EN 13160-4:2016

(Main)Leak detection systems - Part 4: Requirements and test/assessment methods for sensor based leak detection systems

Leak detection systems - Part 4: Requirements and test/assessment methods for sensor based leak detection systems

This European Standard gives requirements and the corresponding test/assessment methods applicable to leak detection kits based on the detection of the presence of liquid and/or vapour in interstitial spaces, leakage containments or monitoring wells. The kits are usually composed by:

- sensing device(s);

- evaluation device;

- alarm device.

Leckanzeigesysteme - Teil 4: Anforderungen und Prüf-/Bewertungsmethoden für sensorbasierte Leckanzeigesysteme

Diese Europäische Norm legt Anforderungen an und die einschlägigen Prüf-/Bewertungsverfahren für sensorbasierte Leckanzeigesysteme (Leckanzeiger) fest. Die Leckanzeiger sind für die Verwendung in Überwachungsräumen, Leckageräumen oder Überwachungsschächten bestimmt. Die Leckanzeiger bestehen in der Regel aus:

Messfühlereinrichtung(en);

Auswerteeinrichtung;

Alarmeinrichtung.

Systèmes de détection de fuites - Partie 4: Exigences et méthodes d'essai/d'évaluation des systèmes de détection de fuites par capteur

La présente Norme spécifie les exigences et les méthodes d'essai/d'évaluation correspondantes applicables aux kits de détection de fuites, fondées sur la présence de liquide et/ou de vapeur dans les espaces interstitiels, les espaces de confinement des fuites ou les puits piézométriques. Les kits sont généralement constitués des éléments suivants :

- dispositif(s) de mesurage ;

- dispositif d'évaluation ;

- dispositifs d'alarme ;

Sistemi za kontrolo tesnosti - 4. del: Zahteve in metode za preskušanje in ocenjevanje senzorskih sistemov za zaznavanje netesnosti

Ta standard določa zahteve ter ustrezne metode za preskušanje in ocenjevanje, ki se uporabljajo za komplete za kontrolo tesnosti, ki temeljijo na zaznavanju prisotnosti tekočine in/ali hlapov v vmesnih prostorih, zadrževalnikih ali nadzornih jaških. Kompleti so običajno sestavljeni iz:

– senzorjev,

– naprave za ocenjevanje,

– alarmne naprave.

General Information

- Status

- Withdrawn

- Publication Date

- 05-Jul-2016

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 393 - Equipment for storage tanks and for service stations

- Drafting Committee

- CEN/TC 393/WG 2 - Leak detecting devices for tanks and pipes

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Nov-2024

- Completion Date

- 14-Apr-2025

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 13-Jul-2016

- Effective Date

- 18-Sep-2024

Frequently Asked Questions

EN 13160-4:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Leak detection systems - Part 4: Requirements and test/assessment methods for sensor based leak detection systems". This standard covers: This European Standard gives requirements and the corresponding test/assessment methods applicable to leak detection kits based on the detection of the presence of liquid and/or vapour in interstitial spaces, leakage containments or monitoring wells. The kits are usually composed by: - sensing device(s); - evaluation device; - alarm device.

This European Standard gives requirements and the corresponding test/assessment methods applicable to leak detection kits based on the detection of the presence of liquid and/or vapour in interstitial spaces, leakage containments or monitoring wells. The kits are usually composed by: - sensing device(s); - evaluation device; - alarm device.

EN 13160-4:2016 is classified under the following ICS (International Classification for Standards) categories: 23.020.01 - Fluid storage devices in general; 23.040.99 - Other pipeline components; 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13160-4:2016 has the following relationships with other standards: It is inter standard links to EN 13160-4:2003, EN 13160-4:2016+A1:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13160-4:2016 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/131. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 13160-4:2016 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sistemi za kontrolo tesnosti - 4. del: Zahteve in metode za preskušanje in ocenjevanje senzorskih sistemov za zaznavanje netesnostiLeckanzeigesysteme - Teil 4: Anforderungen und Prüf-/Bewertungsverfahren für sensorbasierte LeckanzeigesystemeSystèmes de détection de fuites - Partie 4 : Exigences et méthodes d'essai/d'évaluation des systèmes de détection de fuite par capteurLeak detection systems - Part 4: Requirements and test/assessment methods for sensor based leak detection systems23.020.01Fluid storage devices in generalICS:Ta slovenski standard je istoveten z:EN 13160-4:2016SIST EN 13160-4:2016en,fr,de01-november-2016SIST EN 13160-4:2016SLOVENSKI

STANDARDSIST EN 13160-4:20031DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13160-4

July

t r s x ICS

t uä r t rä r sâ

t uä r v rä { {â

t {ä t x rä t r Supersedes EN

s u s x ræ vã t r r uEnglish Version

Leak detection systems æ Part

vã Requirements and systems Systèmes de détection de fuites æ Partie

vã Exigences et détection de fuites par capteur

Leckanzeigesysteme æ Teil

vã Anforderungen und PrüfæLeckanzeigesysteme This European Standard was approved by CEN on

z April

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u s x ræ vã t r s x ESIST EN 13160-4:2016

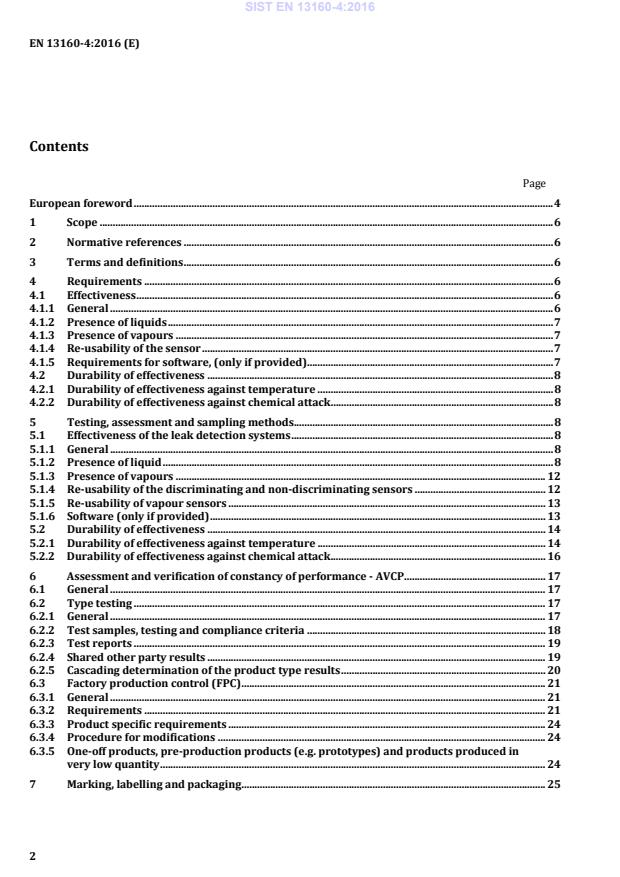

Environmental aspects . 27 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Regulation . 29 ZA.1 Scope and relevant characteristics . 29 ZA.2 Procedure for AVCP of sensor based leak detection systems . 30 ZA.2.1 System(s) of AVCP . 30 ZA.2.2 Declaration of performance (DoP) . 31 ZA.2.2.1 General . 31 ZA.2.2.2 Content . 32 ZA.2.2.3 Example of DoP . 32 ZA.3 CE marking and labelling . 34 Bibliography . 38

· 30 kPa at 20 °C floating on water. 4.1.3 Presence of vapours The sensor shall detect specific vapours from flammable liquids with a vapour pressure

· 30 kPa at 20 °C when their concentration is a volume fraction less than or equal to 1000 × 10 «6. 4.1.4 Re-usability of the sensor Any re-useable sensor shall be able to detect a new leak condition after removal of liquid or vapour. The recovery time shall be: — not higher than 24 h from after the removal of the vapour leak conditions for any vapour sensors; — not higher than 7 days from after the removal of the liquid leak conditions for any liquid sensor (or after the removal of the water for the vapour sensors) that doesn't need any manual reset procedure. 4.1.5 Requirements for software, (only if provided) The software, where provided, shall have a facility for self-checking by fulfilling the following requirements: SIST EN 13160-4:2016

«20 °C to +60 °C — Type 2: 0 °C to +40 °C — Type 3:

« v r °C to +40 °C 4.2.2 Durability of effectiveness against chemical attack Parts of leak detection kits which can come into contact with the stored/conveyed liquid/water or its vapour and air shall be resistant. 5 Testing, assessment and sampling methods 5.1 Effectiveness of the leak detection systems 5.1.1 General For the tests minimum one sample shall be provided by the manufacturer. For the tests the following documentation shall be provided by the manufacturer: — documentation according to Clause 7; — datasheet of the parts of the leak detection kit; — electrical diagrams of the parts of the leak detection kit; — design and application drawings; — lists of the parts used including material data. Leak detection kits shall be inspected visually to confirm that the sample complies with the documentation. 5.1.2 Presence of liquid 5.1.2.1 Non-discriminating liquid sensors (Category 1) 5.1.2.1.1 Test equipment — mounting device for fixing the sensor; — temperature sensor with an accuracy of ± 1 K; SIST EN 13160-4:2016

¶ 20 % (V/V) ethanol 20 % (V/V) ethanol 37,7 % (V/V) toluene 24,2 % (V/V) isooctane (2,2,4- trimethylpentane) 13,5 % (V/V) n-heptane 3 % (V/V) methanol 1,6 % (V/V) butanol The tolerance for the component of the test liquid shall be 0,1 %. b) for other petroleum products: liquids according to EN 14879-4:2007, Annex C. 5.1.2.1.2 Preparation The tests shall be carried out at a temperature of (20 ± 5) °C. The output values of the current or voltage or the signal frequency for sensors without evaluation/alarm device shall be measured at the beginning of the test. When using an evaluation device this shall indicate the operation condition. a) The sensor shall be installed in the mounting device. SIST EN 13160-4:2016

¶ 20 % (V/V) ethanol 20 % (V/V) ethanol 37,7 % (V/V) toluene SIST EN 13160-4:2016

Key 1 test sample 2 variable power supply 3 measuring device Figure 1 — Test setup for software The power supply is done over a transformer to vary the power supply. 5.1.6.3 Test method The test shall be carried out at (20 ± 5) °C. Check of the software documentation whether and for which situations the self-diagnostic is defined. Followed by a check on the hardware. The input data are modified and in the result shall be an alarm/error message. This alarm condition shall be different from the alarm coming out of the intended use. 5.1.6.4 Evaluation The test deemed to have been passed if the software — provides an alarm condition in case of a negative result of self-diagnostic mode; — has a facility to check the consistency of the input and output data, malfunction shall result in an alarm condition. 5.2 Durability of effectiveness 5.2.1 Durability of effectiveness against temperature 5.2.1.1 Test equipment — An environmental chamber with an opening on the top, the temperature of which can be varied over the range from

« v r °C to +60 °C; — test rack with vertical hub to move the sensor; — basin; — cycle counter; SIST EN 13160-4:2016

¶ 20 % (V/V) ethanol 20 % (V/V) ethanol 37,7 % (V/V) toluene 24,2 % (V/V) isooctane (2,2,4-trimethylpentane) 13,5 % (V/V) n-heptane 3 % (V/V) methanol 1,6 % (V/V) butanol The tolerance for the component of the test liquid shall be 0,1 %. b) for other petroleum products: liquids according to EN 14879-4:2007, Annex C; — for acids: 60 % sulphuric acid; — for lyes: 40 % soda lye; SIST EN 13160-4:2016

— Presence of liquids; 4.1.2 5.1.2

4.1.2 — Presence of vapour; 4.1.3 5.1.3 3 4.1.3 — Re-usability; 4.1.4 5.1.4, 5.1.5

4.1.4 software (only if provided) 4.1.5 5.1.6

4.1.5 Durability of effectiveness:

against temperature; 4.2.1 5.2.1 1 4.2.1 against chemical attacks 4.2.2 5.2.2 4.2.2 6.2.3 Test reports The results of the determination of the product type shall be documented in test reports. All test reports shall be retained by the manufacturer for at least 10 years after the last date of production of the sensor based leak detection systems to which they relate. 6.2.4 Shared other party results NOTE The sharing of other party results is in principle applicable to all systems of assessment and evaluation of constancy of performance. A manufacturer may use the results of the product type determination obtained by someone else (e.g. by another manufacturer, as a common service to manufacturers, or by a product developer), to justify his own declaration of performance regarding a product that is manufactured according to the same design (e.g. dimensions) and with raw materials, constituents and manufacturing methods of the same kind, provided that: — the results are known to be valid for products with the same essential characteristics relevant for the product performance; — in addition to any information essential for confirming that the product has such same performances related to specific essential characteristics, the other party who has carried out the determination of the product type concerned or has had it carried out, has expressly accepted1 to transmit to the manufacturer the results and the test report to be used for the latter’s product type determination, as well as information regarding production facilities and the production control process that can be taken into account for FPC; — the manufacturer using other party results accepts to remain responsible for the product having the declared performances and he also: — ensures that the product has the same characteristics relevant for performance as the one that has been subjected to the determination of the product type, and that there are no significant differences with regard to production facilities and the production control process compared to that used for the product that was subjected to the determination of the product type; and

1 The formulation of such an agreement can be done by license, contract, or any other type of written consent. SIST EN 13160-4:2016

2 This can be, for instance, a contract, license or whatever kind of written agreement, which should also contain clear provisions with regard to responsibility and liability of the component producer (system house, on the one hand, and the assembler of the finished product, on the other hand. 3 These companies may produce components but they are not required to do so. SIST EN 13160-4:2016

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...