prEN IEC 60851-5:2025

(Main)Winding wires - Test methods - Part 5: Electrical properties

Winding wires - Test methods - Part 5: Electrical properties

Wickeldrähte - Prüfverfahren - Teil 5: Elektrische Eigenschaften

Fils de bobinage - Méthodes d'essai - Partie 5: Propriétés électriques

Navijalne žice - Preskusne metode - 5. del: Električne lastnosti

General Information

- Status

- Not Published

- Publication Date

- 03-Jan-2027

- Technical Committee

- CLC/TC 55 - Winding wires

- Current Stage

- 4060 - Enquiry results established and sent to TC, SR, BTTF - Enquiry

- Start Date

- 05-Sep-2025

- Completion Date

- 05-Sep-2025

Relations

- Effective Date

- 04-Jul-2023

- Effective Date

- 04-Jul-2023

- Effective Date

- 04-Jul-2023

Overview

The prEN IEC 60851-5:2025 standard, developed by the International Electrotechnical Commission (IEC) Technical Committee 55, focuses on test methods for evaluating the electrical properties of winding wires. This standard is part 5 in the IEC 60851 series, which comprehensively addresses insulated wires used for windings in electrical equipment. The standard outlines precise procedures to assess key electrical characteristics such as electrical resistance, breakdown voltage, insulation continuity, dielectric dissipation, and the presence of pin holes.

By adhering to this standard, manufacturers and quality assurance professionals can ensure winding wires meet stringent performance and safety requirements, resulting in reliable and efficient electrical devices.

Key Topics

Electrical Resistance Testing (Test 5)

- Measures the direct current (DC) resistance at 20 °C over specified wire lengths.

- For bunched wires, a 10-meter sample is used with soldered ends to improve accuracy.

- Includes temperature adjustments using the temperature coefficient to calculate resistance at standard conditions.

Breakdown Voltage Testing (Test 13)

- Determines the voltage at which the insulation fails.

- Methods cover various wire types including enamelled round wire, fibre wound wire, and rectangular wire.

- Testing includes both room temperature and elevated temperature conditions.

- Involves specific specimen preparation techniques detailed for different wire grades and sizes.

Continuity of Insulation (Test 14)

- Ensures the integrity of the wire insulation by checking for electrical continuity faults.

- Distinguishes between low-voltage and high-voltage continuity tests depending on wire diameter and insulation grade.

- Inline high-voltage continuity testing is addressed for industrial-grade wires.

Dielectric Dissipation Factor (Test 19)

- Measures insulation quality by examining energy losses as an alternating current passes through the wire.

- Test methods described include usage of metal bath electrodes or conductive suspension electrodes.

- Critical for assessing the efficiency and longevity of the insulating materials used in winding wires.

Pin Hole Testing (Test 23)

- Identifies microscopic defects in the insulation coating that could lead to breakdowns.

Applications

The prEN IEC 60851-5:2025 standard is essential for:

- Manufacturers of Electric Motors, Transformers, and Generators

- Ensures winding wires comply with electrical performance requirements.

- Quality Control and Testing Laboratories

- Provides standardized procedures for reliable and reproducible testing of electrical properties.

- Design Engineers

- Assists in selecting appropriate winding wire types based on electrical properties to enhance device performance and safety.

- Certification Bodies

- References for conformity assessments related to winding wire electrical attributes.

- Research and Development

- Framework for developing advanced insulating materials and wire coatings with improved electrical characteristics.

Related Standards

prEN IEC 60851-5:2025 is part of a larger set of standards within the IEC 60851 series that addresses winding wires comprehensively:

- IEC 60851-1: Test methods – Part 1: General requirements and definitions relevant across winding wire testing procedures.

- IEC 60317: Specifications for particular types of winding wires, including materials and performance criteria.

- IEC 60264: Packaging standards for winding wires, ensuring protection and preservation during transport and storage.

These related standards foster a consistent and harmonized approach to the manufacture, testing, and application of insulated winding wires globally.

By implementing the prEN IEC 60851-5:2025 standard, stakeholders can achieve enhanced quality, safety, and performance in electrical equipment that relies on winding wires, promoting international uniformity and advancing technological innovation in the electrotechnical industry.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

prEN IEC 60851-5:2025 is a draft published by CLC. Its full title is "Winding wires - Test methods - Part 5: Electrical properties". This standard covers: Winding wires - Test methods - Part 5: Electrical properties

Winding wires - Test methods - Part 5: Electrical properties

prEN IEC 60851-5:2025 is classified under the following ICS (International Classification for Standards) categories: 29.060.10 - Wires. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN IEC 60851-5:2025 has the following relationships with other standards: It is inter standard links to EN 60851-5:2008, EN 60851-5:2008/A1:2011, EN 60851-5:2008/A2:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN IEC 60851-5:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2025

Navijalne žice - Preskusne metode - 5. del: Električne lastnosti

Winding wires - Test methods - Part 5: Electrical properties

Wickeldrähte - Prüfverfahren - Teil 5: Elektrische Eigenschaften

Fils de bobinage - Méthodes d'essai - Partie 5: Propriétés électriques

Ta slovenski standard je istoveten z: prEN IEC 60851-5:2025

ICS:

29.060.10 Žice Wires

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

55/2066/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 60851-5 ED5

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2025-06-13 2025-09-05

SUPERSEDES DOCUMENTS:

55/2061/CD, 55/2064/CC

IEC TC 55 : WINDING WIRES

SECRETARIAT: SECRETARY:

United States of America Mr Mike Leibowitz

OF INTEREST TO THE FOLLOWING COMMITTEES: HORIZONTAL FUNCTION(S):

TC 2,TC 14

ASPECTS CONCERNED:

Safety

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of

CENELEC, is drawn to the fact that this Committee Draft

for Vote (CDV) is submitted for parallel voting.

The CENELEC members are invited to vote through the

CENELEC online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of

which they are aware and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some

Countries” clauses to be included should this proposal proceed. Recipients are reminded that the CDV stage is

the final stage for submitting ISC clauses. (SEE AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

Winding wires - Test methods - Part 5: Electrical properties

PROPOSED STABILITY DATE: 2027

NOTE FROM TC/SC OFFICERS:

electronic file, to make a copy and to print out the content for the sole purpose of preparing National Committee positions.

You may not copy or "mirror" the file or printed version of the document, or any part of it, for any other purpose without

permission in writing from IEC.

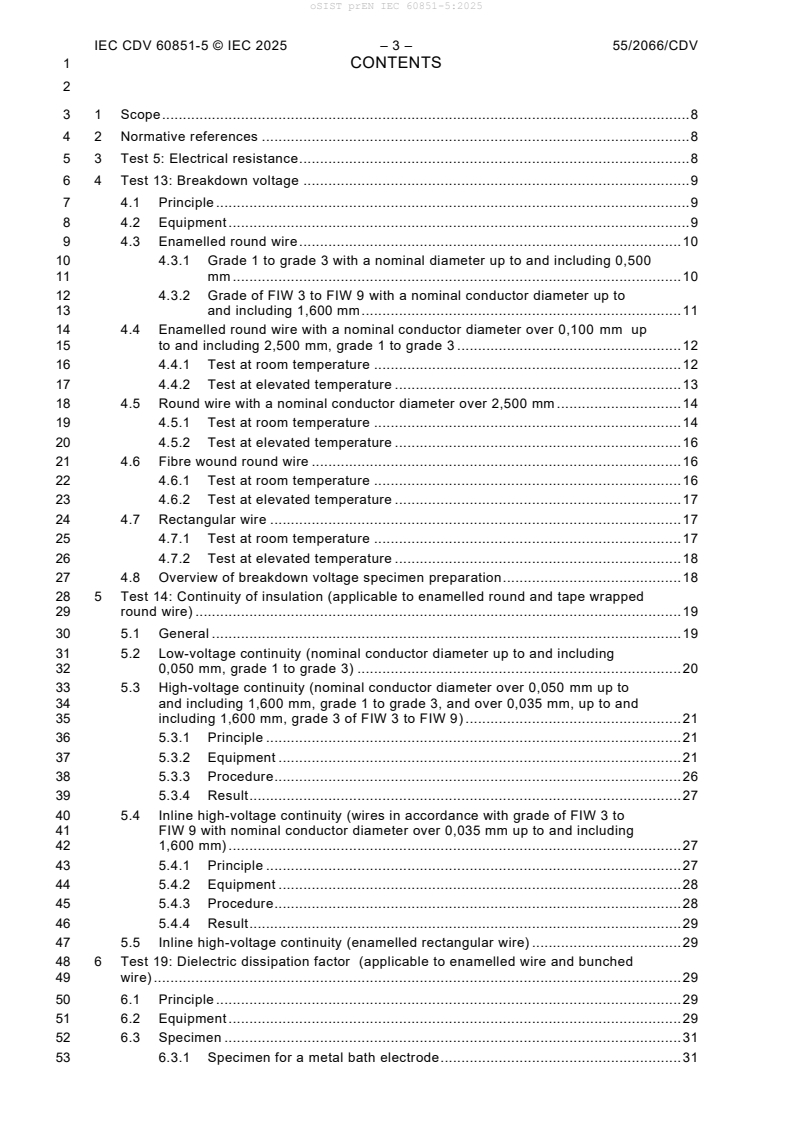

IEC CDV 60851-5 © IEC 2025 – 3 – 55/2066/CDV

1 CONTENTS

3 1 Scope . 8

4 2 Normative references . 8

5 3 Test 5: Electrical resistance. 8

6 4 Test 13: Breakdown voltage . 9

7 4.1 Principle . 9

8 4.2 Equipment . 9

9 4.3 Enamelled round wire . 10

10 4.3.1 Grade 1 to grade 3 with a nominal diameter up to and including 0,500

11 mm . 10

12 4.3.2 Grade of FIW 3 to FIW 9 with a nominal conductor diameter up to

13 and including 1,600 mm . 11

14 4.4 Enamelled round wire with a nominal conductor diameter over 0,100 mm up

15 to and including 2,500 mm, grade 1 to grade 3 . 12

16 4.4.1 Test at room temperature . 12

17 4.4.2 Test at elevated temperature . 13

18 4.5 Round wire with a nominal conductor diameter over 2,500 mm . 14

19 4.5.1 Test at room temperature . 14

20 4.5.2 Test at elevated temperature . 16

21 4.6 Fibre wound round wire . 16

22 4.6.1 Test at room temperature . 16

23 4.6.2 Test at elevated temperature . 17

24 4.7 Rectangular wire . 17

25 4.7.1 Test at room temperature . 17

26 4.7.2 Test at elevated temperature . 18

27 4.8 Overview of breakdown voltage specimen preparation. 18

28 5 Test 14: Continuity of insulation (applicable to enamelled round and tape wrapped

29 round wire) . 19

30 5.1 General . 19

31 5.2 Low-voltage continuity (nominal conductor diameter up to and including

32 0,050 mm, grade 1 to grade 3) . 20

33 5.3 High-voltage continuity (nominal conductor diameter over 0,050 mm up to

34 and including 1,600 mm, grade 1 to grade 3, and over 0,035 mm, up to and

35 including 1,600 mm, grade 3 of FIW 3 to FIW 9) . 21

36 5.3.1 Principle . 21

37 5.3.2 Equipment . 21

38 5.3.3 Procedure . 26

39 5.3.4 Result . 27

40 5.4 Inline high-voltage continuity (wires in accordance with grade of FIW 3 to

41 FIW 9 with nominal conductor diameter over 0,035 mm up to and including

42 1,600 mm) . 27

43 5.4.1 Principle . 27

44 5.4.2 Equipment . 28

45 5.4.3 Procedure . 28

46 5.4.4 Result . 29

47 5.5 Inline high-voltage continuity (enamelled rectangular wire) . 29

48 6 Test 19: Dielectric dissipation factor (applicable to enamelled wire and bunched

49 wire) . 29

50 6.1 Principle . 29

51 6.2 Equipment . 29

52 6.3 Specimen . 31

53 6.3.1 Specimen for a metal bath electrode . 31

IEC CDV 60851-5 © IEC 2025 – 4 – 55/2066/CDV

54 6.3.2 Specimen for a conductive suspension electrode . 31

55 6.4 Procedure . 31

56 6.5 Result . 31

57 7 Test 23: Pin hole test. 31

58 Annex A (informative) Dissipation factor methods . 33

59 A.1 Tangent delta – Intersection point . 33

60 A.2 Test methods . 33

61 A.2.1 Method A . 33

62 A.2.2 Method B – Wire coated with a conductive film . 34

63 A.3 Interpretation of results . 34

64 A.3.1 General . 34

65 A.3.2 Linear method . 34

66 A.3.3 Logarithmic method . 35

68 Figure 1 – Arrangement of cylinder and specimen for the breakdown voltage test . 11

69 Figure 2 – Device for twisting the specimen for breakdown voltage test . 13

70 Figure 3 – U-bend specimen for the breakdown voltage test (specimen placed in shot

71 bath) . 15

72 Figure 4 – Coil-wound specimen for the breakdown voltage test . 17

73 Figure 5 – Apparatus for testing the low-voltage continuity of covering . 20

74 Figure 6 – High-voltage d.c. continuity – Pulleys for wire size 0,050 mm to 0,250 mm . 23

75 Figure 7 – Pulley dimensions and spacing for wire size 0,250 mm to 1,600 mm . 23

76 Figure 8a – Graphite fibre single brush electrode assembly . 24

77 Figure 8b – Graphite fibre dual brush electrode assembly . 25

78 Figure 8 – Graphite fibre single or dual brush electrode asssembly . 25

79 Figure 9 – Suitable electrode arrangement for testing the dielectric dissipation factor . 30

80 Figure A.1 – Example of linear method for sole coating . 35

81 Figure A.2 – Example of logarithmic method for sole coating . 35

83 Table 1 – Rates of test voltage increase . 9

84 Table 2.1 – Loads applied to enamelled wire . 10

85 Table 2.2 – Loads and diameters of test cylinders applied to wire . 12

86 Table 3 – Loads applied to the wire and number of twists . 13

87 Table 4.1 – Off-line HVC test voltages for grades 1 – 3 . 26

88 Table 4.2 – Off-line HVC test voltages for grade of FIW 3 – FIW 9 . 27

89 Table 5 – In-line HVC test voltages . 29

IEC CDV 60851-5 © IEC 2025 – 5 – 55/2066/CDV

93 INTERNATIONAL ELECTROTECHNICAL COMMISSION

94 ____________

96 WINDING WIRES –

97 TEST METHODS –

99 Part 5: Electrical properties

103 FOREWORD

104 1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

105 all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

106 co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

107 in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

108 Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

109 preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

110 may participate in this preparatory work. International, governmental and non-governmental organizations liaising

111 with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

112 Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

113 2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

114 consensus of opinion on the relevant subjects since each technical committee has representation from all

115 interested IEC National Committees.

116 3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

117 Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

118 Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

119 misinterpretation by any end user.

120 4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

121 transparently to the maximum extent possible in their national and regional publications. Any divergence between

122 any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

123 5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

124 assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

125 services carried out by independent certification bodies.

126 6) All users should ensure that they have the latest edition of this publication.

127 7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

128 members of its technical committees and IEC National Committees for any personal injury, property damage or

129 other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

130 expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

131 8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

132 indispensable for the correct application of this publication.

133 9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

134 rights. IEC shall not be held responsible for identifying any or all such patent rights.

136 International Standard IEC 60851-5 has been prepared by IEC technical committee 55: Winding

137 wires.

138 Significant revisions to the previous edition include the following points:

139 • Subclause 4.3.2 modified to expand the conductor size range for the loads applied during

140 cylinder method testing for dielectric breakdown voltage of enameled wires and for fully

141 insulated wires.

142 • Addition of subclause 5.5 for inline continuity testing of rectangular wire (under

143 consideration).

146 This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

147 A list of all the parts in the IEC 60851 series, under the general title Winding wires − Test

148 methods, can be found on the website.

IEC CDV 60851-5 © IEC 2025 – 6 – 55/2066/CDV

149 The committee has decided that the contents of the base publication and its amendments will

150 remain unchanged until the stability date indicated on the IEC web site under

151 "http://webstore.iec.ch" in the data related to the specific publication. At this date, the

152 publication will be

153 • reconfirmed,

154 • withdrawn,

155 • replaced by a revised edition, or

156 • amended.

IEC CDV 60851-5 © IEC 2025 – 7 – 55/2066/CDV

160 INTRODUCTION

162 This part of IEC 60851 forms an element of a series of standards which deals with insulated

163 wires used for windings in electrical equipment. The series has three groups describing

164 a) winding wires – Test methods (IEC 60851);

165 b) specifications for particular types of winding wires (IEC 60317);

166 c) packaging of winding wires (IEC 60264).

IEC CDV 60851-5 © IEC 2025 – 8 – 55/2066/CDV

169 WINDING WIRES –

170 TEST METHODS –

172 Part 5: Electrical properties

176 1 Scope

177 This part of IEC 60851 specifies the following tests:

178 – Test 5: Electrical resistance;

179 – Test 13: Breakdown voltage;

180 – Test 14: Continuity of insulation;

181 – Test 19: Dielectric dissipation factor;

182 – Test 23: Pin hole.

183 For definitions, general notes on methods of test and the complete series of methods of test for

184 winding wires, see IEC 60851-1.

185 2 Normative references

186 The following referenced documents are indispensable for the application of this document. For

187 dated references, only the edition cited applies. For undated references, the latest edition of

188 the referenced document (including any amendments) applies.

189 IEC 60851-1, Winding wires – Test methods – Part 1: General

190 3 Test 5: Electrical resistance

191 Electrical resistance is the d.c. resistance at 20 °C of 1 m of wire.

192 The method used shall provide a precision of 0,5 %.

193 For bunched wires a length of up to 10 m shall be used and the ends shall be soldered before

194 the measurement. When measuring the resistance to check for an excessive number of broken

195 wires, a length of 10 m of bunched wire shall be used.

196 If the resistance R is measured at a temperature t other than 20 °C, the resistance R at 20 °C

t 20

197 shall be calculated by means of the following formula:

R

t

198 R =

1+ (t − 20)

199 where

200 t is the actual temperature in degrees Celsius during the measurement;

–1

201 is the temperature coefficient in K .

IEC CDV 60851-5 © IEC 2025 – 9 – 55/2066/CDV

203 In the temperature range from 15 °C to 25 °C, the temperature coefficient to be used shall be:

–3 –1

204 – for copper: = 3,96 10 K ;

–3 –1

205 – for aluminium: = 4,07 10 K .

206 One test shall be made. The electrical resistance shall be reported.

207 4 Test 13: Breakdown voltage

208 4.1 Principle

209 The test voltage shall be an a.c. voltage of 50 Hz or 60 Hz nominal frequency. The test voltage

210 shall be applied at zero and increased at a uniform rate according to Table 1.

211 Table 1 – Rates of test voltage increase

Breakdown voltage

Rate of

V

increase

Up to and

V/s

Over

including

– 500 20

500 2 500 100

2 500 – 500

213 An overview of breakdown voltage specimen preparations specified in 4.3 – 4.7 is provided in

214 4.8.

215 4.2 Equipment

216 The following equipment shall be used:

217 – test transformer with a rated power of at least 500 VA providing an a.c. voltage of an

218 undistorted sine waveform under test conditions, with a peak factor being within the limits

219 of 2 5 % (1,34 to 1,48) and with a capacity to supply a current of 5 mA with a maximum

220 voltage drop of 2 %;

221 – fault detection circuit, which operates at a current of 5 mA or more;

222 – arrangement to provide a uniform rise of the test voltage at the specified rate;

223 – oven with forced air circulation;

224 – polished metal cylinder, 25 mm 1 mm in diameter, mounted with its axis horizontal

225 (see Figure 1) and electrically connected to one terminal of the test voltage supply;

226 – twisting device according to Figure 2, that allows to twist two pieces of wire for a length of

227 125 mm;

228 – strips of metal foil, 6 mm in width and pressure sensitive tape, 12 mm in width;

229 – container with metal shot of stainless steel or nickel-plated iron. The diameter of the shot

230 shall not exceed 2 mm. The shot shall be cleaned periodically by suitable means;

231 – metal mandrel, 50 mm 2 mm in diameter;

232 – metal mandrel, 25 mm 1 mm in diameter;

233 – metal mandrel, 80 mm 3 mm in diameter.

IEC CDV 60851-5 © IEC 2025 – 10 – 55/2066/CDV

235 4.3 Enamelled round wire

236 4.3.1 Grade 1 to grade 3 with a nominal diameter up to and including 0,500 mm

237 The test is carried out on a cylinder with a diameter of 25 mm 1 mm. A straight piece of wire

238 with the insulation removed at one end shall be connected to the upper terminal as shown in

239 Figure 1 and wound once around the cylinder. A load as specified in Table 2.1 shall be applied

240 to the lower end of the wire to keep the specimen in close contact with the cylinder.

241 The test voltage shall be applied according to 4.1 between the conductor of the wire and the

242 cylinder. The test shall be carried out at room temperature.

243 Five specimens shall be tested. The five single values shall be reported.

244 Table 2.1 – Loads applied to enamelled wire

Nominal conductor diameter

Load

mm

Up to and

Over

including N

–

0,018 0,013

0,018

0,020 0,015

0,020

0,022 0,020

0,022

0,025 0,025

0,025

0,028 0,030

0,028

0,032 0,040

0,032

0,036 0,050

0,036

0,040 0,060

0,040

0,045 0,080

0,045

0,050 0,100

0,050

0,056 0,120

0,056

0,063 0,150

0,063

0,071 0,200

0,071

0,080 0,250

0,080

0,090 0,300

0,090

0,100 0,400

0,100

0,160 0,600

0,160

0,250 0,850

0,250

0,355 1,700

0,355

0,500 3,400

IEC CDV 60851-5 © IEC 2025 – 11 – 55/2066/CDV

Test voltage Test voltage

Load

IEC 1271/08

249 1 specimen

250 2 insulating material

251 3 upper terminal

252 4 cylinder

253 Figure 1 – Arrangement of cylinder and specimen

254 for the breakdown voltage test

255 4.3.2 Grade of FIW 3 to FIW 9 with a nominal conductor diameter up to

256 and including 1,600 mm

257 The test is carried out on a cylinder with a diameter as set out in Table 2.2.

258 A straight piece of wire with the insulation removed at one end shall be connected to the upper

259 terminal as shown in Figure 1 and wound once around the cylinder. A load as specified in Table

260 2.2 shall be applied to the lower end of the wire to keep the specimen in close contact with the

261 cylinder.

262 The test voltage shall be applied according to 4.1 between the conductor of the wire and the

263 cylinder. The test shall be carried out at room temperature. Five specimens shall be tested. The

264 five single values shall be reported.

IEC CDV 60851-5 © IEC 2025 – 12 – 55/2066/CDV

266 Table 2.2 – Loads and diameters of test cylinders applied to wire

Nominal diameter Nominal diameter Load Diameter of test cylinder

mm mm N mm

Over Up to and including

- 0,040 0,080 25 1

0,040 0,045 0,100 25 1

0,045 0,050 0,130 25 1

0,050 0,056 0,160 25 1

0,056 0,063 0,200 25 1

0,063 0,071 0,260 25 1

0,071 0,080 0,330 25 1

0,080 0,090 0,400 25 1

0,090 0,100 0,500 25 1

0,100 0,160 0,600 25 1

0,160 0,250 0,850 25 1

0,250 0,355 1,700 25 1

0,355 0,500 3,400 25 1

0,500 0,710 7,000 50 2

0,710 1,060 13,500 50 2

1,060 1,400 27,000 80 3

1,400 1,600 54,000 80 3

268 4.4 Enamelled round wire with a nominal conductor diameter over 0,100 mm

269 up to and including 2,500 mm, grade 1 to grade 3

270 4.4.1 Test at room temperature

271 A straight piece of wire, approximately 400 mm in length, with the insulation removed at both

272 ends, shall be twisted back on itself for a distance of (125 5) mm on the twisting device as

273 shown in Figure 2. The ends of the wire shall be joined, and the load applied with the number

274 of twists, as given in Table 3. The loop at the end of the twisted section shall be cut at two

275 places to provide a maximum spacing between the cut ends. Any bending to ensure adequate

276 separation between the two wire ends shall avoid sharp bends or damage to the coating.

277 The test voltage shall be applied according to 4.1 between the conductors of the wires.

278 Five specimens shall be tested. The five single values shall be reported.

IEC CDV 60851-5 © IEC 2025 – 13 – 55/2066/CDV

280 Table 3 – Loads applied to the wire and number of twists

Nominal conductor diameter

Load

mm Number

of twists

Up to and

N

Over

including

0,100 0,250 0,85 33

0,250 0,355 1,70 23

0,355 0,500 3,40 16

0,500 0,710 7,00 12

0,710 1,060 13,50 8

1,060 1,400 27,00 6

1,400 2,000 54,00 4

2,000 2,500 108,00 3

Load

1 3 2

IEC 1272/08

283 1 spacer

284 2 rotary hook

285 3 specimen

286 Figure 2 – Device for twisting the specimen for breakdown voltage test

287 4.4.2 Test at elevated temperature

288 A specimen prepared according to 4.4.1 shall be placed in the oven preheated to the specified

289 test temperature 3 °C. The test voltage shall be applied according to 4.1 between the

290 conductors of the wires in not less than 15 min after placing the specimen in the oven. The test

291 shall be completed within 30 min.

292 Five specimens shall be tested. The five single values shall be reported.

IEC CDV 60851-5 © IEC 2025 – 14 – 55/2066/CDV

294 4.5 Round wire with a nominal conductor diameter over 2,500 mm

295 4.5.1 Test at room temperature

296 A straight piece of wire of sufficient length, with the insulation removed at one end, shall be

297 bent around a mandrel as shown in Figure 3.

298 The diameter of the mandrel shall be 50 mm 2 mm.

299 The specimen shall be placed in the container and shall be surrounded by shot at least 5 mm

300 between the specimen and the inner walls of the container. The ends of the specimen shall be

301 sufficiently long to avoid flashover.

302 The shot shall be poured gently into a container until the specimen is covered by shot at a depth

303 of 90 mm. The metal shot shall be not more than 2 mm in diameter; balls of stainless steel,

304 nickel or nickel-plated iron have been found suitable. The shot shall be cleaned periodically

305 with a suitable solvent (for example, 1,1,1-trichloroethane).

306 The test voltage shall be applied according to 4.1, between the conductor and the shot.

307 NOTE By agreement between the purchaser and the supplier, the test may be carried out with the specimen under

308 oil. Oil should be in accordance with IEC 60296 or as agreed upon between customer and supplier.

309 Five specimens shall be tested. The five single values shall be reported.

IEC CDV 60851-5 © IEC 2025 – 15 – 55/2066/CDV

311 Dimensions in millimetres

Test voltage electrodes

Bent wire specimen

~

Filling of metal shot not

more than 2 mm

diameter

5 5

25

or

50

IEC 1273/08

313 Figure 3 – U-bend specimen for the breakdown voltage test

314 (specimen placed in shot bath)

5 90

IEC CDV 60851-5 © IEC 2025 – 16 – 55/2066/CDV

316 4.5.2 Test at elevated temperature

317 A specimen prepared according to 4.5.1 shall be placed in the oven preheated to the specified

318 test temperature 3 °C. The shot and container shall be preheated within the oven at the test

319 temperature and kept there during the loading of the test specimen. The loading operation of

320 the test specimen shall be performed very gently in order to avoid damage to the specimen.

321 The test voltage shall be applied according to 4.1 between the conductor and the shot in not

322 less than 15 min after placing the specimen in the oven. The test shall be completed within

323 30 min.

324 The temperature shall be kept within 3 °C.

325 Five specimens shall be tested. The five single values shall be reported.

326 4.6 Fibre wound round wire

327 4.6.1 Test at room temperature

328 A straight piece of wire of sufficient length with the insulation removed at one end shall be bent

329 10 turns around a mandrel as shown in Figure 4. The diameter of the mandrel shall be

330 – 25 mm 1 mm for nominal diameter up to and including 2,500 mm;

331 – 50 mm 2 mm for nominal diameter over 2,500 mm.

332 The specimen shall be placed in the container as shown in Figure 4 and shall be surrounded

333 by shot at least 5 mm between the specimen and the inner walls of the container. There shall

334 be a minimum distance of 2,5 mm between adjacent turns. The ends of the specimen shall be

335 sufficiently long to avoid flashover.

336 The shot shall be poured gently into the container until the specimen is covered by shot at a

337 depth of 90 mm. The metal shot shall not be more than 2 mm in diameter; balls of stainless

338 steel, nickel or nickel-plated iron have been found suitable. The shot shall be cleaned once per

339 year.

340 The test voltage shall be applied according to 4.1 between the conductor of the wire and the

341 shot.

342 NOTE By agreement between the purchaser and the supplier, the test may be carried out with the specimen under

343 oil. Oil should be in accordance with IEC 60296 or as agreed upon between customer and supplier.

344 Five specimens shall be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...