ISO 23500-5:2024

(Main)Preparation and quality management of fluids for haemodialysis and related therapies — Part 5: Quality of dialysis fluid for haemodialysis and related therapies

Preparation and quality management of fluids for haemodialysis and related therapies — Part 5: Quality of dialysis fluid for haemodialysis and related therapies

This document specifies the minimum chemical and microbiological quality requirements for dialysis fluids used in haemodialysis and related therapies. This document applies to — dialysis fluids used for haemodialysis and haemodiafiltration, — substitution fluid produced online for haemodiafiltration and haemofiltration based on dialysis fluid This document does not apply to — the water and concentrates used to prepare dialysis fluid or the equipment to produce dialysis fluid — sorbent-based dialysis fluid regeneration systems that regenerate and recirculate small volumes of dialysis fluid, — systems for continuous renal replacement therapy that use pre-packaged solutions, and — systems and solutions for peritoneal dialysis. The delivery and monitoring of the dialysis fluid composition and its permitted deviation from set points is governed by protective systems defined in IEC 60601-2-16.

Préparation et management de la qualité des liquides d'hémodialyse et de thérapies annexes — Partie 5: Qualité des liquides de dialyse pour hémodialyse et thérapies apparentées

Le présent document spécifie les exigences minimales de qualité chimique et microbiologique pour les liquides de dialyse dans le cadre d’hémodialyses et de thérapies apparentées. Le présent document s’applique à ce qui suit: — les liquides de dialyse utilisés à des fins d’hémodialyse et d’hémodiafiltration; — le liquide de substitution produit en ligne à des fins d’hémodiafiltration et d’hémofiltration sur la base du liquide de dialyse. Le présent document ne s’applique pas à ce qui suit: — l’eau et les concentrés utilisés pour préparer le liquide de dialyse ou l’équipement permettant de produire du liquide de dialyse; — les systèmes de régénération de liquide de dialyse à base de sorbants qui régénèrent et recyclent de petites quantités de liquide de dialyse; — les systèmes d’épuration extrarénale continue qui utilisent des solutions prêtes à l’emploi; et — les systèmes et solutions utilisés en dialyse péritonéale. La fourniture et la surveillance de la composition du liquide de dialyse et ses écarts admis par rapport aux points de consigne sont régis par des systèmes de protection définis dans l’IEC 60601-2-16.

General Information

- Status

- Published

- Publication Date

- 16-Apr-2024

- Technical Committee

- ISO/TC 150/SC 2 - Cardiovascular implants and extracorporeal systems

- Drafting Committee

- ISO/TC 150/SC 2 - Cardiovascular implants and extracorporeal systems

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 13-Oct-2025

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 12-Feb-2026

- Effective Date

- 06-Jun-2022

Overview

ISO 23500-5:2024 - Preparation and quality management of fluids for haemodialysis and related therapies - Part 5: Quality of dialysis fluid for haemodialysis and related therapies defines minimum chemical and microbiological quality requirements for dialysis fluids. It covers dialysis fluid used in haemodialysis and haemodiafiltration and online-produced substitution fluid based on dialysis fluid. The standard complements ISO 23500-3 (water) and ISO 23500-4 (concentrates) and interfaces with equipment safety and monitoring requirements in IEC 60601-2-16.

Key topics and requirements

- Microbiological quality

- Standard dialysis fluid: total viable microbial count < 100 CFU/ml and endotoxin < 0.5 EU/ml.

- Ultrapure dialysis fluid: total viable microbial count < 0.1 CFU/ml and endotoxin < 0.03 EU/ml.

- Action levels: recommended (typically ~50% of maximum allowable) to trigger corrective measures such as disinfection and retesting.

- Online substitution fluid: must be sterile and nonpyrogenic; production systems (e.g., ultrafiltration with validated bacteria- and endotoxin-retentive filters) require validation and ongoing surveillance.

- Chemical composition and contaminants

- Dialysis fluid shall be prepared from water and acid/bicarbonate concentrates that meet ISO 23500-3 and ISO 23500-4.

- Delivery systems and materials must not leach chemical contaminants; trace element and heavy metal limits (referenced in Annex B) are specified.

- Testing and conformity

- Guidance on sampling (e.g., aseptic capture at the dialyser inlet or sampling ports), microbiological culture methods, endotoxin testing (including updated alternatives), and chemical analyses are provided.

- Where validated bacteria-/endotoxin-retentive filters are used and operated per manufacturer instructions, routine microbial testing may be waived unless specified by the manufacturer.

Practical applications

- Ensures patient safety by minimizing exposure to biological and chemical contaminants in dialysis fluid.

- Supports clinical protocols for routine surveillance, disinfection, and corrective actions in dialysis centers.

- Informs validation and commissioning of online substitution fluid systems for haemodiafiltration and haemofiltration.

- Guides laboratory testing strategies (microbiology, endotoxin, trace metals) and sampling procedures used by clinical labs and hospital quality teams.

Who uses this standard

- Nephrologists and physicians responsible for dialysis therapy

- Dialysis facility managers and infection-control teams

- Clinical engineers and biomedical technicians

- Medical device manufacturers of dialysis machines, filters and central delivery systems

- Regulatory and accreditation bodies

Related standards

- ISO 23500-1 - General requirements for preparation and quality management of dialysis fluids

- ISO 23500-3 - Quality of water for haemodialysis

- ISO 23500-4 - Concentrates for haemodialysis

- IEC 60601-2-16 - Safety/monitoring for haemodialysis equipment

Keywords: ISO 23500-5:2024, dialysis fluid quality, haemodialysis, ultrapure dialysis fluid, microbiological requirements, chemical contaminants, online substitution fluid, dialysis fluid testing.

ISO 23500-5:2024 - Preparation and quality management of fluids for haemodialysis and related therapies — Part 5: Quality of dialysis fluid for haemodialysis and related therapies Released:17. 04. 2024

REDLINE ISO 23500-5:2024 - Preparation and quality management of fluids for haemodialysis and related therapies — Part 5: Quality of dialysis fluid for haemodialysis and related therapies Released:4/17/2024

ISO 23500-5:2024 - Préparation et management de la qualité des liquides d'hémodialyse et de thérapies annexes — Partie 5: Qualité des liquides de dialyse pour hémodialyse et thérapies apparentées Released:17. 04. 2024

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

ISO 23500-5:2024 is a standard published by the International Organization for Standardization (ISO). Its full title is "Preparation and quality management of fluids for haemodialysis and related therapies — Part 5: Quality of dialysis fluid for haemodialysis and related therapies". This standard covers: This document specifies the minimum chemical and microbiological quality requirements for dialysis fluids used in haemodialysis and related therapies. This document applies to — dialysis fluids used for haemodialysis and haemodiafiltration, — substitution fluid produced online for haemodiafiltration and haemofiltration based on dialysis fluid This document does not apply to — the water and concentrates used to prepare dialysis fluid or the equipment to produce dialysis fluid — sorbent-based dialysis fluid regeneration systems that regenerate and recirculate small volumes of dialysis fluid, — systems for continuous renal replacement therapy that use pre-packaged solutions, and — systems and solutions for peritoneal dialysis. The delivery and monitoring of the dialysis fluid composition and its permitted deviation from set points is governed by protective systems defined in IEC 60601-2-16.

This document specifies the minimum chemical and microbiological quality requirements for dialysis fluids used in haemodialysis and related therapies. This document applies to — dialysis fluids used for haemodialysis and haemodiafiltration, — substitution fluid produced online for haemodiafiltration and haemofiltration based on dialysis fluid This document does not apply to — the water and concentrates used to prepare dialysis fluid or the equipment to produce dialysis fluid — sorbent-based dialysis fluid regeneration systems that regenerate and recirculate small volumes of dialysis fluid, — systems for continuous renal replacement therapy that use pre-packaged solutions, and — systems and solutions for peritoneal dialysis. The delivery and monitoring of the dialysis fluid composition and its permitted deviation from set points is governed by protective systems defined in IEC 60601-2-16.

ISO 23500-5:2024 is classified under the following ICS (International Classification for Standards) categories: 11.040.40 - Implants for surgery, prosthetics and orthotics. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 23500-5:2024 has the following relationships with other standards: It is inter standard links to EN ISO 23500-1:2024, EN ISO 23500-4:2024, EN ISO 23500-5:2024, ISO 23500-5:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 23500-5:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

International

Standard

ISO 23500-5

Second edition

Preparation and quality

2024-04

management of fluids for

haemodialysis and related

therapies —

Part 5:

Quality of dialysis fluid for

haemodialysis and related therapies

Préparation et management de la qualité des liquides

d'hémodialyse et de thérapies annexes —

Partie 5: Qualité des liquides de dialyse pour hémodialyse et

thérapies apparentées

Reference number

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Requirements . 2

4.1 Microbiological contaminants in dialysis fluid .2

4.1.1 General .2

4.1.2 Microbiological requirements for standard dialysis fluid .2

4.1.3 Microbiological requirements for ultrapure dialysis fluid .2

4.1.4 Microbiological requirements for online prepared substitution fluid .2

4.2 Chemical composition of dialysis fluid .3

4.3 Chemical contaminants in dialysis fluid .3

5 Tests for conformity . 3

5.1 Microbiological requirements.3

5.1.1 Sampling .3

5.1.2 Culture methods .3

5.2 Chemical requirements . .5

Annex A (informative) Rationale for the development and provisions of this document . 6

Annex B (informative) Reference tables . 9

Bibliography .11

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 150, Implants for surgery, Subcommittee

SC 2, Cardiovascular implants and extracorporeal systems, in collaboration with the European Committee for

Standardization (CEN) Technical Committee CEN/TC 205, Non-active medical devices, in accordance with the

Agreement on technical cooperation between ISO and CEN (Vienna Agreement).

This second edition cancels and replaces the first edition (ISO 23500-5:2019), which has been technically

revised.

The main changes are: alternatives to classic microbial analytical methods [endotoxin testing using rFC (tp)]

have been incorporated.

A list of all parts of the ISO 23500 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

Haemodialysis patients are directly exposed to large volumes of dialysis fluid, with the dialyser membrane

being the only barrier against transfer of hazardous contaminants from the dialysis fluid to the patient. It has

long been known that there can be hazardous contaminants in the water and concentrates used to prepare

the dialysis fluid. To minimize this hazard, ISO 23500-3 and ISO 23500-4 set forth quality requirements

for the water and concentrates used to prepare dialysis fluid. However, if the dialysis fluid is not prepared

carefully, it can contain unacceptable levels of contaminants even though it is prepared from water and

concentrates, conforming to the requirements of ISO 23500-3 and ISO 23500-4. Further, the dialysis fluid

can be used as the starting material for the online preparation of fluids intended for infusion into the

patient, for example, in therapies such as online haemodiafiltration. For these reasons, this document was

developed to complement the existing International Standards for water and concentrates, ISO 23500-3 and

ISO 23500-4, respectively. Guidelines to aid the user in routinely meeting the requirements of this document

and ISO 23500-3 can be found in ISO 23500-1.

Within these International Standards, measurement techniques current at the time of preparation have been

cited. Other standard methods can be used, provided that such methods have been appropriately validated

and are comparable to the cited methods. The rationale for the development of this document is given in

Annex A.

This document reflects the conscientious efforts of healthcare professionals, patients and medical device

manufacturers to develop recommendations for the quality of dialysis fluid. This document is applicable to

healthcare professionals involved in the management of dialysis facilities and the routine care of patients

treated in dialysis facilities, since they are responsible for the final preparation of dialysis fluid.

This document aims to help protect haemodialysis patients from adverse effects arising from known

chemical and microbiological contaminants that can be found in improperly prepared dialysis fluid.

However, the physician in charge of dialysis has the ultimate responsibility for ensuring that the dialysis

fluid is correctly formulated and meets the applicable quality standards.

The concepts incorporated in this document should not be considered inflexible or static. The requirements

and recommendations presented in this document should be reviewed periodically in order to assimilate

increased understanding of the role of dialysis fluid purity in patient outcomes and technological

developments.

v

International Standard ISO 23500-5:2024(en)

Preparation and quality management of fluids for

haemodialysis and related therapies —

Part 5:

Quality of dialysis fluid for haemodialysis and related

therapies

1 Scope

This document specifies the minimum chemical and microbiological quality requirements for dialysis fluids

used in haemodialysis and related therapies.

This document applies to

— dialysis fluids used for haemodialysis and haemodiafiltration,

— substitution fluid produced online for haemodiafiltration and haemofiltration based on dialysis fluid

This document does not apply to

— the water and concentrates used to prepare dialysis fluid or the equipment to produce dialysis fluid

— sorbent-based dialysis fluid regeneration systems that regenerate and recirculate small volumes of

dialysis fluid,

— systems for continuous renal replacement therapy that use pre-packaged solutions, and

— systems and solutions for peritoneal dialysis.

The delivery and monitoring of the dialysis fluid composition and its permitted deviation from set points is

governed by protective systems defined in IEC 60601-2-16.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 23500-1, Preparation and quality management of fluids for haemodialysis and related therapies — Part 1:

General requirements

ISO 23500-3, Preparation and quality management of fluids for haemodialysis and related therapies — Part 3:

Quality of water for haemodialysis and related therapies

ISO 23500-4, Preparation and quality management of fluids for haemodialysis and related therapies — Part 4:

Concentrates for haemodialysis and related therapies

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 23500-1 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

4 Requirements

4.1 Microbiological contaminants in dialysis fluid

4.1.1 General

The requirements contained in Clause 4 apply to a sample of the dialysis fluid collected at the inlet to the

dialyser or the reinfusion point.

4.1.2 Microbiological requirements for standard dialysis fluid

Standard dialysis fluid shall contain a total viable microbial count of less than 100 CFU/ml (when tested in

accordance with Clause 5) and an endotoxin concentration of less than 0,5 EU/ml (when tested in accordance

with Clause 5).

Action levels for the total viable microbial count and endotoxin concentration in dialysis fluid should also be

set based on knowledge of the microbial dynamics of the system. Typically, the action levels are set at 50 %

of the maximum allowable levels for total viable microbial count and endotoxin; other levels can be set.

If microbial counts exceeding the action levels are observed in the dialysis fluid, corrective measures, such

as disinfection and retesting, should be taken promptly to reduce the levels.

Associated with the presence of bacteria and endotoxin in dialysis fluid is the likely presence of fungi (yeasts

and filamentous fungi).

Tests for microbial growth and endotoxins are not required if the dialysis machine fluid pathway is fitted

with an appropriate capacity bacteria-retentive and endotoxin-retentive filter validated by the manufacturer,

and operated and surveyed according to the manufacturer's instructions, unless the manufacturer requires

such tests in the instructions for use.

4.1.3 Microbiological requirements for ultrapure dialysis fluid

Ultrapure dialysis fluid shall contain a total viable microbial count of less than 0,1 CFU/ml (when tested in

accordance with Clause 5) and an endotoxin concentration less than 0,03 EU/ml (when tested in accordance

with Clause 5). If those limits are exceeded in ultrapure dialysis fluid, corrective measures should be taken to

reduce the levels to an acceptable level. The user is responsible for surveying the dialysis fluid bacteriology

of the system following installation. It is incumbent on the user to establish a regular surveillance routine.

Tests for microbial growth and endotoxins are not required if the dialysis machine fluid pathway is fitted

with an appropriate capacity bacteria-retentive and endotoxin-retentive filter validated by the manufacturer,

and operated and surveyed according to the manufacturer's instructions, unless the manufacturer requires

such tests in the instructions for use.

4.1.4 Microbiological requirements for online prepared substitution fluid

The requirements contained in this subclause apply to online prepared fluid intended to be infused into the

patient as it enters the patient's blood.

This fluid shall be sterile and nonpyrogenic.

Substitution fluid for convective therapies, such as haemodiafiltration and haemofiltration, can be produced

online by a process of ultrafiltration with bacteria- and endotoxin-retentive filters. This online process shall

be validated to produce fluid that is sterile and nonpyrogenic.

Conformity of online produced fluid with the requirements of this document cannot be demonstrated with

traditional test procedures. For this reason, conformity with this document shall be ensured by proper

operation of a validated system, verified in accordance with the manufacturer's instructions at the time

of installation, and confirmed by the user with a regular surveillance and maintenance schedule. The user

shall follow the manufacturer’s instructions for use of the validated system and the user’s surveillance and

maintenance schedule shall be designed to confirm that the water and concentrates used to prepare the

substitution fluid continue to meet the specifications of ISO 23500-3 and ISO 23500-4.

4.2 Chemical composition of dialysis fluid

Dialysis fluid shall be prepared from water meeting the requirements of ISO 23500-3 and acid and

bicarbonate concentrates meeting the requirements of ISO 23500-4. The water and concentrates shall be

combined in accordance with the concentrate manufacturers dilution instructions using individual dialysis

fluid delivery systems as specified in IEC 60601-2-16 or a central dialysis fluid delivery system.

4.3 Chemical contaminants in dialysis fluid

The water and concentrates shall be combined using individual dialysis fluid delivery systems or a central

dialysis fluid delivery system constructed from materials that do not contribute chemical contaminants to

the final dialysis fluid.

The maximum levels of chemical contaminants permitted in water used to prepare dialysis fluid and

concentrates are given in ISO 23500-3 and are also shown in Annex B (see Tables B.1 and B.2) together with

methods of determination (see Table B.3). Other equivalent analytical methods can be used. Where testing

for the individual trace elements listed in Table B.2 is not available, an analysis for total heavy metals can be

used with a maximum allowable level of 0,1 mg/l.

5 Tests for conformity

5.1 Microbiological requirements

5.1.1 Sampling

In some newer dialysis machines, dialysis fluid flow stops when the effluent line is disconnected from

the dialyser. In these instances, the machines are equipped with dialysis fluid sampling ports that can be

accessed using a syringe. Sample ports can be disinfected with alcohol and allowed to air-dry. A sterile

syringe should be used to aspirate at least 10 ml of dialysis fluid out of the sampling port. The filled syringe

is discarded and a fresh sample of dialysis fluid collected using a new sterile syringe. For sample ports

consisting of a simple septum penetrated with a needle, the use of a second syringe is not necessary. If no

sampling port is available and if the dialysis machine permits, samples can be collected immediately before

the dialyser by disconnecting the inlet connector and aseptically collecting a “free/clean” catch sample after

allowing dialysis fluid to run for at least 60 s unless manufacturers’ instructions state otherwise.

Microbial analysis of any fluid sample should be conducted as soon as possible after collection to avoid

unpredictable changes in the microbial population. If samples cannot be analysed within 4 h of collection,

they should be stored at <10 °C without freezing and during transit to the laboratory. Sample storage for

more than 24 h should be avoided and sample shipping should be according to the laboratory’s instructions.

5.1.2 Culture methods

Accurate microbiological surveillance is important in the indication of the microbial content of dialysis water

and dialysis fluid. Culture results obtained using the methods outlined in this document and summarized in

Table 1 are only a relative indicator of the bioburden and do not provide an absolute measure of the absolute

microbial burden.

Total viable microbial counts (standard plate counts) shall be obtained using conventional microbiological

assay procedures (pour plate, spread plate, membrane filter techniques). The calibrated loop technique shall

not be used.

Preferred methods and sample volumes are:

— for standard dialysis fluid:

— spread plate, 0,1 ml to 0,3 ml;

— pour plate, typically 1 ml;

— for ultrapure dialysis fluid: membrane filtration, 10 ml to 1 000 ml;

— for substitution fluid: sterility cannot be proven by sampling.

Different media types and incubation periods can result in varying colony concentrations and types of

microorganisms recovered.

The use of Reasoner’s 2A agar (R2A) has been shown in published studies to result in higher colony

[20][21]

counts than tryptic soy agar (TSA) for water and dialysis fluids samples . However, in a more recent

[22]

publication , the authors indicated that there were no significant differences for comparisons of bacterial

burden of standard dialysis water and standard dialysis fluid yielding colony counts ≥50 CFU/ml when

assayed using R2A and TSA at the conditions stated in Table 1.

Tryptone glucose extract agar (TGEA) incubated at 17 °C to 23 °C for a period of 7 d in previous studies also

yielded higher colony counts than TSA. In Reference [22], a comparison of this medium with TSA showed

that the proportion of standard dialysis water samples yielding colony counts ≥50 CFU/ml was significantly

different from that found using TSA at an incubation temperature of 35 °C to 37 °C and an incubation time of

48 h (p = 0,001). The proportions of dialysis fluid samples in which microbial burden was ≥50 CFU/ml were

not significantly different on the two media and incubation conditions.

The culture medium and incubation times selected should be based on the type of fluid to be analysed, for

example, standard dialysis fluid, water used in the preparation of standard dialysis fluid, ultrapure dialysis

fluid, water used for the preparation of ultrapure dialysis fluid or fluid used for on line therapies such as

haemodiafiltration. The method selected should be based on the analysis of the advantages, disadvantages and

sensitivity of each of the suggested methods. It should also ensure that patient safety is safeguarded and allow

for consideration of local laboratory working practices, and that reimbursement requirements can be met.

Blood agar and chocolate agar shall not be used.

Table 1 — Culture techniques

Culture medium Incubation temperature Incubation time

TGEA 17 °C to 23 °C 7 d

R2A 17 °C to 23 °C 7 d

a

TSA 35 °C to 37 °C 48 h

a [22]

The use of TSA has only been validated for dialysis water and standard dialysis fluid .

Other medium, incubation conditions and colony counting times can be used provided it has been

demonstrated that such methods have been appropriately validated and are comparable to the cited

methods.

Currently there are no requirements for routine surveillance for the presence of fungi (i.e. yeasts and

filamentous fungi), however if quantification is required, membrane filtration is suggested as the method

for obtaining a sample suitable for analysis. For culture, Sabouraud or malt extract agar (MEA) are

recommended.

The detection of bacterial endotoxins, which originate from gram-negative bacteria, is mainly carried out

using Limulus amoebocyte lysate (LAL), which is obtained from horseshoe crab blood (Limulus polyphemus

or Tachypleus tridentatus). The corresponding chapters have been harmonized between the European

[16] [13]

Pharmacopoeia ((EP) <2.6.14>), the Pharmacopoeia of the United States-National Formulary, (<85>)

[19]

and the Japanese Pharmacopoeia (<4.01>) .

The LAL test is based on the humoral coagulation cascade of the horseshoe crab Limulus polyphemus. The

first enzyme in this coagulation cascade reacts with endotoxin and is called Factor C. This factor is now

produced recombinantly (i.e. with biotechnology) and offered as the rFC test by several manufacturers for

the determination of bacterial endotoxins. Compared to the LAL test, the rFC test has proven to be at least

as sensitive and reliable, but less susceptible to certain interfering factors and b

...

International

Standard

Redline version

compares Second edition

to First edition

ISO 23500-5

Preparation and quality

management of fluids for

haemodialysis and related

therapies —

Part 5:

Quality of dialysis fluid for

haemodialysis and related therapies

Préparation et management de la qualité des liquides

d'hémodialyse et de thérapies annexes —

Partie 5: Qualité des liquides de dialyse pour hémodialyse et

thérapies apparentées

Reference number

ISO 23500-5:redline:2024(en) © ISO 2024

ISO 23500-5:redline:2024(en)

IMPORTANT — PLEASE NOTE

This is a provisional mark-up copy and uses the following colour coding:

Text example 1 — indicates added text (in green)

— indicates removed text (in red)

Text example 2

— indicates added graphic figure

— indicates removed graphic figure

1.x . — Heading numbers containg modifications are highlighted in yellow in

the Table of Contents

All changes in this document have yet to reach concensus by vote and as such should only

be used internally for review purposes.

DISCLAIMER

This Redline version is not an official IEC Standard and is intended only to provide the

user with an indication of what changes have been made to the previous version. Only the

current version of the standard is to be considered the official document.

This Redline version provides you with a quick and easy way to compare all the changes

between this standard and its previous edition. A vertical bar appears in the margin

wherever a change has been made. Additions and deletions are displayed in red, with

deletions being struck through.

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

ISO 23500-5:redline:2024(en)

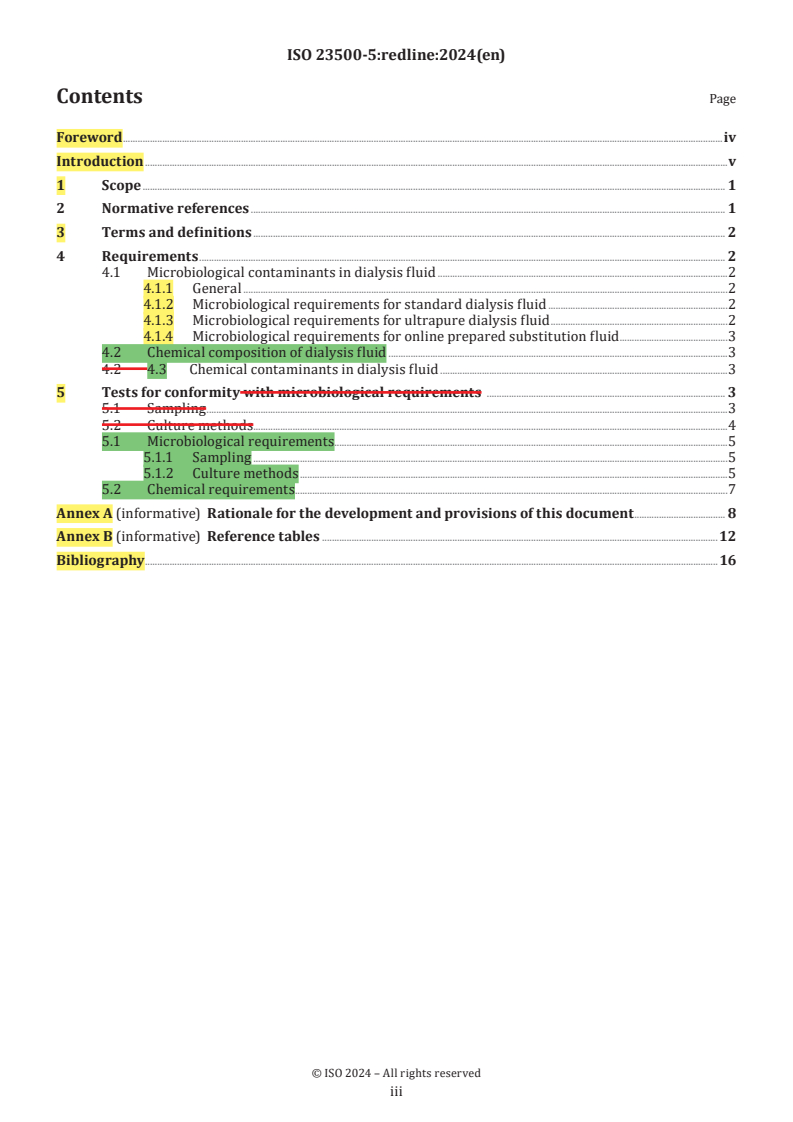

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Requirements . 2

4.1 Microbiological contaminants in dialysis fluid .2

4.1.1 General .2

4.1.2 Microbiological requirements for standard dialysis fluid .2

4.1.3 Microbiological requirements for ultrapure dialysis fluid .2

4.1.4 Microbiological requirements for online prepared substitution fluid .3

4.2 Chemical composition of dialysis fluid .3

4.2 4.3 Chemical contaminants in dialysis fluid .3

5 Tests for conformity with microbiological requirements . 3

5.1 Sampling .3

5.2 Culture methods.4

5.1 Microbiological requirements.5

5.1.1 Sampling .5

5.1.2 Culture methods .5

5.2 Chemical requirements . .7

Annex A (informative) Rationale for the development and provisions of this document . 8

Annex B (informative) Reference tables .12

Bibliography .16

iii

ISO 23500-5:redline:2024(en)

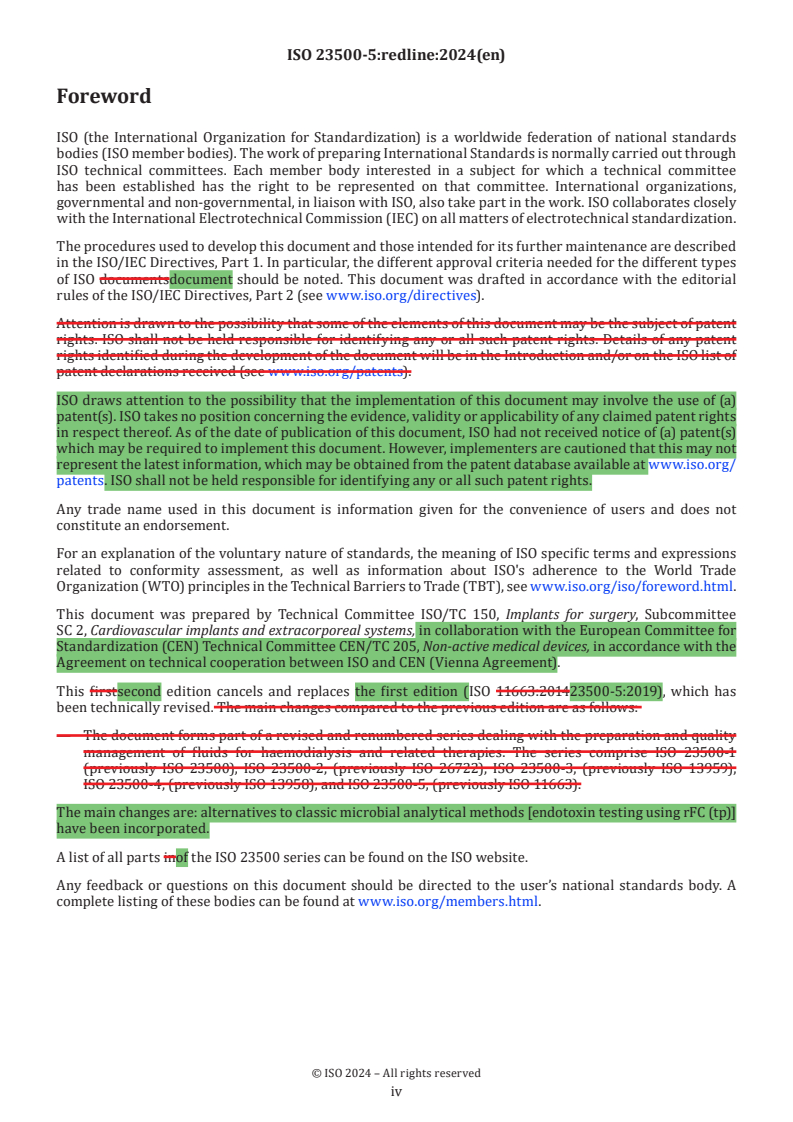

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO documentsdocument should be noted. This document was drafted in accordance with the editorial

rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any patent

rights identified during the development of the document will be in the Introduction and/or on the ISO list of

patent declarations received (see www .iso .org/ patents).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent rights

in respect thereof. As of the date of publication of this document, ISO had not received notice of (a) patent(s)

which may be required to implement this document. However, implementers are cautioned that this may not

represent the latest information, which may be obtained from the patent database available at www .iso .org/

patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 150, Implants for surgery, Subcommittee

SC 2, Cardiovascular implants and extracorporeal systems, in collaboration with the European Committee for

Standardization (CEN) Technical Committee CEN/TC 205, Non-active medical devices, in accordance with the

Agreement on technical cooperation between ISO and CEN (Vienna Agreement).

This firstsecond edition cancels and replaces the first edition (ISO 11663:201423500-5:2019), which has

been technically revised. The main changes compared to the previous edition are as follows:

— The document forms part of a revised and renumbered series dealing with the preparation and quality

management of fluids for haemodialysis and related therapies. The series comprise ISO 23500-1

(previously ISO 23500), ISO 23500-2, (previously ISO 26722), ISO 23500-3, (previously ISO 13959),

ISO 23500-4, (previously ISO 13958), and ISO 23500-5, (previously ISO 11663).

The main changes are: alternatives to classic microbial analytical methods [endotoxin testing using rFC (tp)]

have been incorporated.

A list of all parts inof the ISO 23500 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

iv

ISO 23500-5:redline:2024(en)

Introduction

Haemodialysis patients are directly exposed to large volumes of dialysis fluid, with the dialyser membrane

being the only barrier against transfer of hazardous contaminants from the dialysis fluid to the patient.

It has long been known that there couldcan be hazardous contaminants in the water and concentrates

used to prepare the dialysis fluid. To minimize this hazard, ISO 23500-3 and ISO 23500-4 set forth quality

requirements for the water and concentrates used to prepare dialysis fluid. However, if the dialysis fluid is

not prepared carefully, it couldcan contain unacceptable levels of contaminants even though it is prepared

from water and concentrates, conforming to the requirements of ISO 23500-3 and ISO 23500-4. Further,

the dialysis fluid mightcan be used as the starting material for the online preparation of fluids intended for

infusion into the patient, for example, in therapies such as online haemodiafiltration. For these reasons, this

document for dialysis fluid quality was developed to complement the existing International Standards for

water and concentrates, ISO 23500-3 and ISO 23500-4, respectively. Guidelines to aid the user in routinely

meeting the requirements of this document and ISO 23500-3 can be found in ISO 23500-1.

Within these International Standards, measurement techniques current at the time of preparation have been

cited. Other standard methods can be used, provided that such methods have been appropriately validated

and are comparable to the cited methods. The rationale for the development of this document is given in

Annex A.

This document reflects the conscientious efforts of healthcare professionals, patients and medical device

manufacturers to develop recommendations for the quality of dialysis fluid. This document is directed at

theapplicable to healthcare professionals involved in the management of dialysis facilities and the routine

care of patients treated in dialysis facilities, since they are responsible for the final preparation of dialysis

fluid. The recommendations contained in this document are not intended for regulatory application.

This document aims to help protect haemodialysis patients from adverse effects arising from known

chemical and microbiological contaminants that can be found in improperly prepared dialysis fluid.

However, the physician in charge of dialysis has the ultimate responsibility for ensuring that the dialysis

fluid is correctly formulated and meets the applicable quality standards.

The concepts incorporated in this document should not be considered inflexible or static. The requirements

and recommendations presented herein this document should be reviewed periodically in order to

assimilate increased understanding of the role of dialysis fluid purity in patient outcomes and technological

developments.

v

ISO 23500-5:redline:2024(en)

Preparation and quality management of fluids for

haemodialysis and related therapies —

Part 5:

Quality of dialysis fluid for haemodialysis and related

therapies

1 Scope

This document specifies minimumthe minimum chemical and microbiological quality requirements for

dialysis fluids used in haemodialysis and related therapies.

This document includes dialysis fluids used for haemodialysis and haemodiafiltration, including substitution

fluid for haemodiafiltration and haemofiltration.

This document excludes the water and concentrates used to prepare dialysis fluid or the equipment used in

its preparation. Those areas are covered by other International Standards.

Sorbent-based dialysis fluid regeneration systems that regenerate and recirculate small volumes of dialysis

fluid, systems for continuous renal replacement therapy that use pre-packaged solutions, and systems and

solutions for peritoneal dialysis are excluded from this document.

This document applies to

— dialysis fluids used for haemodialysis and haemodiafiltration,

— substitution fluid produced online for haemodiafiltration and haemofiltration based on dialysis fluid

This document does not apply to

— the water and concentrates used to prepare dialysis fluid or the equipment to produce dialysis fluid

— sorbent-based dialysis fluid regeneration systems that regenerate and recirculate small volumes of

dialysis fluid,

— systems for continuous renal replacement therapy that use pre-packaged solutions, and

— systems and solutions for peritoneal dialysis.

The delivery and monitoring of the dialysis fluid composition and its permitted deviation from set points is

governed by protective systems defined in IEC 60601-2-16.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 23500-1, Preparation and quality management of fluids for haemodialysis and related therapies — Part 1:

General requirements

ISO 23500-3, Preparation and quality management of fluids for haemodialysis and related therapies — Part 3:

Quality of water for haemodialysis and related therapies

ISO 23500-5:redline:2024(en)

ISO 23500-4, Preparation and quality management of fluids for haemodialysis and related therapies — Part 4:

Concentrates for haemodialysis and related therapies

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 23500-1 apply.

ISO and IEC maintain terminologicalterminology databases for use in standardization at the following

addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at httphttps:// www .electropedia .org/

4 Requirements

4.1 Microbiological contaminants in dialysis fluid

4.1.1 General

The requirements contained in thisClause 4 clause apply to a sample of the dialysis fluid collected at the

inlet to the dialyser or the reinfusion point.

4.1.2 Microbiological requirements for standard dialysis fluid

Standard dialysis fluid shall contain a total viable microbial count of less than 100 CFU/ml (when tested in

accordance with Clause 5) and an endotoxin concentration of less than 0,5 EU/ml (when tested in accordance

with Clause 5).

Action levels for the total viable microbial count and endotoxin concentration in dialysis fluid should also be

set based on knowledge of the microbial dynamics of the system. Typically, the action levels are set at 50 %

of the maximum allowable levels for total viable microbial count and endotoxin; other levels can be set.

If microbial counts exceeding the action levels are observed in the dialysis fluid, corrective measures, such

as disinfection and retesting, should be taken promptly to reduce the levels.

Associated with the presence of bacteria and endotoxin in dialysis fluid is the likely presence of fungi (yeasts

and filamentous fungi). After extensive discussion, the working group has not recommended maximum

limits, for such contaminants.

Tests for bacterialmicrobial growth and endotoxins are not required if the dialysis machine fluid pathway

is fitted with an appropriate capacity bacteria-retentive and endotoxin-retentive filter validated by the

manufacturer, and operated and surveilledsurveyed according to the manufacturer's instructions, unless

the manufacturer requires such tests in the instructions for use.

4.1.3 Microbiological requirements for ultrapure dialysis fluid

Ultrapure dialysis fluid shall contain a total viable microbial count of less than 0,1 CFU/ml (when tested in

accordance with Clause 5) and an endotoxin concentration less than 0,03 EU/ml (when tested in accordance

with Clause 5). If those limits are exceeded in ultrapure dialysis fluid, corrective measures should be taken

to reduce the levels to an acceptable level. The user is responsible for surveillingsurveying the dialysis

fluid bacteriology of the system following installation. It is incumbent on the user to establish a regular

surveillance routine.

Tests for bacterialmicrobial growth and endotoxins are not required if the dialysis machine fluid pathway

is fitted with an appropriate capacity bacteria-retentive and endotoxin-retentive filter validated by the

manufacturer, and operated and surveilledsurveyed according to the manufacturer's instructions, unless

the manufacturer requires such tests in the instructions for use.

ISO 23500-5:redline:2024(en)

4.1.4 Microbiological requirements for online prepared substitution fluid

The requirements contained in this clausesubclause apply to online prepared fluid intended to be infused

into the patient as it enters the patient's blood.

This fluid shall be sterile and nonpyrogenic.

Substitution fluid for convective therapies, such as haemodiafiltration and haemofiltration, can be produced

online by a process of ultrafiltration with bacteria-retentive and endotoxin-retentive filters. This online

process shall be validated to produce fluid that is sterile and nonpyrogenic.

Conformity of online produced fluid with the requirements of this document cannot be demonstrated with

traditional test procedures. For this reason, conformity with this document shall be ensured by proper

operation of a validated system, verified according toin accordance with the manufacturer's instructions at

the time of installation, and confirmed by the user with a regular surveillance and maintenance schedule. The

user shall follow the manufacturer’s instructions for use of the validated system and the user’s surveillance

and maintenance schedule shall be designed to confirm that the water and concentrates used to prepare the

substitution fluid continue to meet the specifications of ISO 23500-3 and ISO 23500-4.

4.2 Chemical composition of dialysis fluid

Dialysis fluid shall be prepared from water meeting the requirements of ISO 23500-3 and acid and

bicarbonate concentrates meeting the requirements of ISO 23500-4. The water and concentrates shall be

combined in accordance with the concentrate manufacturers dilution instructions using individual dialysis

fluid delivery systems as specified in IEC 60601-2-16 or a central dialysis fluid delivery system.

4.2 4.3 Chemical contaminants in dialysis fluid

Dialysis fluid shall be prepared from water meeting the requirements of ISO 23500-3 and acid and

bicarbonate concentrates meeting the requirements of ISO 23500-4. The water and concentrates shall

be combined using individual dialysis fluid delivery systems or a central dialysis fluid delivery system

constructed from materials that do not contribute chemical contaminants to the final dialysis fluid.

The maximum levels of chemical contaminants permitted in water used to prepare dialysis fluid and

concentrates are given in ISO 23500-3 and are also shown in informative Annex B of this document ((see

Tables B.1 and B.2) together with methods of determination (see Table B.3). Other equivalent analytical

methods can be used. Where testing for the individual trace elements listed in Table B.2 is not available, an

analysis for total heavy metals can be used with a maximum allowable level of at 0,1 mg/l.

5 Tests for conformity with microbiological requirements

5.1 Sampling

In some newer dialysis machines, dialysis fluid flow stops when the effluent line is disconnected from the

dialyser. In these instances, the machines are equipped with dialysis fluid sampling ports that can be accessed

using a syringe. Sample ports can be disinfected with alcohol and allowed to air-dry. A sterile syringe should

be used to aspirate at least 10 ml of dialysis fluid out of the sampling port. The filled syringe is discarded

and a fresh sample of dialysis fluid collected using a new sterile syringe. For sample ports consisting of a

simple septum penetrated with a needle, the use of a second syringe is not necessary. Alternatively, if the

dialysis machine permits, samples can be collected immediately before the dialyser by disconnecting the

inlet connector and aseptically collecting a “free/clean” catch sample after allowing dialysis fluid to run for

at least 60 s unless manufacturers’ instructions state otherwise.

Microbial analysis of any fluid sample should be conducted as soon as possible after collection to avoid

unpredictable changes in the microbial population. If samples cannot be analysed within 4 h of collection,

they should be stored at <10 °C without freezing and during transit to the laboratory. Sample storage for

more than 24 h should be avoided, and sample shipping should be in accordance with the laboratory’s

instructions.

ISO 23500-5:redline:2024(en)

5.2 Culture methods

Accurate microbiological surveillance is important in the indication of the microbial content of dialysis water

and dialysis fluid. Culture results obtained using the methods outlined in this document and summarized in

Table 1 are only a relative indicator of the bioburden and do not provide an absolute measure of the absolute

bacterial burden.

Total viable microbial counts (standard plate counts) shall be obtained using conventional microbiological

assay procedures (pour plate, spread plate, membrane filter techniques). The calibrated loop technique shall

not be used.

Preferred methods and sample volumes:

Standard dialysis fluid:

— spread plate, 0,1 ml to 0,3 ml;

— pour plate, typically 1 ml.

Ultrapure dialysis fluid:

— membrane filtration, 10 ml to 1 000 ml.

Substitution fluid:

— sterility cannot be proven by sampling.

Different media types and incubation periods can result in varying colony concentrations and types of

microorganisms recovered.

The use of Reasoner’s 2A agar (R2A) has been shown in previous studies to result in higher colony counts

[][] []

than tryptic soy agar (TSA) for water and dialysis fluids samples . In a more recent publication, 2016 , the

authors indicated that there were no significant differences for comparisons of bacterial burden of standard

dialysis water and standard dialysis fluid yielding colony counts ≥50 CFU/ml when assayed using R2A and

TSA at the conditions stated in Table 1.

Tryptone glucose extract agar (TGEA) incubated at 17 °C to 23 °C for a period of 7 days in previous studies

[]

also yielded higher colony counts than TSA . Maltais et al. in their comparison of this medium with TSA

showed that the proportion of standard dialysis water samples yielding colony counts ≥50 CFU/ml was

significantly different from that found using TSA at an incubation temperature of 35 °C to 37 °C and an

incubation time of 48 hours (p=0,001). The proportions of dialysis fluid samples in which microbial burden

[]

was ≥50 CFU/ml were not significantly different on the two media and incubation conditions .

The culture medium and incubation times selected should be based on the type of fluid to be analysed

e.g. standard dialysis fluid, water used in the preparation of standard dialysis fluid, ultrapure dialysis

fluid, water used for the preparation of ultrapure dialysis fluid or fluid used for on line therapies such as

haemodiafiltration. The method selected should be based on the analysis of the advantages, disadvantages

and sensitivity of each of the suggested methods. It should also ensure that patient safety is safeguarded and

allow for consideration of local laboratory working practices, and that local regulatory and reimbursement

requirements can be met.

Blood agar and chocolate agar shall not be used.

Table 1 — Culture techniques

Incubation

Culture medium Incubation time

temperature

Tryptone Glucose Extract Agar (TGEA) 17 °C to 23 °C 7 d

Reasoner's agar no. 2 (R2A) 17 °C to 23 °C 7 d

a

Tryptic Soy Agar (TSA) 35 °C to 37 °C 48 h

a

The use of TSA has been only validated for measurement of standard dialysis fluid.

ISO 23500-5:redline:2024(en)

Other medium, incubation conditions and colony counting times can be used provided it has been

demonstrated that such methods have been appropriately validated and are comparable to the cited

methods.

Currently there are no requirements for routine surveillance for the presence of fungi (i.e. yeasts and

filamentous fungi), however if quantification is required, membrane filtration is suggested as the method

for obtaining a sample suitable for analysis. For culture, Sabouraud or Malt Extract Agar (MEA) are

recommended.

The presence of endotoxins shall be determined by a Limulus amoebocyte lysate (LAL) assay or another

validated method.

Conformity with the microbial standards for ultrapure dialysis fluid and substitution fluid prepared online

with a validated system can be met by following the requirements and instructions of the manufacturer of

the dialysis fluid delivery system.

5.1 Microbiological requirements

5.1.1 Sampling

In some newer dialysis machines, dialysis fluid flow stops when the effluent line is disconnected from

the dialyser. In these instances, the machines are equipped with dialysis fluid sampling ports that can be

accessed using a syringe. Sample ports can be disinfected with alcohol and allowed to air-dry. A sterile

syringe should be used to aspirate at least 10 ml of dialysis fluid out of the sampling port. The filled syringe

is discarded and a fresh sample of dialysis fluid collected using a new sterile syringe. For sample ports

consisting of a simple septum penetrated with a needle, the use of a second syringe is not necessary. If no

sampling port is available and if the dialysis machine permits, samples can be collected immediately before

the dialyser by disconnecting the inlet connector and aseptically collecting a “free/clean” catch sample after

allowing dialysis fluid to run for at least 60 s unless manufacturers’ instructions state otherwise.

Microbial analysis of any fluid sample should be conducted as soon as possible after collection to avoid

unpredictable changes in the microbial population. If samples cannot be analysed within 4 h of collection,

they should be stored at <10 °C without freezing and during transit to the laboratory. Sample storage for

more than 24 h should be avoided and sample shipping should be according to the laboratory’s instructions.

5.1.2 Culture methods

Accurate microbiological surveillance is important in the indication of the microbial content of dialysis water

and dialysis fluid. Culture results obtained using the methods outlined in this document and summarized in

Table 1 are only a relative indicator of the bioburden and do not provide an absolute measure of the absolute

microbial burden.

Total viable microbial counts (standard plate counts) shall be obtained using conventional microbiological

assay procedures (pour plate, spread plate, membrane filter techniques). The calibrated loop technique shall

not be used.

Preferred methods and sample volumes are:

— for standard dialysis fluid:

— spread plate, 0,1 ml to 0,3 ml;

— pour plate, typically 1 ml;

— for ultrapure dialysis fluid: membrane filtration, 10 ml to 1 000 ml;

— for substitution fluid: sterility cannot be proven by sampling.

Different media types and incubation periods can result in varying colony concentrations and types of

microorganisms recovered.

ISO 23500-5:redline:2024(en)

The use of Reasoner’s 2A agar (R2A) has been shown in published studies to result in higher colony

[20][21]

counts than tryptic soy agar (TSA) for water and dialysis fluids samples . However, in a more recent

[22]

publication , the authors indicated that there were no significant differences for comparisons of bacterial

burden of standard dialysis water and standard dialysis fluid yielding colony counts ≥50 CFU/ml when

assayed using R2A and TSA at the conditions stated in Table 1.

Tryptone glucose extract agar (TGEA) incubated at 17 °C to 23 °C for a period of 7 d in previous studies also

yielded higher colony counts than TSA. In Reference [22], a comparison of this medium with TSA showed

that the proportion of standard dialysis water samples yielding colony counts ≥50 CFU/ml was significantly

different from that found using TSA at an incubation temperature of 35 °C to 37 °C and an incubation time of

48 h (p = 0,001). The proportions of dialysis fluid samples in which microbial burden was ≥50 CFU/ml were

not significantly different on the two media and incubation conditions.

The culture medium and incubation times selected should be based on the type of fluid to be analysed, for

example, standard dialysis fluid, water used in the preparation of standard dialysis fluid, ultrapure dialysis

fluid, water used for the preparation of ultrapure dialysis fluid or fluid used for on line therapies such as

haemodiafiltration. The method selected should be based on the analysis of the advantages, disadvantages and

sensitivity of each of the suggested methods. It should also ensure that patient safety is safeguarded and allow

for consideration of local laboratory working practices, and that reimbursement requirements can be met.

Blood agar and chocolate agar shall not be used.

Table 1 — Culture techniques

Culture medium Incubation temperature Incubation time

TGEA 17 °C to 23 °C 7 d

R2A 17 °C to 23 °C 7 d

a

TSA 35 °C to 37 °C 48 h

a [22]

The use of TSA has only been validated for dialysis water and standard dialysis fluid .

Other medium, incubation conditions and colony counting times can be used provided it has been

demonstrated that such methods have been appropriately validated and are comparable to the cited

methods.

Currently there are no requirements for routine surveillance for the presence of fungi (i.e. yeasts and

filamentous fungi), however if quantification is required, membrane filtration is suggested as the method

for obtaining a sample suitable for analysis. For culture, Sabouraud or malt extract agar (MEA) are

recommended.

The detection of bacterial endotoxins, which originate from gram-negative bacteria, is mainly carried out

using Limulus amoebocyte lysate (LAL), which is obtained from horseshoe crab blood (Limulus polyphemus

or Tachypleus tridentatus). The corresponding chapters have been harmonized between the European

[16] [13]

Pharmacopoeia ((EP) <2.6.14>), the Pharmacopoeia of the United States-National Formulary, (<85>)

[19]

and the Japanese Pharmacopoeia (<4.01>) .

The LAL test is based on the humoral coagulation cascade of the horseshoe crab Limulus polyphemus. The

first enzyme in this coagulation cascade reacts with endotoxin and is called Factor C. This factor is now

produced recombinantly (i.e. with biotechnology) and offered as the rFC test by several manufacturers for

the determination of bacterial endotoxins. Compared to the LAL test, the rFC test has proven to be at least

as sensitive and reliable, but less susceptible to certain interfering factors and batch fluctuations. Due to

biotechnological production, no live animals are required as blood donors.

[17]

This new method has been incorporated into the European Pharmacopoeia <2.6.32> and will also be

[14]

included into the USP-NF <1085.1> .

Conformity with the microbial standards for ultrapure dialysis fluid and substitution fluid prepared online

with a validated system can be met by following the requirements and instructions of the manufacturer of

the dialysis fluid delivery system.

ISO 23500-5:redline:2024(en)

5.2 Chemical requirements

Conformity with the requirements for the chemical contents of the dialysis fluid is determined by local

regulations or as recommended by the manufacturer of the dialysis fluid delivery system (continuous

surveillance for proportionating systems, see ISO 23500-1).

ISO 23500-5:redline:2024(en)

Annex A

(informative)

Rationale for the development and provisions of this document

A.1 Introduction

The information in this annex is intended to give the reader a historical perspective of the development of

the microbiological and chemical contaminant limits in this document.

A.1 2 Microbiological contaminants in dialysis fluid

NOTE The information in this clause is intended to give the reader a historical perspective of how the microbial

limits were developed for this document.

Pyrogenic reactions are caused by lipopolysaccharides or endotoxins that are associated with gram-negative

bacteria. Furthermore, gram-negative water bacteria have been shown to have the capability of multiplying

rapidly in a variety of hospital-associated fluids, including distilled, deionized, reverse osmosis and softened

water, all of which have been used in the past as supply water for haemodialysis systems. The dialysis fluid,

which is a balanced salt solution made with this water, likewise provides a very good growth medium

for these types of bacteria. Several studies have demonstrated that the incidence of pyrogenic reactions

can be related directly to the number of bacteria in dialysis fluid even at low levels of bacterialmicrobial

contamination, pyrogenic reactions have been reported when the source of endotoxin was exogenous to the

[10][11][12][13]

dialysis system (i.e. present in the community water supply) . The presence of non-tuberculous

mycobacteria has also been associated with outbreaks of infection in dialysis units.

Several investigators have shown that bacteria growing in dialysis fluid can produce products that

[14][15][23]-[25]

cross dialysis membranes . It has also been shown that gram-negative bacteria growing in

dialysis fluid produced endotoxins, that in turn stimulated the production of anti-endotoxin antibodies in

[16][17][25]

haemodialysis patients . These data suggest that endotoxins do indeed cross dialysis membranes,

either intact or as fragments. The use of the very permeable membranes known as high-flux membranes has

raised the possibility of a greater likelihood of passage of endotoxins into the blood path. Several studies

support this contention. Vanholder et al. observed Reference [24] notes an increase in plasma endotoxin

3 4

concentrations during dialysis against dialysis fluid containing 10 CFU/ml to 10 CFU/ml of Pseudomonas

[18]

species . In vitro studies using both radiolabelled lipopolysaccharide and biological assays have

demonstrated that biologically active substances derived from bacteria found in dialysis fluid can cross a

[19] to [25]

variety of dialysis membranes . Also, patients treated with high-flux membranes are reported to have

higher levels of anti-endotoxin antibodies than normal subjects or patients treated with conventional low-

[26]

flux membranes . Finally, it was reported that the use of high-flux dialysers is a significant risk factor for

[27]

pyrogenic reactions . Although other investigators have not been able to demonstrate endotoxin transfer

[28][29]

across dialysis membranes , the preponderance of reports now supports the ability of endotoxin

to transfer across at least some high-flux membranes under some operating conditions. Furthermore,

in a In a Japanese Society for Dialysis Therapy (JSDT) survey, the 1-year mortality rate was significantly

[30][31][26]

higher at facilities with a dialysis fluid endotoxin concentration of >0,100 EU/ml . Consequently,

it seemsseemed prudent to impose an upper limit on the endotoxin content of dialysis water and dialysis

fluid. A level of 2 EU/ml was chosen by AAMI in 2001 as the upper limit for endotoxin, since these levels

were easily achieved with contemporary water treatment systems using reverse osmosis, ultrafiltration, or

both. At the same time, the European Community chose to use 0,25 EU/ml as the maximum allowable level

of endotoxin in dialysis water. When ISO 13959 was revised in 2009, the 0,25 EU/ml limit for dialysis water

was included. In developingDuring the development of this document for dialysis fluid quality, the maximum

allowable level of endotoxin was set at 0,5 EU/ml analysed by the Limulus amebocyte lysate test. The level

is set higher than that for dialysis water in recognition that both the water and concentrates used in the

preparation of dialysis fluid can contribute endotoxins.

ISO 23500-5:redline:2024(en)

The level is set higher than that for dialysis water in recognition that both the water and concentrates used

in the preparation of dialysis fluid can contribute endotoxin.

In addition to the acute risk of pyrogenic reactions, there is increasing indirect evidence that chronic

exposure to low amounts of endotoxin mightcan play a role in some of the long-term complications of

haemodialysis therapy. Patients treated with ultrafilteredultrapure dialysis fluid have demonstrated a

decrease in serum β-microglobulin concentrations, a decrease in markers of an inflammatory response and

oxidant stress, and an increased responsiveness to erythropoietin. In longer term studies, use of ultrafiltered

dialysis fluid has been associated with a decreased incidence of β -microglobulin-associated amyloidosis,

better preservation of residual renal function, and, an improved nutritional status and a decline in renal

[27]-[29][14][17][25][32] to [44]

function .

These observations have led to the recommendation that dialysis fluid of a higher microbiological quality,

[45][29]

so-called “ultrapure” dialysis fluid, should be used for routine haemodialysis . Ultrapure dialysis fluid

is definedspecified as one having a bacterial content of less than 0,1 CFU/ml and an endotoxin content of less

[46]

than 0,03 EU/ml using sensitive assays . This definition is now widely accepted, particularly in Europe,

as the standard for dialysis fluid used to prepare substitution solution for online convective therapies. In

developing. During the development of this document, the desirability of using ultrapure dialysis fluid on a

routine basis was recognized, but it was accepted thatalthough obtaining this level of puritybacterial and

endotoxin content on a routine basis might not yet beis not always feasible in all dialysis settings.

As up to 7 d can elapse between sampling dialysis fluid for the determination of microbiological contamination

and the receipt of results depending on the analytical method used, and because bacterialmicrobial

proliferation can be rapid, action levels for microbial counts were introduced into this document. These

action levels allow the user to initiate corrective action before levels exceed the maximum levels established

byin this document.

In haemodialysis, the net movement of water is from the blood to the dialysis fluid, although within the

dialyser there can be movement of dialysis fluid to the blood due to the phenomenon of back-filtration,

[47]

particularly in dialysers with highly permeable membranes . In contrast, haemofiltration and

haemodiafiltration feature infusions of large volumes of electrolyte solution (20 l to more than 100 l) into the

blood. Increasingly, such solution is being prepared online from ultrapure dialysis fluid. The large volumes

of fluid infused in haemofiltration and haemodiafiltration, and concerns about the transfer of endotoxin and

endotoxin fragments across high-flux membranes, necessitate the use of such fluid to minimize patient risk.

A.2 Chemical contaminants in dialysis fluid

When this document was being developed, the need to include maximum levels for chemical contaminants in

dialysis fluid was discussed. It was proposed that the maximum allowable levels of chemical contaminants

in dialysis fluid should be the same as those in the water used to prepare the dialysis fluid since there

were no data supporting the need for lower levels. Dialysis fluid is prepared from water and concentrates,

meeting the requirements of ISO 23500-3:2019 and ISO 23500-4:2019, including the same requirements for

maximum levels of chemical contaminants that were proposed for inclusion in this document. Because the

water and concentrates are combined using individual dialysis machines or central dialysis fluid delivery

systems that are required to be constructed of materials that do not contribute chemical contaminants to

the dialysis fluid, it was concluded that including maximum allowable levels of chemical contaminants in the

dialysis fluid would be redundant and impose an unnecessary burden on dialysis facilities.

A.3 Tests for conformity with microbiological requirements

The original clinical observations showing a relationship between bacterial levels in dialysis fluid and

pyrogenic reactions were based on cultures performed with standard methods agar (SMA), a medium

[11]

containing relatively few nutrients . Later, the use of tryptic soy agar (TSA)TSA, a general-purpose

medium for isolating and cultivating fastidious organisms was recommended because it was thought more

appropriate for culturing bicarbonate-containing dialysis fluid.

Recommended methods for assaying fluid microbiological content are shown in Table 1. Such methods

provide only a relative indication of the bacterial bioburden rather than an absolute measure. Different media

...

Norme

internationale

ISO 23500-5

Deuxième édition

Préparation et management de la

2024-04

qualité des liquides d'hémodialyse

et de thérapies annexes —

Partie 5:

Qualité des liquides de dialyse

pour hémodialyse et thérapies

apparentées

Preparation and quality management of fluids for haemodialysis

and related therapies —

Part 5: Quality of dialysis fluid for haemodialysis and related

therapies

Numéro de référence

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2024

Tous droits réservés. Sauf prescription différente ou nécessité dans le contexte de sa mise en œuvre, aucune partie de cette

publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique,

y compris la photocopie, ou la diffusion sur l’internet ou sur un intranet, sans autorisation écrite préalable. Une autorisation peut

être demandée à l’ISO à l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Case postale 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Genève

Tél.: +41 22 749 01 11

E-mail: copyright@iso.org

Web: www.iso.org

Publié en Suisse

ii

Sommaire Page

Avant-propos .iv

Introduction .v

1 Domaine d’application . 1

2 Références normatives . 1

3 Termes et définitions . 2

4 Exigences . 2

4.1 Contaminants microbiologiques dans le liquide de dialyse .2

4.1.1 Généralités .2

4.1.2 Exigences microbiologiques relatives au liquide de dialyse standard .2

4.1.3 Exigences microbiologiques relatives au liquide de dialyse ultrapur .2

4.1.4 Exigences microbiologiques relatives au liquide de substitution préparé en ligne .3

4.2 Composition chimique du liquide de dialyse .3

4.3 Contaminants chimiques présents dans le liquide de dialyse.3

5 Essais de conformité . 3

5.1 Exigences microbiologiques .3

5.1.1 Échantillonnage.3

5.1.2 Méthodes de culture .4

5.2 Exigences chimiques .5

Annexe A (informative) Justification de l’élaboration et des dispositions du présent document . 6

Annexe B (informative) Tableaux de référence .10

Bibliographie .12

iii

Avant-propos

L'ISO (Organisation internationale de normalisation) est une fédération mondiale d'organismes nationaux

de normalisation (comités membres de l'ISO). L'élaboration des Normes internationales est en général

confiée aux comités techniques de l'ISO. Chaque comité membre intéressé par une étude a le droit de faire

partie du comité technique créé à cet effet. Les organisations internationales, gouvernementales et non

gouvernementales, en liaison avec l'ISO participent également aux travaux. L'ISO collabore étroitement avec

la Commission électrotechnique internationale (IEC) en ce qui concerne la normalisation électrotechnique.

Les procédures utilisées pour élaborer le présent document et celles destinées à sa mise à jour sont

décrites dans les Directives ISO/IEC, Partie 1. Il convient, en particulier, de prendre note des différents

critères d'approbation requis pour les différents types de documents ISO. Le présent document a

été rédigé conformément aux règles de rédaction données dans les Directives ISO/IEC, Partie 2 (voir

www.iso.org/directives).

L’ISO attire l’attention sur le fait que la mise en application du présent document peut entraîner l’utilisation

d’un ou de plusieurs brevets. L’ISO ne prend pas position quant à la preuve, à la validité et à l’applicabilité de

tout droit de brevet revendiqué à cet égard. À la date de publication du présent document, l’ISO n'avait pas