prEN IEC 60068-2-64:2025

(Main)Environmental testing - Part 2-64: Tests - Test Fh: Vibration, broadband random and guidance

Environmental testing - Part 2-64: Tests - Test Fh: Vibration, broadband random and guidance

Essais d'environnement - Partie 2-64: Essais - Essai Fh: Vibrations aléatoires à large bande et guide

Okoljski preskusi - 2-64. del: Preskusi - Preskus Fh: Vibracije, naključne širokopasovne in vodilo

General Information

- Status

- Not Published

- Publication Date

- 20-Jun-2027

- Technical Committee

- CLC/SR 104 - Environmental conditions, classification and methods of test

- Current Stage

- 4060 - Enquiry results established and sent to TC, SR, BTTF - Enquiry

- Start Date

- 20-Feb-2026

- Completion Date

- 20-Feb-2026

Relations

- Effective Date

- 14-Jan-2025

- Effective Date

- 14-Jan-2025

Overview

prEN IEC 60068-2-64:2025 is an important draft international standard published by CLC, focusing on environmental testing - specifically, Test Fh: Vibration, broadband random and guidance. This standard outlines procedures for subjecting products, components, and systems to random vibration tests that simulate real-world stochastic mechanical stresses experienced during transportation, handling, or operational environments. Using digital, computer-controlled vibration generators, the standard provides guidance on test setup, measurement, control strategies, and quality assurance. The goal is to ensure product reliability and performance under realistic vibrational conditions.

Key Topics

This standard encompasses several critical aspects of broadband random vibration testing:

Test Apparatus Requirements

- General requirements for vibration generation equipment.

- Specification for mounting, motion control, and cross-axis motion.

- Guidelines for measuring systems and vibration tolerances.

Control Strategies and Test Quality

- Digital control methods for generating random vibration profiles.

- Procedures for single-point and multipoint control of test vibrations.

- Ensuring reproducibility and reliability in test results.

Test Procedures and Documentation

- Steps for preconditioning specimens and performing initial measurements.

- Detailed approach to performing random vibration exposure.

- Functional performance testing before, during, and after vibration testing.

- Instructions for reporting results and including all necessary test information.

Guidance & Recommendations

- Annexes with advice on selecting test severities (e.g., for transportation and stationary installations).

- Recommendations for ensuring good test quality, taking into account temperature effects, transmissibility, and statistical accuracy.

- Guidance on advanced topics, including non-Gaussian (high kurtosis) random vibration testing when such profiles are relevant.

Applications

prEN IEC 60068-2-64:2025 has broad applicability across industries that require environmental and reliability testing of products:

Electronics and Electrical Components

- Ensures reliability in transportation, mobile installations, or field operations for circuit boards, connectors, and subassemblies.

Industrial and Automotive Equipment

- Evaluates resilience of machinery, sensors, and vehicle components to random vibration loads found in transport and usage.

Aerospace and Railway Industries

- Critical for flight hardware, on-board rail systems, and equipment subject to rigorous vibrational environments.

Consumer Goods and Appliances

- Validates the durability of products shipped or used in vibration-prone settings.

This standard supports engineers, manufacturers, and testing laboratories in simulating realistic vibrational environments, enhancing product development, and improving quality assurance processes.

Related Standards

prEN IEC 60068-2-64:2025 is part of the comprehensive IEC 60068 series, which covers various environmental tests for electronic, electrical, and electromechanical products. Key related standards include:

- IEC 60068-1 - General guidance for environmental testing

- IEC 60068-2 series - Range of specific tests for temperature, humidity, shock, and additional vibration methods

- ISO 16750-3 - Road vehicles – Environmental conditions and testing for electrical and electronic equipment – Mechanical loads

- IEC 60068-2-6 - Test Fc: Vibration (sinusoidal)

These references provide further guidance for selecting appropriate test regimes and integrating vibration testing into comprehensive environmental assessment programs.

Keywords: environmental testing, vibration test, broadband random vibration, reliability testing, mechanical stress, IEC 60068-2-64, product reliability, random vibration simulation, electrodynamic vibration, digital control vibration test, high kurtosis vibration.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

prEN IEC 60068-2-64:2025 is a draft published by CLC. Its full title is "Environmental testing - Part 2-64: Tests - Test Fh: Vibration, broadband random and guidance". This standard covers: Environmental testing - Part 2-64: Tests - Test Fh: Vibration, broadband random and guidance

Environmental testing - Part 2-64: Tests - Test Fh: Vibration, broadband random and guidance

prEN IEC 60068-2-64:2025 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN IEC 60068-2-64:2025 has the following relationships with other standards: It is inter standard links to EN 60068-2-64:2008, EN 60068-2-64:2008/A1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN IEC 60068-2-64:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2026

Okoljski preskusi - 2-64. del: Preskusi - Preskus Fh: Vibracije, naključne

širokopasovne in vodilo

Environmental testing - Part 2-64: Tests - Test Fh: Vibration, broadband random and

guidance

Essais d'environnement - Partie 2-64: Essais - Essai Fh: Vibrations aléatoires à large

bande et guide

Ta slovenski standard je istoveten z: prEN IEC 60068-2-64:2025

ICS:

19.040 Preskušanje v zvezi z Environmental testing

okoljem

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

104/1136/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 60068-2-64 ED3

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2025-11-28 2026-02-20

SUPERSEDES DOCUMENTS:

104/1090/CD, 104/1119A/CC

IEC TC 104 : ENVIRONMENTAL CONDITIONS, CLASSIFICATION AND METHODS OF TEST

SECRETARIAT: SECRETARY:

Sweden Mr Joakim Grafström

OF INTEREST TO THE FOLLOWING COMMITTEES: HORIZONTAL FUNCTION(S):

TC 9,TC 17,SC 17C,TC 21,TC 23,SC 23E,TC 40,TC TC 104 Horizontal Basic Safety

45,SC 45B,TC 48,SC 48D,TC 49,TC 61,TC 62,SC

62A,TC 65,SC 65B,TC 82,TC 86,SC 86B,TC 94,TC 105

ASPECTS CONCERNED:

Safety

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of

CENELEC, is drawn to the fact that this Committee Draft

for Vote (CDV) is submitted for parallel voting.

The CENELEC members are invited to vote through the

CENELEC online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of

which they are aware and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some

Countries” clauses to be included should this proposal proceed. Recipients are reminded that the CDV stage is the

final stage for submitting ISC clauses. (SEE AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

Environmental testing - Part 2-64: Tests - Test Fh: Vibration, broadband random and guidance

PROPOSED STABILITY DATE: 2031

NOTE FROM TC/SC OFFICERS:

download this electronic file, to make a copy and to print out the content for the sole purpose of preparing National

Committee positions. You may not copy or "mirror" the file or printed version of the document, o r any part of it, for

any other purpose without permission in writing from IEC.0

IEC CDV 60068-2-64 Ed.3 © IEC 2025

1 CONTENTS

2 1 Scope . 7

3 2 Normative references . 7

4 3 Terms and definitions . 8

5 4 Requirements for test apparatus . 13

6 4.1 General . 13

7 4.2 Basic motion . 14

8 4.3 Cross-axis motion. 14

9 4.4 Mounting . 15

10 4.5 Measuring systems . 15

11 4.6 Vibration tolerances . 16

12 4.6.1 ASD and RMS value . 16

13 4.6.2 Distribution . 16

14 4.6.3 Statistical accuracy . 17

15 4.6.4 Frequency resolution . 18

16 4.7 Control strategy . 19

17 4.7.1 Single/multipoint control . 19

18 4.7.2 Multireference control . 20

19 4.8 Vibration response investigation . 20

20 4.9 Exceptions and Deviations . 20

21 5 Severities . 21

22 5.1 Test frequency range. 21

23 5.2 RMS value of acceleration . 21

24 5.3 Shape of acceleration spectral density curve . 21

25 5.4 Test duration . 21

26 6 Preconditioning . 21

27 7 Initial measurements and functional performance test . 22

28 8 Testing . 22

29 8.1 General . 22

30 8.2 Initial vibration response investigation . 23

31 8.3 Low-level excitation for equalization prior to testing . 23

32 8.4 Random testing . 24

33 8.4.1 General . 24

34 8.4.2 Intermediate measurements and functional performance . 25

35 8.5 Final vibration response investigation . 25

36 9 Recovery . 26

37 10 Final measurements and functional performance . 26

38 11 Information to be given in the relevant specification. 26

39 12 Information to be given in the test report . 27

40 Annex A (informative) Guidance on test severities . 28

41 A.1 Transportation . 28

42 A.2 Stationary installations . 28

43 Annex B (informative) Guidance on good test quality and reproducibility . 32

44 B.1 General introduction . 32

45 B.2 Requirements for testing . 33

46 B.2.1 Single-point and multipoint control . 33

IEC CDV 60068-2-64 Ed.3 © IEC 2025

47 B.2.2 Distribution . 33

48 B.2.3 Initial and final slope . 35

49 B.3 Testing procedures . 36

50 B.4 Equipment normally used with vibration isolators . 36

51 B.4.1 Transmissibility factors for isolators . 36

52 B.4.2 Temperature effect . 36

53 B.5 Test severities . 36

54 B.6 Equipment performance . 37

55 B.7 Initial and final measurements . 37

56 Annex C (informative) Guidance on non-Gaussian distribution/high kurtosis tests . 38

57 C.1 Non-Gaussian random vibration . 38

58 C.2 Methods to generate non-Gaussian random vibration . 38

59 C.2.1 General . 38

60 C.2.2 Amplitude modulation technique . 39

61 C.2.3 Phase modification technique . 39

62 C.2.4 Non-uniform phase technique . 40

63 C.3 Additional analysis . 40

64 C.4 Frequency range . 41

65 C.5 Beta distribution . 41

66 Annex D (informative) Verification against the environmental test specification and

67 test purpose . 42

68 D.1 Scope of test verification . 42

69 D.2 Purpose of test verification . 42

70 D.3 Information required for test verification . 43

71 D.4 Verification of test procedures and severities . 43

72 D.5 Verification of sequential test programme . 43

73 D.6 Technical verification of vibration tests . 44

75 Figure 1 – Tolerance bands for acceleration spectral density; initial and final slope

76 (see B.2.3) . 17

77 Figure 2 – Time history of stochastically excitation; probability density function with

78 Gaussian (normal) distribution (example with crest factor = 3, see also 3.16 and 4.6.2 ) . 18

79 Figure 3 – Statistical accuracy of acceleration spectral density versus degrees of

80 freedom for different confidence levels (see also 4.6.3) . 19

81 Figure 4 – Time history of non-Gaussian excitation – Probability density function

82 compared with Gaussian (normal) distribution . 26

IEC CDV 60068-2-64 Ed.3 © IEC 2025

85 INTERNATIONAL ELECTROTECHNICAL COMMISSION

86 ____________

88 ENVIRONMENTAL TESTING –

90 Part 2-64: Tests – Test Fh: Vibration,

91 broadband random and guidance

94 FOREWORD

95 1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

96 all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

97 co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

98 in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

99 Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

100 preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

101 may participate in this preparatory work. International, governmental and non-governmental organizations liaising

102 with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

103 Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

104 2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

105 consensus of opinion on the relevant subjects since each technical committee has representation from all

106 interested IEC National Committees.

107 3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

108 Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

109 Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

110 misinterpretation by any end user.

111 4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

112 transparently to the maximum extent possible in their national and regional publications. Any divergence between

113 any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

114 5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any equipment

115 declared to be in conformity with an IEC Publication.

116 6) All users should ensure that they have the latest edition of this publication.

117 7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

118 members of its technical committees and IEC National Committees for any personal injury, property damage or

119 other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

120 expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

121 8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

122 indispensable for the correct application of this publication.

123 9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

124 rights. IEC shall not be held responsible for identifying any or all such patent rights.

125 International Standard IEC 60068-2-64 has been prepared by IEC technical committee 104:

126 Environmental conditions, classification and methods of test.

127 This third edition cancels and replaces the second edition, published in 2008, and constitutes

128 a technical revision.

129 The major changes with regard to the previous edition concern the update of Annex A with

130 references to examples, the introduction of an organizational deviation treatment and some

131 clarification on requirements.

IEC CDV 60068-2-64 Ed.3 © IEC 2025

133 The text of this document is based on the following documents:

FDIS Report on voting

134 Full information on the voting for the approval of this document can be found in the report on

135 voting indicated in the above table.

136 This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

137 A list of all the parts in the IEC 60068 series, under the general title Environmental testing, can

138 be found on the IEC website.

139 The committee has decided that the contents of this publication will remain unchanged until the

140 maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

141 related to the specific publication. At this date, the publication will be

142 • reconfirmed,

143 • withdrawn,

144 • replaced by a revised edition, or

145 • amended.

IEC CDV 60068-2-64 Ed.3 © IEC 2025

148 INTRODUCTION

149 This part of IEC 60068 deals with broadband random vibration testing intended for general

150 application to components, equipment and other products, hereinafter referred to as specimens,

151 that may be subjected to vibrations of a stochastic nature. The methods and techniques in this

152 document are based on digital control of random vibration. It permits the introduction of

153 variations to suit individual cases if these are prescribed by the relevant specification.

154 Compared with most other vibration tests, test Fh is not based on deterministic but on statistical

155 techniques. Broad-band random vibration testing is therefore described in terms of probability

156 and statistical averages.

157 It is emphasized that random testing always demands a certain degree of engineering

158 judgement, and both equipment supplier and purchaser as well as the test house should be

159 fully aware of this fact. The writer of the relevant specification is expected to select the testing

160 procedure and the values of severity appropriate to the specimen and its use.

161 The test method is based primarily on the use of an electrodynamic or a servo-hydraulic

162 vibration generator with an associated computer based control system relying on measurement

163 sensors used as a vibration testing system.

164 The traditional general purpose broad-band random vibration test utilizes waveforms with a

165 Gaussian distribution of amplitudes. However, when so specified, this test procedure can also

166 be utilized with random vibration tests with a non-Gaussian distribution of amplitudes. Such

167 tests are sometimes alternatively known as high kurtosis tests.

168 Annexes A and B are informative annexes giving reference to examples of test spectra for

169 different environmental conditions and a list of details to be considered for inclusion in

170 specifications and guidance.

171 Annex C is an informative annex giving information on non-Gaussian distribution/high kurtosis

172 tests.

173 Annex D is an informative annex giving guidance on technical measures of verification that the

174 intended test purpose is achieved by the test.

IEC CDV 60068-2-64 Ed.3 © IEC 2025

176 ENVIRONMENTAL TESTING –

178 Part 2-64: Tests-Test Fh: Vibration,

179 broadband random and guidance

183 1 Scope

184 This part of IEC 60068 demonstrates the adequacy of specimens to resist dynamic loads

185 without unacceptable degradation of its functional and/or structural integrity when subjected to

186 the specified random vibration test requirements.

187 Broadband random vibration may be used to identify accumulated stress effects and the

188 resulting mechanical weakness and degradation in the specified performance. This information,

189 in conjunction with the relevant specification, may be used to assess the acceptability of

190 specimens.

191 This document is applicable to specimens which may be subjected to vibration of a stochastic

192 nature resulting from transportation or operational environments, for example, in aircraft, space

193 vehicles and land vehicles. It is primarily intended for unpackaged specimens, and for items in

194 their transportation container when the latter may be considered as part of the specimen itself.

195 However, if the item is packaged, then the item itself is referred to as a product and the item

196 and its packaging together are referred to as a test specimen. This document may be used in

197 conjunction with IEC 60068-2-47:2005, for testing packaged products.

198 If the specimens are subjected to vibration of a combination of random and deterministic nature

199 resulting from transportation or real life environments, for example, in aircraft, space vehicles

200 and for items in their transportation container, testing with pure random may not be sufficient.

201 See IEC 60068-3-8:2003 for estimating the dynamic vibration environment of the specimen and

202 based on that, selecting the appropriate test method.

203 Although primarily intended for electrotechnical specimens, this document is not restricted to

204 them and may be used in other fields where desired (see Annex A).

205 2 Normative references

206 The following documents are referred to in the text in such a way that some or all of their content

207 constitutes requirements of this document. For dated references, only the edition cited applies.

208 For undated references, the latest edition of the referenced document (including any

209 amendments) applies.

210 IEC 60050-300: International Electrotechnical Vocabulary – Electrical and electronic

211 measurements and measuring instruments

212 – Part 311: General terms relating to measurements

213 – Part 312: General terms relating to electrical measurements

214 – Part 313: Types of electrical measuring instruments

215 – Part 314: Specific terms according to the type of instrument

216 IEC 60068-1: Environmental testing – Part 1: General and guidance

IEC CDV 60068-2-64 Ed.3 © IEC 2025

217 IEC 60068-2-6: Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

218 IEC 60068-2-47, Environmental testing – Part 2-47: Tests – Mounting of specimens for vibration,

219 impact and similar dynamic tests

220 IEC 60068-2-86: Environmental testing – Part 2-86: Tests -Test Fx: Vibration – Multi-exciter

221 and multi-axis method

222 IEC 60068-3-8: Environmental testing – Part 3-8: Supporting documentation and guidance –

223 Selecting amongst vibration tests

224 IEC 60068-5-2: Environmental testing – Part 5-2: Guide to drafting of test methods – Terms and

225 definitions

226 3 Terms and definitions

227 For the purposes of this document, the following terms and definitions apply.

228 ISO and IEC maintain terminological databases for use in standardization at the following

229 addresses:

230 – IEC Electropedia: available at http://www.electropedia.org/

231 – ISO Online browsing platform: available at http://www.iso.org/obp

232 NOTE 1 The terms used are generally defined in IEC 60050-300, IEC 60068-1, IEC 60068-2-6, and IEC 60068-5-2

233 and ISO 2041. If a definition from one of those sources is included here, the derivation is indicated and departures

234 from the definitions in those sources are also indicated.

235 3.1

236 cross-axis motion

237 motion not in the direction of the stimulus; generally specified in the two axes orthogonal to the

238 direction of the stimulus

239 Note 1 to entry: The cross-axis motion should be measured close to the fixing points.

240 3.2

241 actual motion

242 motion represented by the wideband signal returned from the reference point transducer

243 3.3

244 fixing point

245 part of the specimen in contact with the fixture or vibration table at a point where the specimen

246 is normally fastened in service

247 Note 1 to entry: If a part of the real mounting structure is used as the fixture, the fixing points are taken as those of

248 the mounting structure and not of the specimen.

249 Note 2 to entry: Where the specimen consists of a packaged product, fixing point can be interpreted as the surface

250 of the specimen which is in contact with the vibration table.

252 3.4

253 control methods

254 3.4.1

255 single point control

256 control method using the signal from the transducer at the reference point in order to maintain

257 this point at the specified vibration level

258 3.4.2

259 multipoint control

260 control method using the signals from each of the transducers at the checkpoints

IEC CDV 60068-2-64 Ed.3 © IEC 2025

261 Note 1 to entry: The signals are either continuously averaged arithmetically or processed by using comparison

262 techniques, depending upon the relevant specification. See also 3.13.

263 3.5

264 g

n

265 standard acceleration due to the earth’s gravity, which itself varies with altitude and

266 geographical latitude

267 Note 1 to entry: For the purposes of this document, the value of g is rounded up to the nearest whole number, that

n

268 is 10 m/s .

269 3.6

270 measuring points

271 specific points at which data are gathered for conducting the test

272 Note 1 to entry: These points are of three types, as defined in 3.7 to 3.9.

273 3.7

274 checkpoint

275 point located on the fixture, on the vibration table or on the specimen as close as possible to

276 one of its fixing points, and in any case, rigidly connected to it

277 Note 1 to entry: A number of checkpoints are used as a means of ensuring that the test requirements are satisfied.

278 3.8

279 reference point,

280 point, chosen from amongst the checkpoints, whose signal is used to control the test, such that

281 the requirements of this standard are satisfied

282 3.9

283 fictitious reference point,

284 point, derived from multiple checkpoints either manually or automatically, the result of which is

285 used to control the test so that the requirements of this document are satisfied

286 3.10

287 response points

288 specific points on the specimen from which data is gathered for the purpose of the v ibration

289 response investigation

290 Note 1 to entry: These points are not the same as checkpoints or reference points.

291 3.11

292 preferred testing axes

293 three (usually) orthogonal axes that correspond to the most vulnerable axes of the specimen.

294 Note 1 to entry: The selection of the preferred testing axes can be depending on the specimen’s design and the

295 sub-components inside, may not always be orthogonal; the in-service mounting orientation of the specimen can also

296 play a role in the selection of the preferred testing axes. See also IEC 60068-2-86 for more information on multi-axis

297 testing.

298 3.12

299 Sampling frequency

300 number of discrete magnitude values taken per second to record or represent a time -history in

301 a digital form

302 3.13

303 multipoint control strategies

304 method for calculating the reference control signal when using multipoint control

305 Note 1 to entry: Different frequency domain control strategies are discussed to in 4.7.1.

IEC CDV 60068-2-64 Ed.3 © IEC 2025

306 3.14

307 averaging

308 process of determining the control acceleration spectral density formed from the arithmetic

309 average of the acceleration spectral densities at each frequency line of more than one

310 checkpoint

311 3.15

312 extremal

313 process of determining the control acceleration spectral density formed from the maximum or

314 minimum acceleration spectral density at each frequency line of more than one checkpoint

315 3.16

316 crest factor

317 ratio of the peak value to the RMS value of the time history

318 3.17

319 –3 dB bandwidth

320 frequency bandwidth between two points in a frequency response function which are at 0,707

321 of the maximum response when associated with a single resonance peak. Can be applied to

322 power or field dimensions but chosen dimension is to be given

323 3.18

324 acceleration spectral density

325 ASD

326 mean-square value of that part of an acceleration signal passed by a narrow-band filter of a

327 centre frequency, per unit bandwidth, in the limit as the bandwidth approaches zero and the

328 averaging time approaches infinity

329 3.19

330 control acceleration spectral density

331 acceleration spectral density measured at the reference point or the fictitious reference point

332 3.20

333 control system loop

334 sum of the following actions:

335 – digitizing the analogue waveform of the signal derived from the reference point or

336 fictitious reference point;

337 – performing the necessary processing;

338 – producing an updated analogue drive waveform to the vibration system power amplifier

339 (see Clause B.1.)

340 Note 1 to entry: Subsystems in the control system loop and steps in the signal processing chain can be:

341 - Transducer (measurement instrument transferring the physical quantity to be measured – usually kinetic

342 like acceleration – to an electric signal), feeding to

343 - Signal conditioning – can be included in controller (power supply, AC-coupling) or the transducer (charge

344 amplifier), feeding to

345 - Controller (producing a defined output signal to achieve a certain wanted vibration environment), feeding

346 drive signal to

347 - Power amplifier (including further control loops and signal processing), feeding to

348 - Shaker (transfer from electric actuation power to mechanical movement and force), movement measurement

349 by transducer

IEC CDV 60068-2-64 Ed.3 © IEC 2025

350 3.21

351 drive signal clipping

352 limitation of the maximum crest factor imposed on the drive signal within the effective frequency

353 range. It is process to apply the required crest factor (3.15) to the drive signal(s) produced by

354 the digital control system

355 3.22

356 effective frequency range

357 frequency range of measurement and control between 0,5 times f and 2,0 times f of the test

1 2

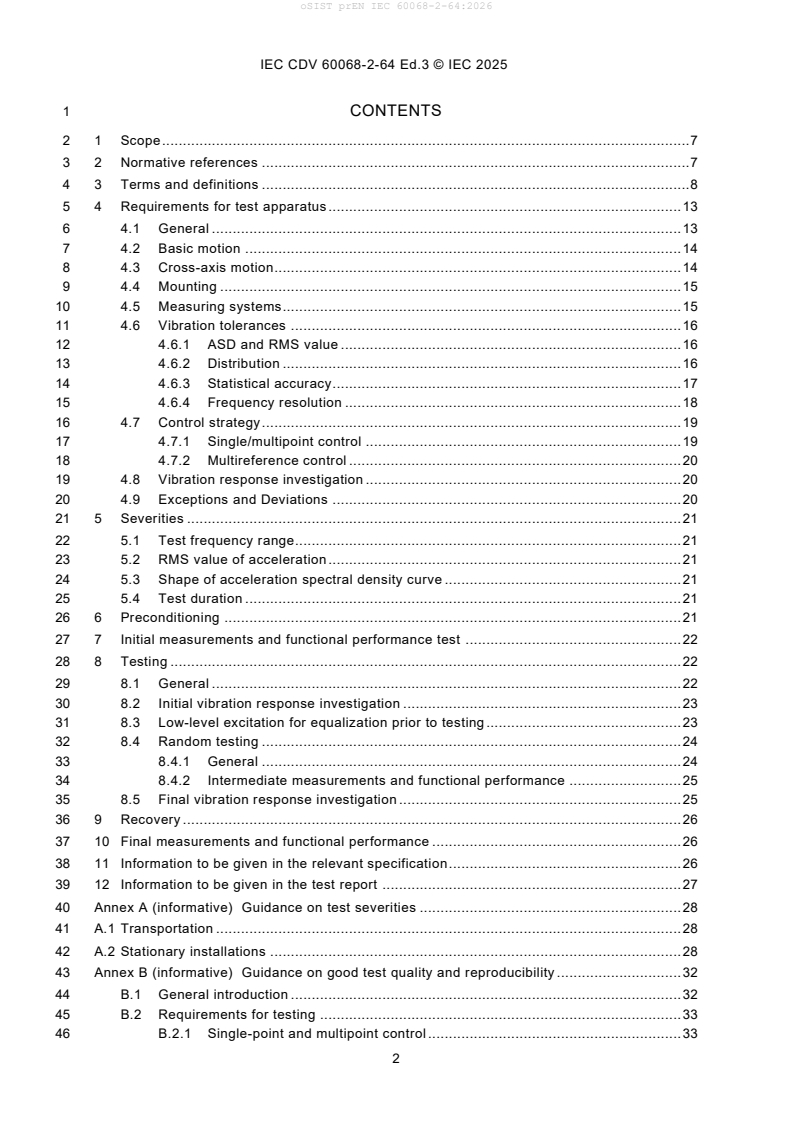

358 frequency range, (see also Figure 1)

359 Note 1 to entry: Due to initial and final slope, the effective frequency range is higher than the test frequency range

360 between f and f .

1 2

361 3.23

362 error acceleration spectral density

363 difference between the specified acceleration spectral density and the control acceleration

364 spectral density

365 3.24

366 equalization

367 minimization of the error acceleration spectral density

368 3.25

369 final slope

370 part of the specified acceleration spectral density above f , (see also Figure 1)

371 3.26

372 frequency resolution

373 B

e

374 width of the frequency intervals in the acceleration spectral density in Hertz

375 Note 1 to entry: It is equal to the reciprocal of the record block length (T) in digital analysis; the number of frequency

376 lines is equal to the number of intervals in a given frequency range

377 3.27

378 indicated acceleration spectral density

379 estimate of the true acceleration spectral density read from the analyser presentation distorted

380 by the instrument error and the random error

381 3.28

382 initial slope (see also Figure 1)

383 part of the specified acceleration spectral density below f

384 3.29

385 instrument error

386 error associated with each analogue item of the input to the control system and control system

387 analogue items

388 3.30

389 random error

390 error changing from one estimate to another of the acceleration spectral density because of the

391 limitation of averaging time and filter bandwidth in practice; with an infinite averaging time the

392 error would converge towards zero

393 3.31

394 record

395 collection of equally spaced data points in the time domain that are used in the calculation of

396 the Fast Fourier Transform

IEC CDV 60068-2-64 Ed.3 © IEC 2025

397 3.32

398 reproducibility

399 closeness of the agreement between the results of measurements of the same value of the

400 same quantity, where the individual measurements are made

401 – by different methods,

402 – with different measuring instruments,

403 – with different signal generation,

404 – by different observers,

405 – in different laboratories,

406 – after intervals of time which are long compared with the duration of a single

407 measurement,

408 – under different customary conditions of use of the instruments employed

409 Note 1 to entry: The term “reproducible” also applies to the case where only certain of the preceding conditions are

410 taken into account.

411 3.33

412 root-mean-square value

413 root-mean-square value (RMS value) of a single-valued function over an interval between two

414 frequencies is the square root of the average of the squared values of all functions over the

415 total frequency interval f and f , (see also Figure 2)

1 2

416 3.34

417 standard deviation)

418

419 The RMS value of the deviation of a random time history from a mean value, (see also Figure

420 2

421 Note 1 to entry: In vibration theory, the mean value of vibration is equal to zero; therefore, for a random time history,

422 the standard deviation is equal to the RMS value. For non-gaussian distribution see Annex C.

423 3.35

424 statistical accuracy

425 ratio of true acceleration spectral density to indicated acceleration spectral density

426 3.36

427 statistical degrees of freedom

428 DOF

429 effective number derived from the frequency resolution and the effective averaging time for

430 estimation of acceleration spectral density of random data with a time-averaging technique,

431 (see also Figure 3)

432 3.37

433 test frequency range

434 frequency range between f and f (see Figure 1) in which the ASD is constant or shaped as

1 2

435 given in the relevant specification

436 3.38

437 true acceleration spectral density

438 acceleration spectral density of the random signal acting on the specimen

IEC CDV 60068-2-64 Ed.3 © IEC 2025

439 3.39

440 kurtosis

th

441 4 statistical moment, which provides a measure of the shape of an amplitude distribution

442 Note 1 to entry: Typically, a waveform with Gaussian distribution will have a kurtosis of 3, if considered over an

443 infinite period.

444 Note 2 to entry: Kurtosis is given by:

N

kurtosis=− .xx

( )

i

N

i =1

446 where:

447 σ is the standard deviation of the N values which describe the waveform;

448 x are individual values representing the waveform described by N such values;

i

449 𝑥̅ is the mean value of the N values which describe the waveform.

450 3.40

451 skewness

rd

452 3 statistical moment, which provides a measure of non-symmetry of an amplitude distribution

453 NOTE 1 TO ENTRY: Typically, a waveform with Gaussian distribution will have a skewness of 0, if considered over

454 an infinite period.

455 NOTE 2 TO ENTRY: Skewness is given by:

N

skewness=− .xx

( )

i

N

i =1

457 where:

458 σ is the standard deviation of the N values which describe the waveform;

459 x are individual values representing the waveform described by N such values;

i

460 𝑥̅ is the mean value of the N values which describe the waveform.

461 4 Requirements for test apparatus

462 4.1 General

463 The required characteristics apply to the complete vibration system, which includes the power

464 amplifier, vibrator, test fixture, specimen and control system when loaded for testing.

465 The standardized test method consists of the following test sequence normally applied in each

466 of the mutually perpendicular axes of the test specimen:

467 1) An initial vibration response investigation, with low level sinusoidal excitation, or low level

468 random excitation, (see 8.2).

469 2) The random excitation as the mechanical load or stress test.

470 3) A final vibration response investigation to compare the results with the initial one and to

471 detect possible mechanical failures due to a change of the dynamic behaviour (see 8.2 and

472 8.5).

473 Where the dynamic behaviour is known, and it is not considered relevant, or sufficient data can

474 be gathered during the test at full level, the relevant specification may not require pre and post -

475 test vibration response investigations.

IEC CDV 60068-2-64 Ed.3 © IEC 2025

476 For non-Gaussian testing, the test apparatus shall be able to produce a signal with a specified

477 probability distribution and crest factor. Generally, non-Gaussian random vibration testing

478 requires shaker and amplifier systems that are designed for Gaussian random vibrations but

479 with increased crest factor capabilities.

480 4.2 Basic motion

481 The basic motion of the fixing points of the specimen shall be prescribed by the relevant

482 specification and measured as actual motion. The fixing points should have substantially

483 identical motions in phase and amplitude (within the requirements set here and in the test

484 specification) and shall be rectilinear relative to the direction of excitation. If substantially

485 identical motions are difficult to achieve, then a multipoint control strategy shall be used.

486 Deviations between the excitation points shall be monitored and documented.

487 Definition and guidance on appropriate fixtures are found in IEC 60068-2-47 (Mounting). For

488 technical measures to verify that the test purpose is still fulfilled, see Annex D.

489 NOTE 1 For large structures and a high frequency range, for example, 20 Hz to 2 000 Hz, the dynamics of the test

490 specimen is likely to require multipoint control.

491 NOTE 2 If four or fewer fixing points exist, each is used as a checkpoint. For packaged products, where a fixing

492 point can be interpreted as the packaging surface in contact with the vibration table, one checkpoint can be used,

493 provided that there are no effects due to resonances of the vibration table or the mounting structure in the frequency

494 range specified for the test. If this is the case, multipoint control may be recommended, but see also NOTE 3. If more

495 than four fixing points exist, four representative fixing points will be defined in the relevant specification to be used

496 as checkpoints.

497 NOTE 3 In special cases, for example, for large or complex specimens, the checkpoints will be prescribed by the

498 relevant specification if not close to the fixing points.

499 NOTE 4 Where a large number of small specimens are mounted on one fixture, or in the case of a small specimen

500 with a number of fixing points, a single checkpoint (that is the reference point) can be selected for the derivation of

501 the control signal. This signal is then related to the fixture rather than to the fixing points of the specimen(s). This

502 procedure is only valid when the lowest resonance frequency of the loaded fixture is well above the upper frequency

503 of the test.

505 4.3 Cross-axis motion

506 Unless specified otherwise by the relevant specification cross-axis motion shall be checked,

507 either before the test is applied by conducting a sine or random investigation at a level

508 prescribed by the relevant specification, or during testing by utilising additional monitoring

509 channels in the two perpendicular axes.

510 If not specified otherwise, the following applies:

511 The ASD value of each frequency at the checkpoints in both axes perpendicular to the specified

512 axis shall not exceed the specified ASD values above 500 Hz and below 500 Hz shall not

513 exceed –3 dB of the specified ASD values. The total RMS value of acceleration in both axes

514 perpendicular to the specified axis shall not exceed 50 % of the RMS value for the specified

515 axis. For example, for a small specimen, the ASD value of the permissible cross axis motion

516 may be limited such that it does not exceed –3 dB of the basic motion, if so prescribed by the

517 relevant specification.

518 At some frequencies or with large-size or high-mass specimens, it may be difficult to achieve

519 these values. Also, in those cases where the relevant specification requires severities with a

520 large dynamic range, it may also be difficult to achieve these. In such cases, the relevant

521 specification shall state which of the following requirements applies:

522 a) any cross-axis motion in excess of that given above shall be stated in the test report;

523 b) cross-axis motion which is known to offer no hazard to the specimen and comply with the

524 test purpose need not be monitored (see Annex D).

IEC CDV 60068-2-64 Ed.3 © IEC 2025

525 Often, the cross-axis motion is produced by torsion, when the mass centre and stiffness centre

526 are not at same point, usually resulting in a rotation. This may be important especially for large

527 specimen.

528 Exception clauses from sub-clause 4.9 apply accordingly for organizational measures in case

529 of exceptions and deviations. For technical measures to verify that the test purpose is still

530 fulfilled, see Annex D.

531 4.4 Mounting

532 Unless specified otherwise in the relevant specification, the test specimen shall be mounted in

533 accordance with IEC 60068-2-47.

534 However, when a test specimen that is normally used with a vibration isolator is tested without

535 the isolator, the vibration level should be adjusted accordingly.

536 In this case, and unless another method is specified in the relevant specification, the

537 appropriate transfer function curve shall be selected from IEC 60068-2-6, Figure A.1, and

538 multiply the specified ASD with the square of the value obtained from this curve to make the

539 correction.

540 4.5 Measuring systems

541 The characteristics of the measuring system shall be such that it can be determined whether

542 the true value of the vibration as measured in the intended axis at the reference point is within

543 the tolerance required for the test.

544 The frequency response of the overall measuring system, which includes the transducer, the

545 signal conditioner and the data acquisition with a chosen sampling frequency and processing

546 device, has a significant effect on the accuracy of the measurements. The effective frequency

547 range of the measuring system shall extend from at least 0,5 times the lowest frequency ( f ) to

548 2,0 times the highest frequency (f ) of the test frequency range (see Figure 1). The frequency

549 response of the measuring system shall be flat within 5 % of the test frequency range. Outside

550 of this range any further deviation shall be stated in the test report.

IEC CDV 60068-2-64 Ed.3 © IEC 2025

+3 dB

–3 dB

Initial slope Final slope

normally –24 dB/octave

+6 dB/octave or steeper

or steeper

0,5f1 f1 f2 2f2

Frequency (Hz) (log. scale)

IEC 581/08

552 Figur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...