details of current dose rate levels around and within the areas to be surveyed;

j) limitations on access;

k) need for personal protective equipment (overalls, breathing apparatus, rubber gloves);

l) facilities for disposal of radioactive waste;

m) liaison with other organizations (e.g. police, national regulatory agencies);

n) environmental conditions (e.g. temperature, humidity);

o) types of surfaces to be monitored (e.g. rough concrete, painted contaminated surfaces).

Having gathered the relevant information listed above, an appropriate measurement programme

should be developed and documented. The measurement programme should include the calculations

and assumptions used in establishing the action levels. It is recommended that the measurement

programme expresses where possible, the action levels in the same units that are displayed on the

specified instruments. The measurement programme should include the steps to be taken whenever

those levels are exceeded and the designation of those personnel who can authorize the resumption of

the measurement programme if action levels have been exceeded.

5 Direct and indirect methods of assessing surface contamination

5.1 General

Contamination on a surface can be assessed either directly or indirectly.

The initial investigation into the contamination of premises should assume the worst case. The premises

should be approached assuming that there may be a significant dose rate. This may be applicable to

only one laboratory or maybe the whole building. If the initial investigation establishes that the dose

rate does not present a shielding problem or radiological hazard, then the issue of contamination can

then be addressed.

The applicability and the reliability of direct measurement or indirect evaluation of surface

contamination are strongly dependent on the particular circumstances, i.e. the physical and chemical

form of the contamination, the adherence of contamination on the surface (fixed or removable), the

accessibility of the surface for measurement or the presence of interfering radiation fields.

Direct measurement is used when the surface is readily accessible without

— interfering inactive liquid or solid deposits that cannot be taken into account, or

— interfering radiation fields that cannot be taken into account.

Indirect evaluation of surface contamination is generally more applicable when the surfaces are not

readily accessible because of difficult location or configuration, or where interfering radiation fields

adversely affect contamination monitors, or when methods of direct measurement with standard

instrumentation are not available. An indirect method cannot assess fixed contamination, and because

of the great uncertainty usually related to the wiping efficiency, application of the indirect method

usually results in conservative estimations of removable contamination.

Due to the inherent shortcomings of both the direct measurement and the indirect evaluation of surface

contamination, in many cases, the use of both methods in tandem can help ensure results which best

meet the aims of the evaluation.

5.2 Direct method

The direct method is the best approach whenever possible. In the direct method, the monitor probe

is moved over a surface, with the face of the probe at a minimal distance of approximately 3 mm from

the surface. The probe shall be kept stationary for a minimum to obtain sufficient accuracy. This

measurement can then be used to determine the radiation emitted from the surface.

There are many circumstances where the above measurement might not be possible. A surface may be

so convoluted that it is not possible to monitor it directly, or the background radiation may be so high

that it is impossible to obtain meaningful results from the measurements; however, these results should

be recorded because a calibration could be provided later. In these instances, an indirect measurement

has to be made using a wipe test.

5.3 Indirect method (wipe tests)

A test procedure is often carried out using a filter paper or other wipe, typically 20 mm to 60 mm in

diameter, which can be placed in commercial holder for measurement. The filter paper should be wiped

over the area, usually at least 100 cm , or whatever area is locally defined for the surface that may be

contaminated with radionuclides. The filter paper can either be placed in a lab counter drawer to assess

the level and type of activity, or sent to a radiochemistry laboratory for a full assessment of nuclide type

and activity. In both instances, all measurements should be traceable to national standards or governed

by local requirements.

Wipe tests can be either “dry wipe” or “wet wipe”. In general, it is a senior health physics professional

who makes the decision on which to use.

The indirect surface evaluation contamination method is described in detail in ISO 7503-2.

5.4 Wipe test uncertainties

A brief discussion on uncertainties is given in 10.3.

6 Radionuclide identification and spectral analysis

Normally, the radionuclides are known. If not, they need to be identified. Radionuclide identification

of contaminants using hand-held instruments is only practicable where the contaminants are gamma

emitting nuclides with energies in the range of 50 keV to 1500 keV. If the contaminant does not emit

photons in this range, it may not be possible to identify the radionuclide with hand-held instruments.

In cases such as an accident or where only one radionuclide is in use, it may not be necessary for it to

be determined as the contamination is known. Otherwise, more sophisticated techniques such as beta

and alpha spectroscopy are required and these techniques are usually only available in a well-equipped

laboratory where samples from the contaminated site can be prepared and analysed.

Small hand-held instruments exist that permit spectroscopic analysis of gamma radiation. In general,

the instruments use a small, approximately 40 mm × 40 mm, NaI crystal as the principle detector. The

sensitivity of a NaI crystal to gamma radiation makes these instruments particularly useful as “search

and locate” devices particularly for finding and identifying lost or hidden gamma sources. However, it

is not possible to make an accurate assessment of contamination levels using this type of instrument.

A small NaI crystal connected to a multichannel analyser (MCA) permits spectral analysis of the

6 © ISO 2016 – All rights reserved

ambient radiation. The MCA may also contain an electronic library of many common nuclides and their

associated photo-peaks.

The instrument shall be properly calibrated before use in a calibration facility that can provide

traceability to national standards. The calibration should confirm not only the dose rate accuracy but

also that the Multi Channel Analyser (MCA) has been correctly set up. If the MCA is not properly set

up, the instrument is not able to perform automatic nuclide identification. The user should understand

that automatic nuclide identification is limited to those nuclides in the instrument library. If peaks

occur in the gamma spectrum, that are not automatically identified, the photon peak energy should be

assessed from the spectrum and the literature consulted to try and identify the parent radionuclide.

Alternatively, the user should consult with an experienced health physics professional or radio chemist.

In a situation where there are a number of gamma emitting nuclides present, the instrument may be

unable to resolve the individual photo peaks because the resolution of small NaI crystals is poor when

compared with germanium crystals. In this situation, germanium detectors can be used instead.

The time taken to collect a spectrum is mainly dependent on the ambient background radiation and the

level of contamination. If the background is high or variable, it may be difficult or impossible to collect

an adequate spectrum. If the background is particularly high, it may cause a spectrum shift which

prevents automatic nuclide identification. Well shielded apparatus is also recommended.

7 Monitoring instruments

7.1 Selection of monitors

NOTE Dose rate monitors are included in this clause as, prior to any survey to assess surface contamination,

it is good practice to measure the ambient dose rates.

The selection of appropriate monitors depends on the following:

— the type(s) of radiation that are expected to be encountered (alpha, beta, photon);

— the levels of contamination that may be expected;

— the detection limits required;

— the accuracy required from the measurements.

The selection should be undertaken under the advice of a suitably qualified expert.

7.2 Introduction to the calibration of surface contamination instruments for direct

measurement

For regulatory purposes, the maximum permissible levels for surface contamination are expressed in

−2

terms of activity per unit area (Bq·cm ).

In most situations, it is possible to identify the individual radionuclide which is the major constituent

99m

of the surface contamination. For example, in a hospital which only uses Tc for routine diagnostic

purposes and no other radionuclides are brought onto the site, the nature of the contamination is

obvious. The surfaces which might have become contaminated may also be well-defined in terms of

material and surface finish. In this scenario, it would be appropriate to calibrate the contamination

monitor(s) directly with the radionuclide concerned by depositing traceable activities to samples of the

surfaces that might be affected by contamination. Exposing the monitor to these surfaces, at defined

distances, provides a series of calibration factors which, during normal monitoring procedures, can be

selected according to the relevant monitoring characteristics such as the nature of the surface, source

to detector separation, and contamination area. These calibration factors can be expressed in units of

response per unit area (activity per unit area).

In many other situations, this simple scenario does not occur. The worst case situation is that multiple

unidentified radionuclides are involved in varying activity concentrations and on a variety of different

surfaces. These could include distributions of activity below the surface up to and beyond the maximum

path length of any particulate ionizing radiations. In such a case, the immediate concern is to determine

the extent of the spread, and the variation in levels of the contamination. Random sampling combined

with spectrometry can provide some estimate of the radionuclide mix and relative activities. Combined

with knowledge of the response characteristics of the surface contamination monitor, an estimate can

then be made of the surface contamination.

The calibration of individual monitors for every potential scenario is impracticable. The practical

alternative is to demonstrate that the monitor is fit for purpose so that users can rely on type test

data and other published response data which provide sufficient information to determine the energy-

response characteristics for alpha-, beta- and photon emissions. The approach to calibration of

individual monitors is to confirm that they comply with type test data. This can be a very simple, rapid,

robust and inexpensive exercise. It can be performed with a minimum of high quality reference sources,

which do not need to be representative of the surfaces to be monitored in practice. The confirmation

of compliance with type test data then allows response factors to be interpolated for all radionuclides

based on the known decay data; this interpolation can either be carried out in-house or by third parties.

Calibration is described in detail in ISO 7503-3.

All monitors should be calibrated to standards that meet the legal requirements of the relevant country.

All monitors should be recalibrated periodically, in line with national regulations, usually every 12

months, but in many countries, longer than 12 months.

Calibration should be done in calibration laboratories that provide traceability to national standards

and meet the quality assurance requirements of ISO/IEC 17025.

The calibration status of the monitor shall not be expired.

New instruments should be thoroughly checked to ensure they meet the manufacturer’s specifications.

Occasionally, the manufacturer provides this service, but it may also be necessary for the user to have

the instrument checked and calibrated by an independent qualified laboratory. This is sometimes

known as Test Before First Use (TBFU).

The nature of the calibration programmes for surface contamination and dose monitors are determined

by the nature of the contamination scenarios that are expected to be encountered.

7.3 Tests before first use (TBFU)

The TBFU should, as appropriate, provide information on the following characteristics of the

instrument:

Surface contamination monitors

a) response to the type(s) and energy(s) of ionizing radiation appropriate to the intended use

b) linearity of response with emission rate over the likely range of use

c) relative sensitivity to different types of ionizing radiation

d) sensitivity to light

e) uniformity of response across the entrance window of the detector probe

f) the effects of any special environmental conditions deemed relevant

g) over range indication

h) background specification

i) detection limits

j) alarm threshold

8 © ISO 2016 – All rights reserved

Dose rate meters

k) response to the type(s) and energy(s) of ionizing radiation appropriate to the intended use

l) response to high dose rates

m) linearity of response with dose rate over the likely range of use

n) energy dependence

o) directional dependence

p) response to possible interfering ionizing radiations

q) the effects of any special environmental conditions deemed relevant

r) demonstration of correct operation when used in unusual circumstances, for example instruments

used in unusual orientations, such as upside down

It is essential that the instrument is set up in accordance with the manufacturer's specifications

and has a current calibration certificate.

7.4 Periodic calibration

Instruments should undergo a periodic calibration. The calibration interval is dependent on relevant

national legislation, however, annually is generally accepted as a suitable period. If there is no

legislative guidance, the recommended period is annually, and also, following any repair or adjustment

which is likely to affect the detection characteristics. The periodic calibration should include checks a)

to d) above and a thorough check on the condition of the instrument, for example, the battery state

and any physical damage. Specific guidance on the calibration of monitors is given in Annex A (surface

contamination monitors) and Annex C (dose meters).

7.5 Function check

It may also be necessary, depending on the way the instrument is used and the conditions of use, to

do frequent function checks. Function checks are not calibrations but they give a reasonable degree of

confidence that the instrument is still operating correctly and the calibration is still valid. A function

check can be as simple as ensuring the instrument is giving the correct response to background or

exposing it to a small radioactive source to confirm the reading is normal. Before the test of first use,

it is important that the background, alarm threshold, alarm indication and rate meter constant is also

checked.

8 Estimation of surface contamination monitor response and calibration factors

8.1 General

When response or calibration factors are not available for the particular combination of radionuclide(s)

and surfaces that are being monitored, it is necessary to estimate the appropriate response and

calibration factors. The fit for purpose calibration procedure described in Annex A provides

characterization data which may be used to make these estimations. The standard method is to

measure the calibration factor with traceable sources.

Monitors respond to the emissions which enter their detection volumes, they do not respond directly to

activity. The same activity on two different surfaces, which have two different emissions, can produce

two different responses from the monitors. The measured quantity is the response of the instrument to

the emissions incident on the detector entrance window. In practice, surfaces emit ionizing radiations

into 2π. The basic response factor is the response of the instrument either to (a) the emissions per unit

area from the surface for a spread source, or (b) the emissions from a point source. In practice, the

former is more useful.

The response factors may be expressed in any one of two forms which are linked to each other. The

factors are:

ρρ−

c0

IE , Instrument response Emission = (1)

() ()

R/ S

()

cc

−1 −1 −2

Units: s /(s cm )

where

−1

ρ is the observed count rate from the calibration source, in s ;

c

−1

ρ is the background count rate, in s ;

−1

R is the emission rate of the calibration source, in s ;

c

S is the area of the calibration source, in cm .

c

ρρ− ρρ−

c0 c0

IA , Instrument response Activity == (2)

() ()

R/ SP× A /S

() ()

cc ccc

−1 −2

Units: s /(Bq·cm )

where

A is the activity of the calibration source, in Bq;

c

P is the ratio of the particle or photon generation rate (activity) and the emission rate from

the surface (see ISO 7503-3).

8.2 Relationship between surface emission rate and activity

If the instrument indicates “becquerels per square centimetre”, a calibration factor has been stored

in the instrument. Conversion of counts per second to becquerels per square centimetre can be

complicated. A method to do this can be found in ISO 7503-3. This task requires a comprehensive

knowledge of the decay schemes, instrument performance and an estimation of how the local conditions

(e.g. surface construction) might affect the observed count rate. Measurements should be made using

calibrated reference sources.

A calibration certificate records the instrument’s response to a range of ISO 8769 reference sources at

a specified distance. These are a set of specialist sources produced for the purpose of calib

...

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 7503-1

ISO/TC 85/SC 2

Measurement of radioactivity —

Secretariat: AFNOR

Measurement and evaluation of

Voting begins on:

2015-09-17 surface contamination —

Voting terminates on:

Part 1:

2015-11-17

General principles

Mesurage de la radioactivité — Mesurage et évaluation de la

contamination de surface —

Partie 1: Principes généraux

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/FDIS 7503-1:2015(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

©

NATIONAL REGULATIONS. ISO 2015

ISO/FDIS 7503-1:2015(E)

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

ISO/FDIS 7503-1:2015(E)

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions, symbols and abbreviations . 2

3.1 Terms and definitions . 2

3.2 Symbols and abbreviated terms. 4

4 Objectives of surface contamination measurements . 4

4.1 General . 4

4.2 National and international regulations. 4

4.3 Definition of the measuring programme . 5

5 Direct and indirect methods of assessing surface contamination . 6

5.1 General . 6

5.2 Direct method . 6

5.3 Indirect method (wipe tests) . 6

5.4 Wipe test uncertainties . 7

6 Radionuclide identification and spectral analysis . 7

7 Monitoring instruments . 7

7.1 Selection of monitors . 7

7.2 Introduction to the calibration of surface contamination instruments for

direct measurement . 8

7.3 Tests before first use (TBFU) . 9

7.4 Periodic calibration . 9

7.5 Function check .10

8 Estimation of surface contamination monitor response and calibration factors.10

8.1 General .10

8.2 Relationship between surface emission rate and activity .11

9 Evaluation of measurement data.12

10 Uncertainties .13

10.1 General .13

10.2 Assessment of uncertainty in the calibration factor .13

10.3 Assessment of uncertainty in the measurement .14

10.4 Wipe test uncertainties .14

11 Test report for a surface contamination instrument .15

Annex A (informative) Calibration of surface contamination instruments .16

Annex B (informative) Example of surface contamination estimation.21

Annex C (informative) Calibration of dose rate measuring instruments .23

Bibliography .25

ISO/FDIS 7503-1:2015(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 85, Nuclear energy nuclear technologies and

radiological protection, Subcommittee SC 2, Radiation protection.

This second edition cancels and replaces the first edition (ISO 7503-1:1988), which has been

technically revised.

ISO 7503 consists of the following parts, under the general title Measurement of radioactivity —

Measurement and evaluation of surface contamination:

— Part 1: General principles

— Part 2: Test method using wipe-test samples

— Part 3: Apparatus calibration

iv © ISO 2015 – All rights reserved

ISO/FDIS 7503-1:2015(E)

Introduction

ISO 7503 gives guidance on the measurement of surface contamination. This International Standard is

applicable to many situations where radioactive contamination can occur. Contamination arises from

the release of radioactivity into the local environment. In most circumstances, the release is inadvertent

but, on occasion, may be deliberate. Although the purpose and scope of the investigation may differ, the

approaches taken to measure the levels and extent of the contamination are essentially similar.

Radioactive contamination can arise from a number of activities or events such as the following:

— routine laboratory use of radio-chemicals;

— medical treatments;

— industrial applications;

— transport accidents;

— equipment malfunctions;

— malevolent incidents;

— nuclear accidents.

Without process knowledge or documentation, it is not always possible to identify or distinguish the

different radionuclides constituting a surface contamination, and the evaluation of such a contamination

cannot be made on a quantitative basis. Instead of using instruments with nuclide specific calibrations,

it may be necessary to use other instruments which are fit for such a purpose.

However, there may be cases (e.g. a contaminated fuel material transport container) where the

radionuclide or the radionuclide mixture can be clearly characterized. A surface contamination

evaluation exceeding a pure qualitative assessment of fixed and removable surface contamination

may then be needed. Moreover, following requirements laid down in national regulations and in

international conventions, a measured surface contamination activity per unit area has to be compared

with surface contamination guideline values or surface contamination limits.

Surface contamination guideline values are radionuclide-specific and thus require complex

radionuclide-specific calibrations of measurement equipment. Calibration quality assurance is crucial

in order to avoid non-detection (i.e. type II decision errors) leading to incorrectly assuming compliance

with given surface contamination guideline values or limits. Evaluation of surfaces contaminated by a

mixture of radionuclides with known ratios requires respectively proportionated calibration factors.

ISO 7503 is concerned with the measurement and estimation of radioactivity levels. It does not provide

advice on decommissioning, planning and surveillance techniques.

Surface contamination is specified in terms of activity per unit area and the limits are based on the

recommendations by the International Commission on Radiological Protection (ICRP 103).

This part of ISO 7503 deals with the evaluation of surface contamination by direct measurement using

a surface contamination instrument, and in the case of the indirect method, using wipe tests. This

part of ISO 7503 is primarily concerned with direct monitoring, practical guidance on measurements,

it describes principles to keep an instrument in a fitness-for-purpose state. This part of ISO 7503

also presents instrument calibration principles and compiles the basic uncertainties of both surface

contamination evaluation methods.

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 7503-1:2015(E)

Measurement of radioactivity — Measurement and

evaluation of surface contamination —

Part 1:

General principles

1 Scope

ISO 7503 (all parts) and ISO 8769 are addressed to the people responsible for determining the

radioactivity present on solid surfaces. ISO 7503 is published in three parts and can be used jointly or

separately according to needs.

This part of ISO 7503 relates to the assessment of surface contamination by direct and indirect

measurements and the calibration of the associated instrumentation.

The standard applies to alpha-, beta- and photon emitters and is intended for use by hospitals,

universities, police, or industrial establishments. The standard also can be used in the assessment of

activity on trucks, containers, parcels, equipment and is applicable in any organization which handles

radioactive materials. Generally, it is applicable to well defined flat surfaces where direct methods are

applicable, however, it can also be used for surfaces which are not flat and where indirect wipe tests

would be appropriate. These investigations may be carried out on containers, inaccessible areas, non-

flat areas where wipe tests can be used. This part of ISO 7503 may be useful in emergency situations,

i.e. in nuclear accidents where health physics professionals would be involved.

This part of ISO 7503 does not apply to the evaluation of contamination of the skin, of clothing and of

loose material such as gravel.

NOTE The test method using wipe-test samples for the evaluation of radioactive surface contaminations is

dealt with in ISO 7503-2. The calibration of instruments for the evaluation of radioactive surface contaminations

is dealt with in ISO 7503-3.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 8769, Reference sources — Calibration of surface contamination monitors — Alpha-, beta- and

photon emitters

ISO 11929, Determination of the characteristic limits (decision threshold, detection limit, and limits of the

confidence interval) for measurements of ionizing radiation — Fundamentals and application

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

ISO/FDIS 7503-1:2015(E)

3 Terms and definitions, symbols and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

activity per unit area

ratio between the activity of the radionuclides present on a surface and the area of that surface,

expressed in becquerels per square centimetre

3.1.2

surface contamination

radioactive substances deposited on defined surfaces

3.1.3

fixed surface contamination

surface contamination which cannot be removed or transferred by non-destructive means

3.1.4

removable surface contamination

radioactive material that can be removed from surfaces by non-destructive means, including casual

contact, wiping, or washing

Note 1 to entry: It should be noted that under the influence of moisture, chemicals, etc., or as a result of corrosion

or diffusion, fixed contamination may become removable or vice versa without any human action. Furthermore,

surface contaminations may decrease due to evaporation and volatilization.

Note 2 to entry: It should be emphasized that the ratio between fixed and removable contamination can vary

over time, and that some decisions, such as those related to clearance, should be based on total activity with the

potential to become removable over time, not just the amount that is removable at the time of a survey.

3.1.5

direct measurement of surface contamination

measurement of surface contamination by means of a contamination meter or monitor

3.1.6

indirect evaluation of surface contamination

evaluation of the removable surface contamination by means of a wipe test

3.1.7

wipe test

test to determine if removable contamination is present through wiping the surface with a dry or wet

material, followed by evaluation of the wipe material for removable contamination

3.1.8

wiping efficiency

ratio of the activity of the radionuclides removed from the surface by one wipe sample to the activity of

the radionuclides of the removable surface contamination prior to this sampling

Note 1 to entry: In practice, it is almost impossible to measure the total amount of removable activity on the

surface, and in most cases, a value for the wiping efficiency cannot be assessed but can only be estimated.

3.1.9

surface emission rate of a source

number of particles of a given type above a given energy or of photons emerging from the front face of

the source per unit time

2 © ISO 2015 – All rights reserved

ISO/FDIS 7503-1:2015(E)

3.1.10

instrument efficiency

ratio between the instrument net reading and the surface emission rate of a source under given

geometrical conditions

3.1.11

emission instrument response

instrument efficiency times detector window area, equals the observed net count rate per surface

emission rate per unit area of a calibration source

3.1.12

activity instrument response

instrument efficiency times detector window area times the probability of a particle or photon leaving

the source surface, equals the observed net count rate per Bq per unit area of a calibration source

3.1.13

emission calibration factor

reciprocal of instrument efficiency times window area

3.1.14

activity calibration factor

reciprocal of instrument efficiency times window area times probability of a particle leaving the

source surface

3.1.15

calibration

operation that, under specified conditions, in a first step, establishes a relation between the quantity

values with measurement uncertainties provided by measurement standards and corresponding

indications with associated measurement uncertainties and, in a second step, uses this information to

establish a relation for obtaining a measurement result from an indication

3.1.16

guideline value

value which corresponds to scientific, legal or other requirements for which the measuring procedure

is intended to assess

ISO/FDIS 7503-1:2015(E)

3.2 Symbols and abbreviated terms

For the purposes of this part of ISO 7503, the following symbols apply:

−1 −1 −2

I(E) emission instrument response in s /(s cm )

−1

ρ observed count rate from the calibration source in s

c

−1

ρ background count rate in s

−1

R emission rate of the calibration source in s

c

S area of the calibration source in cm

c

−1 −1 −2 −1 −2

I(A) activity instrument response in s /(s cm ) or s /(Bq cm )

A activity of the calibration source in Bq

c

P inverse of probability of a particle emerging from the surface, equal ratio of the particle or photon

generation rate (activity) and the emission rate from the surface

S effective detector or probe area in cm

p

−1 −2 −1

C(E) emission calibration factor in (s cm )/s

−1 −2 −1 −1 −2

C(A) activity calibration factor in (s cm )/s or s /(Bq cm )

ε instrument efficiency

−2

A activity per unit area of fixed and removable contamination in Bq cm

s

−1

ρ measured total (gross) count rate in s

g

4 Objectives of surface contamination measurements

4.1 General

Initial investigations into possible surface contamination need to assume a worst case scenario. The

area environment or premises need to be approached assuming that there may be significant dose-

rates. If the initial investigation establishes that the dose rates do not present a radiological hazard

where shielding may be necessary, the issue of contamination needs to be addressed.

If the investigation is routine, then the initial investigation into possible high dose rates does not need

to be undertaken. The investigation only needs to proceed into possible surface contamination.

Having established the presence of surface contamination, the question of contamination

instrumentation needs to be considered. Factors such as the instrument response to the likely

radionuclide contamination and other aspects shall be assessed. The area to be monitored may

determine the size of the most suitable detectors.

The bibliography contains publications which provide guidance on suitable instrumentation.

4.2 National and international regulations

It is necessary to comply with current national and international regulations or existing standards and

guidance in addition to the customer requirements. National and international regulations provide

guidance on averaging areas. In particular, it is essential to establish the areas over which measurements

may be averaged for the purposes of demarcating areas on the basis of contamination levels.

4 © ISO 2015 – All rights reserved

ISO/FDIS 7503-1:2015(E)

4.3 Definition of the measuring programme

The objectives of a surface contamination monitoring programme are

— the detection of ionizing particles or photons emitted from a surface contaminated with radioactive

material, and

— the evaluation of the instrument readings which can be used to provide an estimate of the quantities

and characteristics radioactive contaminants.

In order to achieve these objectives with a reasonable degree of confidence, it is necessary to plan the

monitoring procedure. In many organizations, there are standard procedures that state how routine

radiation protection monitoring should be done. The monitoring takes place in familiar areas, carried

out by an organization‘s own staff, using its own monitoring equipment and reporting system.

In some circumstances, there may be no standard procedures in place to develop a suitable monitoring

programme. In these circumstances, information needs to be gathered, which might include the

collection and documentation of the following details:

a) identification of the operator;

b) defining the areas or items to be monitored;

c) history of the areas to be monitored to include

1) radionuclide’s used in the area and at what times and in what quantities,

2) refurbishment, repair and maintenance histories, and

3) previous survey results and possibly trend analysis;

d) the level of detail and levels of accuracy required by the operator;

e) the sampling strategy;

f) the need to distinguish between fixed and removable contamination;

g) the need for any direct or indirect measurements;

h) types and quantities of monitoring equipment required for specific measurements and available

including status of calibration;

i) details of current dose rate levels around and within the areas to be surveyed;

j) limitations on access;

k) need for personal protective equipment (overalls, breathing apparatus, rubber gloves);

l) facilities for disposal of radioactive waste;

m) liaison with other organizations (e.g. police, national regulatory agencies);

n) environmental conditions (e.g. temperature, humidity);

o) types of surfaces to be monitored (e.g. rough concrete, painted contaminated surfaces).

Having gathered the relevant information listed above, an appropriate measurement programme

should be developed and documented. The measurement programme should include the calculations

and assumptions used in establishing the action levels. It is recommended that the monitoring

programme expresses where possible, the action levels in the same units that are displayed on the

specified instruments. The measurement program should include the steps to be taken whenever those

levels are exceeded and the designation of those personnel who can authorize the resumption of the

monitoring programme if action levels have been exceeded.

ISO/FDIS 7503-1:2015(E)

5 Direct and indirect methods of assessing surface contamination

5.1 General

Contamination on a surface can be assessed either directly or indirectly.

The initial investigation into the contamination of premises should assume the worst case. The premises

should be approached assuming that there may be a significant dose rate. This may be applicable to

only one laboratory or maybe the whole building. If the initial investigation establishes that the dose

rate does not present a shielding problem or radiological hazard, then the issue of contamination can

then be addressed.

The applicability and the reliability of direct measurement or indirect evaluation of surface

contamination are strongly dependent on the particular circumstances, i.e. the physical and chemical

form of the contamination, the adherence of contamination on the surface (fixed or removable), the

accessibility of the surface for measurement or the presence of interfering radiation fields.

Direct measurement is used when the surface is readily accessible without

— interfering inactive liquid or solid deposits that cannot be taken into account, or

— interfering radiation fields that cannot be taken into account.

Indirect evaluation of surface contamination is generally more applicable when the surfaces are not

readily accessible because of difficult location or configuration, or where interfering radiation fields

adversely affect contamination monitors, or when methods of direct measurement with standard

instrumentation are not available. An indirect method cannot assess fixed contamination, and because

of the great uncertainty usually related to the wiping efficiency, application of the indirect method

usually results in conservative estimations of removable contamination.

Due to the inherent shortcomings of both the direct measurement and the indirect evaluation of surface

contamination, in many cases, the use of both methods in tandem can help ensures results which best

meet the aims of the evaluation.

Having established that the investigation does not present a significant radiological hazard, the choice

of contamination measurement instrumentation needs to be addressed.

5.2 Direct method

The direct method is the best approach whenever possible. In the direct method, the monitor probe

is moved over a surface, with the face of the probe at a minimal distance of approximately 3 mm from

the surface. The probe shall be kept stationary for a minimum to obtain sufficient accuracy. This

measurement can then be used to determine the radiation emitted from the surface.

There are many circumstances where the above measurement might not be possible. A surface may be

so convoluted that it is not possible to monitor it directly, or the background radiation may be so high

that it is impossible to obtain meaningful results from the measurements; however, these results should

be recorded because a calibration could be provided later. In these instances, an indirect measurement

has to be made using a wipe test.

5.3 Indirect method (wipe tests)

A test procedure is often carried out using a filter paper or other wipe, typically 20 mm to 60 mm in

diameter, which can be placed in commercial holder for measurement. The filter paper should be wiped

over the area, usually at least 100 cm , or whatever area is locally defined for the surface that may be

contaminated with radionuclides. The filter paper can either be placed in a lab counter drawer to assess

the level and type of activity, or sent to a radiochemistry laboratory for a full assessment of nuclide type

and activity. In both instances, all measurements should be traceable to national standards or governed

by local requirements.

6 © ISO 2015 – All rights reserved

ISO/FDIS 7503-1:2015(E)

Wipe tests can be either “dry wipe” or “wet wipe”. In general, it is a senior health physics professional

who makes the decision on which to use.

The indirect surface evaluation contamination method is described in detail in ISO 7503-2.

5.4 Wipe test uncertainties

A brief discussion on uncertainties is given in 10.3.

6 Radionuclide identification and spectral analysis

Normally, the radionuclides are known, if not, they need to be identified. Radionuclide identification

of contaminants using hand-held instruments is only practicable where the contaminants are gamma

emitting nuclides with energies in the range of 50 keV to 1500 keV. If the contaminant does not emit

photons in this range, it may not be possible to identify the radionuclide with hand-held instruments.

In cases such as an accident or where only one radionuclide is in use, it may not be necessary for it to

be determined as the contamination is known. Otherwise, more sophisticated techniques such as beta

and alpha spectroscopy are required and these techniques are usually only available in a well-equipped

laboratory where samples from the contaminated site can be prepared and analysed.

Small hand-held instruments exist that permit spectroscopic analysis of gamma radiation. In general,

the instruments use a small, approximately 40 mm × 40 mm, NaI crystal as the principle detector. The

sensitivity of a NaI crystal to gamma radiation makes these instruments particularly useful as “search

and locate” devices particularly for finding and identifying lost or hidden gamma sources. However, it

is not possible to make an accurate assessment of contamination levels using this type of instrument.

A small NaI crystal connected to a multichannel analyser (MCA) permits spectral analysis of the

ambient radiation. The MCA may also contain an electronic library of many common nuclides and their

associated photo-peaks.

The instrument shall be properly calibrated before use in a calibration facility that can provide

traceability to national standards. The calibration should confirm not only the dose rate accuracy but

also that the Multi Channel Analyser (MCA) has been correctly set up. If the MCA is not properly set

up, the instrument is not able to perform automatic nuclide identification. The user should understand

that automatic nuclide identification is limited to those nuclides in the instrument library. If peaks

occur in the gamma spectrum, that is not automatically identified, the photon peak energy should be

assessed from the spectrum and the literature consulted to try and identify the parent radionuclide.

Alternatively, the user should consult with an experienced health physics professional or radio chemist.

In a situation where there are a number of gamma emitting nuclides present, the instrument may be

unable to resolve the individual photo peaks because the resolution of small NaI crystals is poor when

compared with germanium crystals. In this situation, germanium detectors can be used instead.

The time taken to collect a spectrum is mainly dependent on the ambient background radiation and the

level of contamination. If the background is high or variable, it may be difficult or impossible to collect

an adequate spectrum. If the background is particularly high, it may cause a spectrum shift which

prevents automatic nuclide identification. Well shielded apparatus is also recommended.

7 Monitoring instruments

7.1 Selection of monitors

NOTE Dose rate monitors are included in this clause as, prior to any survey to assess surface contamination,

it is good practice to measure the ambient dose rates.

The selection of appropriate monitors depends on the following:

— the type(s) of radiation that are expected to be encountered (alpha, beta, photon);

ISO/FDIS 7503-1:2015(E)

— the levels of contamination that may be expected;

— the detection limits required;

— the accuracy required from the measurements.

The selection should be undertaken under the advice of a suitably qualified expert.

7.2 Introduction to the calibration of surface contamination instruments for direct

measurement

For regulatory purposes, the maximum permissible levels for surface contamination are expressed in

−2

terms of activity per unit area (Bq cm ).

In most situations, it is possible to identify the individual radionuclide which is the cause of the surface

99m

contamination. For example, in a hospital which only uses Tc for routine diagnostic purposes and no

other radionuclides are brought onto the site, the nature of the contamination is obvious. The surfaces

which might have become contaminated may also be well-defined in terms of material and surface

finish. In this scenario, it would be appropriate to calibrate the contamination monitor(s) directly with

the radionuclide concerned by depositing traceable activities to samples of the surfaces that might be

affected by contamination. Exposing the monitor to these surfaces, at defined distances, provides a

series of calibration factors which, during normal monitoring procedures, can be selected according to

the relevant monitoring characteristics such as the nature of the surface, source to detector separation,

and contamination area. These calibration factors can be expressed in units of response per unit area

(activity per unit area).

In many other situations, this simple scenario does not occur. The worst case situation is that multiple

unidentified radionuclides are involved in varying activity concentrations and on a variety of different

surfaces. These could include distributions of activity below the surface up to and beyond the maximum

path length of any particulate ionizing radiations. In such a case, the immediate concern is to determine

the extent of the spread, and the variation in levels of the contamination. Random sampling combined

with spectrometry can provide some estimate of the radionuclide mix and relative activities. Combined

with knowledge of the response characteristics of the surface contamination monitor, an estimate can

then be made of the surface contamination.

The calibration of individual monitors for every potential scenario is impracticable. The practical

alternative is to demonstrate that the monitor is fit for purpose so that users can rely on type test

data and other published response data which provide sufficient information to determine the

energy-response characteristics for alpha-, beta- and photon emissions. The approach to calibration