IEC 61300-3-45:2023

(Main)Fibre optic interconnecting devices and passive components - Basic test and measurement procedures - Part 3-45: Examinations and measurements - Attenuation of random mated multi-fibre connectors

Fibre optic interconnecting devices and passive components - Basic test and measurement procedures - Part 3-45: Examinations and measurements - Attenuation of random mated multi-fibre connectors

IEC 61000-3-45:2023 describes the procedure required to measure the statistical distribution and mean attenuation for random mated optical connectors with physical contact (PC) and angled physical contact (APC) polished multi-fibre rectangular ferrules as defined in the IEC 61754 series. This measurement method is applicable to cable assemblies. This second edition cancels and replaces the first edition published in 2011. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) addition of sample size for > 12-fibre connector measurement;

b) inclusion of guidance for multimode measurement.

Dispositifs d'interconnexion et composants passifs fibroniques - Procédures fondamentales d'essais et de mesures - Partie 3-45: Examens et mesures - Affaiblissement dû à l’accouplement sans choix préalable de connecteurs multifibres

L'IEC 61000-3-45:2023 décrire la procédure exigée pour mesurer la distribution statistique et l’affaiblissement moyen des connecteurs optiques accouplés sans choix préalable avec férules rectangulaires polies multifibres à contact physique (PC), et à contact physique avec angle (APC), comme défini dans la série IEC 61754. Cette méthode de mesure s’applique aux câbles assemblés. Cette seconde édition annule et remplace la première édition parue en 2011. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l’édition précédente:

a) ajout nombre d’échantillons pour la mesure de connecteurs à plus de 12 fibres;

b) ajout de recommandations pour les mesures multimodales.

General Information

- Status

- Published

- Publication Date

- 26-Jun-2023

- Technical Committee

- SC 86B - Fibre optic interconnecting devices and passive components

- Drafting Committee

- WG 4 - TC 86/SC 86B/WG 4

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Jun-2023

- Completion Date

- 28-Jul-2023

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61300-3-45:2023 specifies standardized test procedures to measure the attenuation of random mated multi‑fibre connectors. The standard defines how to obtain the statistical distribution and mean attenuation for one‑row multi‑fibre rectangular ferrule connectors with PC (physical contact) and APC (angled physical contact) polishing, as referenced in the IEC 61754 series. The methods apply to cable assemblies and provide repeatable, unbiased results for design approval and production control.

Key topics and requirements

- Scope of measurement: Statistical distribution and mean attenuation for random mating of multi‑fibre connectors (PC and APC) using cable assemblies.

- Two test methods:

- Method 1 - Reference design‑approval procedure using pinned (“launch test plugs”) and unpinned plugs in a predefined test matrix. Intended as the authoritative method in disputes.

- Method 2 - Practical procedure for process control using selected reference and test cords; suitable for routine verification after design approval.

- Random sampling: Cable assemblies and any adaptors must be chosen at random to ensure statistically unbiased estimates.

- Launch and detection: Procedures include requirements for launch conditions, light sources (LS), detectors (D), and analysis of results (see apparatus and analysis sections).

- Test matrices and labelling: Detailed matrices for 2‑, 4‑, 8‑, 10‑, 12‑ and >12‑fibre connectors are specified to organize measurements and reporting.

- Multimode guidance: This edition adds specific guidance and normative annex content for multimode measurements (launch fibre and launch plug requirements).

- Sample size updates: New sample size rules for connectors with more than 12 fibres.

- Reporting: The standard defines the calculation, analysis and the details to be specified and reported for traceability.

Applications and practical value

- Ensures consistent, repeatable attenuation data for multi‑fibre connectors used in high‑density fibre systems (e.g., data centres, telecom trunks, MPO/MTP® style assemblies).

- Supports design validation, supplier qualification and production process control by providing objective criteria for connector mating loss.

- Used by:

- Test and calibration laboratories

- Cable and connector manufacturers

- Quality assurance and incoming inspection teams

- System integrators and network operators evaluating batch performance

- Practical outputs include mean loss values, distribution statistics and pass/fail assessment for batches of cable assemblies.

Related standards

- IEC 61300‑1 - General guidance for fibre optic test procedures

- IEC 61300‑3‑1, IEC 61300‑3‑35 - Visual inspection and endface inspection procedures

- IEC 61754 - Connector interface definitions

- IEC 63267 - Interfaces for enhanced macro‑bend loss multimode fibres

Keywords: IEC 61300‑3‑45:2023, attenuation, random mated multi‑fibre connectors, PC, APC, multimode, Method 1, Method 2, cable assemblies, IEC 61754.

REDLINE IEC 61300-3-45:2023 RLV - Fibre optic interconnecting devices and passive components - Basic test and measurement procedures - Part 3-45: Examinations and measurements - Attenuation of random mated multi-fibre connectors Released:27. 06. 2023 Isbn:9782832271698

REDLINE IEC 61300-3-45:2023 - Fibre optic interconnecting devices and passive components - Basic test and measurement procedures - Part 3-45: Examinations and measurements - Attenuation of random mated multi-fibre connectors Released:6/27/2023

IEC 61300-3-45:2023 - Fibre optic interconnecting devices and passive components - Basic test and measurement procedures - Part 3-45: Examinations and measurements - Attenuation of random mated multi-fibre connectors Released:6/27/2023 Isbn:9782832271513

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 61300-3-45:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fibre optic interconnecting devices and passive components - Basic test and measurement procedures - Part 3-45: Examinations and measurements - Attenuation of random mated multi-fibre connectors". This standard covers: IEC 61000-3-45:2023 describes the procedure required to measure the statistical distribution and mean attenuation for random mated optical connectors with physical contact (PC) and angled physical contact (APC) polished multi-fibre rectangular ferrules as defined in the IEC 61754 series. This measurement method is applicable to cable assemblies. This second edition cancels and replaces the first edition published in 2011. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) addition of sample size for > 12-fibre connector measurement; b) inclusion of guidance for multimode measurement.

IEC 61000-3-45:2023 describes the procedure required to measure the statistical distribution and mean attenuation for random mated optical connectors with physical contact (PC) and angled physical contact (APC) polished multi-fibre rectangular ferrules as defined in the IEC 61754 series. This measurement method is applicable to cable assemblies. This second edition cancels and replaces the first edition published in 2011. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) addition of sample size for > 12-fibre connector measurement; b) inclusion of guidance for multimode measurement.

IEC 61300-3-45:2023 is classified under the following ICS (International Classification for Standards) categories: 33.180.20 - Fibre optic interconnecting devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61300-3-45:2023 has the following relationships with other standards: It is inter standard links to IEC 61300-3-45:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61300-3-45:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61300-3-45 ®

Edition 2.0 2023-06

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures –

Part 3-45: Examinations and measurements – Attenuation of random mated

multi-fibre connectors

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61300-3-45 ®

Edition 2.0 2023-06

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures –

Part 3-45: Examinations and measurements – Attenuation of random mated

multi-fibre connectors

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 33.180.20 ISBN 978-2-8322-7169-8

– 2 – IEC 61300-3-45:2023 RLV © IEC 2023

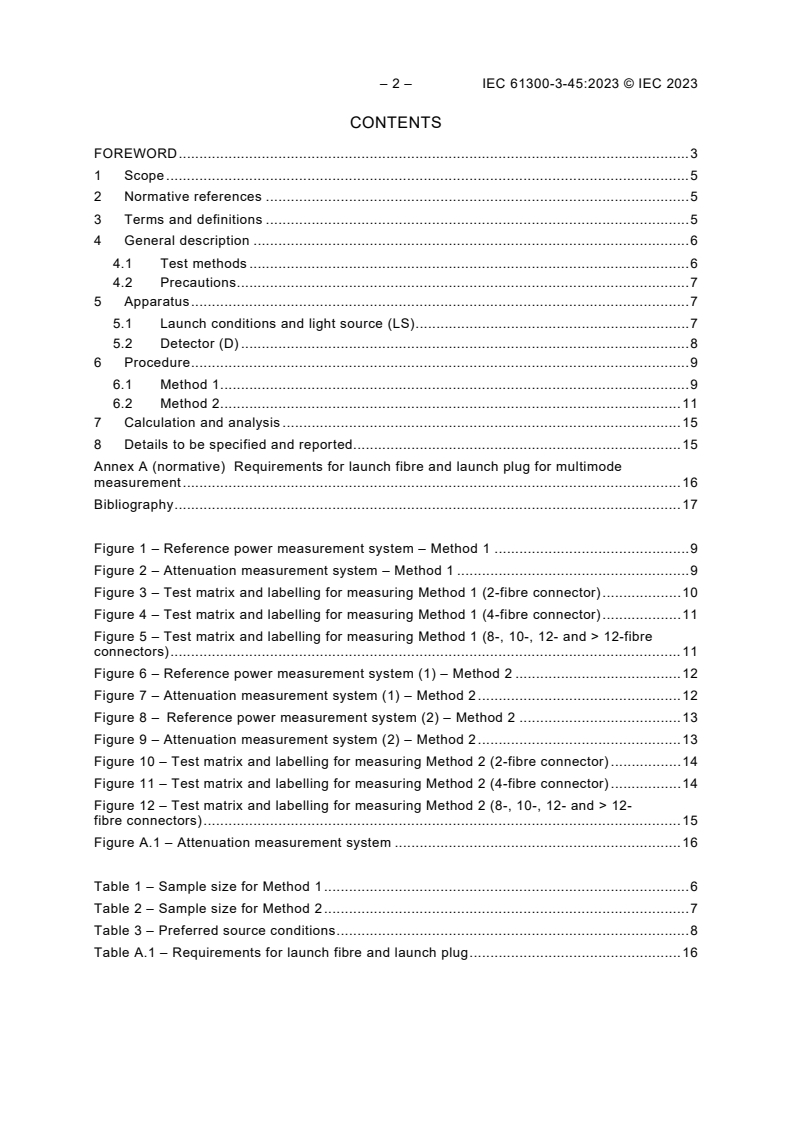

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General description . 6

4.1 Test methods . 7

4.2 Precautions . 8

5 Apparatus . 9

5.1 Launch conditions and light source (LS) . 9

4.2 Launch conditions (E) .

5.2 Detector (D) . 10

5.3 Analysis of results .

6 Procedure . 10

6.1 Method 1. 10

6.2 Method 2. 16

7 Calculation and analysis . 23

8 Details to be specified and reported. 24

Annex A (normative) Requirements for launch fibre and launch plug for multimode

measurement . 25

Bibliography . 26

Figure 1 – “Reference” cord measurement – Method 1 .

Figure 1 – Reference power measurement system – Method 1 . 12

Figure 2 – Test cord measurement – Method 1 .

Figure 2 – Attenuation measurement system – Method 1 . 12

Figure 3 – Test matrix and labelling for measuring Method 1 (2-fibre connector) . 14

Figure 4 – Test matrix and labelling for measuring Method 1 (4-fibre connector) . 15

Figure 5 – Test matrix and labelling for measuring Method 1 (8-, 10-, 12- and > 12-fibre

connectors) . 16

Figure 6 – “Reference” cord measurement (1) – Method 2 .

Figure 6 – Reference power measurement system (1) – Method 2 . 19

Figure 7 – Test cord measurement (1) – Method 2 .

Figure 7 – Attenuation measurement system (1) – Method 2 . 19

Figure 8 – “Reference” cord measurement (2) – Method 2 .

Figure 8 – Reference power measurement system (2) – Method 2 . 20

Figure 9 – Test cord measurement (2) – Method 2 .

Figure 9 – Attenuation measurement system (2) – Method 2 . 20

Figure 10 – Test matrix and labelling for measuring Method 2 (2-fibre connector) . 21

Figure 11 – Test matrix and labelling for measuring Method 2 (4-fibre connector) . 22

Figure 12 – Test matrix and labelling for measuring Method 2 (8-, 10-, 12- and > 12-

fibre connectors) . 23

Figure A.1 – Attenuation measurement system . 25

Table 1 – Sample size for Method 1 . 8

Table 2 – Sample size for Method 2 . 8

Table 3 – Preferred source conditions . 9

Table A.1 – Requirements for launch fibre and launch plug . 25

– 4 – IEC 61300-3-45:2023 RLV © IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIBRE OPTIC INTERCONNECTING DEVICES AND PASSIVE

COMPONENTS – BASIC TEST AND MEASUREMENT PROCEDURES –

Part 3-45: Examinations and measurements –

Attenuation of random mated multi-fibre connectors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition IEC 61300-3-45:2011. A vertical bar appears in the margin

wherever a change has been made. Additions are in green text, deletions are in

strikethrough red text.

IEC 61300-3-45 has been prepared by subcommittee 86B: Fibre optic interconnecting devices

and passive components, of IEC technical committee 86: Fibre optics. It is an International

Standard.

This second edition cancels and replaces the first edition published in 2011. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) addition of sample size for > 12-fibre connector measurement;

b) inclusion of guidance for multimode measurement.

The text of this International Standard is based on the following documents:

Draft Report on voting

86B/4757/FDIS 86B/4774/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 61300 series, published under the general title Fibre optic

interconnecting devices and passive components – Basic test and measurement procedures,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC 61300-3-45:2023 RLV © IEC 2023

FIBRE OPTIC INTERCONNECTING DEVICES AND PASSIVE

COMPONENTS – BASIC TEST AND MEASUREMENT PROCEDURES –

Part 3-45: Examinations and measurements –

Attenuation of random mated multi-fibre connectors

1 Scope

The purpose of this part of IEC 61300 is to describe the procedure required to measure the

statistical distribution and mean attenuation for random mated optical connectors with physical

contact (PC) and angled physical contact (APC) polished 1-row multi-fibre rectangular ferrules

as defined in the IEC 61754 series. This measurement method is applicable to cable assemblies.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61300-1, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 1: General and guidance

IEC 61300-3-1, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 3-1: Examinations and measurements – Visual examination

IEC 61300-3-35, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 3-35: Examinations and measurements – Visual inspection of

fibre optic connector endface visual and automated inspection connectors and fibre-stub

transceivers

IEC 61754 (all parts), Fibre optic interconnecting devices and passive components – Fibre optic

connector interfaces

IEC 63267 (all parts), Fibre optic interconnecting devices and passive components – Connector

optical interfaces for enhanced macro bend loss multimode fibres

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 General description

4.1 Test methods

Two test methods are described for measuring the attenuation of random mated optical

connectors. Both provide an estimate of the expected average performance that a group of

cable assemblies (including an adaptor, if applicable) selected from a batch will exhibit when

used in an optical system. The device under test (DUT) is a cable assembly with on one side a

plug with pins (pinned plug) and on the other side a plug without pins (unpinned plug). The

cable assemblies, and any adaptors, must shall be chosen at random to ensure that the

measurements provide a statistically unbiased estimate.

Method 1 describes a procedure using a sample of cable assemblies and adaptors specified in

Table 1. In this case the pinned plugs (with pins) are used as “reference” plugs "launch test

plugs” and the unpinned plugs (without pins) are tested against them sequentially. The results,

based on the number of measurements specified in Table 1, are recorded in the test matrix

shown in Figure 3 to Figure 5.

Method 1 is intended to be part of a design approval exercise that may involve one or more

suppliers. Once approval is achieved, Method 2 would be relied on to maintain process control.

However, in the event of a dispute, Method 1 shall act as the reference measurement method.

Method 2 describes a procedure for the measurement of a sample of cable assemblies and

adaptors specified in Table 2. Three cable assemblies are selected from the sample as

“reference” cable assemblies and pins are fitted. The other test cable assemblies (without pins)

are tested against each of the three “reference cable assemblies” sequentially. Three cable

assemblies are selected from the sample as "launch test cords” and the remaining cable

assemblies are grouped as “receive test cords”. First, the pinned plugs of the launch test cords

are used as launch test plugs and the unpinned plugs of the receive test cords are tested against

them sequentially. Then the unpinned plugs of the launch test cords are used as launch test

plugs and the pinned plugs of the receive test cords are tested. This produces the number of

measurements specified in Table 2 and the results are recorded in the test matrix shown in

Figure 10 to Figure 12.

Method 1 is intended to be part of a design approval exercise that can involve one or more

suppliers. It is recognised that the number of measurements required by Method 1 may can be

excessive for day-to-day routine checking of either in-house or supplier produced products. In

this case, as indicated above once approval is achieved, Method 2 may would be relied on to

maintain process control as an alternative option. However, in the event of a dispute, Method 1

shall act as the reference measurement method.

NOTE In this measurement method, the terms “reference” plug or “reference” cord are used to define those

components chosen at random from a batch, against which a number of comparative measurements are made. In

this measurement method, the term “launch test cord” is used to define one of the mated DUTs which is installed on

the light source side. On the other hand, the other DUT which is installed on the detector side is defined as “receive

test cord”. In the same way, the plugs mated at the connection point under test are defined as “launch test plug” and

“receive test plug”, respectively. "Launch test plug” and "launch test cord” are used to define those components

chosen at random from the sample, against which a number of comparative measurements are made. It is not

intended that the terms should imply specially chosen or manufactured components, such as those used, for example,

in screen testing.

– 8 – IEC 61300-3-45:2023 RLV © IEC 2023

Table 1 – Sample size for Method 1

Connectors Sample sizes

(n-fibre connector) Cords and adaptors Measurements Fibres

2-fibre connector 15 210 420

4-fibre connector 12 132 528

8-fibre connector 10 90 720

10-fibre connector 10 90 900

12-fibre connector 10 90 1 080

> 12-fibre connector 10 90 90*n

NOTE Parameter n is the number of fibres in the connector.

Table 2 – Sample size for Method 2

Sample size

Connector

Cord and adaptors

(n-fibre connector) Measurements Fibres

Total Reference Test :N

2-fibre connector 12 3 9 54 108

4-fibre connector 8 3 5 30 120

8-fibre connector 6 3 3 18 144

10-fibre connector 6 3 3 18 180

12-fibre connector 6 3 3 18 216

Sample sizes

Connectors (n Cords

‑fibre connector)

Adaptors Measurements Fibres

Launch test Receive

Total

cord test cord

2-fibre connector 12 3 9 3 54 108

4-fibre connector 8 3 5 3 30 120

8-fibre connector 6 3 3 3 18 144

10-fibre connector 6 3 3 3 18 150

12-fibre connector 6 3 3 3 18 216

> 12-fibre connector 6 3 3 3 18 18*n

NOTE Parameter n is the number of fibres in the connector.

4.2 Precautions

The following test requirements shall be met.

a) Precautions shall be taken to ensure that The cladding modes do shall not affect the

measurement. Cladding modes shall be stripped as a function of the fibre coating.

b) Precautions shall be taken to ensure that the position of the fibres in the test remains fixed

between the measurement of P and P to avoid changes in attenuation due to bending

1 2

losses.

b) The fibres in the test shall remain fixed between the reference power measurement and the

corresponding attenuation measurements to avoid changes in attenuation due to bending

losses.

b) The stability performance of the test equipment shall be ≤ 0,05 dB or 10 % of the attenuation

to be measured, whichever is the lower value. The stability shall be maintained over the

measurement time and operational temperature range. The required measurement

resolution shall be 0,01 dB for both multimode and single-mode.

c) To achieve consistent results, clean and inspect all connectors and adaptors prior to the

setup of the measurement system and if contaminated clean them. During measurement

steps, inspect all connectors and adaptors except those in the unchanged connections and

if contaminated clean them before mating. Visual examination shall be undertaken in

accordance with IEC 61300-3-1 and IEC 61300-3-35.

NOTE A cladding mode stripper usually comprises a material having a refractive index equal to or greater than that

of the fibre cladding.

5 Apparatus

5.1 Launch conditions and light source (LS)

The source consists of an optical emitter, the means to connect to it and associated drive

electronics. In addition to meeting the stability and power level requirements, the source shall

have the following characteristics:

– Centre wavelength, as detailed in the performance and product standard;

– Spectral width, filtered light emitting diode (LED) ≤ 150 nm full width half maximum (FWHM);

– Spectral width, laser diode (LD) < 10 nm FWHM.

For multimode fibres, broadband sources such as an LED shall be used.

For single mode fibres either an LED or LD may be used.

The source unit consists of an optical emitter, the associated drive electronics, and fibre pigtail

(if any). Preferred source conditions are given in Table 3. The stability of the single-mode fibre

source at 23 °C shall be ±0,01 dB over the duration of the measurement. The stability of the

multimode fibre source at 23 °C shall be ±0,05 dB over the duration of the measurement. The

source output power shall be ≥ 20 dB above the minimum measurable power level.

Table 3 – Preferred source conditions

Central Source type

No. Type Spectral width (RMS)

wavelength

nm nm

S1 Multimode 660 ± 30 ≥ 10 Monochromator or LED

S2 Multimode 780 ± 30 ≥ 10 Monochromator or LED

S3 Multimode 850 ± 30 ≥ 10 Monochromator or LED

S4 Multimode 1 300 ± 30 ≥ 10 Monochromator or LED

S5 Single-mode 1 310 ± 30 To be reported Laser diode, monochromator, or LED

S6 Single-mode 1 550 ± 30 To be reported Laser diode, monochromator, or LED

S7 Single-mode 1 625 ± 30 To be reported Laser diode, monochromator, or LED

It is recognized that some components, for example for coarse wavelength division multiplexing (CWDM), can

require the use of other source types such as tunable lasers. It is therefore recommended in these cases that the

preferred source characteristics are specified on the basis of the component to be measured.

NOTE Central wavelength and spectral width are defined in IEC 61280-1-3.

– 10 – IEC 61300-3-45:2023 RLV © IEC 2023

The launch condition shall be specified in accordance with IEC 61300-1. In case the specified

launch condition is not obtained by the original light from the source, an appropriate apparatus

for launch condition control (E) shall be used.

NOTE The interference of modes from a coherent source will create speckle patterns in

multimode fibres. These speckle patterns give rise to speckle or modal noise and are observed

as power fluctuations, since their characteristic times are longer than the resolution time of the

detector. As a result, it may be impossible to achieve stable launch conditions cannot be

achieved using coherent sources for multimode measurements. Consequently, lasers, including

optical time domain reflectometer (OTDR) sources, should be avoided in favour of LEDs or

other incoherent sources for measuring multimode components.

4.2 Launch conditions (E)

The launch condition shall be specified in accordance with IEC 61300-1.

5.2 Detector (D)

The detector consists of an optical detector, the means to connect to it and associated

electronics. The connection to the detector will be an adaptor that accepts a connector plug of

the appropriate design. The detector shall capture all light emitted by the connector plug.

In addition to meeting the stability and resolution requirements, the detector shall have the

following characteristics:

– linearity of multimode, ≤ ±0,25 dB (over −5 dBm up to −60 dBm);

– linearity of single-mode, ≤ ±0,1 dB (over −5 dBm up to −60 dBm).

NOTE The power meter detector linearity should be referenced to a power level of −23 dBm at

the operational wavelength.

Where the connection to the detector is broken between the reference power measurement of

P the corresponding attenuation measurements, the measurement repeatability shall

and P

1 2

be within 0,05 dB or 10 % of the attenuation to be measured, whichever is the lower value. A

large sensitive area detector may can be used to achieve this.

The precise characteristics of the detector shall be compatible with the measurement

requirements. The dynamic range of the power meter detector shall be capable of measuring

the power level exiting from the device under test (DUT) at the wavelength being measured.

6 Procedure

6.1 Method 1

a) Randomly select the sample number of cable assemblies specified in Table 1. Sequentially

label the plugs under test as shown in Figures 3 to 5.

b) Randomly select the sample size of adaptors as specified in Table 1. Sequentially label the

adaptors under test as shown in Figures 3 to 5.

c) Set up the measurement system as shown in Figure 1, with cord 1as the “reference” cord

and with plug 1 as the “reference” plug. Measure power P to P for all fibres in the

1-1 1-n

cord.

Fan-out cord “Reference” cord

Ch 1

D

S E

Plug

Plug

1(without pins)

1(with pins)

Ch n

P

1-n

IEC 900/11

Figure 1 – “Reference” cord measurement – Method 1

d) Connect test cord 2 and adaptor 1 to the system and mate plug 1 (with pins) to plug 2

(without pins) as shown in Figure 2. Measure the power P to P for all fibres in the cord.

2-1 2-n

Adaptor 1

Test cord

Ch 1 Fan-out cord “Reference” cord

D

E

S

Plug 1 Plug 1 Plug 2 Plug 2

(without pins) (with pins) (without pins) (with pins)

Ch n

P

2-n

IEC 901/11

Figure 2 – Test cord measurement – Method 1

e) Calculate the attenuation of the mated plug pair 1 (with pins) / 2 (without pins) with adaptor

1, using Equation (1):

Attenuation = [-10 log (P /P )] - (A × L) dB (1)

2-i 1-i

Where

i is fibre number of Test cord.

A is fibre attenuation per km;

L is length of fibre in km.

NOTE The product A × L may be ignored for both single mode and multimode [50/125 µm and 62,5/125 µm] where

the cord length is small, i.e. < 10 m.

f) Record the attenuation results for each fibre into an appropriate matrix format.

NOTE An example of record table (for 4 fibre connectors) is shown in Figure 13.

g) Keeping plug 1 (with pins) and adaptor 1 as the “reference” configuration, replace test cord

2 by test cord 3 and mate plug 3 (without pins) with plug 1 (with pins).

h) Measure the power P to P and record the attenuation results for each fibre.

3-1 3-n

i) Repeat steps g) and h) until all the plugs (without pins) of the remaining test cable

assemblies have been tested against the “reference” plug 1 (with pins).

j) After step i) has been completed, replace the “reference” plug and adaptor so that plug 2

(with pins) and adaptor 2 are the “reference” configuration.

k) Measure the attenuation for all plugs against “reference” plug 2 (with pins) and adaptor 2.

l) Continue this process until all allocated plugs have been used as “reference” plugs.

a) Randomly select the sample number of cable assemblies specified in Table 1. Sequentially

label the cable assemblies and plugs under test as shown in Figure 3 to Figure 5.

b) Randomly select the sample size of adaptors as specified in Table 1. Sequentially label the

adaptors under test as shown in Figure 3 to Figure 5.

– 12 – IEC 61300-3-45:2023 RLV © IEC 2023

c) Set up the reference power measurement system as shown in Figure 1, with cord 1 as the

launch test cord and plug 1 (pinned) as the launch test plug. Measure power P to P for

1-1 1-n

all fibres in the cord. For multimode measurement, tight tolerance fibre and tight tolerance

plug as specified in Annex A shall be used for the launch plug. The launch condition at the

launch plug shall comply with IEC 61300-1.

Key

LS light source 3 launch test cord

E launch condition control 31 unpinned plug of launch test cord

1 fan-out cord 32 pinned plug of launch test cord

2 launch plug (launch test plug)

Figure 1 – Reference power measurement system – Method 1

d) Pick up cord 2 as the receive test cord. Mate plug 1 (pinned) to plug 2 (unpinned) using

adaptor 1 as shown in Figure 2. Measure the power P to P for all fibres in the cord.

2-1 2-n

Key

LS light source 4 receive test cord

E launch condition control 41 unpinned plug of receive test cord

1 fan-out cord (receive test plug)

2 launch plug 42 pinned plug of receive test cord

3 launch test cord 5 adaptor

31 unpinned plug of launch test cord

32 pinned plug of launch test cord

(launch test plug)

Figure 2 – Attenuation measurement system – Method 1

e) Calculate the attenuation A of the mated plug pair 1 (pinned)/2 (unpinned) with adaptor 1,

using Formula (1):

P

2−i

A=−10log −×A L dB

( )

f

(1)

P

1−i

where

A is the attenuation;

i is the number of fibres of the test cord;

A is the fibre attenuation per kilometre;

f

L is the length of the fibre in kilometre.

The product A × L depends on the fibre attenuation level and can be neglectable when it is

f

small enough compared to the connection losses.

f) Record the attenuation results for each fibre into an appropriate matrix format.

g) Keeping plug 1 (pinned) as the launch test plug, replace cord 2 with cord 3 and mate plug

3 (unpinned) to plug 1 (pinned) using adaptor 1.

h) Measure the power P to P and record the attenuation results for each fibre.

3-1 3-n

i) Repeat steps g) and h) until all the unpinned plugs of the remaining cable assemblies have

been tested against the launch test plug 1 (pinned).

j) After step i) has been completed, replace the launch test cord and the adaptor so that plug

2 (pinned) is used as the launch test plug. Measure the reference power for the

configuration.

k) Measure the attenuation for all plugs (unpinned) against the launch test plug 2 (pinned)

using adaptor 2.

l) Continue this process until all allocated plugs (pinned) have been used as launch test plugs.

– 14 – IEC 61300-3-45:2023 RLV © IEC 2023

Test cord and labelling

“Reference”

Plug (without pins)

Configuration

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Plug 1 (with pins) Adaptor 1

-

Plug 2 (with pins) Adaptor 2

-

Plug 3 (with pins)) Adaptor 3

-

Plug 4 (with pins) Adaptor 4

-

Plug 5 (with pins) Adaptor 5

-

Plug 6 (with pins) Adaptor 6

-

Plug 7 (with pins) Adaptor 7

-

Plug 8 (with pins) Adaptor 8

-

Plug 9 (with pins) Adaptor 9

-

Plug 10 (with pins) Adaptor 10

-

Plug 11 (with pins) Adaptor 11

-

Plug 12 (with pins) Adaptor 12

-

Plug 13 (with pins) Adaptor 13

-

Plug 14 (with pins) Adaptor 14

-

Plug 15 (with pins) Adaptor 15

-

IEC 902/11

Figure 3 – Test matrix and labelling for measuring Method 1 (2-fibre connector)

Test cord and labelling

“Reference”

Plug (without pins)

configuration

1 2 3 4 5 6 7 8 9 10 11 12

Plug 1 (with pins) Adaptor 1

-

Plug 2 (with pins) Adaptor 2

-

Plug 3 (with pins) Adaptor 3

-

Plug 4 (with pins) Adaptor 4

-

Plug 5 (with pins) Adaptor 5

-

Plug 6 (with pins) Adaptor 6

-

Plug 7 (with pins) Adaptor 7

-

Plug 8 (with pins) Adaptor 8

-

Plug 9 (with pins) Adaptor 9

-

Plug 10 (with pins) Adaptor 10

-

Plug 11 (with pins) Adaptor 11

-

Plug 12 (with pins) Adaptor 12

-

IEC 903/11

IEC 904/11

Figure 4 – Test matrix and labelling for measuring Method 1 (4-fibre connector)

– 16 – IEC 61300-3-45:2023 RLV © IEC 2023

Test cord and labelling

“Reference”

Plug (without pins)

configuration

1 2 3 4 5 6 7 8 9 10

Plug 1 (with pins) Adaptor 1

-

Adaptor 2

Plug 2 (with pins)

-

Plug 3 (with pins) Adaptor 3

-

Plug 4 (with pins) Adaptor 4

-

Plug 5 (with pins) Adaptor 5

-

Plug 6 (with pins) Adaptor 6

-

Plug 7 (with pins) Adaptor 7

-

Plug 8 (with pins) Adaptor 8

-

Plug 9 (with pins) Adaptor 9

-

Plug 10 (with pins) Adaptor 10

-

Figure 5 – Test matrix and labelling for measuring Method 1

(8-, 10-, 12- and > 12-fibre connectors)

6.2 Method 2

a) Randomly select the sample number of cable assemblies specified in Table 2.

b) Choose three cable assemblies at random and sequentially label the plugs of each cord as

“reference” plugs. Sequentially label the plugs of the remaining cable assemblies as test

plugs. Sequentially label three adaptors 1 to 3 (as shown in Figures 10 to 12).

c) Set up the measurement system as shown in Figure 6, with “reference” cord 1 so that the

plug 1 (with pins) is the “reference” plug. Measure power P to P for all fibres in the

1-1 1-n

cord.

Fan-out cord “Reference” cord

Ch 1

D

S E

Plug 1

Plug 1

(without pins)

(with pins)

Ch n

P

1-n

IEC 905/11

Figure 6 – “Reference” cord measurement (1) – Method 2

d) Connect test cord 2 and adaptor 1 to the measurement system and mate reference plug 1

(with pins) with test plug 2 (without pins) as shown in Figure 7. Measure the power P to

2-1

P .

2-n

Adaptor 1

Test cord

“Reference” cord

Ch 1 Fan-out cord

D

E

S

Plug 1 Plug 1 Plug 2 Plug 2

(without pins) (with pins) (without pins) (with pins)

Ch n

P

2-n

IEC 906/11

Figure 7 – Test cord measurement (1) – Method 2

e) Calculate the attenuation of the mated plug pair 1 (with pins) / 2 (without pins) with adaptor

1, using Equation (2):

Insertion loss = [-10 log (P /P )] - (A × L) dB (2)

2-i 1-i

Where

i is fiber number of Test cord

A is fibre attenuation per km

L is length of fibre in km

NOTE The product A × L may be ignored for both single mode and multimode [50/125 µm and 62.5/125 µm] where

the cord length is small, i.e. < 10 m.

f) Record the attenuation results for each fibre into an appropriate matrix format.

g) Repeat steps d) to f) until all test plugs (without pins) have been tested against “reference”

plug 1 (with pins) and adaptor 1.

h) After step g) has been completed, replace the “reference” plug and adaptor so that

“reference” plug 2 (with pins) and adaptor 2 are the “reference” configuration.

i) Measure the attenuation for all test plugs (without pins) against “reference” plug 2 (with

pins) and adaptor 2, using the procedures described above.

j) Continue this process until all allocated “reference” plugs (with pins) and adaptors have

been used and all test cable assemblies (without pins) have been tested.

k) Set up the measurement system shown in Figure 8, with “reference” cord 1 so that the plug

(without pins) 1 is the “reference” plug, Measure power P to P for all fibres in the cord.

1-1 1-n

– 18 – IEC 61300-3-45:2023 RLV © IEC 2023

Fan-out cord “Reference” cord

Ch 1

D

S E

Plug 1

Plug 1

(with pins)

(without pins)

Ch n

P

1-n

IEC 907/11

Figure 8 – “Reference” cord measurement (2) – Method 2

l) Connect test cord 2 and adaptor 1 to the measurement system and mate “reference” plug 1

(without pins) with test plug 2 (with pins) as shown in Figure 9. Measure the power P to

2-1

P .

2-n

Adaptor 1

Test cord

“Reference” cord

Ch 1 Fan-out cord

D

E

S

Plug 1 Plug 1 Plug 2 Plug 2

(with pins) (without pins) (with pins) (without pins)

Ch n

P

2-n

IEC 908/11

Figure 9 – Test cord measurement (2) – Method 2

m) Calculate the attenuation of the mated plug pair 1 (without pins) / 2 (with pins) with adaptor

1, using the equation given above.

n) Record the attenuation results for each fibre into an appropriate matrix format.

o) Repeat steps l) to n) until all test plugs (with pins) have been tested against the “reference”

plug 1 (without pins) and adaptor 1.

p) After step m) has been completed, replace the “reference” plug and adaptor so that

“reference” plug 2 (without pins) and adaptor 2 are the “reference” configuration.

q) Measure the attenuation for all test plugs (with pins) against “reference” plug 2 (without

pins) and adaptor 2, using the procedures described above.

r) Continue this process until all allocated “reference” plugs (without pins) and adaptors have

been used and all test cable assemblies (with pins) have been tested.

a) Randomly select the sample number of cable assemblies specified in Table 2.

b) Choose three cable assemblies at random and sequentially label them as launch test cords,

and the plugs of each cord as launch test plugs as shown in Figure 10 to Figure 12.

Sequentially label the remaining cable assemblies as receive test cords, and the plugs of

each cord as receive test plugs as shown in Figure 10 to Figure 12. Sequentially label three

adaptors 1 to 3.

c) Set up the reference power measurement system as shown in Figure 6, with launch test

cord L1 so that plug L1 (pinned) is the launch test plug. Measure power P to P for all

1-1 1-n

fibres in the cord. For multimode measurement, tight tolerance fibre and tight tolerance plug

as specified in Annex A shall be used for the launch plug. The launch condition at the launch

plug shall comply with IEC 61300-1.

Key

LS light source 3 launch test cord

E launch condition control 31 unpinned plug of launch test cord

1 fan-out cord 32 pinned plug of launch test cord

2 launch plug (launch test plug)

Figure 6 – Reference power measurement system (1) – Method 2

d) Pick up receive test cord R1 and mate launch test plug L1 (pinned) to receive test plug R1

(unpinned) using adaptor 1 as shown in Figure 7. Measure the power P to P .

2-1 2-n

Key

LS light source 4 receive test cord

E launch condition control 41 unpinned plug of receive test cord

1 fan-out cord receive test plug)

2 launch plug 42 pinned plug of receive test cord

3 launch test cord 5 adaptor

31 unpinned plug of launch test cord

32 pinned plug of launch test cord

(launch test plug)

Figure 7 – Attenuation measurement system (1) – Method 2

e) Calculate the attenuation of the mated plug pair L1 (pinned)/R1 (unpinned) with adaptor 1,

using Formula (1).

f) Record the attenuation results for each fibre into an appropriate matrix format.

g) Repeat steps d) to f) until all receive test plugs (unpinned) have been tested against launch

test plug L1 (pinned) and adaptor 1.

h) After step g) has been completed, replace the launch test cord and the adaptor so that

launch test plug L2 (pinned) is used as the launch test plug. Measure the reference power

for the configuration.

i) Measure the attenuation for all receive test plugs (unpinned) against launch test plug L2

(pinned) and adaptor 2, using the procedures described above.

j) Continue this process until all allocated launch test plugs (pinned) and adaptors have been

used and all receive test plugs (unpinned) have been tested.

– 20 – IEC 61300-3-45:2023 RLV © IEC 2023

k) Set up the measurement system shown in Figure 8, with launch test cord 1 so that plug L1

(unpinned) is the launch test plug. Measure power P to P for all fibres in the cord.

1-1 1-n

Key

LS light source 3 launch test cord

E launch condition control 31 unpinned plug of launch test cord

1 fan-out cord 32 pinned plug of launch test cord

2 launch plug (launch test plug)

Figure 8 – Reference power measurement system (2) – Method 2

l) Pick up receive test cord R1 and mate launch test plug L1 (unpinned) to receive test plug

R1 (pinned) using adaptor 1 as shown in Figure 9. Measure the power P to P .

2‑1 2‑n

Key

LS light source 4 receive test cord

E launch condition control 41 unpinned plug of receive test cord

1 fan-out cord (receive test plug)

2 launch plug 42 pinned plug of receive test cord

3 launch test cord 5 adaptor

31 unpinned plug of launch test cord

32 pinned plug of launch test cord

(launch test plug)

Figure 9 – Attenuation measurement system (2) – Method 2

m) Calculate the attenuation of the mated plug pair L1 (unpinned)/R1 (pinned) with adaptor 1,

using Formula (1).

n) Record the attenuation results for each fibre into an appropriate matrix format.

o) Repeat steps l) to n) until all receive test plugs (pinned) have been tested against launch

test plug L1 (unpinned) and adaptor 1.

p) After step o) has been completed, replace the launch test cord and the adaptor so that

launch test p

...

IEC 61300-3-45 ®

Edition 2.0 2023-06

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures –

Part 3-45: Examinations and measurements – Attenuation of random mated

multi-fibre connectors

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61300-3-45 ®

Edition 2.0 2023-06

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures –

Part 3-45: Examinations and measurements – Attenuation of random mated

multi-fibre connectors

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 33.180.20 ISBN 978-2-8322-7169-8

– 2 – IEC 61300-3-45:2023 RLV © IEC 2023

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General description . 6

4.1 Test methods . 7

4.2 Precautions . 8

5 Apparatus . 9

5.1 Launch conditions and light source (LS) . 9

4.2 Launch conditions (E) .

5.2 Detector (D) . 10

5.3 Analysis of results .

6 Procedure . 10

6.1 Method 1. 10

6.2 Method 2. 16

7 Calculation and analysis . 23

8 Details to be specified and reported. 24

Annex A (normative) Requirements for launch fibre and launch plug for multimode

measurement . 25

Bibliography . 26

Figure 1 – “Reference” cord measurement – Method 1 .

Figure 1 – Reference power measurement system – Method 1 . 12

Figure 2 – Test cord measurement – Method 1 .

Figure 2 – Attenuation measurement system – Method 1 . 12

Figure 3 – Test matrix and labelling for measuring Method 1 (2-fibre connector) . 14

Figure 4 – Test matrix and labelling for measuring Method 1 (4-fibre connector) . 15

Figure 5 – Test matrix and labelling for measuring Method 1 (8-, 10-, 12- and > 12-fibre

connectors) . 16

Figure 6 – “Reference” cord measurement (1) – Method 2 .

Figure 6 – Reference power measurement system (1) – Method 2 . 19

Figure 7 – Test cord measurement (1) – Method 2 .

Figure 7 – Attenuation measurement system (1) – Method 2 . 19

Figure 8 – “Reference” cord measurement (2) – Method 2 .

Figure 8 – Reference power measurement system (2) – Method 2 . 20

Figure 9 – Test cord measurement (2) – Method 2 .

Figure 9 – Attenuation measurement system (2) – Method 2 . 20

Figure 10 – Test matrix and labelling for measuring Method 2 (2-fibre connector) . 21

Figure 11 – Test matrix and labelling for measuring Method 2 (4-fibre connector) . 22

Figure 12 – Test matrix and labelling for measuring Method 2 (8-, 10-, 12- and > 12-

fibre connectors) . 23

Figure A.1 – Attenuation measurement system . 25

Table 1 – Sample size for Method 1 . 8

Table 2 – Sample size for Method 2 . 8

Table 3 – Preferred source conditions . 9

Table A.1 – Requirements for launch fibre and launch plug . 25

– 4 – IEC 61300-3-45:2023 RLV © IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIBRE OPTIC INTERCONNECTING DEVICES AND PASSIVE

COMPONENTS – BASIC TEST AND MEASUREMENT PROCEDURES –

Part 3-45: Examinations and measurements –

Attenuation of random mated multi-fibre connectors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition IEC 61300-3-45:2011. A vertical bar appears in the margin

wherever a change has been made. Additions are in green text, deletions are in

strikethrough red text.

IEC 61300-3-45 has been prepared by subcommittee 86B: Fibre optic interconnecting devices

and passive components, of IEC technical committee 86: Fibre optics. It is an International

Standard.

This second edition cancels and replaces the first edition published in 2011. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) addition of sample size for > 12-fibre connector measurement;

b) inclusion of guidance for multimode measurement.

The text of this International Standard is based on the following documents:

Draft Report on voting

86B/4757/FDIS 86B/4774/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 61300 series, published under the general title Fibre optic

interconnecting devices and passive components – Basic test and measurement procedures,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC 61300-3-45:2023 RLV © IEC 2023

FIBRE OPTIC INTERCONNECTING DEVICES AND PASSIVE

COMPONENTS – BASIC TEST AND MEASUREMENT PROCEDURES –

Part 3-45: Examinations and measurements –

Attenuation of random mated multi-fibre connectors

1 Scope

The purpose of this part of IEC 61300 is to describe the procedure required to measure the

statistical distribution and mean attenuation for random mated optical connectors with physical

contact (PC) and angled physical contact (APC) polished 1-row multi-fibre rectangular ferrules

as defined in the IEC 61754 series. This measurement method is applicable to cable assemblies.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61300-1, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 1: General and guidance

IEC 61300-3-1, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 3-1: Examinations and measurements – Visual examination

IEC 61300-3-35, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 3-35: Examinations and measurements – Visual inspection of

fibre optic connector endface visual and automated inspection connectors and fibre-stub

transceivers

IEC 61754 (all parts), Fibre optic interconnecting devices and passive components – Fibre optic

connector interfaces

IEC 63267 (all parts), Fibre optic interconnecting devices and passive components – Connector

optical interfaces for enhanced macro bend loss multimode fibres

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 General description

4.1 Test methods

Two test methods are described for measuring the attenuation of random mated optical

connectors. Both provide an estimate of the expected average performance that a group of

cable assemblies (including an adaptor, if applicable) selected from a batch will exhibit when

used in an optical system. The device under test (DUT) is a cable assembly with on one side a

plug with pins (pinned plug) and on the other side a plug without pins (unpinned plug). The

cable assemblies, and any adaptors, must shall be chosen at random to ensure that the

measurements provide a statistically unbiased estimate.

Method 1 describes a procedure using a sample of cable assemblies and adaptors specified in

Table 1. In this case the pinned plugs (with pins) are used as “reference” plugs "launch test

plugs” and the unpinned plugs (without pins) are tested against them sequentially. The results,

based on the number of measurements specified in Table 1, are recorded in the test matrix

shown in Figure 3 to Figure 5.

Method 1 is intended to be part of a design approval exercise that may involve one or more

suppliers. Once approval is achieved, Method 2 would be relied on to maintain process control.

However, in the event of a dispute, Method 1 shall act as the reference measurement method.

Method 2 describes a procedure for the measurement of a sample of cable assemblies and

adaptors specified in Table 2. Three cable assemblies are selected from the sample as

“reference” cable assemblies and pins are fitted. The other test cable assemblies (without pins)

are tested against each of the three “reference cable assemblies” sequentially. Three cable

assemblies are selected from the sample as "launch test cords” and the remaining cable

assemblies are grouped as “receive test cords”. First, the pinned plugs of the launch test cords

are used as launch test plugs and the unpinned plugs of the receive test cords are tested against

them sequentially. Then the unpinned plugs of the launch test cords are used as launch test

plugs and the pinned plugs of the receive test cords are tested. This produces the number of

measurements specified in Table 2 and the results are recorded in the test matrix shown in

Figure 10 to Figure 12.

Method 1 is intended to be part of a design approval exercise that can involve one or more

suppliers. It is recognised that the number of measurements required by Method 1 may can be

excessive for day-to-day routine checking of either in-house or supplier produced products. In

this case, as indicated above once approval is achieved, Method 2 may would be relied on to

maintain process control as an alternative option. However, in the event of a dispute, Method 1

shall act as the reference measurement method.

NOTE In this measurement method, the terms “reference” plug or “reference” cord are used to define those

components chosen at random from a batch, against which a number of comparative measurements are made. In

this measurement method, the term “launch test cord” is used to define one of the mated DUTs which is installed on

the light source side. On the other hand, the other DUT which is installed on the detector side is defined as “receive

test cord”. In the same way, the plugs mated at the connection point under test are defined as “launch test plug” and

“receive test plug”, respectively. "Launch test plug” and "launch test cord” are used to define those components

chosen at random from the sample, against which a number of comparative measurements are made. It is not

intended that the terms should imply specially chosen or manufactured components, such as those used, for example,

in screen testing.

– 8 – IEC 61300-3-45:2023 RLV © IEC 2023

Table 1 – Sample size for Method 1

Connectors Sample sizes

(n-fibre connector) Cords and adaptors Measurements Fibres

2-fibre connector 15 210 420

4-fibre connector 12 132 528

8-fibre connector 10 90 720

10-fibre connector 10 90 900

12-fibre connector 10 90 1 080

> 12-fibre connector 10 90 90*n

NOTE Parameter n is the number of fibres in the connector.

Table 2 – Sample size for Method 2

Sample size

Connector

Cord and adaptors

(n-fibre connector) Measurements Fibres

Total Reference Test :N

2-fibre connector 12 3 9 54 108

4-fibre connector 8 3 5 30 120

8-fibre connector 6 3 3 18 144

10-fibre connector 6 3 3 18 180

12-fibre connector 6 3 3 18 216

Sample sizes

Connectors (n Cords

‑fibre connector)

Adaptors Measurements Fibres

Launch test Receive

Total

cord test cord

2-fibre connector 12 3 9 3 54 108

4-fibre connector 8 3 5 3 30 120

8-fibre connector 6 3 3 3 18 144

10-fibre connector 6 3 3 3 18 150

12-fibre connector 6 3 3 3 18 216

> 12-fibre connector 6 3 3 3 18 18*n

NOTE Parameter n is the number of fibres in the connector.

4.2 Precautions

The following test requirements shall be met.

a) Precautions shall be taken to ensure that The cladding modes do shall not affect the

measurement. Cladding modes shall be stripped as a function of the fibre coating.

b) Precautions shall be taken to ensure that the position of the fibres in the test remains fixed

between the measurement of P and P to avoid changes in attenuation due to bending

1 2

losses.

b) The fibres in the test shall remain fixed between the reference power measurement and the

corresponding attenuation measurements to avoid changes in attenuation due to bending

losses.

b) The stability performance of the test equipment shall be ≤ 0,05 dB or 10 % of the attenuation

to be measured, whichever is the lower value. The stability shall be maintained over the

measurement time and operational temperature range. The required measurement

resolution shall be 0,01 dB for both multimode and single-mode.

c) To achieve consistent results, clean and inspect all connectors and adaptors prior to the

setup of the measurement system and if contaminated clean them. During measurement

steps, inspect all connectors and adaptors except those in the unchanged connections and

if contaminated clean them before mating. Visual examination shall be undertaken in

accordance with IEC 61300-3-1 and IEC 61300-3-35.

NOTE A cladding mode stripper usually comprises a material having a refractive index equal to or greater than that

of the fibre cladding.

5 Apparatus

5.1 Launch conditions and light source (LS)

The source consists of an optical emitter, the means to connect to it and associated drive

electronics. In addition to meeting the stability and power level requirements, the source shall

have the following characteristics:

– Centre wavelength, as detailed in the performance and product standard;

– Spectral width, filtered light emitting diode (LED) ≤ 150 nm full width half maximum (FWHM);

– Spectral width, laser diode (LD) < 10 nm FWHM.

For multimode fibres, broadband sources such as an LED shall be used.

For single mode fibres either an LED or LD may be used.

The source unit consists of an optical emitter, the associated drive electronics, and fibre pigtail

(if any). Preferred source conditions are given in Table 3. The stability of the single-mode fibre

source at 23 °C shall be ±0,01 dB over the duration of the measurement. The stability of the

multimode fibre source at 23 °C shall be ±0,05 dB over the duration of the measurement. The

source output power shall be ≥ 20 dB above the minimum measurable power level.

Table 3 – Preferred source conditions

Central Source type

No. Type Spectral width (RMS)

wavelength

nm nm

S1 Multimode 660 ± 30 ≥ 10 Monochromator or LED

S2 Multimode 780 ± 30 ≥ 10 Monochromator or LED

S3 Multimode 850 ± 30 ≥ 10 Monochromator or LED

S4 Multimode 1 300 ± 30 ≥ 10 Monochromator or LED

S5 Single-mode 1 310 ± 30 To be reported Laser diode, monochromator, or LED

S6 Single-mode 1 550 ± 30 To be reported Laser diode, monochromator, or LED

S7 Single-mode 1 625 ± 30 To be reported Laser diode, monochromator, or LED

It is recognized that some components, for example for coarse wavelength division multiplexing (CWDM), can

require the use of other source types such as tunable lasers. It is therefore recommended in these cases that the

preferred source characteristics are specified on the basis of the component to be measured.

NOTE Central wavelength and spectral width are defined in IEC 61280-1-3.

– 10 – IEC 61300-3-45:2023 RLV © IEC 2023

The launch condition shall be specified in accordance with IEC 61300-1. In case the specified

launch condition is not obtained by the original light from the source, an appropriate apparatus

for launch condition control (E) shall be used.

NOTE The interference of modes from a coherent source will create speckle patterns in

multimode fibres. These speckle patterns give rise to speckle or modal noise and are observed

as power fluctuations, since their characteristic times are longer than the resolution time of the

detector. As a result, it may be impossible to achieve stable launch conditions cannot be

achieved using coherent sources for multimode measurements. Consequently, lasers, including

optical time domain reflectometer (OTDR) sources, should be avoided in favour of LEDs or

other incoherent sources for measuring multimode components.

4.2 Launch conditions (E)

The launch condition shall be specified in accordance with IEC 61300-1.

5.2 Detector (D)

The detector consists of an optical detector, the means to connect to it and associated

electronics. The connection to the detector will be an adaptor that accepts a connector plug of

the appropriate design. The detector shall capture all light emitted by the connector plug.

In addition to meeting the stability and resolution requirements, the detector shall have the

following characteristics:

– linearity of multimode, ≤ ±0,25 dB (over −5 dBm up to −60 dBm);

– linearity of single-mode, ≤ ±0,1 dB (over −5 dBm up to −60 dBm).

NOTE The power meter detector linearity should be referenced to a power level of −23 dBm at

the operational wavelength.

Where the connection to the detector is broken between the reference power measurement of

P the corresponding attenuation measurements, the measurement repeatability shall

and P

1 2

be within 0,05 dB or 10 % of the attenuation to be measured, whichever is the lower value. A

large sensitive area detector may can be used to achieve this.

The precise characteristics of the detector shall be compatible with the measurement

requirements. The dynamic range of the power meter detector shall be capable of measuring

the power level exiting from the device under test (DUT) at the wavelength being measured.

6 Procedure

6.1 Method 1

a) Randomly select the sample number of cable assemblies specified in Table 1. Sequentially

label the plugs under test as shown in Figures 3 to 5.

b) Randomly select the sample size of adaptors as specified in Table 1. Sequentially label the

adaptors under test as shown in Figures 3 to 5.

c) Set up the measurement system as shown in Figure 1, with cord 1as the “reference” cord

and with plug 1 as the “reference” plug. Measure power P to P for all fibres in the

1-1 1-n

cord.

Fan-out cord “Reference” cord

Ch 1

D

S E

Plug

Plug

1(without pins)

1(with pins)

Ch n

P

1-n

IEC 900/11

Figure 1 – “Reference” cord measurement – Method 1

d) Connect test cord 2 and adaptor 1 to the system and mate plug 1 (with pins) to plug 2

(without pins) as shown in Figure 2. Measure the power P to P for all fibres in the cord.

2-1 2-n

Adaptor 1

Test cord

Ch 1 Fan-out cord “Reference” cord

D

E

S

Plug 1 Plug 1 Plug 2 Plug 2

(without pins) (with pins) (without pins) (with pins)

Ch n

P

2-n

IEC 901/11

Figure 2 – Test cord measurement – Method 1

e) Calculate the attenuation of the mated plug pair 1 (with pins) / 2 (without pins) with adaptor

1, using Equation (1):

Attenuation = [-10 log (P /P )] - (A × L) dB (1)

2-i 1-i

Where

i is fibre number of Test cord.

A is fibre attenuation per km;

L is length of fibre in km.

NOTE The product A × L may be ignored for both single mode and multimode [50/125 µm and 62,5/125 µm] where

the cord length is small, i.e. < 10 m.