IEC 60172:2020

(Main)Test procedure for the determination of the temperature index of enamelled and tape wrapped winding wires

Test procedure for the determination of the temperature index of enamelled and tape wrapped winding wires

IEC 60172:2020 specifies, in accordance with the provisions of IEC 60216-1, a method for evaluating the temperature index of enamelled wire, varnished or unvarnished with an impregnating agent, and of tape wrapped round and rectangular wire, in air at atmospheric pressure by periodically monitoring changes in response to AC proof voltage tests. This procedure does not apply to fibre-insulated wire or wire covered with tapes containing inorganic fibres. NOTE The data obtained according to this test procedure provide the designer and development engineer with information for the selection of winding wire for further evaluation of insulation systems and equipment tests. This fifth edition cancels and replaces the fourth edition published in 2015. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- revision of 3.1, definition of thermal index;

- revision of 3.3, time to failure;

- revisions to 5.1.1 for clarity and to reduce the range wire size range to which the test applies;

- revisions to 5.1.2 for tape wrapped round and enamelled or tape wrapped rectangular wire for clarity;

- revision to Clause 9 to add the correlation coefficient, r to the report.

Méthode d'essai pour la détermination de l'indice de température des fils de bobinage émaillés et enveloppés de ruban

L'IEC 60172:2020 spécifie, conformément aux dispositions de l’IEC 60216-1, une méthode pour l’évaluation de l'indice de température du fil émaillé, imprégné ou non imprégné avec un matériau d’imprégnation, et du fil de section circulaire ou rectangulaire, enveloppé de ruban, dans l’air à la pression atmosphérique, en contrôlant périodiquement les variations de réponse aux essais de tension d'épreuve en courant alternatif. Cette méthode ne concerne pas le fil avec revêtement fibreux ou le fil recouvert de rubans contenant des fibres non organiques. NOTE Les données obtenues au moyen de cette méthode d'essai fournissent à l'ingénieur d'étude et de développement les informations pour sélectionner le fil de bobinage et obtenir une meilleure évaluation des systèmes isolants et des essais d'équipement. Cette cinquième édition annule et remplace la quatrième édition parue en 2015. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- révision du 3.1, définition d’indice thermique;

- révision du 3.3, durée de fonctionnement avant défaillance;

- révisions du 5.1.1 à des fins de clarification et pour limiter la plage des dimensions de fils à laquelle l’essai s’applique;

- révisions à des fins de clarification du 5.1.2 relatif au fil de section circulaire enveloppé d'un ruban et au fil de section rectangulaire émaillé ou enveloppé d'un ruban;

- révision de l’Article 9 afin d’ajouter le coefficient de corrélation, r au rapport.

General Information

- Status

- Published

- Publication Date

- 22-Nov-2020

- Technical Committee

- TC 55 - Winding wires

- Drafting Committee

- WG 1 - TC 55/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 23-Nov-2020

- Completion Date

- 27-Dec-2020

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60172:2020 - Test procedure for the determination of the temperature index of enamelled and tape‑wrapped winding wires - specifies a standardized method to evaluate the thermal capability of winding wire insulation. Aligned with IEC 60216‑1, the procedure exposes specimens to controlled heat‑storage cycles in air at atmospheric pressure and periodically applies AC proof voltage tests to monitor insulation deterioration. The temperature index (TI) is the Celsius temperature corresponding to an extrapolated lifetime of 20 000 hours on an Arrhenius thermal‑endurance plot.

Key topics and requirements

- Scope and exclusions: Applies to enamelled wire (varnished or unvarnished, with or without impregnation) and tape‑wrapped round/rectangular wire. Does not apply to fibre‑insulated wire or tapes containing inorganic fibres.

- Specimen preparation: Detailed methods for enamelled non‑tape wrapped round wire (nominal conductor diameters from 0.224 mm up to 2.65 mm) and for tape‑wrapped round/rectangular wire are specified to ensure repeatable results.

- Test cycle: Repeated heat‑storage exposure at selected temperatures followed by room‑temperature AC proof voltage tests until sufficient specimen failures occur.

- Data analysis: Calculation of specimen failure time, time‑to‑failure statistics, linear regression of log(life) versus reciprocal absolute temperature, and plotting on thermal endurance graph paper to derive TI.

- Reporting: Test report must include results and statistical metrics - Clause 9 now requires inclusion of the correlation coefficient (r) for the regression.

- Normative references: IEC 60216‑1 (ageing procedures/evaluation) and IEC 60216‑3 (calculating thermal endurance characteristics).

Applications and who uses it

- Winding wire manufacturers use IEC 60172 to characterize enamel and tape insulation and to support product datasheets (temperature index, thermal class guidance).

- Motor, transformer and generator designers rely on TI data to select appropriate winding wire for insulation systems and for further equipment qualification tests.

- R&D and materials engineers use the method to compare insulation formulations, varnish impregnation effects, or tape systems under accelerated thermal ageing.

- Test laboratories and certification bodies apply this standardized procedure to provide reproducible, comparable thermal‑endurance data.

Practical value

- Provides a reproducible, internationally recognized method to quantify insulation thermal performance.

- TI data support material selection, comparative evaluations, and risk‑based design decisions for electrical rotating machines and other wound components.

- Inclusion of statistical metrics (e.g., correlation coefficient r) increases confidence in TI extrapolations and design use.

Related standards

- IEC 60216‑1 - Electrical insulating materials: Thermal endurance procedures and evaluation.

- IEC 60216‑3 - Instructions for calculating thermal endurance characteristics.

Keywords: IEC 60172, temperature index, enamelled winding wire, tape wrapped winding wire, thermal endurance, AC proof voltage, winding wire testing, IEC 60216.

Buy Documents

IEC 60172:2020 RLV - Test procedure for the determination of the temperature index of enamelled and tape wrapped winding wires Released:11/23/2020

IEC 60172:2020 - Test procedure for the determination of the temperature index of enamelled and tape wrapped winding wires Released:11/23/2020

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60172:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test procedure for the determination of the temperature index of enamelled and tape wrapped winding wires". This standard covers: IEC 60172:2020 specifies, in accordance with the provisions of IEC 60216-1, a method for evaluating the temperature index of enamelled wire, varnished or unvarnished with an impregnating agent, and of tape wrapped round and rectangular wire, in air at atmospheric pressure by periodically monitoring changes in response to AC proof voltage tests. This procedure does not apply to fibre-insulated wire or wire covered with tapes containing inorganic fibres. NOTE The data obtained according to this test procedure provide the designer and development engineer with information for the selection of winding wire for further evaluation of insulation systems and equipment tests. This fifth edition cancels and replaces the fourth edition published in 2015. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - revision of 3.1, definition of thermal index; - revision of 3.3, time to failure; - revisions to 5.1.1 for clarity and to reduce the range wire size range to which the test applies; - revisions to 5.1.2 for tape wrapped round and enamelled or tape wrapped rectangular wire for clarity; - revision to Clause 9 to add the correlation coefficient, r to the report.

IEC 60172:2020 specifies, in accordance with the provisions of IEC 60216-1, a method for evaluating the temperature index of enamelled wire, varnished or unvarnished with an impregnating agent, and of tape wrapped round and rectangular wire, in air at atmospheric pressure by periodically monitoring changes in response to AC proof voltage tests. This procedure does not apply to fibre-insulated wire or wire covered with tapes containing inorganic fibres. NOTE The data obtained according to this test procedure provide the designer and development engineer with information for the selection of winding wire for further evaluation of insulation systems and equipment tests. This fifth edition cancels and replaces the fourth edition published in 2015. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - revision of 3.1, definition of thermal index; - revision of 3.3, time to failure; - revisions to 5.1.1 for clarity and to reduce the range wire size range to which the test applies; - revisions to 5.1.2 for tape wrapped round and enamelled or tape wrapped rectangular wire for clarity; - revision to Clause 9 to add the correlation coefficient, r to the report.

IEC 60172:2020 is classified under the following ICS (International Classification for Standards) categories: 29.060.10 - Wires. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60172:2020 has the following relationships with other standards: It is inter standard links to IEC 60172:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60172:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60172 ®

Edition 5.0 2020-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Test procedure for the determination of the temperature index of enamelled and

tape wrapped winding wires

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60172 ®

Edition 5.0 2020-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Test procedure for the determination of the temperature index of enamelled and

tape wrapped winding wires

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.060.10 ISBN 978-2-8322-9123-8

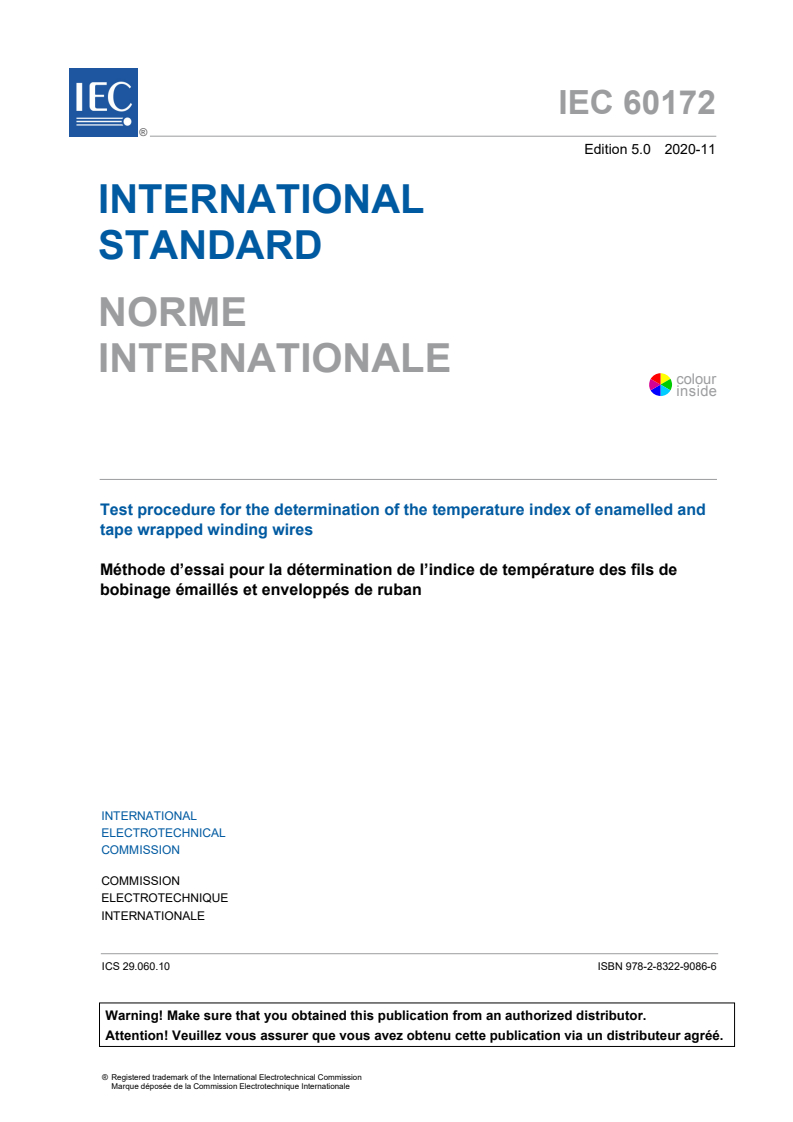

– 2 – IEC 60172:2020 RLV © IEC 2020

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Summary of procedure . 7

5 Test specimens . 7

5.1 Preparation . 7

5.1.1 Enamelled round wire with a nominal conductor diameter of 0,224 mm

up to and including 2,65 mm Enamelled non-tape wrapped round wire . 7

5.1.2 Tape wrapped round wire and enamelled or tape wrapped rectangular

wire . 11

5.2 Varnish impregnation . 13

5.3 Notes on number of test specimens . 14

5.4 Specimen holder . 14

5.4.1 For specimens according to 5.1.1 . 14

5.4.2 For specimens according to 5.1.2 . 15

6 Temperature exposure. 15

7 Test voltage and its application . 17

8 Calculations . 17

8.1 Specimen failure time . 17

8.2 Time to failure . 18

8.3 Linearity of data . 18

8.4 Calculating and plotting thermal endurance and temperature index . 18

9 Report . 19

Annex A (normative) Method for calculation of the regression line . 20

Annex B (normative) Correlation coefficient . 25

Bibliography . 26

Figure 1 – Device used to form enamelled round wire test specimen . 8

Figure 2 – Spacer . 9

Figure 3 – Twist forming jig . 9

Figure 4 – Test specimen set up in forming jig . 10

Figure 5 – Test specimen formed with loop cut . 10

Figure 6 – Jig for bending large magnet wire, dielectric test specimen . 12

Figure 7 – Forming jig and test specimen . 13

Figure 8 – Specimen holder . 14

Figure 9 – Specimen holder and electrical connection fixture .

Figure 9 – Thermal endurance graph – Temperature index . 19

Figure A.1 – Plot of regression line based on sample calculation (Table A.2) . 24

Table 1 – Force and number of twists for specimens . 8

Table 2 – Proof voltage for round enamelled wire . 10

Table 3 – Recommended exposure times in days per cycle. 16

Table 4 – Proof voltage for tape-wrapped round and for enamelled or tape-wrapped

rectangular wire . 17

Table A.1 – Commonly used test temperatures in degrees Celsius and the

corresponding kelvins with its reciprocal and reciprocal squared values . 22

Table A.2 – Sample calculation . 23

– 4 – IEC 60172:2020 RLV © IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST PROCEDURE FOR THE DETERMINATION OF THE TEMPERATURE

INDEX OF ENAMELLED AND TAPE WRAPPED WINDING WIRES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60172 has been prepared by IEC Technical Committee 55:

Winding wires.

This fifth edition cancels and replaces the fourth edition published in 2015. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– revision of 3.1, definition of thermal index;

– revision of 3.3, time to failure;

– revisions to 5.1.1 for clarity and to reduce the range wire size range to which the test

applies;

– revisions to 5.1.2 for tape wrapped round and enamelled or tape wrapped rectangular wire

for clarity;

– revision to Clause 9 to add the correlation coefficient, r to the report.

The text of this International Standard is based on the following documents:

FDIS Report on voting

55/1876/FDIS 55/1893/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 60172:2020 RLV © IEC 2020

TEST PROCEDURE FOR THE DETERMINATION OF THE TEMPERATURE

INDEX OF ENAMELLED AND TAPE WRAPPED WINDING WIRES

1 Scope

This International Standard specifies, in accordance with the provisions of IEC 60216-1, a

method for evaluating the temperature index of enamelled wire, varnished or unvarnished with

an impregnating agent, and of tape wrapped round and rectangular wire, in air at atmospheric

pressure by periodically monitoring changes in response to AC proof voltage tests. This

procedure does not apply to fibre-insulated wire or wire covered with tapes containing

inorganic fibres.

NOTE The data obtained according to this test procedure provide the designer and development engineer with

information for the selection of winding wire for further evaluation of insulation systems and equipment tests.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60216-1, Electrical insulating materials – Thermal endurance properties – Part 1: Ageing

procedures and evaluation of test results

IEC 60216-3, Electrical insulating materials – Thermal endurance properties – Part 3:

Instructions for calculating thermal endurance characteristics

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

temperature index

TI

numerical value of the Celsius temperature expressed in degrees Celsius characterizing the

thermal capability of an insulating material or an insulation system

number which permits comparison of the temperature/time characteristics of an electrical

insulating material, or a simple combination of materials, based on the temperature in degrees

Celsius which is obtained by extrapolating the Arrhenius plot of life versus temperature to a

lifetime of 20 000 h

Note 1 to entry: In case of insulating materials, the temperature index is derived from the thermal endurance

relationship at a given time, normally 20 000 hours. It may be used as basis for determination of the material’s

temperature class.

Note 2 1 to entry: In case of insulation systems, the temperature index may be derived from known service

experience or from a known comparative functional evaluation of an evaluated and established reference insulation

system as basis.

[SOURCE: IEC 60050-212:2010, 212-12-11 modified by merging Note 1 into the definition,

and to specify a lifetime of 20 000 h.]

3.2

specimen failure time

number of hours at the exposure temperature that have elapsed at the time a specimen

proof test

fails the

3.3

time to failure

L

number of hours to failure calculated from the specimen mean value or logarithmic mean

value failure times for a set of specimens at one exposure temperature, in accordance with

8.2

4 Summary of procedure

A set of specimens in accordance with Clause 5 is subjected to a testing cycle. This cycle

consists of a heat-storing heat-exposure period at a temperature given in Clause 6,

followed by a proof voltage test at room temperature in accordance with Clause 7.

This cycle is repeated until a sufficient number of specimens has failed. The time to failure is

calculated in accordance with Clause 8. The test is carried out at three or more

temperatures. A regression line is calculated in accordance with 8.4 and the time to failure

values plotted on thermal endurance graph paper as a function of the exposure

temperature.

The temperature in degrees Celsius, corresponding to the point of intersection of the

regression line with the ordinate of 20 000 h endurance represents the temperature index of

the winding wire under test.

5 Test specimens

5.1 Preparation

5.1.1 Enamelled round wire with a nominal conductor diameter of 0,224 mm up to and

including 2,65 mm

Enamelled non-tape wrapped round wire

The grade of insulation used for determining the thermal index shall be grade 2 or grade 2B

for self-bonding winding wires.

Wire sizes 0,315 mm and 0,28 mm are permitted for use when the specification size range is

limited to 0,50 mm and finer.

NOTE For round enamelled winding wires, in order to avoid undue fragility of the test specimen, experience has

shown that nominal conductor diameters of 0,800 mm up to and including 2,65 mm are generally found convenient

to handle and test.

This procedure applies to enamelled round wires that are not tape wrapped. The thermal

index can be determined by evaluating enamelled non-tape wrapped round wire with a

nominal conductor diameter of 0,224 mm up to and including 2,65 mm.

NOTE For round enamelled winding wires, experience has shown that nominal conductor diameters of 0,800 mm

up to and including 1,60 mm are generally found convenient to handle and test.

Wires with a nominal conductor diameter between 0,280 mm and 0,500 mm are permitted for

use when the specification range of diameters is limited to 0,500 mm and finer.

– 8 – IEC 60172:2020 RLV © IEC 2020

The grade of insulation used for determining the thermal index shall be grade 2 or grade 2B

for self-bonding winding wires.

Specimens shall be prepared as follows:

a) A wire specimen approximately 400 mm in length shall be twisted together over a distance

of 125 mm with a device as shown in Figure 1. The force (weight) applied to the wire pair

while being twisted and the number of twists are specified in Table 1.

Figure 1 – Device used to form enamelled round wire test specimen

Table 1 – Force and number of twists for specimens

Nominal diameter Force applied to Number of twists

wire pairs per

mm N 125 mm

Over Up to and

including

0,224 0,25 0,85 33

0,25 0,35 1,7 23

0,35 0,50 3,4 16

0,50 0,75 7,0 12

0,75 1,05 13,5 8

1,05 1,50 27,0 6

1,50 2,15 54,0 4

2,15 3,50 2,65 108,0 3

b) Spacers may be prepared as shown in Figure 2. Such thermally stable insulating

materials as ceramic or silicone glass fibre laminate may be used. The spacers are

marked with a suitable identifying letter or number.

Dimensions in millimetres

Material: Silicone glass laminate

Figure 2 – Spacer

c) The test specimens may be shaped in a jig, an engineering drawing of which is shown

in Figure 3. A specimen is placed in the jig and a spacer, placed on the parallel leads

of the twisted pair, is brought up to the face of the jig as shown in Figure 4. The leads

are then bent parallel to hold the spacer in position. The forming jig provides more

uniform test specimens. If a specimen holder is used, the spacers are unnecessary.

Dimensions in millimetres

R = Radius of bend

Figure 3 – Twist forming jig

– 10 – IEC 60172:2020 RLV © IEC 2020

Figure 4 – Test specimen set up in forming jig

d) The loop at the end of the twisted section shall be cut at two places (not one) to

provide the maximum spacing between the cut ends as shown in Figure 5. Any bending

of the wires, at this end or the other untwisted end, to ensure adequate separation

between the wires shall avoid sharp bends or damage to the insulation.

Figure 5 – Test specimen formed with loop cut

e) In order to ensure homogeneity of the batch set of test specimens, it is recommended

that test specimens be subjected to, and withstand without breakdown, a test voltage three

times the value given in Table 2 for 1 s prior to starting thermal exposure cycling.

Table 2 – Proof voltage for round enamelled wire

Increase in diameter due to the insulation Voltage

(mm) (rms)

Over Up to and including

– 0,015 300

0,015 0,024 300

0,024 0,035 400

0,035 0,050 500

0,050 0,070 700

0,070 0,090 1 000

0,090 0,130 1 200

5.1.2 Tape wrapped round wire and enamelled or tape wrapped rectangular wire

NOTE This procedure applies to any convenient dimension of round or rectangular wire. However, selecting wires

having dimensions that minimize the bending force needed to shape the test specimen will make the procedure

easier to perform. Wire with high stiffness will yield specimens with poor wire-to-wire contact areas.

This procedure applies to any convenient dimension of tape wrapped round or tape wrapped

or enamelled rectangular wire.

It is recommended to select a wire having dimensions that minimize the bending force

necessary to shape the test specimen, since wire with high stiffness will yield specimens with

poor wire-to-wire contact areas.

Specimens shall be prepared as follows:

a) Two straight specimens of wire each of 250 mm length shall be cut from the supply spool.

b) 10 mm to 15 mm of the insulation shall be removed from one end of each piece of wire to

provide for electrical connection.

c) Each specimen shall be formed in a jig, as shown in Figure 6. This produces a straight

centre section of about 150 mm with bent ends, which provide the necessary flare at both

ends of the final specimen.

– 12 – IEC 60172:2020 RLV © IEC 2020

Dimensions in millimetres

Figure 6 – Jig for bending large magnet wire, dielectric test specimen

d) The two formed specimens shall be placed together back-to-back and tightly wrapped with

glass yarn over the straight centre section of the specimen, as shown in Figure 7.

Figure 7 – Forming jig and test specimen

Care shall be taken that the centre section shows a close contact between the two pieces.

After tying, further bending of the ends shall be avoided. Pre-annealing of the specimen

prior to testing or impregnating will remove stress and craze marks and therefore may be

desirable with certain material.

e) Prior to testing starting the thermal exposure cycles, the specimen shall be proof-tested at

1 000 V AC.

5.2 Varnish impregnation

Experience has shown that Insulated wire according to IEC 60317 and impregnating agents

according to IEC 60455-3-5 or IEC 60464-3-2 can affect one another during the thermal

ageing process.

NOTE 1 Testing varnished specimens will allow for evaluation of the compatibility of the wire insulation with an

impregnating agent. Thus, the temperature indices of different combinations can be compared.

Interaction between wire insulation and such agent may increase or decrease the relative

thermal life of this combination compared with the life of the wire tested without impregnation.

Therefore, with impregnated specimens, this test procedure may give an indication of the

thermal endurance of a combination of wire insulation and impregnating agent.

If such impregnation is required, the following procedure shall be applied:

– 14 – IEC 60172:2020 RLV © IEC 2020

With the specimen in the vertical position, it shall be immersed in the impregnating agent for

(60 ± 10) s (see note). It shall be removed slowly and uniformly at a rate of about 1 mm/s. It

shall be drained horizontally for 10 min to 15 min and cured horizontally according to the

manufacturer's recommendation or to an agreed schedule. If more than one treatment is to be

given, immerse, drain and cure the specimen vertically reversing the specimen for each

subsequent treatment.

NOTE 2 Some impregnating agents, such as high viscosity or thixotropic products require alternative processing

methods.

5.3 Notes on number of test specimens

The accuracy of the test results depends largely upon the number of test specimens aged at

each temperature. A greater number of test specimens is required to achieve an acceptable

degree of accuracy if there is a wide spread in results among the specimens exposed at each

temperature.

Experience has shown that twenty specimens without impregnation and ten specimens with

impregnation give results with an acceptable tolerance. A minimum of ten specimens shall be

used.

5.4 Specimen holder

5.4.1 For specimens according to 5.1.1

Since individual handling of the twisted specimens may result in premature failures, it is

recommended that the specimens be placed in a suitable holder, as shown in Figure 8. The

holder should be designed in a manner that will protect the twisted specimens from external

mechanical damage and warping. The holder will be so constructed as to allow the ends of

the twist to protrude from the holder to make electrical connections for the proof testing as

shown in Figure 9. The holder shall be designed for at least ten specimens to decrease

handling time.

Figure 8 – Specimen holder

IEC

Figure 9 – Specimen holder and electrical connection fixture

5.4.2 For specimens according to 5.1.2

The specimen shall be hung in the oven. No special holder is required.

6 Temperature exposure

Recommended temperatures to which the test specimens are subjected are given in this

Clause 6.

Test specimens shall be subjected to the temperatures given in this Clause 6.

In Table 3, the recommended The test temperature and time of exposure in each cycle are

given in Table 3. A test cycle is defined as one exposure to a high temperature followed by

one proof-voltage test at room temperature (20 – 30 °C). The test specimens shall be placed

directly into and removed from the ageing ovens without controlling the heating or cooling

rate.

The ovens should shall be heated to the proper temperatures before the specimens are

subjected to the exposure temperature.

The specimens should shall be aged in a forced air circulation oven which is capable of

maintaining the temperature of the specimens under test within 2 °C of the selected exposure

temperature.

The exposure times are selected to subject the test specimens to approximately 10 cycles at

each temperature before the time to failure is reached.

– 16 – IEC 60172:2020 RLV © IEC 2020

Table 3 – Recommended exposure times in days per cycle

Exposure or ageing

Estimated temperature index

temperature

(ºC)

105-109 120-130 150-159 180-189 200-209 220-239 240-249

320 – – – – – – 1

310 – – – – – – 2

300 – – – – – 1 4

290 – – – – – 2 7

280 – – – – 1 4 14

270 – – – – 2 7 28

260 – – – 1 4 14 49

250 – – – 2 7 28 –

240 – – – 4 14 49 –

230 – – – 7 28 – –

220 – – 1 14 49 – –

210 – 1 2 28 – – –

200 – 2 4 49 – – –

190 1 4 7 – – – –

180 2 7 14 – – – –

170 4 14 28 – – – –

160 7 28 49 – – – –

150 14 49 – – – – –

140 28 – – – – – –

130 49 – – – – – –

120 – – – – – – –

NOTE The recommendations in Table 3 differ from those in IEC 60216-3 but have been found to be more

suitable for enamelled wires.

Thermal endurance values obtained from test specimens subjected to an average of less than

eight or more than twenty cycles at the exposed temperature may not be reliable and should

not be used to predict the temperature rating of the enamelled wire. Therefore, a shorter or

longer cycle time than those given in Table 3 may be chosen for certain exposure

temperatures, to ensure that the average number of cycles to failure falls within this range.

After the specimens have been subjected to a particular cycle, the time may be appropriately

increased or decreased to control the number of cycles required to reach the time to failure.

shall be exposed to a minimum of three and preferably four exposure

Test specimens should

temperatures. The lowest temperature, recommended at 20 °C above the desired thermal

class, should shall be one which results in a time frame to failure of more than 5 000 h. The

highest exposure temperature shall have a value of at least 100 h to be considered a valid

data point. Exposure temperatures should not be more than 20 °C apart. The accuracy of the

temperature index predicted from the results will improve as the exposure temperature

approaches the temperature to which the insulation is exposed in service.

7 Test voltage and its application

The voltage to be applied shall be an AC voltage and shall have a nominal frequency of 50 Hz

or 60 Hz of an approximately sine-wave form, the peak factor being within the limits of

√2 ± 5 % (1,34 to 1,48). The test transformer shall have a rated power of at least 500 VA and

shall provide a current of essentially undistorted waveform under test conditions.

To detect failure, the overcurrent indication device shall operate when a current of 5 mA or

more flows through the high-voltage circuit. The test voltage source shall have a capacity to

supply the detection current (5 mA or more) with a maximum voltage drop of 10 %.

The test specimens are removed from the ovens and cooled to room temperature. Each

specimen shall be subjected to a proof voltage according to the increase in diameter due to

insulation average thickness of the enamel as specified in Table 3 for specimens according to

5.1.1 and in Table 4 for specimens according to 5.1.2. In the case of self-bonding wires, the

self-bonding layer is included in the increase in diameter due to the insulation.

Table 4 – Proof voltage for tape-wrapped round and for enamelled

or tape-wrapped rectangular wire

Increase in dimension due to the insulation Voltage

(mm) (rms)

Over Up to and including

0,035 0,050 300

0,050 0,065 375

0,065 0,080 450

0,080 0,090 550

0,090 0,100 650

0,100 0,115 700

0,115 0,130 750

0,130 0,140 800

0,140 0,150 850

The proof voltage shall be applied to the test specimens for approximately 1 s.

NOTE A relatively short time of application of the test voltage is desirable to minimize minimizes the effects of

corona and dielectric fatigue.

Care shall be taken in all cases to avoid mechanical damage to the test specimens. The

specimens that fail the proof test shall can be discarded and the remaining specimens

returned to the oven for another temperature exposure.

8 Calculations

8.1 Specimen failure time

The failure time of an individual specimen at one exposure temperature is determined by

calculating the mid-point between the total hours of exposure temperature at which the

specimen failed the proof voltage and the total hours of exposure of the previous cycles. This

assumes that the specimen would probably have failed the proof voltage at some point in the

middle of the last temperature exposure cycle. Thus, the specimen failure time is the sum of

the total hours at the time to failure, minus half the hours of the last exposure cycle.

– 18 – IEC 60172:2020 RLV © IEC 2020

8.2 Time to failure

The time to failure of a set of specimens at one exposure temperature shall be calculated by

using either the median value or the logarithmic mean value. For many materials, the median

value is statistically valid. In most cases, use of the median will significantly reduce testing

time, since the test ceases once the median value has been obtained.

When using the median value, the time to failure is calculated as follows:

Where there are a total number of n specimens in a set of specimens, the time to failure of the

set equals:

a) the specimen failure time of specimen number (n + 1)/2; if n is odd (see 8.1);

b) the logarithmic mean value of the specimen failure times of specimens number n/2 and

(n + 2)/2; if n is even (see 8.1).

For instance, if n is 12, the time to failure of the set would be the mean value of the specimen

failure times of the sixth and the seventh specimen. For convenience, it is suggested that

when the median value is used for calculating the time to failure of the set, the total number of

specimens of a set be odd, thus simplifying calculation.

When using the logarithmic mean value, the time to failure is calculated by dividing the sum of

the logarithms of the specimen failure times of the set (see 8.1) by the total number n of

specimens in the set. The antilogarithm of this mean value is the time to failure of the set.

8.3 Linearity of data

To avoid misleading extrapolations (see 8.4), the correlation coefficient should shall be

calculated as shown in Annex B, to provide a measure of linearity.

If the correlation coefficient r is equal to or greater than 0,95, the data are said to be linear

and the data points will be reasonably close to a straight line. In the event that the correlation

coefficient is less than 0,95, the data are said to be non-linear and an additional test should

shall be performed at a temperature below the lowest previous temperature.

The new temperature point may be 10 °C below the previous lowest temperature point. When

re-calculating the temperature Index and correlation coefficient, one temperature point may be

deleted, starting with the highest temperature, for each new temperature point obtained.

The data will be linear if the thermal deterioration of the enamelled wire or the varnished

enamelled wire appears as one chemical reaction. Non-linearity may indicate that:

a) two or more reactions which have different activation energies (slopes) are predominant at

different temperatures within the testing range; or

b) errors have been introduced through the sampling technique and/or the testing procedure.

Non-linear data should shall not be used for extrapolation.

8.4 Calculating and plotting thermal endurance and temperature index

Thermal endurance is graphically presented by plotting the time to failure (see 8.2) versus its

respective exposure temperature on graph paper having a logarithmic time scale as the

ordinate and the reciprocal of absolute temperature as the abscissa. The exposure

temperatures at 2 000 h and 20 000 h are estimated based on the first order regression

calculation presented in Annex A. A regression line is drawn through these two points on the

graph, which represents the thermal endurance of the enamelled winding wire (see Figure 9).

Figure 9 – Thermal endurance graph – Temperature index

The temperature index of the enamelled wire is the number corresponding to the temperature

in degrees Celsius at which the regression line intersects the 20 000 h line. It is listed without

reference to degrees Celsius.

If further statistical analysis of the data is necessary, reference may be made to IEC 60216-3.

9 Report

The report of the results shall contain the following information as a minimum:

a) identification or description of the wire enamel, grade and the type of conductor

(e.g. copper, aluminium, etc.);

b) identification or description of the impregnating varnish and varnishing process;

c) time to failure of each set of specimens at each exposure temperature;

d) a graph of the first order regression line through the time to failure values;

e) the temperature index (TI);

f) the correlation coefficient, r.

– 20 – IEC 60172:2020 RLV © IEC 2020

Annex A

(normative)

Method for calculation of the regression line

Annex A presents a method for quickly plotting the regression line for thermal endurance

data. This method may be used for any number of measurements at various test

temperatures. If information concerning the confidence limits is required, a more detailed

analysis shall be made in accordance with IEC 60216-3.

It has been established that many insulations deteriorate in such a manner that the following

formula applies:

B/T

L = Ae (A.1)

where:

L = insulation endurance in hours;

T = absolute temperature in kelvins;

A, B = constants for each insulation, and

e = base of natural logarithms.

Formula (A.1) may be expressed as a linear function by taking logarithms:

B

log LAlog (log e) (A.2)

10 10 10

T

Let:

Y = log L;

a = log A;

X = 1/T;

b = (log e) B.

Then:

Y a bX (A.3)

Thus, data from testing at higher temperatures may be plotted on log L versus 1/ T

graph paper and a straight line extrapolated to lower temperatures. However, since the

nature of logarithmic plots does not allow accurate extrapolation by the method of drawing

the best apparent straight line through the data points, a more rigorous method shall be

used for greater accuracy and uniformity. By using the method of least squares, the

constants a and b may be derived in terms of the experimental data obtained. These

equations are as follows:

Yb X

a (A.4)

N

N XY XY

b (A.5)

NX () X

where:

X = 1/T = reciprocal of the test temperature in kelvins (θ °C + 273 °C);

N = number of test temperatures used;

Y = log L = logarithm of time to failure;

Ʃ = summation of N values.

Knowing the constant a, and the slope b of the regression line, the temperature at any

required life value may be calculated as follows:

Y a bX

1 b

T (A.6)

X Ya-

b

Temperature at 20 000 h in °C = -273 (A.7)

4,3010- a

(temperature index)

b

Temperature at 2 000 h in °C = -273 (A.8)

3,3010- a

To simplify the handling of the test data used in Formulae (A.4) to (A.8), it is suggested

that the steps for a sample calculation be followed as outlined below (see Table A.1 and

Table A.2):

a) In column 1, list the temperatures in °C, as illustrated in Table A.2, at which a set of

specimens was tested;

2 2

b) In columns 2 and 3, list the reciprocals (X = 1/T) and the reciprocals squared (X = 1/T )

of the above test temperatures converted to kelvins (see also Table A.1);

c) In the column 4, list the time to failure L, in hours, of each set of specimens, and in the

column 5, list the log of the values in the fourth column (Y = log L);

10 10

d) In column 6, list the products of X and Y;

e) Provide summation for columns 2, 3, 5 and 6 and enter the summation (indicated by

Ʃ) at the bottom of the respective column;

f) Indicate the number N of times to failure on the worksheet;

g) Using the values obtained in steps e) and f), compute b (Formula (A.5)) and a

(Formula (A.4)) in that order. The constant a will always be negative;

h) Using constants a and b, calculate the temperature in degrees °C at 20 000 h

(Formula (A.7)) and at 2 000 h (Formula (A.8));

i) Plot the above two temperature points from step h) on a log L versus 1/T graph

paper graphing system and draw the regression line through them as shown in

Figure A.1. It is recommended that this graph supplement the minimum test report

;

information required in Clause 9

j) Plot the times to failure L at their respective temperatures on the same graph.

– 22 – IEC 60172:2020 RLV © IEC 2020

Table A.1 – Commonly used test temperatures in degrees Celsius and the

corresponding kelvins with its reciprocal and reciprocal squared values

2 2

θ T X = 1/T X = 1/T

−1 −2

(°C) (K) (K ) (K )

−3 −6

105 378 2,646 × 10 6,999 × 10

−3 −6

120 393 2,545 × 10 6,475 × 10

−3 −6

125 398 2,513 × 10 6,313 × 10

−3 −6

130 403 2,481 × 10 6,157 × 10

−3 −6

140 413 2,421 × 10 5,863 × 10

−3 −6

150 423 2,364 × 10 5,589 × 10

−3 −6

155 428 2,336 × 10 5,459 × 10

−3 −6

165 438 2,283 × 10 5,212 × 10

−3 −6

175 448 2,232 × 10 4,982 × 10

−3 −6

180 453 2,208 × 10 4,873 × 10

−3 −6

185 458 2,183 × 10 4,767 × 10

−3 −6

190 463 2,160 × 10 4,665 × 10

−3 −6

200 473 2,114 × 10 4,470 × 10

−3 −6

210 483 2,070 × 10 4,287 × 10

−3 −6

220 493 2,028 × 10 4,114 × 10

−3 −6

225 498 2,008 × 10 4,032 × 10

−3 −6

230 503 1,988 × 10 3,952 × 10

−3 −6

240 513 1,949 × 10 3,800 × 10

−3 −6

250 523 1,912 × 10 3,656 × 10

−3 −6

260 533 1,876 × 10 3,520 × 10

−3 −6

270 543 1,842 × 10 3,392 × 10

−3 −6

280 553 1,808 × 10 3,270 × 10

−3 −6

300 573 1,745 × 10 3,048 × 10

−3 −6

320 593 1,686 × 10 2,844 × 10

NOTE Calculations for X are based on non-rounded values.

Table A.2 – Sample calculation

Column 1 Column 2 Column 3 Column 4 Column 5 Column 6

2 2

Temperature X = 1/T X = 1/T L (h) Y = log L XY = (log L)/T

10 10

(°C)

−3 −6 −3

170 2,257 73 × 10 5,095 57 × 10 5 600 3,748 19 8,460 92 × 10

−3 −6 −3

185 2,183 41 × 10 4,767 26 × 10 2 600 3,414 97 7,456 27 × 10

−3 −6 −3

200 2,114 16 × 10 4,469 69 × 10 1 500 3,176 09 6,714 78 × 10

−3 −6 −3

215 2,049 18 × 10 4,199 14 × 10 640 2,806 18 5,750 37 × 10

−3 −6 −3

Ʃ 8,604 09 × 10 18,531 66 × 10 13,145 43 28,382 34 × 10

N = 4

-3 -3

N XY XY 4 x28,38234 x10 8,60409 x10 x13,14543

b 4413

2 2 -6 -3 -3

NX () X 4 x18,53166 x10 8,60409 xx10 8,60409 x10

-3

Yb X 13,145434413 x8,60409 x10

a 6,20610

N 4

b

Temperature at 20 000 h in degrees °C =

273

Ya

°C

-273=147

4,301 0+6,20610

b

Temperature at 2 000 h in degrees Celsius =

-273

Ya

°C

-273=191

3,301 0+6,20610

– 24 – IEC 60172:2020 RLV © IEC 2020

Figure A.1 – Plot of regression line based on sample calculation (Table A.2)

Annex B

(normative)

Correlation coefficient

The correlation coefficient r is a measure of the amount of relationship between variables.

When r = 1,0, a perfect association between the variable exists, and when r = 0, a completely

random relation exists.

aY + bXY - N(Avg Y )

r = (B.1)

2 2

Y - N(Avg Y )

where:

a = Y intercept of the regression line;

b = Slope of the regression line;

...

IEC 60172 ®

Edition 5.0 2020-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test procedure for the determination of the temperature index of enamelled and

tape wrapped winding wires

Méthode d’essai pour la détermination de l’indice de température des fils de

bobinage émaillés et enveloppés de ruban

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60172 ®

Edition 5.0 2020-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test procedure for the determination of the temperature index of enamelled and

tape wrapped winding wires

Méthode d’essai pour la détermination de l’indice de température des fils de

bobinage émaillés et enveloppés de ruban

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.060.10 ISBN 978-2-8322-9086-6

– 2 – IEC 60172:2020 © IEC 2020

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Summary of procedure . 7

5 Test specimens . 7

5.1 Preparation . 7

5.1.1 Enamelled non-tape wrapped round wire . 7

5.1.2 Tape wrapped round wire and enamelled or tape wrapped rectangular

wire . 10

5.2 Varnish impregnation . 12

5.3 Notes on number of test specimens . 13

5.4 Specimen holder . 13

5.4.1 For specimens according to 5.1.1 . 13

5.4.2 For specimens according to 5.1.2 . 13

6 Temperature exposure. 14

7 Test voltage and its application . 15

8 Calculations . 16

8.1 Specimen failure time . 16

8.2 Time to failure . 16

8.3 Linearity of data . 16

8.4 Calculating and plotting thermal endurance and temperature index . 17

9 Report . 18

Annex A (normative) Method for calculation of the regression line . 19

Annex B (normative) Correlation coefficient . 24

Bibliography . 25

Figure 1 – Device used to form enamelled round wire test specimen . 8

Figure 2 – Spacer . 8

Figure 3 – Twist forming jig . 9

Figure 4 – Test specimen set up in forming jig . 9

Figure 5 – Test specimen formed with loop cut . 10

Figure 6 – Jig for bending large magnet wire, dielectric test specimen . 11

Figure 7 – Forming jig and test specimen . 12

Figure 8 – Specimen holder . 13

Figure 9 – Thermal endurance graph – Temperature index . 17

Figure A.1 – Plot of regression line based on sample calculation (Table A.2) . 23

Table 1 – Force and number of twists for specimens . 8

Table 2 – Proof voltage for round enamelled wire . 10

Table 3 – Recommended exposure times in days per cycle. 14

Table 4 – Proof voltage for tape-wrapped round and for enamelled or tape-wrapped

rectangular wire . 15

Table A.1 – Commonly used test temperatures in degrees Celsius and the

corresponding kelvins with its reciprocal and reciprocal squared values . 21

Table A.2 – Sample calculation . 22

– 4 – IEC 60172:2020 © IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST PROCEDURE FOR THE DETERMINATION OF THE TEMPERATURE

INDEX OF ENAMELLED AND TAPE WRAPPED WINDING WIRES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60172 has been prepared by IEC Technical Committee 55:

Winding wires.

This fifth edition cancels and replaces the fourth edition published in 2015. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– revision of 3.1, definition of thermal index;

– revision of 3.3, time to failure;

– revisions to 5.1.1 for clarity and to reduce the range wire size range to which the test

applies;

– revisions to 5.1.2 for tape wrapped round and enamelled or tape wrapped rectangular wire

for clarity;

– revision to Clause 9 to add the correlation coefficient, r to the report.

The text of this International Standard is based on the following documents:

FDIS Report on voting

55/1876/FDIS 55/1893/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 60172:2020 © IEC 2020

TEST PROCEDURE FOR THE DETERMINATION OF THE TEMPERATURE

INDEX OF ENAMELLED AND TAPE WRAPPED WINDING WIRES

1 Scope

This International Standard specifies, in accordance with the provisions of IEC 60216-1, a

method for evaluating the temperature index of enamelled wire, varnished or unvarnished with

an impregnating agent, and of tape wrapped round and rectangular wire, in air at atmospheric

pressure by periodically monitoring changes in response to AC proof voltage tests. This

procedure does not apply to fibre-insulated wire or wire covered with tapes containing

inorganic fibres.

NOTE The data obtained according to this test procedure provide the designer and development engineer with

information for the selection of winding wire for further evaluation of insulation systems and equipment tests.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60216-1, Electrical insulating materials – Thermal endurance properties – Part 1: Ageing

procedures and evaluation of test results

IEC 60216-3, Electrical insulating materials – Thermal endurance properties – Part 3:

Instructions for calculating thermal endurance characteristics

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

temperature index

TI

number which permits comparison of the temperature/time characteristics of an electrical

insulating material, or a simple combination of materials, based on the temperature in degrees

Celsius which is obtained by extrapolating the Arrhenius plot of life versus temperature to a

lifetime of 20 000 h

Note 1 to entry: In case of insulation systems, the temperature index may be derived from known service

experience or from a known comparative functional evaluation of an evaluated and established reference insulation

system as basis.

[SOURCE: IEC 60050-212:2010, 212-12-11] modified by merging Note 1 into the definition,

and to specify a lifetime of 20 000 h.]

3.2

specimen failure time

number of hours at the exposure temperature that have elapsed at the time a specimen

fails the proof test

3.3

time to failure

number of hours to failure calculated from the specimen mean value or logarithmic mean

value failure times for a set of specimens at one exposure temperature, in accordance with

8.2

4 Summary of procedure

A set of specimens in accordance with Clause 5 is subjected to a testing cycle. This cycle

consists of a heat-exposure period at a temperature given in Clause 6, followed by a proof

voltage test at room temperature in accordance with Clause 7.

This cycle is repeated until a sufficient number of specimens has failed. The time to failure is

calculated in accordance with Clause 8. The test is carried out at three or more

temperatures. A regression line is calculated in accordance with 8.4 and the time to failure

values plotted on thermal endurance graph paper as a function of the exposure

temperature.

The temperature in degrees Celsius, corresponding to the point of intersection of the

regression line with the ordinate of 20 000 h endurance represents the temperature index of

the winding wire under test.

5 Test specimens

5.1 Preparation

5.1.1 Enamelled non-tape wrapped round wire

This procedure applies to enamelled round wires that are not tape wrapped. The thermal

index can be determined by evaluating enamelled non-tape wrapped round wire with a

nominal conductor diameter of 0,224 mm up to and including 2,65 mm.

NOTE For round enamelled winding wires, experience has shown that nominal conductor diameters of 0,800 mm

up to and including 1,60 mm are generally found convenient to handle and test.

Wires with a nominal conductor diameter between 0,280 mm and 0,500 mm are permitted for

use when the specification range of diameters is limited to 0,500 mm and finer.

The grade of insulation used for determining the thermal index shall be grade 2 or grade 2B

for self-bonding winding wires.

Specimens shall be prepared as follows:

a) A wire specimen approximately 400 mm in length shall be twisted together over a distance

of 125 mm with a device as shown in Figure 1. The force (weight) applied to the wire pair

while being twisted and the number of twists are specified in Table 1.

– 8 – IEC 60172:2020 © IEC 2020

Figure 1 – Device used to form enamelled round wire test specimen

Table 1 – Force and number of twists for specimens

Nominal diameter Force applied to Number of twists

wire pairs per

mm N 125 mm

Over Up to and

including

0,224 0,25 0,85 33

0,25 0,35 1,7 23

0,35 0,50 3,4 16

0,50 0,75 7,0 12

0,75 1,05 13,5 8

1,05 1,50 27,0 6

1,50 2,15 54,0 4

2,15 2,65 108,0 3

b) Spacers may be prepared as shown in Figure 2. Such thermally stable insulating

materials as ceramic or silicone glass fibre laminate may be used. The spacers are

marked with a suitable identifying letter or number.

Dimensions in millimetres

Material: Silicone glass laminate

Figure 2 – Spacer

c) The test specimens may be shaped in a jig, an engineering drawing of which is shown

in Figure 3. A specimen is placed in the jig and a spacer, placed on the parallel leads

of the twisted pair, is brought up to the face of the jig as shown in Figure 4. The leads

are then bent parallel to hold the spacer in position. The forming jig provides more

uniform test specimens. If a specimen holder is used, the spacers are unnecessary.

Dimensions in millimetres

R = Radius of bend

Figure 3 – Twist forming jig

Figure 4 – Test specimen set up in forming jig

d) The loop at the end of the twisted section shall be cut at two places (not one) to

provide the maximum spacing between the cut ends as shown in Figure 5. Any bending

of the wires, at this end or the other untwisted end, to ensure adequate separation

between the wires shall avoid sharp bends or damage to the insulation.

– 10 – IEC 60172:2020 © IEC 2020

Figure 5 – Test specimen formed with loop cut

In order to ensure homogeneity of the set of test specimens, it is recommended that test

specimens be subjected to, and withstand without breakdown, a test voltage three times the

value given in Table 2 for 1 s prior to starting thermal exposure cycling.

Table 2 – Proof voltage for round enamelled wire

Increase in diameter due to the insulation Voltage

(mm) (rms)

Over Up to and including

– 0,015 300

0,015 0,024 300

0,024 0,035 400

0,035 0,050 500

0,050 0,070 700

0,070 0,090 1 000

0,090 0,130 1 200

5.1.2 Tape wrapped round wire and enamelled or tape wrapped rectangular wire

This procedure applies to any convenient dimension of tape wrapped round or tape wrapped

or enamelled rectangular wire.

It is recommended to select a wire having dimensions that minimize the bending force

necessary to shape the test specimen, since wire with high stiffness will yield specimens with

poor wire-to-wire contact areas.

Specimens shall be prepared as follows:

a) Two straight specimens of wire each of 250 mm length shall be cut from the supply spool.

b) 10 mm to 15 mm of the insulation shall be removed from one end of each piece of wire to

provide for electrical connection.

c) Each specimen shall be formed in a jig, as shown in Figure 6. This produces a straight

centre section of about 150 mm with bent ends, which provide the necessary flare at both

ends of the final specimen.

Dimensions in millimetres

Figure 6 – Jig for bending large magnet wire, dielectric test specimen

– 12 – IEC 60172:2020 © IEC 2020

d) The two formed specimens shall be placed together back-to-back and tightly wrapped with

glass yarn over the straight centre section of the specimen, as shown in Figure 7.

Figure 7 – Forming jig and test specimen

Care shall be taken that the centre section shows a close contact between the two pieces.

After tying, further bending of the ends shall be avoided. Pre-annealing of the specimen

prior to testing or impregnating will remove stress and craze marks and therefore may be

desirable with certain material.

e) Prior to starting the thermal exposure cycles, the specimen shall be proof-tested at

1 000 V AC.

5.2 Varnish impregnation

Insulated wire according to IEC 60317 and impregnating agents according to IEC 60455-3-5

or IEC 60464-3-2 can affect one another during the thermal ageing process.

NOTE 1 Testing varnished specimens will allow for evaluation of the compatibility of the wire insulation with an

impregnating agent. Thus, the temperature indices of different combinations can be compared.

Interaction between wire insulation and such agent may increase or decrease the relative

thermal life of this combination compared with the life of the wire tested without impregnation.

Therefore, with impregnated specimens, this test procedure may give an indication of the

thermal endurance of a combination of wire insulation and impregnating agent.

If such impregnation is required, the following procedure shall be applied:

With the specimen in the vertical position, it shall be immersed in the impregnating agent for

(60 ± 10) s. It shall be removed slowly and uniformly at a rate of about 1 mm/s. It shall be

drained horizontally for 10 min to 15 min and cured horizontally according to the

manufacturer's recommendation or to an agreed schedule. If more than one treatment is to be

given, immerse, drain and cure the specimen vertically reversing the specimen for each

subsequent treatment.

NOTE 2 Some impregnating agents, such as high viscosity or thixotropic products require alternative processing

methods.

5.3 Notes on number of test specimens

The accuracy of the test results depends largely upon the number of test specimens aged at

each temperature. A greater number of test specimens is required to achieve an acceptable

degree of accuracy if there is a wide spread in results among the specimens exposed at each

temperature.

Experience has shown that twenty specimens without impregnation and ten specimens with

impregnation give results with an acceptable tolerance. A minimum of ten specimens shall be

used.

5.4 Specimen holder

5.4.1 For specimens according to 5.1.1

Since individual handling of the twisted specimens may result in premature failures, it is

recommended that the specimens be placed in a suitable holder, as shown in Figure 8. The

holder should be designed in a manner that will protect the twisted specimens from external

mechanical damage and warping. The holder will be so constructed as to allow the ends of

the twist to protrude from the holder to make electrical connections for proof testing. The

holder shall be designed for at least ten specimens to decrease handling time.

Figure 8 – Specimen holder

5.4.2 For specimens according to 5.1.2

The specimen shall be hung in the oven. No special holder is required.

– 14 – IEC 60172:2020 © IEC 2020

6 Temperature exposure