IEC 61755-3-31:2015

(Main)Fibre optic interconnecting devices and passive components - Connector optical interfaces - Part 3-31: Connector parameters of non-dispersion shifted single mode physically contacting fibres - Angled polyphenylene sulphide rectangular ferrules

Fibre optic interconnecting devices and passive components - Connector optical interfaces - Part 3-31: Connector parameters of non-dispersion shifted single mode physically contacting fibres - Angled polyphenylene sulphide rectangular ferrules

IEC 61755-3-31:2015 defines certain dimensional limits of an angled PC rectangular polyphenylene sulphide (PPS) ferrule optical interface in order to meet specific requirements for fibre-to-fibre interconnection. Ferrules made from the material specified in this standard are suitable for use in categories C, U, E, and O as defined in IEC 61753-1. Ferrule interface dimensions and features are contained in the IEC 61754 series, which deals with fibre optic connector interfaces. Keywords: dimensional limits of an angled PC rectangular polyphenylene sulphide (PPS) ferrule optical interface, fibre-to-fibre interconnection

Dispositifs d'interconnexion et composants passifs à fibres optiques - Interfaces optiques de connecteurs - Partie 3-31: Paramètres de connecteurs pour fibres unimodales à dispersion non décalée, en contact physique - Férules rectangulaires avec angle en poly(sulfure de phénylène)

L'IEC 61755-3-31:2015 définit un certain nombre de limites dimensionnelles des interfaces optiques à férules rectangulaires en poly(sulfure de phénylène) (PPS), PC avec angle afin de satisfaire aux exigences particulières d'une interconnexion fibre à fibre. Les férules réalisées dans le matériau spécifié dans la présente norme sont adaptées à une utilisation dans les catégories C, U, E et O définies dans l'IEC 61753-1. Les dimensions et les caractéristiques des interfaces des férules sont contenues dans la série IEC 61754 qui traite des interfaces de connecteurs pour fibres optiques. Mots clés: limites dimensionnelles des interfaces optiques à férules rectangulaires en poly(sulfure de phénylène) (PPS), PC avec angle afin, interconnexion fibre à fibre

General Information

- Status

- Published

- Publication Date

- 11-Jun-2015

- Technical Committee

- SC 86B - Fibre optic interconnecting devices and passive components

- Current Stage

- PPUB - Publication issued

- Start Date

- 12-Jun-2015

- Completion Date

- 30-Jun-2015

Relations

- Effective Date

- 09-Feb-2026

Overview

IEC 61755-3-31:2015 is an internationally recognized standard published by the International Electrotechnical Commission (IEC). This standard defines the dimensional limits and key parameters of angled physically contacting (PC) rectangular ferrule optical interfaces made from polyphenylene sulphide (PPS) material. It specifically applies to non-dispersion shifted single mode fibre optic connectors used in fibre-to-fibre interconnection systems. The standard supports the reliable and precise alignment necessary to maintain high-performance optical communications.

As part of the IEC 61755 series, IEC 61755-3-31 addresses the detailed connector parameters essential for ensuring compatibility, optical performance, and mechanical robustness in fibre optic networks. This standard complements the IEC 61754 series, which specifies ferrule interface dimensions and features for fibre optic connectors.

Key Topics

- Angled Polyphenylene Sulphide (PPS) Rectangular Ferrules: Defines the material specifications and design parameters for angled PPS ferrules to optimize physical contact and minimize back reflections in single mode fibre interfaces.

- Dimensional Limits: Establishes precise tolerances related to lateral and angular offsets, longitudinal positioning, and end-face geometry to ensure optimal fibre alignment and connection quality.

- Optical Interface Variants: Covers multiple interface variants (e.g., 1002, 1104, 1108, 1112), detailing their respective dimensional requirements for various fibre counts and connector designs.

- Physical Contact and Fibre Alignment: Includes parameters to achieve stable physical contact between fibres, essential for minimizing insertion loss and return loss in optical connections.

- Compliance with Fibre Categories: Specifies suitability for categories C, U, E, and O as described in IEC 61753-1, ensuring compatibility with various fibre classifications used in telecommunications and data networks.

- Testing and Measurement Methods: References relevant IEC normative documents for testing fibre position, polish angle, alignment pin deformation, and other critical connector interface properties.

Applications

IEC 61755-3-31:2015 applies primarily to the design, manufacturing, and quality control of fibre optic connectors that utilize angled PPS rectangular ferrules with non-dispersion shifted single mode fibres. Key practical applications include:

- Telecommunications Networks: Ensures low-loss, reliable fibre interconnection in long-haul and metro optical links.

- Data Centers and High-Speed Networks: Supports high-density multi-fibre connectors with stringent alignment requirements for minimal signal degradation.

- Passive Optical Networks (PONs): Enables consistent connector performance critical for subscriber-side fibre optics.

- Optical Test Equipment: Provides standardized interface parameters that facilitate accurate testing and measurement of fibre optic components.

- Military and Aerospace Communications: Enhances connector durability and performance under challenging environmental conditions.

By standardizing ferrule dimensions and interface parameters, IEC 61755-3-31 enables interoperability among manufacturers, reduces insertion loss and reflection issues, and supports the fast deployment of fiber optic communication systems worldwide.

Related Standards

- IEC 61755 Series: General series covering fibre optic connector optical interfaces and connector parameters for various fibre types.

- IEC 61754 Series: Defines fibre optic connector interfaces for different connector families such as MT, MPO, Mini-MPO, and MT-RJ connectors.

- IEC 61300 Series: Describes test and measurement procedures for fibre optic interconnecting devices, including polish angle and fibre position measurements.

- IEC 61753-1: Specifies performance categories (C, U, E, O) for fibre optic components, applicable in categorizing devices using IEC 61755-3-31 defined ferrules.

- IEC 60793-2-50: Covers product specifications for class B single mode optical fibres, relevant for non-dispersion shifted fibres.

- IEC 61300-3-52: Provides guidelines on alignment pin deformation constants for angled PC rectangular ferrules.

Conclusion

IEC 61755-3-31:2015 is critical for manufacturers and users of fibre optic connectors that employ angled PPS rectangular ferrules, ensuring they meet stringent dimensional and performance requirements for non-dispersion shifted single mode fibres. This fosters high-quality fibre-to-fibre interconnections with low optical loss and high reliability, crucial in advanced telecom, data communication, and high-performance network environments. Adhering to this standard helps maintain global interoperability and consistent connector quality in fibre optic systems.

IEC 61755-3-31:2015 - Fibre optic interconnecting devices and passive components - Connector optical interfaces - Part 3-31: Connector parameters of non-dispersion shifted single mode physically contacting fibres - Angled polyphenylene sulphide rectangular ferrules

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 61755-3-31:2015 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fibre optic interconnecting devices and passive components - Connector optical interfaces - Part 3-31: Connector parameters of non-dispersion shifted single mode physically contacting fibres - Angled polyphenylene sulphide rectangular ferrules". This standard covers: IEC 61755-3-31:2015 defines certain dimensional limits of an angled PC rectangular polyphenylene sulphide (PPS) ferrule optical interface in order to meet specific requirements for fibre-to-fibre interconnection. Ferrules made from the material specified in this standard are suitable for use in categories C, U, E, and O as defined in IEC 61753-1. Ferrule interface dimensions and features are contained in the IEC 61754 series, which deals with fibre optic connector interfaces. Keywords: dimensional limits of an angled PC rectangular polyphenylene sulphide (PPS) ferrule optical interface, fibre-to-fibre interconnection

IEC 61755-3-31:2015 defines certain dimensional limits of an angled PC rectangular polyphenylene sulphide (PPS) ferrule optical interface in order to meet specific requirements for fibre-to-fibre interconnection. Ferrules made from the material specified in this standard are suitable for use in categories C, U, E, and O as defined in IEC 61753-1. Ferrule interface dimensions and features are contained in the IEC 61754 series, which deals with fibre optic connector interfaces. Keywords: dimensional limits of an angled PC rectangular polyphenylene sulphide (PPS) ferrule optical interface, fibre-to-fibre interconnection

IEC 61755-3-31:2015 is classified under the following ICS (International Classification for Standards) categories: 33.180.20 - Fibre optic interconnecting devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61755-3-31:2015 has the following relationships with other standards: It is inter standard links to EN 16603-50-11:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61755-3-31:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61755-3-31 ®

Edition 1.0 2015-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Fibre optic interconnecting devices and passive components – Connector

optical interfaces –

Part 3-31: Connector parameters of non-dispersion shifted single mode

physically contacting fibres – Angled polyphenylene sulphide rectangular

ferrules

Dispositifs d’interconnexion et composants passifs à fibres optiques –

Interfaces optiques de connecteurs –

Partie 3-31: Paramètres de connecteurs pour fibres unimodales à dispersion

non décalée, en contact physique – Férules rectangulaires avec angle en

poly(sulfure de phénylène)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

15 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC Plus de 60 000 entrées terminologiques électrotechniques, en

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61755-3-31 ®

Edition 1.0 2015-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Fibre optic interconnecting devices and passive components – Connector

optical interfaces –

Part 3-31: Connector parameters of non-dispersion shifted single mode

physically contacting fibres – Angled polyphenylene sulphide rectangular

ferrules

Dispositifs d’interconnexion et composants passifs à fibres optiques –

Interfaces optiques de connecteurs –

Partie 3-31: Paramètres de connecteurs pour fibres unimodales à dispersion

non décalée, en contact physique – Férules rectangulaires avec angle en

poly(sulfure de phénylène)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 33.180.20 ISBN 978-2-8322-2712-1

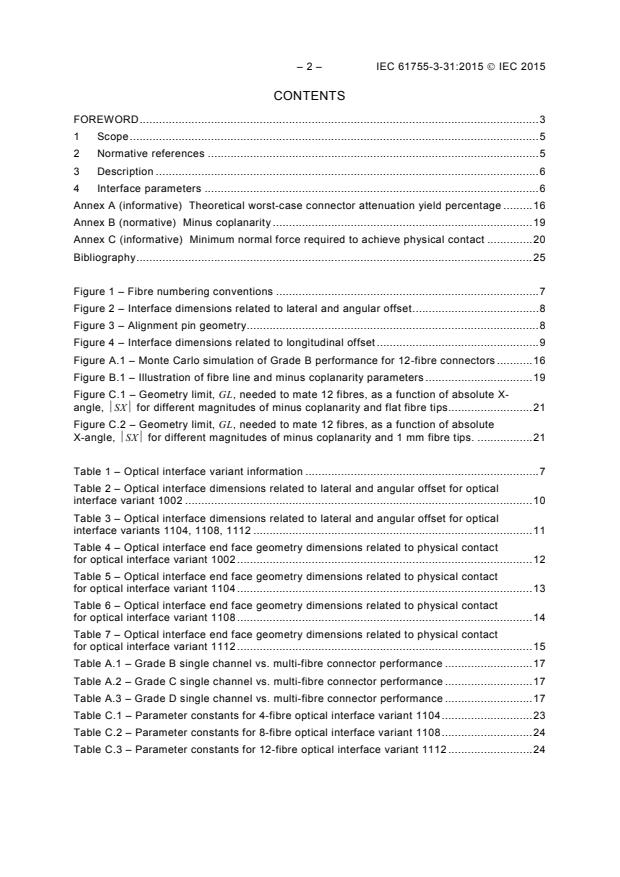

– 2 – IEC 61755-3-31:2015 IEC 2015

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Description . 6

4 Interface parameters . 6

Annex A (informative) Theoretical worst-case connector attenuation yield percentage . 16

Annex B (normative) Minus coplanarity . 19

Annex C (informative) Minimum normal force required to achieve physical contact . 20

Bibliography . 25

Figure 1 – Fibre numbering conventions . 7

Figure 2 – Interface dimensions related to lateral and angular offset . 8

Figure 3 – Alignment pin geometry . 8

Figure 4 – Interface dimensions related to longitudinal offset . 9

Figure A.1 – Monte Carlo simulation of Grade B performance for 12-fibre connectors . 16

Figure B.1 – Illustration of fibre line and minus coplanarity parameters . 19

Figure C.1 – Geometry limit, GL, needed to mate 12 fibres, as a function of absolute X-

angle, SX for different magnitudes of minus coplanarity and flat fibre tips. 21

Figure C.2 – Geometry limit, GL, needed to mate 12 fibres, as a function of absolute

X-angle, SX for different magnitudes of minus coplanarity and 1 mm fibre tips. . 21

Table 1 – Optical interface variant information . 7

Table 2 – Optical interface dimensions related to lateral and angular offset for optical

interface variant 1002 . 10

Table 3 – Optical interface dimensions related to lateral and angular offset for optical

interface variants 1104, 1108, 1112 . 11

Table 4 – Optical interface end face geometry dimensions related to physical contact

for optical interface variant 1002 . 12

Table 5 – Optical interface end face geometry dimensions related to physical contact

for optical interface variant 1104 . 13

Table 6 – Optical interface end face geometry dimensions related to physical contact

for optical interface variant 1108 . 14

Table 7 – Optical interface end face geometry dimensions related to physical contact

for optical interface variant 1112 . 15

Table A.1 – Grade B single channel vs. multi-fibre connector performance . 17

Table A.2 – Grade C single channel vs. multi-fibre connector performance . 17

Table A.3 – Grade D single channel vs. multi-fibre connector performance . 17

Table C.1 – Parameter constants for 4-fibre optical interface variant 1104 . 23

Table C.2 – Parameter constants for 8-fibre optical interface variant 1108 . 24

Table C.3 – Parameter constants for 12-fibre optical interface variant 1112 . 24

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIBRE OPTIC INTERCONNECTING

DEVICES AND PASSIVE COMPONENTS –

CONNECTOR OPTICAL INTERFACES –

Part 3-31: Connector parameters of non-dispersion

shifted single mode physically contacting fibres –

Angled polyphenylene sulphide rectangular ferrules

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61755-3-31 has been prepared by subcommittee 86B: Fibre optic

interconnecting devices and passive components, of IEC technical committee 86: Fibre optics.

The text of this standard is based on the following documents:

FDIS Report on voting

86B/3888FDIS 86B/3914/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

– 4 – IEC 61755-3-31:2015 IEC 2015

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61755 series, published under the general title Fibre optic

interconnecting devices and passive components –Connector optical interfaces, can be found

on the IEC website.

Future standards in this series will carry the new general title as cited above. Titles of existing

standards in this series will be updated at the time of the next edition.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

FIBRE OPTIC INTERCONNECTING

DEVICES AND PASSIVE COMPONENTS –

CONNECTOR OPTICAL INTERFACES –

Part 3-31: Connector parameters of non-dispersion

shifted single mode physically contacting fibres –

Angled polyphenylene sulphide rectangular ferrules

1 Scope

This part of IEC 61755 defines certain dimensional limits of an angled PC rectangular

polyphenylene sulphide (PPS) ferrule optical interface in order to meet specific requirements

for fibre-to-fibre interconnection. Ferrules made from the material specified in this standard

are suitable for use in categories C, U, E, and O as defined in IEC 61753-1.

Ferrule interface dimensions and features are contained in the IEC 61754 series, which deals

with fibre optic connector interfaces.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60793-2-50, Optical fibres – Part 2-50: Product specifications – Sectional specification for

class B single-mode fibres

IEC 61300-3-30, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 3-30: Examinations and measurements – Polish angle and

fibre position on single ferrule multifibre connectors

IEC 61300-3-52, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 3-52: Examinations and measurements – Guide hole and

alignment pin deformation constant, CD for 8 degree angled PC rectangular ferrule, single

mode fibres

IEC 61754 (all parts), Fibre optic interconnecting devices and passive components – Fibre

optic connector interfaces

IEC 61754-5:2005, Fibre optic connector interfaces – Part 5: Type MT connector family

IEC 61754-7:2008, Fibre optic interconnecting devices and passive components – Fibre optic

connector interfaces – Part 7: Type MPO connector family

IEC 61754-7-1:2014, Fibre optic interconnecting devices and passive components – Fibre

optic connector interfaces – Part 7-1: Type MPO connector family – One fibre row

IEC 61754-10:2005, Fibre optic connector interfaces – Part 10: Type Mini-MPO connector

family

IEC 61754-18:2001, Fibre optic connector interfaces – Part 18: Type MT-RJ connector family

– 6 – IEC 61755-3-31:2015 IEC 2015

IEC 61755-1, Fibre optic connector optical interfaces – Part 1: Optical interfaces for single

mode non-dispersion shifted fibres – General and guidance

3 Description

The performance of a single mode angled PC rectangular ferrule optical interface is

determined by the accuracy with which the optical datum targets of two mating ferrules are

aligned with each other. There are three conditions affecting the alignment of the optical

datum targets: lateral offset, angular offset, and longitudinal offset.

Parameters influencing the lateral and angular offset of the optical fibre axes include the

following:

– fibre hole deviation from designated location;

– fibre cladding diameter relative to fibre hole clearance;

– fibre hole angular misalignment;

– fibre core concentricity relative to the cladding diameter;

– alignment pin diameter relative to the guide hole clearance.

Parameters influencing the longitudinal offset of the optical fibre axes include the following:

– fibre protrusion;

– fibre array minus coplanarity;

– adjacent fibre height differential;

– end face angle in the x-axis;

– end face angle in the y-axis;

– end face radius in the x-axis;

– end face radius in the y-axis;

– fibre tip spherical radii;

– axial force on ferrule end face;

– ferrule and fibre material constants;

– frictional force of alignment pins in ferrule guide holes.

4 Interface parameters

This standard defines the dimensional limits of angled PC rectangular ferrules with a single

row of up to 12 fibres. The fibre centres are spaced with a nominal alignment pitch of 0,25 mm.

Interface variants, which identify nominal ferrule cross-sections and applicable fibre counts,

are given in Table 1. The fibre numbering conventions are illustrated in Figure 1.

Optical interface dimensions related to lateral and angular offset are defined in Figure 2 and

the alignment pin geometry is shown in Figure 3. The end face geometry parameters that

influence longitudinal offset are outlined in Figure 4.

The parameter values related to lateral and angular offset are given in Table 2 and Table 3.

End face geometry limits associated with longitudinal offset are specified in Table 4 to Table 7.

Table 1 – Optical interface variant information

Nominal ferrule

Variant Number

a

cross section

b,c

number of fibres

(mm´ mm)

1002 2,45´ 4,4 2

1104 2,45´ 6,4 4

1108 2,45´ 6,4 8

1112 2,45´ 6,4 12

a

Refer to the applicable IEC 61754 series fibre optic connector interface standard for

dimensional requirements.

b

The four digit variant code describes a combination of material type, nominal ferrule

cross-section, and number of fibres. The first digit defines 1 for PPS ferrule

materials; the second digit represents 2,45 mm´ 4,4 mm with 0 and 2,45 mm´ 6,4

mm with 1; and the last two digits designates the number of fibres.

c

All ferrule materials for rectangular type ferrules are intended to be intermateable,

in the lowest specified performance category as described within IEC 61755-1,

provided that the last three digits of the variant number are the same. It is also

possible to mate ferrules with different fibre counts, in which case all mating fibres

shall meet the designated performance category.

IEC

Figure 1 – Fibre numbering conventions

To provide optical fibre-to-fibre interconnection, mating ferrules have to be correctly keyed.

Refer to the applicable IEC 61754 series document to ensure correct key orientation.

– 8 – IEC 61755-3-31:2015 IEC 2015

Key

2× ØD

ØA U V

Y

ØE U

C

XX

Yi

V

U

Xi

B

IEC

Figure 2 – Interface dimensions related to lateral and angular offset

The optical interface coordinate system is established with an x-axis, which passes through

the guide hole centres and a perpendicular y-axis that passes through the midpoint of the line

connecting the guide hole centres.

The basic x-location, Xi, for each fibre core centre is defined as:

Xi = (2i – n – 1) 0,125

th

Where, i corresponds to the i fibre per the numbering conventions outlined in Figure 1 and n

is the total number of fibres in the array.

The basic y-location, Yi, for each fibre core centre is defined as:

D − D

o i

Yi=α + C

D

The basic alignment pin dimension, D , is 0,698 5 mm and the basic guide hole dimension, D ,

i o

is a nominal value based on the manufacturer designed average hole size. The constant, α,

relates to differences in guide pin pitch and varies between 0 and 1. The term C is a

D

deformation constant based on ferrule structure, material, and moulding condition. Typical

values C are between 0,3 µm and 0,6 µm. Refer to IEC 61300-3-52 for information on how to

D

measure and define Yi.

To ensure compatibility when mating rectangular ferrules with alternative Yi targets,

manufacturers of ferrules shall report their specified values for Yi, α, D , and C .

o D

Rz < G

ØJ

K

IEC

Figure 3 – Alignment pin geometry

Key

Region of interest

YY

SX

RF

SY

XX

RY

CF

HA

H

RX

Four fibres shown for simplicity

IEC

Figure 4 – Interface dimensions related to longitudinal offset

The optical interface coordinate system is established with an x-axis, which passes through

the guide hole centres, a perpendicular y-axis that passes through the midpoint of the line

connecting the guide hole centres, and an orthogonal z-axis pointing away from the ferrule.

All parameters are illustrated as positive values with respect to the defined coordinate system.

Concave ferrule radii are indicated by negative values.

– 10 – IEC 61755-3-31:2015 IEC 2015

Table 2 – Optical interface dimensions related to lateral

and angular offset for optical interface variant 1002

Parameter values

Grade B Grade C Grade D

Ref. Units Remarks

Minimum Maximum Minimum Maximum Minimum Maximum

a,b

A

- 0,001 6 - 0,002 4 - 0,003 4 mm Core position

B

2,598 2,602 2,598 2,602 2,598 2,602 mm Hole pitch

C - 0,2 - 0,2 - 0,2 Fibre angle error

°

c

D 0,699 0 0,699 6 0,699 0 0,700 0 0,699 0 0,700 0 mm Diameter

d

E - 0,012 - 0,012 - 0,012 mm Hole parallelism

G - 200 - 200 - 200 nm RMS roughness

J 0,698 4 0,698 6 0,698 0 0,699 0 0,698 0 0,699 0 mm Diameter

K - 0,000 5 - 0,000 5 - 0,000 5 mm Cylindricity

NOTE 1 The core location and tilt angle values specified in this standard have been calculated to ensure

that the attenuation values specified in IEC 61755-2-1 are met, under all circumstances, at the single

channel level. Refer to Annex A for the relationship between per channel and per connector loss statistics.

NOTE 2 Refer to Figure 2 and Figure 3 for dimensional references.

a

Variation in fibre core centre location, as controlled by true position tolerance ∅A, is composed of

several parameters including the fibre hole deviation, clearance between fibre cladding and hole, and

relative fibre core-to-cladding concentricity. Wherever possible, inspection of the core centre shall be

directly measured. Where this is not possible, due to inspection system capability or other constraints,

the relevant component features may be independently measured and superimposed to establish a

resultant fibre core location.

b

If the fibre core centre location is not directly measured for grade B performance, the fibre hole true

position target shall be less than 0,001 2 mm for ferrules terminated to optical fibres specified in

IEC 60793-2-50 with a fibre hole diameter ranging between 0,125 5 mm and 0,126 5 mm.

c

Each guide hole shall accept a gauge pin as shown in Figure 4 of IEC 61754-10:2005 and Figure 1c of

IEC 61754-18:2001 to a depth of 5,5 mm with a maximum force of 1,7 N. In addition, two guide holes

shall accept a gauge as shown in Figure 5 of IEC 61754-10:2005 and Figure 1d of IEC 61754-18:2001 to

a depth of 5,5 mm with a maximum force of 3,4 N.

d

Parallelism tolerance applies over a hole depth of 3,3 mm.

Table 3 – Optical interface dimensions related to lateral and

angular offset for optical interface variants 1104, 1108, 1112

Parameter values

Ref. Grade B Grade C Grade D Units Remarks

Minimum Maximum Minimum Maximum Minimum Maximum

a,b

A

- 0,001 6 - 0,002 4 - 0,003 4 mm Core position

B

4,598 4,602 4,598 4,602 4,597 4,603 mm Hole pitch

C - 0,2 - 0,2 - 0,2 Fibre angle error

°

c

D 0,699 0 0,699 6 0,699 0 0,700 0 0,699 0 0,700 0 mm Diameter

d

E - 0,012 - 0,012 - 0,012 mm Hole parallelism

G - 200 - 200 - 200 nm RMS roughness

J 0,698 4 0,698 6 0,698 0 0,699 0 0,698 0 0,699 0 mm Diameter

K - 0,000 5 - 0,000 5 - 0,000 5 mm Cylindricity

NOTE 1 The core location and tilt angle values specified in this standard have been calculated to ensure

that the attenuation values specified in IEC 61755-2-1 are met, under all circumstances, at the single

channel level. Refer to Annex A for the relationship between per channel and per connector loss statistics.

NOTE 2 Refer to Figure 2 and Figure 3 for dimensional references.

a

Variation in fibre core centre location, as controlled by true position tolerance ∅A, is composed of

several parameters including the fibre hole deviation, clearance between fibre cladding and hole, and

relative fibre core-to-cladding concentricity. Wherever possible, inspection of the core centre shall be

directly measured. Where this is not possible, due to inspection system capability or other constraints,

the relevant component features may be independently measured and superimposed to establish a

resultant fibre core true position.

b

If the fibre core centre location is not directly measured for grade B performance, the fibre hole true

position target shall be less than 0,0012 mm for ferrules terminated to optical fibres specified in

IEC 60793-2-50 with a fibre hole diameter ranging between 0,1255 mm and 0,1265 mm.

c

Each guide hole shall accept a gauge pin as shown in Figure 2 of IEC 61754-5:2005 and Figure 5 of

IEC 61754-7-1:2014 to a depth of 5,5 mm with a maximum force of 1,7 N. In addition, two guide holes

shall accept a gauge as shown in Figure 6 of IEC 61754-5:2005 and Figure 5 of IEC 61754-7:2008 to a

depth of 5,5 mm with a maximum force of 3,4 N.

d

Parallelism tolerance applies over a hole depth of 3,3 mm.

– 12 – IEC 61755-3-31:2015 IEC 2015

Table 4 – Optical interface end face geometry dimensions related

to physical contact for optical interface variant 1002

Parameter values

Ref. Units Remarks

Minimum Maximum

a

SX

-0,2 0,2 ° Ferrule surface x-angle

b

SY 7,8 8,2 ° Ferrule surface y-angle

c

H

1 3,5 µm Fibre height

HA 0 0,3 µm Adjacent fibre height differential

d

RF 1 - mm Fibre tip spherical radius

2 000 (convex)

RX - mm Ferrule surface x-radius

-10 000 (concave)

RY 5 - mm Ferrule surface y-radius

NOTE 1 End face parameter requirements apply to performance grades B, C, and D.

NOTE 2 Refer to Figure 4 for dimensional references.

NOTE 3 End face geometry to be measured in accordance with IEC 61300-3-30.

NOTE 4 The values in Table 4 above to be specified in the central surface region surrounding fibres of

0,900 mm wide and 0,675 mm high. Furthermore, the outside surface region is lower than the central

surface region of interest.

NOTE 5 The values in Table 4 above apply for polyphenylene sulphide (PPS) ferrules with a Young’s

modulus of 15 GPa to 20 GPa. Ferrule compression force: 7,8 N minimum and 11,8 N maximum.

a

X-angle represents the slope of the ferrule surface as defined by a bi-parabolic fit in accordance with

IEC 61300-3-30.

b

Y-angle represents the slope of the ferrule surface as defined by a bi-parabolic fit in accordance with

IEC 61300-3-30.

c

A positive value indicates a fibre protrusion.

d

Fibre tip spherical radii fitting region is defined within IEC 61300-3-30.

Table 5 – Optical interface end face geometry dimensions related

to physical contact for optical interface variant 1104

Parameter values

Ref. Units Remarks

Minimum Maximum

a

0,4

CF - µm Minus coplanarity

b

SX

-0,2 0,2 ° Ferrule surface x-angle

c

SY 7,8 8,2 ° Ferrule surface y-angle

d

H

1 3,5 µm Fibre height

HA 0 0,3 µm Adjacent fibre height differential

e

RF 1 - mm Fibre tip spherical radius

2 000 (convex)

RX - mm Ferrule surface x-radius

-10 000 (concave)

RY 5 - mm Ferrule surface y-radius

f

GL - 22,6 Geometry limit

NOTE 1 End face parameter requirements apply to performance grades B, C, and D.

NOTE 2 Refer to Figure 4 for dimensional references.

NOTE 3 End face geometry to be measured in accordance with IEC 61300-3-30.

NOTE 4 The values in Table 5 above to be specified in the central surface region surrounding fibres of

2,900 mm wide and 0,675 mm high. Furthermore, the outside surface region is lower than the central

surface region of interest.

NOTE 5 The values in Table 5 apply for polyphenylene sulphide (PPS) ferrules with a Young’s modulus of

15 GPa to 20 GPa. Ferrule compression force: 7,8 N minimum and 11,8 N maximum.

a

Refer to Annex B for a description of minus coplanarity.

b

X-angle represents the slope of the ferrule surface as defined by a bi-parabolic fit in accordance with

IEC 61300-3-30.

c

Y-angle represents the slope of the ferrule surface as defined by a bi-parabolic fit in accordance with

IEC 61300-3-30.

d

A positive value indicates a fibre protrusion.

e

Fibre tip spherical radii fitting region is defined within IEC 61300-3-30.

f

Refer to Annex C for a description of parameter GL.

– 14 – IEC 61755-3-31:2015 IEC 2015

Table 6 – Optical interface end face geometry dimensions related

to physical contact for optical interface variant 1108

Parameter values

Ref. Units Remarks

Minimum Maximum

a

0,4

CF - µm Minus coplanarity

b

SX

-0,15 0,15 ° Ferrule surface x-angle

c

SY 7,8 8,2 ° Ferrule surface y-angle

d

H

1 3,5 µm Fibre height

HA 0 0,3 µm Adjacent fibre height differential

e

RF 1 - mm Fibre tip spherical radius

2 000 (convex)

RX - mm Ferrule surface x-radius

-10 000 (concave)

RY 5 - mm Ferrule surface y-radius

f

GL - 17,9 Geometry limit

NOTE 1 End face parameter requirements apply to performance grades B, C, and D.

NOTE 2 Refer to Figure 4 for dimensional references.

NOTE 3 End face geometry to be measured in accordance with IEC 61300-3-30.

NOTE 4 The values in Table 6 above to be specified in the central surface region surrounding fibres of

2,900 mm wide and 0,675 mm high. Furthermore, the outside surface region is lower than the central

surface region of interest.

NOTE 5 The values in Table 6 above apply for polyphenylene sulphide (PPS) ferrules with a Young’s

modulus of 15GPa to 20 GPa. Ferrule compression force: 7,8 N minimum and 11,8 N maximum.

a

Refer to Annex B for a description of minus coplanarity.

b

X-angle represents the slope of the ferrule surface as defined by a bi-parabolic fit in accordance with

IEC 61300-3-30.

c

Y-angle represents the slope of the ferrule surface as defined by a bi-parabolic fit in accordance with

IEC 61300-3-30.

d

A positive value indicates a fibre protrusion.

e

Fibre tip spherical radii fitting region is defined within IEC 61300-3-30.

f

Refer to Annex C for a description of parameter GL.

Table 7 – Optical interface end face geometry dimensions related

to physical contact for optical interface variant 1112

Parameter values

Ref. Units Remarks

Minimum Maximum

a

0,4

CF - µm Minus Coplanarity

b

SX

-0,15 0,15 ° Ferrule surface x-angle

c

SY 7,8 8,2 ° Ferrule surface y-angle

d

H

1 3,5 µm Fibre height

HA 0 0,3 µm Adjacent fibre height differential

e

RF 1 - mm Fibre tip spherical radius

2 000 (convex)

RX - mm Ferrule surface x-radius

-10 000 (concave)

RY 5 - mm Ferrule surface y-radius

f

GL - 17,4 Geometry limit

NOTE 1 End face parameter requirements apply to performance grades B, C, and D.

NOTE 2 Refer to Figure 4 for dimensional references.

NOTE 3 End face geometry to be measured in accordance with IEC 61300-3-30.

NOTE 4 The values in Table 7 above to be specified in the central surface region surrounding fibres of

2,900 mm wide and 0,675 mm high. Furthermore, the outside surface region is lower than the central

surface region of interest.

NOTE 5 The values in Table 7 above apply for polyphenylene sulphide (PPS) ferrules with a Young’s

modulus of 15 GPa to 20 GPa. Ferrule compression force: 7,8 N minimum and 11,8 N maximum.

a

Refer to Annex B for a description of minus coplanarity.

b

X-angle represents the slope of the ferrule surface as defined by a bi-parabolic fit in accordance with

IEC 61300-3-30.

c

Y-angle represents the slope of the ferrule surface as defined by a bi-parabolic fit in accordance with

IEC 61300-3-30.

d

A positive value indicates a fibre protrusion.

e

Fibre tip spherical radii fitting region is defined within IEC 61300-3-30.

f Refer to Annex C for a description of parameter GL.

– 16 – IEC 61755-3-31:2015 IEC 2015

Annex A

(informative)

Theoretical worst-case connector attenuation yield percentage

Rectangular ferrule connector core alignment specifications are defined at the single channel

level. A population of fibre links interconnected with Grade B rectangular ferrules will yield

≤ 0,25 dB attenuation for > 97% of all channels with a mean of ≤ 0,12 dB. The intra-connector

channel grouping of fully populated multi-fibre connectors results in the following theoretical,

worst-case connector attenuation yield percentage for a completely random core alignment

distribution:

n

Multi-fibre connector attenuation yield % = {single channel attenuation yield %} (A.1)

where n is the total number of populated fibres per ferrule.

A population of channels individually along with the theoretical worst case performance by

connector for Grade B 12 fibre ferrules is illustrated in Figure A.1. Based on the Monte Carlo

simulation, attenuation yield percentages for Grade B, C, and D are given in Tables A.1 to A.3.

IEC

Figure A.1 – Monte Carlo simulation of Grade B performance for 12-fibre connectors

Table A.1 – Grade B single channel vs. multi-fibre connector performance

Attenuation Single channel 4 fibre 8 fibre 12 fibre

(dB) cumulative % cumulative % cumulative % cumulative %

0,25 97,29 89,60 80,29 71,94

0,3 98,71 94,92 90,10 85,53

0,35 99,41 97,66 95,37 93,14

0,4 99,72 98,90 97,81 96,74

0,45 99,87 99,49 98,98 98,48

0,5 99,94 99,75 99,49 99,24

NOTE Mean = 0,07 dB

Table A.2 – Grade C single channel vs. multi-fibre connector performance

Attenuation Single channel 4 fibre 8 fibre 12 fibre

(dB) cumulative % cumulative % cumulative % cumulative %

0,5 97,18 89,19 79,55 70,95

0,55 98,08 92,54 85,63 79,24

0,6 98,66 94,75 89,77 85,05

0,65 99,06 96,29 92,72 89,29

0,7 99,37 97,50 95,07 92,70

0,75 99,57 98,29 96,61 94,96

0,8 99,69 98,77 97,55 96,34

0,85 99,79 99,16 98,33 97,51

0,9 99,85 99,40 98,81 98,21

0,95 99,90 99,60 99,20 98,81

1 99,93 99,72 99,44 99,16

NOTE Mean = 0,14 dB

Table A.3 – Grade D single channel vs. multi-fibre connector performance

Attenuation Single channel 4 fibre 8 fibre 12 fibre

(dB) cumulative % cumulative % cumulative % cumulative %

1 97,80 91,50 83,72 76,60

1,05 98,22 93,06 86,60 80,59

1,1 98,53 94,25 88,84 83,74

1,15 98,82 95,35 90,92 86,70

1,2 99,05 96,25 92,64 89,17

1,25 99,22 96,92 93,93 91,03

1,3 99,38 97,52 95,11 92,75

1,35 99,51 98,04 96,13 94,25

1,4 99,59 98,38 96,79 95,22

1,45 99,67 98,70 97,42 96,15

1,5 99,75 98,99 97,98 96,99

1,55 99,80 99,20 98,41 97,63

1,6 99,85 99,40 98,81 98,21

1,65 99,87 99,48 98,96 98,45

– 18 – IEC 61755-3-31:2015 IEC 2015

Attenuation Single channel 4 fibre 8 fibre 12 fibre

(dB) cumulative % cumulative % cumulative % cumulative %

1,7 99,90 99,60 99,20 98,81

1,75 99,92 99,68 99,36 99,04

1,8 99,94 99,76 99,52 99,28

NOTE Mean = 0,27 dB

Annex B

(normative)

Minus coplanarity

The fibre protrusion distribution for rectangular ferrules is characterized by a parameter

referred to as minus coplanarity. This metric represents the unilateral distance from a least

squares fit line through the array of protrusions, known as the fibre line, to the minimum

height fibre as illustrated in Figure B.1

Fibre tip

Z

Minus

Fibre line

coplanarity

GX

X

Ferrule

surface

IEC

Figure B.1 – Illustration of fibre line and minus coplanarity parameters

The fibre line, which provides a single characterization of the height distribution, takes the

form:

z(x) = tan(GX)⋅x + β (B.1)

The angle of the array, GX, denotes the x-slope angle. A measure of the average fibre height

at the x-origin of the coordinate system is given by the intercept of the fit, β.

Minus coplanarity, CF, can be defined as:

CF = max(z (x) – Z ) (B.2)

i i

Where, z (x) – Z represents the deviation of each fibre tip, i, from the fibre line. The physical

i i

significance of minus coplanarity is that it indicates the requisite axial displacement of the

fibre line needed to ensure physical contact across the fibre array under worst case mating

conditions.

– 20 – IEC 61755-3-31:2015 IEC 2015

Annex C

(informative)

Minimum normal force required to achieve physical contact

To establish limits of acceptance on end face geometry, a mathematical system model was

developed to estimate the minimum normal force required to achieve physical contact across

an array of mated fibres. This model takes into account various factors including:

– fibre tip compression and axial stiffness;

– elastic, foundational deflection of the ferrule structure;

– rotational stiffness of the system;

– frictional resistance between the alignment pins and holes;

– variation in end face geometry dimensions.

For a ferrule with a single row of fibres, there are three dominant end face dimensions that

influence the minimum mating force needed to assure physical contact:

– X-slope angle of the end face, SX;

– minus coplanarity of the fibre array, CF;

– fibre tip spherical radius of curvature, RF.

These parameters were systematically varied to determine their interrelationships with mating

force. As a result of the analysis, a geometry limit, GL, can be used to quantitatively assess

the acceptability of an end face. This term is a calculated merit function, which relates X-slope

angle, coplanarity, and fibre tip radii in comparison to the defined ferrule compression force.

For a specific end face condition, lower calculated values for GL indicate a better geometry.

For instance, GL is zero for interfaces with perfectly coplanar fibres and null X-slope angle. A

maximum allowable limit can therefore be placed on GL to serve as a bound for unacceptable

geometries. Furthermore, the magnitude of the limit may be different depending on the

number of fibres or the ferrule material type.

To develop the relationship between GL, CF, and SX, end faces with flat fibre tips (RF = ∞)

were initially studied as summarized in Figure C.1.

CF (µm)

|SX| (degrees)

IEC

Figure C.1 – Geometry limit, GL, needed to mate 12 fibres, as a function of absolute X-

angle, SX for different magnitudes of minus coplanarity and flat fibre tips

Inspection of the results indicates that the family of curves are linear with equal slopes and

constant offsets between their y-axis intercepts. This gives a functional relationship of the

form

GL(SX ,CF, RF=∞)= B⋅ SX + D⋅ CF (C.1)

When the fibre tips have finite radii of curvature, there is slight nonlinearity and the slopes of

the curves steepen with increasing CF. Additionally, the value of GL when SX= 0 is no

longer directly proportional to CF as illustrated in Figure C.2.

CF (µm)

|SX| (degrees)

IEC

Figure C.2 – Geometry limit, GL, needed to mate 12 fibres, as a function of absolute

X-angle, SX for different magnitudes of minus coplanarity and 1 mm fibre tips.

GL GL

– 22 – IEC 61755-3-31:2015 IEC 2015

A function that fits this behaviour can be expressed as

−A ⋅CF −n⋅ SX −B ⋅CF

− p⋅CF

q q

GL(SX,CF)= [(A − A )⋅ e + A ]⋅(e −1)+ [(B − B )⋅ e + B ]⋅ SX + C⋅(e −1)+

0 1 1 0 1 1

(C.2)

D⋅ CF

where the parameter constants, A , A , A , n, B , B , B , C, p, and D, are related to the fibre

0 1 q 0 1 q

tip radiu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...