ISO/IEC 26580:2021

(Main)Software and systems engineering — Methods and tools for the feature-based approach to software and systems product line engineering

Software and systems engineering — Methods and tools for the feature-based approach to software and systems product line engineering

This document is a specialization of the more general reference model for software and systems product line engineering and management described in ISO/IEC 26550. The specialization defined herein addresses a class of methods and tools referred to as feature-based software and systems product line engineering, or feature-based PLE, which has emerged as a proven and repeatable product line engineering and management (PLE) practice supported by commercial tool providers. This document: — provides the terms and definitions specific to feature-based PLE; — defines how feature-based PLE is a specialization within the general ISO/IEC 26550 reference model for product line engineering and management; — defines a reference model for the overall structure and processes of feature-based PLE and describes how the elements of the reference model fit together; — defines interrelationships and methods for applying the elements and tools of the product line reference model; — defines required and supporting tool capabilities. In this document, products of feature-based PLE include digital work products that support the engineering of a system. Some of the artefacts are actually part of the delivered products, while other artefacts can be non-deliverable, such as physical or digital design models. The intended audience for this document comprises: — technology providers who wish to provide automated tool support for the reference model and processes described in this document; — champions within an organization who wish to introduce feature-based PLE throughout that organization; — IT staff within a PLE organization who will introduce and maintain the necessary technology to support feature-based PLE; — practitioner stakeholders who will use the provided technology to practice feature-based PLE; — technical and business managers who will sponsor and direct the methods necessary to practice feature-based PLE; — university professors, researchers, corporate trainers, and other educators who will create and share pedagogical materials about feature-based PLE and its benefits.

Ingénierie du logiciel et des systèmes — Méthodes et outils pour l'approche basée sur les caractéristiques dans l'ingénierie de lignes de produits logiciels et systèmes

General Information

- Status

- Published

- Publication Date

- 20-Apr-2021

- Technical Committee

- ISO/IEC JTC 1/SC 7 - Software and systems engineering

- Drafting Committee

- ISO/IEC JTC 1/SC 7/WG 4 - Tools and environment

- Current Stage

- 6060 - International Standard published

- Start Date

- 21-Apr-2021

- Due Date

- 11-Jun-2022

- Completion Date

- 21-Apr-2021

Overview

ISO/IEC 26580:2021 provides a feature-based specialization of the ISO/IEC 26550 reference model for software and systems product line engineering (PLE). It standardizes terms, a reference model, process structure, and required tool capabilities for feature-based PLE - a widely adopted, repeatable approach supported by commercial tool vendors. The standard covers the organization of feature catalogues, bill-of-features portfolios, shared asset supersets, PLE factory configurators, and automated production of product asset instances (digital and non‑deliverable artefacts).

Key technical topics and requirements

- Terminology and definitions: Establishes consistent vocabulary specific to feature-based product line engineering (features, feature catalogue, bill-of-features, etc.).

- Reference model: Defines how feature-based PLE fits as a specialization of ISO/IEC 26550 and describes the overall structure, layers, and how elements interrelate.

- Core elements of the PLE factory:

- Feature catalogue and feature language

- Bill-of-features and portfolios

- Shared asset supersets and product asset instances

- PLE factory configurator and automated configuration processes

- Technology and management layers: Specifies expectations for the technology layer (tool support, feature language, configurator) and the technical organization management layer (engineering tasks, configuration, traceability, change management, verification and validation).

- Tool capabilities: Defines required and supporting tool capabilities for automation, configuration management, traceability, and delivery of product instances.

- Cross-cutting concerns: Addresses configuration management, traceability, change management, access control, and hierarchical product-of-product-line support.

Practical applications and who uses this standard

ISO/IEC 26580 is practical for organizations and practitioners implementing or scaling feature-based PLE to produce configurable systems efficiently:

- Technology providers & tool vendors building PLE automation, feature modelling, or configurator tools.

- Enterprise PLE champions planning organization-wide adoption of feature-based product line practices.

- IT and DevOps teams that deploy and maintain PLE toolchains and automated product generation pipelines.

- Practitioners and engineers who model features, create shared asset supersets, and generate product asset instances.

- Managers and decision-makers who oversee PLE governance, ROI, and process integration.

- Academics and trainers creating curricula or training on feature-based PLE and model-driven variability management.

Related standards

- ISO/IEC 26550 - General reference model for software and systems product line engineering and management (parent standard).

- ISO/IEC 26556 - Related technical management processes referenced by the standard.

Keywords: ISO/IEC 26580, feature-based PLE, product line engineering, feature catalogue, bill-of-features, PLE factory, shared asset supersets, configurator, configuration management, traceability, automated product generation.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

BSCIC Certifications Pvt. Ltd.

Established 2006, accredited by NABCB, JAS-ANZ, EIAC, IAS. CDSCO Notified Body.

Intertek India Pvt. Ltd.

Delivers Assurance, Testing, Inspection & Certification since 1993 with 26 labs and 32 offices.

Sponsored listings

Frequently Asked Questions

ISO/IEC 26580:2021 is a standard published by the International Organization for Standardization (ISO). Its full title is "Software and systems engineering — Methods and tools for the feature-based approach to software and systems product line engineering". This standard covers: This document is a specialization of the more general reference model for software and systems product line engineering and management described in ISO/IEC 26550. The specialization defined herein addresses a class of methods and tools referred to as feature-based software and systems product line engineering, or feature-based PLE, which has emerged as a proven and repeatable product line engineering and management (PLE) practice supported by commercial tool providers. This document: — provides the terms and definitions specific to feature-based PLE; — defines how feature-based PLE is a specialization within the general ISO/IEC 26550 reference model for product line engineering and management; — defines a reference model for the overall structure and processes of feature-based PLE and describes how the elements of the reference model fit together; — defines interrelationships and methods for applying the elements and tools of the product line reference model; — defines required and supporting tool capabilities. In this document, products of feature-based PLE include digital work products that support the engineering of a system. Some of the artefacts are actually part of the delivered products, while other artefacts can be non-deliverable, such as physical or digital design models. The intended audience for this document comprises: — technology providers who wish to provide automated tool support for the reference model and processes described in this document; — champions within an organization who wish to introduce feature-based PLE throughout that organization; — IT staff within a PLE organization who will introduce and maintain the necessary technology to support feature-based PLE; — practitioner stakeholders who will use the provided technology to practice feature-based PLE; — technical and business managers who will sponsor and direct the methods necessary to practice feature-based PLE; — university professors, researchers, corporate trainers, and other educators who will create and share pedagogical materials about feature-based PLE and its benefits.

This document is a specialization of the more general reference model for software and systems product line engineering and management described in ISO/IEC 26550. The specialization defined herein addresses a class of methods and tools referred to as feature-based software and systems product line engineering, or feature-based PLE, which has emerged as a proven and repeatable product line engineering and management (PLE) practice supported by commercial tool providers. This document: — provides the terms and definitions specific to feature-based PLE; — defines how feature-based PLE is a specialization within the general ISO/IEC 26550 reference model for product line engineering and management; — defines a reference model for the overall structure and processes of feature-based PLE and describes how the elements of the reference model fit together; — defines interrelationships and methods for applying the elements and tools of the product line reference model; — defines required and supporting tool capabilities. In this document, products of feature-based PLE include digital work products that support the engineering of a system. Some of the artefacts are actually part of the delivered products, while other artefacts can be non-deliverable, such as physical or digital design models. The intended audience for this document comprises: — technology providers who wish to provide automated tool support for the reference model and processes described in this document; — champions within an organization who wish to introduce feature-based PLE throughout that organization; — IT staff within a PLE organization who will introduce and maintain the necessary technology to support feature-based PLE; — practitioner stakeholders who will use the provided technology to practice feature-based PLE; — technical and business managers who will sponsor and direct the methods necessary to practice feature-based PLE; — university professors, researchers, corporate trainers, and other educators who will create and share pedagogical materials about feature-based PLE and its benefits.

ISO/IEC 26580:2021 is classified under the following ICS (International Classification for Standards) categories: 35.080 - Software. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 26580:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 26580

First edition

2021-04

Software and systems engineering —

Methods and tools for the feature-

based approach to software and

systems product line engineering

Ingénierie du logiciel et des systèmes — Méthodes et outils pour

l'approche basée sur les caractéristiques dans l'ingénierie de lignes de

produits logiciels et systèmes

Reference number

©

ISO/IEC 2021

© ISO/IEC 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO/IEC 2021 – All rights reserved

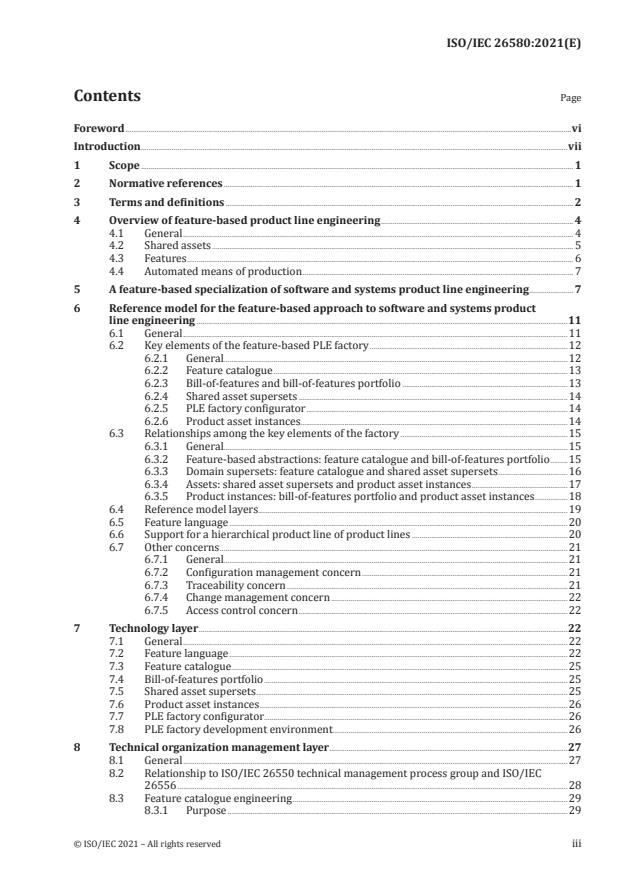

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Overview of feature-based product line engineering . 4

4.1 General . 4

4.2 Shared assets . 5

4.3 Features . 6

4.4 Automated means of production . 7

5 A feature-based specialization of software and systems product line engineering .7

6 Reference model for the feature-based approach to software and systems product

line engineering .11

6.1 General .11

6.2 Key elements of the feature-based PLE factory .12

6.2.1 General.12

6.2.2 Feature catalogue .13

6.2.3 Bill-of-features and bill-of-features portfolio .13

6.2.4 Shared asset supersets .14

6.2.5 PLE factory configurator .14

6.2.6 Product asset instances . .14

6.3 Relationships among the key elements of the factory .15

6.3.1 General.15

6.3.2 Feature-based abstractions: feature catalogue and bill-of-features portfolio .15

6.3.3 Domain supersets: feature catalogue and shared asset supersets .16

6.3.4 Assets: shared asset supersets and product asset instances .17

6.3.5 Product instances: bill-of-features portfolio and product asset instances .18

6.4 Reference model layers .19

6.5 Feature language .20

6.6 Support for a hierarchical product line of product lines .20

6.7 Other concerns .21

6.7.1 General.21

6.7.2 Configuration management concern .21

6.7.3 Traceability concern .21

6.7.4 Change management concern .22

6.7.5 Access control concern .22

7 Technology layer .22

7.1 General .22

7.2 Feature language .22

7.3 Feature catalogue .25

7.4 Bill-of-features portfolio .25

7.5 Shared asset supersets .25

7.6 Product asset instances .26

7.7 PLE factory configurator.26

7.8 PLE factory development environment .26

8 Technical organization management layer .27

8.1 General .27

8.2 Relationship to ISO/IEC 26550 technical management process group and ISO/IEC

26556 .28

8.3 Feature catalogue engineering .29

8.3.1 Purpose .29

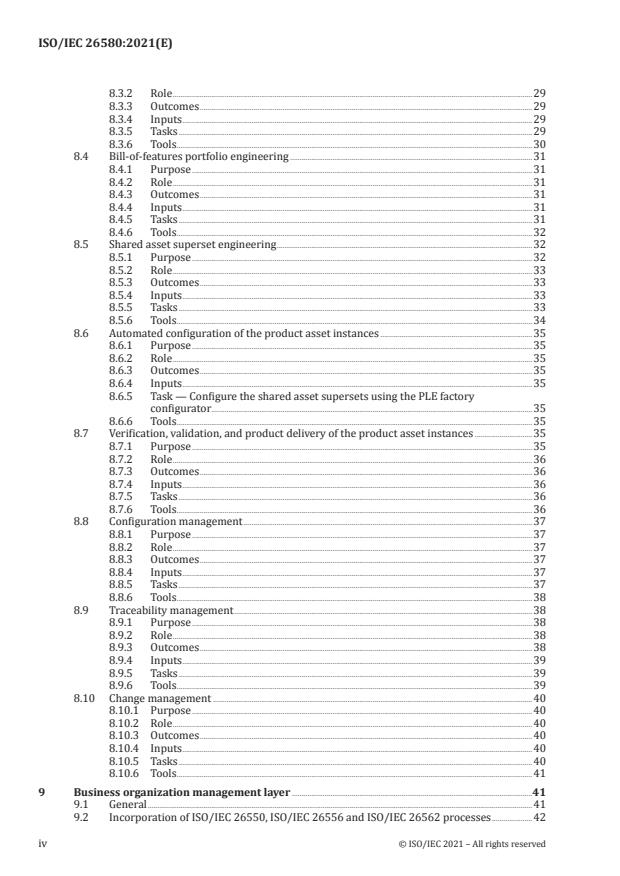

© ISO/IEC 2021 – All rights reserved iii

8.3.2 Role .29

8.3.3 Outcomes .29

8.3.4 Inputs .29

8.3.5 Tasks .29

8.3.6 Tools .30

8.4 Bill-of-features portfolio engineering .31

8.4.1 Purpose .31

8.4.2 Role .31

8.4.3 Outcomes .31

8.4.4 Inputs .31

8.4.5 Tasks .31

8.4.6 Tools .32

8.5 Shared asset superset engineering .32

8.5.1 Purpose .32

8.5.2 Role .33

8.5.3 Outcomes .33

8.5.4 Inputs .33

8.5.5 Tasks .33

8.5.6 Tools .34

8.6 Automated configuration of the product asset instances .35

8.6.1 Purpose .35

8.6.2 Role .35

8.6.3 Outcomes .35

8.6.4 Inputs .35

8.6.5 Task — Configure the shared asset supersets using the PLE factory

configurator.35

8.6.6 Tools .35

8.7 Verification, validation, and product delivery of the product asset instances .35

8.7.1 Purpose .35

8.7.2 Role .36

8.7.3 Outcomes .36

8.7.4 Inputs .36

8.7.5 Tasks .36

8.7.6 Tools .36

8.8 Configuration management .37

8.8.1 Purpose .37

8.8.2 Role .37

8.8.3 Outcomes .37

8.8.4 Inputs .37

8.8.5 Tasks .37

8.8.6 Tools .38

8.9 Traceability management .38

8.9.1 Purpose .38

8.9.2 Role .38

8.9.3 Outcomes .38

8.9.4 Inputs .39

8.9.5 Tasks .39

8.9.6 Tools .39

8.10 Change management .40

8.10.1 Purpose .40

8.10.2 Role .40

8.10.3 Outcomes .40

8.10.4 Inputs .40

8.10.5 Tasks .40

8.10.6 Tools .41

9 Business organization management layer .41

9.1 General .41

9.2 Incorporation of ISO/IEC 26550, ISO/IEC 26556 and ISO/IEC 26562 processes .42

iv © ISO/IEC 2021 – All rights reserved

9.3 Fund the PLE factory .44

9.3.1 Purpose .44

9.3.2 Outcomes .44

9.3.3 Inputs .44

9.3.4 Task — Establish and execute a funding policy for the PLE factory .44

9.3.5 Tools .45

Annex A (informative) Terminology specialization from ISO/IEC 26550 to this document .46

Annex B (informative) UML 2.0 Diagrams for the feature-based PLE factory .50

Bibliography .51

© ISO/IEC 2021 – All rights reserved v

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that

are members of ISO or IEC participate in the development of International Standards through

technical committees established by the respective organization to deal with particular fields of

technical activity. ISO and IEC technical committees collaborate in fields of mutual interest. Other

international organizations, governmental and non-governmental, in liaison with ISO and IEC, also

take part in the work.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for

the different types of document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives or www .iec .ch/ members

_experts/ refdocs).

Attention is drawn to the possibility that some of the elements of this document may be the subject

of patent rights. ISO and IEC shall not be held responsible for identifying any or all such patent

rights. Details of any patent rights identified during the development of the document will be in the

Introduction and/or on the ISO list of patent declarations received (see www .iso .org/ patents) or the IEC

list of patent declarations received (see patents.iec.ch).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso .org/

iso/ foreword .html. In the IEC, see www .iec .ch/ understanding -standards.

This document was prepared by Joint Technical Committee ISO/IEC JTC 1, Information technology,

Subcommittee SC 7, Software and systems engineering.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html and www .iec .ch/ national

-committees.

vi © ISO/IEC 2021 – All rights reserved

Introduction

Feature-based software and systems product line engineering (“feature-based PLE” for short) is

a specialization of software and systems product line (SSPL) engineering and management that is

described in ISO/IEC 26550. ISO/IEC 26550 describes a very generalized approach to SSPL, focusing on

the benefits of exploiting a common platform of reusable assets for a product family. Each organization

that adopts SSPL under ISO/IEC 26550 is free to do so using their preferred techniques and methods.

What is the motivation for creating a standard for a specialization of SSPL? As the SSPL field has

matured and achieved widespread attention in the industry, a specific and repeatable approach to SSPL

has emerged that takes advantage of commercial off-the-shelf industrial-strength tools and technology,

along with robust best practices for methods and processes, that automate and formalize many of the

processes in domain and application engineering. The result is that less upfront analysis, design, and

implementation effort is required prior to gaining the benefits from the approach.

While SSPL in general provides significant benefits, it also requires a significant investment of time and

effort to adopt and to ultimately achieve those benefits. The feature-based PLE specialization is a more

narrowly defined solution that can be supported by off-the-shelf tools and methods, which has resulted

in lower investments when an organization adopts SSPL. Feature-based PLE embodies lessons learned

about SSPL practices that have been shown to provide some of the highest benefits and returns (see, for

example, References [2] and[8]).

This document provides a reference model consisting of an abstract representation of the key technical

elements, tools, and methods of feature-based PLE. The predominant specializations of general SSPL

that characterize feature-based PLE are:

a) a mapping from features to asset variation points that is sufficient to drive a fully automated

configurator that produces assets specific to member products;

b) a methodological shift of all design and implementation effort, change management, and

configuration management to domain engineering, so that application engineering is reduced to

automated configuration of member product instances and testing of configured member products

and member-product-specific assets.

This document embodies a distinct separation of concerns between the feature-based PLE technology

providers and feature-based technology users. For each of these stakeholder concerns, the scope of this

document is to define only what is necessary and sufficient to enable feature-based PLE practice. For

technology providers, this imparts flexibility in how the necessary and sufficient technical capabilities

are provided, as well as the opportunity to offer more expansive capabilities that are possible in an

ideal solution. For technology users, this provides flexibility to select among the technology providers

and to apply the methods that best match their technical and business objectives for feature-based PLE.

© ISO/IEC 2021 – All rights reserved vii

INTERNATIONAL STANDARD ISO/IEC 26580:2021(E)

Software and systems engineering — Methods and tools

for the feature-based approach to software and systems

product line engineering

1 Scope

This document is a specialization of the more general reference model for software and systems

product line engineering and management described in ISO/IEC 26550. The specialization defined

herein addresses a class of methods and tools referred to as feature-based software and systems

product line engineering, or feature-based PLE, which has emerged as a proven and repeatable product

line engineering and management (PLE) practice supported by commercial tool providers.

This document:

— provides the terms and definitions specific to feature-based PLE;

— defines how feature-based PLE is a specialization within the general ISO/IEC 26550 reference model

for product line engineering and management;

— defines a reference model for the overall structure and processes of feature-based PLE and describes

how the elements of the reference model fit together;

— defines interrelationships and methods for applying the elements and tools of the product line

reference model;

— defines required and supporting tool capabilities.

In this document, products of feature-based PLE include digital work products that support the

engineering of a system. Some of the artefacts are actually part of the delivered products, while other

artefacts can be non-deliverable, such as physical or digital design models.

The intended audience for this document comprises:

— technology providers who wish to provide automated tool support for the reference model and

processes described in this document;

— champions within an organization who wish to introduce feature-based PLE throughout that

organization;

— IT staff within a PLE organization who will introduce and maintain the necessary technology to

support feature-based PLE;

— practitioner stakeholders who will use the provided technology to practice feature-based PLE;

— technical and business managers who will sponsor and direct the methods necessary to practice

feature-based PLE;

— university professors, researchers, corporate trainers, and other educators who will create and

share pedagogical materials about feature-based PLE and its benefits.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

© ISO/IEC 2021 – All rights reserved 1

ISO/IEC/IEEE 12207, Systems and software engineering — Software life cycle processes

ISO/IEC/IEEE 15288, Systems and software engineering — System life cycle processes

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO/IEC/IEEE 12207,

ISO/IEC/IEEE 15288, and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

NOTE 1 For additional terms and definitions in the field of systems and software engineering, see

ISO/IEC/IEEE 24765, which is published periodically as a “snapshot” of the SEVOCAB (Systems and software

engineering – Vocabulary) database and is publicly accessible at www .computer .org/ sevocab.

NOTE 2 Because feature-based PLE is a specialization of the more general product line engineering approach

described in ISO/IEC 26550, some of the terminology used herein is noted as a specialization of the terminology

from ISO/IEC 26550, with further details provided in Annex A.

3.1

bill-of-features

specification for a member product (3.8) in the product line (3.16), rendered in terms of the specific

features (3.4) from the feature catalogue (3.5) that are chosen for that member product

3.2

bill-of-features portfolio

collection comprising the bill-of-features (3.1) for each member product (3.8) in a product line (3.16)

3.3

domain supersets

collection comprising the feature catalogue (3.5) and shared asset supersets (3.18)

3.4

feature

characteristic of a member product (3.8) in a product line (3.16) that distinguishes it from other member

products in the product line

Note 1 to entry: Features can a) express the customer-visible or end-user-visible variability among the member

products in a product line, or b) distinguish implementation variability not directly visible to a customer or end

user except through non-functional differences such as price, performance, noise, weight, energy and more.

Note 2 to entry: In feature-based PLE, features express differences among member products. A capability or

other characteristic common to all member products in the product line is not modelled as a feature.

Note 3 to entry: See Annex A for the definition of this term in ISO/IEC 26550.

3.5

feature catalogue

model of the collection of all the feature (3.4) options and feature constraints (3.6) available across the

entire product line (3.16)

3.6

feature constraint

formal relationship between two or more features (3.4) that is necessarily satisfied for all member

products (3.8)

2 © ISO/IEC 2021 – All rights reserved

3.7

feature language

syntax and semantics for the formal representation, structural taxonomy, and relationships among the

concepts and constructs in the feature catalogue (3.5), bill-of-features portfolio (3.2), and shared asset

superset (3.18) variation points (3.20)

3.8

member product

product belonging to the product line (3.16)

[SOURCE: ISO/IEC 26550:2015, 3.15, modified — The preferred term "application" has been removed.]

3.9

mutually exclusive

alternatives from which at most one is selected

3.10

mutually inclusive

alternatives from which zero or more are selected

3.11

PLE factory

technological, organizational, and business infrastructure and processes to support a PLE factory

configurator (3.12) producing product asset instances (3.14) from shared asset supersets (3.18) based on

a bill-of-features (3.1) for a member product (3.8)

3.12

PLE factory configurator

automated mechanism that produces assets for a specific member product (3.8) by processing the bill-

of-features (3.1) for that member product, and exercising the shared assets’ (3.17) variation points (3.20)

in light of the feature (3.4) selections made in that bill-of-features

3.13

PLE factory development environment

toolset for creating, organizing, assembling, and maintaining a collection of elements in a feature

catalogue (3.5), bill-of-features portfolio (3.2), shared asset supersets (3.18), and a hierarchy of a product

line (3.16) of product lines

3.14

product asset instance

instantiation of a shared asset (3.17) specific to a member product (3.8), automatically produced by the

PLE factory configurator (3.12), corresponding to a bill-of-features (3.1) for that member product

Note 1 to entry: A product asset instance is analogous to an application asset (ISO/IEC 26550) with the proviso

that it is produced by the PLE factory configurator.

3.15

product instances

collection comprising the bill-of-features portfolio (3.2) and product asset instances (3.14)

3.16

product line

family of similar products with variations in features (3.4)

Note 1 to entry: See Annex A for the definition of this term in ISO/IEC 26550.

3.17

shared asset

software and systems engineering lifecycle digital artefacts that compose a part of a delivered member

product (3.8) or support the engineering process to create and maintain a member product

Note 1 to entry: A shared asset is analogous to a domain asset (ISO/IEC 26550).

© ISO/IEC 2021 – All rights reserved 3

Note 2 to entry: Typical shared assets are requirements, design specifications or models for mechanical, electrical,

and software, source code, build files or scripts, test plans and test cases, user documentation, repair manuals

and installation guides, project budgets, schedules, and work plans, product calibration and configuration files,

mechanical bills-of-materials, electrical circuit board and wiring harness designs, engineering management

plans, engineering drawings, training plans and training materials, skill set requirements, manufacturing plans

and instructions, and shipping manifests.

3.18

shared asset superset

representation of a shared asset (3.17) that includes all content needed by any of the member products (3.8)

3.19

variant

alternative that can be used to realize a particular variation point (3.20)

[SOURCE: ISO/IEC 26550:2015, 3.28, modified — the word "one" at the beginning of the definition has

been removed; "may" has been changed to "can"; "particular variation points" has been changed to "a

particular variation point"; note 1 to entry has been removed.]

3.20

variation point

identification of a specific piece of shared asset superset (3.18) content and a mapping from feature (3.4)

selection(s) to the form of that content that appears in a product asset instance (3.14)

Note 1 to entry: In this document, all features express characteristics that differ among member products (3.8),

which according to ISO/IEC 26550 would also make every feature a variation point. To avoid this redundancy,

this document does not call out features as variation points.

Note 2 to entry: See Annex A for the definition of this term in ISO/IEC 26550. The definition in this document is

more specific to feature-based PLE and the PLE factory configurator (3.12) approach of producing product asset

instances from shared asset supersets.

4 Overview of feature-based product line engineering

4.1 General

This clause gives a brief informational overview of feature-based product line engineering, as a way

of introducing key concepts that are important for understanding the purpose and content of this

document.

Software and systems product line engineering emerged some time ago as way to engineer a portfolio

of related products in an efficient manner, taking full advantage of the products’ similarities while

respecting and managing their differences. Here “engineer” means all of the activities involved in

planning, producing, delivering, deploying, sustaining, and retiring products. Born in the software

engineering field in the 1970s and 1980s and based largely on the concept of software reuse, PLE has

long been known for delivering significant improvements in development time, cost, and quality of

[1]

products in a product line .

Early attempts to capture and codify best practices recognized a dichotomy between two sides: product

content that applies to multiple products and product content specific to a single product. Some referred

to the two sides as domain engineering and application engineering, respectively, while others referred

[1]

to core asset development vs. product development . Application engineering was often said to include

creating any content that happened to be used only in a single product, and promoting that content to

domain status only if subsequently used in more. Application engineering included the obligation to

choose and carry out a production strategy – that is, a way to turn the shared assets into products –

that was potentially different for each type of shared asset, and was often manual and therefore labour-

intensive and error-prone. Whatever they were called, the two sides stood on roughly equal footing in

terms of the effort required to execute.

4 © ISO/IEC 2021 – All rights reserved

However, starting in the early 2000s, the advent of industrial-strength and commercially available

technology designed specifically to support PLE enabled the rapid emergence of a specialization of PLE

[5]

practices. This approach is called feature-based software and systems product line engineering .

Under this approach, the technology just mentioned allows application engineering, which was so

important under the “classic” PLE approach, to shrink to almost nothing. Products are produced through

the use of high-end industrial-strength automation that configures the shared assets appropriately

for each product. Feature-based PLE explicitly declines to configuration-manage or change-manage

product versions. Instead, the shared assets (and not the individual products or systems) are managed

under CM (configuration management). A new version of a product is not derived from a previous

version of the same product, but from the shared asset supersets themselves. Additionally, any defects

are fixed in the shared assets, not the products. The affected products will then be regenerated, into

a form suitable for testing and deployment. Since regeneration has a low and fixed cost, it matters

very little whether 2 or 200 or 2000 products need to be regenerated. Thus, fixing a defect, making a

systematic enhancement, or carrying out any other kind of multi-product change becomes much more

[4]

economical .

4.2 to 4.4 describe a few more of the key ways that feature-based PLE differs from its antecedents.

4.2 Shared assets

Shared assets are the “soft” artefacts associated with the engineering lifecycle of the products,

the building blocks of the products in the product line. Assets can be whatever artefacts that are

representable digitally and either compose a product or support the engineering process to create a

product. Examples include, but are not limited to, the following:

— requirements;

— design specifications and design models for mechanical, electrical, and software;

— software source code and build files;

— test plans and test cases;

— user documentation, repair manuals, and installation guides;

— project budgets, schedules, and work plans;

— product calibration and configuration files;

— data models;

— process descriptions;

— parts lists and mechanical bills-of-materials;

— engineering drawings;

— electrical circuit board and wiring harness designs;

— training plans and training materials;

— skill set requirements;

— manufacturing plans and instructions;

— shipping manifests;

— marketing brochures;

— product descriptions;

— contract proposals.

© ISO/IEC 2021 – All rights reserved 5

Shared assets are engineered to be used (shared) across the product line. All of this was true before,

but in feature-based PLE, shared assets take the form of supersets, meaning that any asset content used

in any product is included. For example, a shared asset of requirements contains all of the requirements

across the product line; a shared asset of computer software source code contains all of the source

code; and so forth.

The virtue of this approach is that every piece of content for the product line, no matter in which

products it is used, is only created, stored, and maintained once. There is no duplication or replication

of asset content at all. This elimination of duplication (and elimination of replication of work across

[5]

duplicates) is where feature-based PLE derives its savings .

The shared asset supersets include variation points, which are places in the asset that denote content

that is configured according to the feature selections made for the product being built. When a product

is built, a statement of the product’s distinguishing characteristics – its features – is applied to “exercise”

these variation points (that is, cause the content associated with each variation point to be configured

in a way to meet the needs of the product).

Co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...