CEN/TS 16800:2020

(Main)Guideline for the validation of physico-chemical analytical methods

Guideline for the validation of physico-chemical analytical methods

This document describes an approach for the validation of physico-chemical analytical methods for environmental solid matrices and water.

The guidance in this document addresses the initial description of the method and two different validation approaches, in increasing order of complexity. These are:

a) method development, if the method is developed by the laboratory, or conditions of adoption, if the method is a standardized protocol adopted by the laboratory;

b) validation at the level of single laboratories (within-laboratory validation);

c) method validation at the level of several laboratories (between-laboratory or inter-laboratory validation), with a focus on methods that are sufficiently mature and robust to be applied not only by a few expert laboratories but by laboratories operating at the routine level.

The concept is strictly hierarchical, i.e. a method shall fulfil all criteria of within-laboratory validation before it can enter the validation protocol of the between-laboratory.

This document is applicable to the validation of a broad range of quantitative physico-chemical test methods for the analysis of water (including drinking water, surface water, groundwater, waste water, marine water), and of solid environmental matrices, such as soil, sludge, liquid and solid waste, sediment and biota. It is intended for standardized protocols adopted by a laboratory, and either for test methods aiming at substances that have recently become of interest or for test methods applying recently developed technologies.

The minimal requirements that are indispensable for the characterization of the fitness for the intended purpose of an analytical method are: selectivity, precision, trueness, performances characteristics and measurement uncertainty. The aim of validation is to prove that these requirements are met.

In this document after the definitions (Clause 3) and description of the principles (Clause 4) a toolbox is given describing the relevant performance characteristics in the validation process.

Clause 7 and 8 focus on the within laboratory validation process (V1) and Clause 9 on the interlaboratory validation process (V2). Clause 7 and 8 describe largely the same processes, but differ in approach for establishing the LOQ.

Reporting of the results of the validation studies is addressed in Clause 10.

Anleitung zur Validierung physikalisch-chemischer Analysenverfahren

Lignes directrices pour la validation des méthodes d’analyse physico-chimiques

Le présent document décrit une approche de validation des méthodes d’analyse physico-chimiques destinées aux matrices solides environnementales et à l’eau.

Les recommandations du présent document concernent la description initiale de la méthode et deux approches de validation différentes, par ordre croissant de complexité. Ces approches sont les suivantes :

a) développement de méthodes, si la méthode est développée par le laboratoire, ou conditions d’adoption, si la méthode est un protocole normalisé adopté par le laboratoire ;

b) validation de la méthode au niveau de laboratoires individuels (validation intralaboratoire) ;

c) validation des méthodes au niveau de plusieurs laboratoires (validation interlaboratoires), en se concentrant sur les méthodes suffisamment abouties et robustes pour être appliquées par quelques laboratoires experts, mais aussi par des laboratoires de routine.

Le concept est strictement hiérarchisé, c’est-à-dire qu’une méthode doit remplir tous les critères de validation intralaboratoire avant de pouvoir passer au protocole de validation interlaboratoires.

Le présent document est applicable à la validation d’un large éventail de méthodes d’essai physico chimiques quantitatives destinées à l’analyse de l’eau (y compris l’eau potable, les eaux de surface, les eaux souterraines, les eaux usées et l’eau de mer), ainsi qu’à des matrices environnementales solides, telles que du sol, de la boue, des déchets liquides et solides, des sédiments et le biote. Il s’adresse à des protocoles normalisés adoptés par un laboratoire et soit à des méthodes d’essai visant des substances qui ont suscité un intérêt récent, soit à des méthodes d’essai qui appliquent des technologies récemment mises au point.

Les exigences minimales indispensables à la caractérisation de l’adéquation à l’objectif prévu d’une méthode d’analyse sont la sélectivité, la fidélité, la justesse, les caractéristiques de performance et l’incertitude de mesure. La validation a pour objectif de prouver que ces exigences sont satisfaites.

Après les définitions (Article 3) et la description des principes (Article 4), le présent document fournit une boîte à outils décrivant les caractéristiques de performance pertinentes dans le processus de validation.

Les Articles 7 et 8 se concentrent sur le processus de validation intralaboratoire (V1) et l’Article 9 sur le processus de validation interlaboratoires (V2). Les Articles 7 et 8 décrivent en grande partie les mêmes processus, mais se distinguent par l’approche permettant d’établir la LOQ.

La consignation des résultats des études de validation est abordée dans l’Article 10.

Smernica za validacijo fizikalno-kemijskih analiznih metod

General Information

- Status

- Published

- Publication Date

- 22-Dec-2020

- Technical Committee

- CEN/TC 444 - Environmental characterization

- Drafting Committee

- CEN/TC 444/WG 6 - Cross cutting issues

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 16-May-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 07-Aug-2019

- Effective Date

- 09-Feb-2026

Overview

CEN/TS 16800:2020 - Guideline for the validation of physico-chemical analytical methods - provides a harmonized European approach for validating quantitative physico-chemical methods used in environmental analysis. Approved in 2020, the Technical Specification covers method development, within‑laboratory validation (V1) and inter‑laboratory validation (V2) for water and a wide range of environmental solid matrices (soil, sludge, waste, sediment, biota). The document emphasizes a strict hierarchical workflow: a method must meet within‑laboratory criteria before entering inter‑laboratory validation.

Key topics and requirements

- Scope and hierarchy: Describes method development/adoption, V1 (single-lab) and V2 (multi-lab) validation stages (Clauses 1, 7–9).

- Performance toolbox (Clause 5): Defines essential performance characteristics including:

- Selectivity

- Sensitivity

- Robustness

- Trueness

- Precision

- Limit values (LOD/LOQ and LOQ‑V)

- Calibration, application range, measurement uncertainty

- Limit of quantification (LOQ): Distinguishes statistical LOQ determination from experimental verification (LOQ‑V) using spiked matrices; stresses clarity when reporting which LOQ approach was used.

- Validation procedures:

- V1 focuses on intra‑laboratory performance (trueness, precision, LOD/LOQ, uncertainty).

- V2 specifies inter‑laboratory study design, participating labs, sample preparation, replicates and statistical evaluation.

- Reporting (Clause 10): Prescribes the content and structure of validation reports and modules for method definition, applicability, intra‑lab and inter‑lab results.

- Supplementary material: Informative and normative annexes include protocols (e.g., spiking of solid matrices), robustness testing approaches and documentation templates.

Applications and who should use it

CEN/TS 16800:2020 is intended for:

- Environmental and water testing laboratories validating new or adapted physico‑chemical analytical methods.

- Method developers and laboratory quality managers implementing method validation, LOQ verification, and measurement uncertainty estimation.

- Accreditation bodies and regulators seeking harmonized validation evidence for routine monitoring (drinking water, surface water, groundwater, waste water, marine water, soils, sediments, sludge, biota).

- Inter‑laboratory study organizers and standardization committees preparing methods for routine adoption.

Practical benefits include improved comparability of monitoring data across laboratories and borders, clearer LOQ declarations, and structured validation reporting for regulatory and accreditation purposes.

Related standards

CEN/TS 16800:2020 references general metrology and validation guidance (see Clause 2). Users typically apply it alongside laboratory quality standards and matrix‑specific EN/ISO methods when establishing fitness‑for‑purpose for analytical procedures.

Keywords: CEN/TS 16800:2020, method validation, physico‑chemical analytical methods, environmental matrices, water analysis, LOQ, inter‑laboratory validation, measurement uncertainty.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

CEN/TS 16800:2020 is a technical specification published by the European Committee for Standardization (CEN). Its full title is "Guideline for the validation of physico-chemical analytical methods". This standard covers: This document describes an approach for the validation of physico-chemical analytical methods for environmental solid matrices and water. The guidance in this document addresses the initial description of the method and two different validation approaches, in increasing order of complexity. These are: a) method development, if the method is developed by the laboratory, or conditions of adoption, if the method is a standardized protocol adopted by the laboratory; b) validation at the level of single laboratories (within-laboratory validation); c) method validation at the level of several laboratories (between-laboratory or inter-laboratory validation), with a focus on methods that are sufficiently mature and robust to be applied not only by a few expert laboratories but by laboratories operating at the routine level. The concept is strictly hierarchical, i.e. a method shall fulfil all criteria of within-laboratory validation before it can enter the validation protocol of the between-laboratory. This document is applicable to the validation of a broad range of quantitative physico-chemical test methods for the analysis of water (including drinking water, surface water, groundwater, waste water, marine water), and of solid environmental matrices, such as soil, sludge, liquid and solid waste, sediment and biota. It is intended for standardized protocols adopted by a laboratory, and either for test methods aiming at substances that have recently become of interest or for test methods applying recently developed technologies. The minimal requirements that are indispensable for the characterization of the fitness for the intended purpose of an analytical method are: selectivity, precision, trueness, performances characteristics and measurement uncertainty. The aim of validation is to prove that these requirements are met. In this document after the definitions (Clause 3) and description of the principles (Clause 4) a toolbox is given describing the relevant performance characteristics in the validation process. Clause 7 and 8 focus on the within laboratory validation process (V1) and Clause 9 on the interlaboratory validation process (V2). Clause 7 and 8 describe largely the same processes, but differ in approach for establishing the LOQ. Reporting of the results of the validation studies is addressed in Clause 10.

This document describes an approach for the validation of physico-chemical analytical methods for environmental solid matrices and water. The guidance in this document addresses the initial description of the method and two different validation approaches, in increasing order of complexity. These are: a) method development, if the method is developed by the laboratory, or conditions of adoption, if the method is a standardized protocol adopted by the laboratory; b) validation at the level of single laboratories (within-laboratory validation); c) method validation at the level of several laboratories (between-laboratory or inter-laboratory validation), with a focus on methods that are sufficiently mature and robust to be applied not only by a few expert laboratories but by laboratories operating at the routine level. The concept is strictly hierarchical, i.e. a method shall fulfil all criteria of within-laboratory validation before it can enter the validation protocol of the between-laboratory. This document is applicable to the validation of a broad range of quantitative physico-chemical test methods for the analysis of water (including drinking water, surface water, groundwater, waste water, marine water), and of solid environmental matrices, such as soil, sludge, liquid and solid waste, sediment and biota. It is intended for standardized protocols adopted by a laboratory, and either for test methods aiming at substances that have recently become of interest or for test methods applying recently developed technologies. The minimal requirements that are indispensable for the characterization of the fitness for the intended purpose of an analytical method are: selectivity, precision, trueness, performances characteristics and measurement uncertainty. The aim of validation is to prove that these requirements are met. In this document after the definitions (Clause 3) and description of the principles (Clause 4) a toolbox is given describing the relevant performance characteristics in the validation process. Clause 7 and 8 focus on the within laboratory validation process (V1) and Clause 9 on the interlaboratory validation process (V2). Clause 7 and 8 describe largely the same processes, but differ in approach for establishing the LOQ. Reporting of the results of the validation studies is addressed in Clause 10.

CEN/TS 16800:2020 is classified under the following ICS (International Classification for Standards) categories: 13.060.50 - Examination of water for chemical substances. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TS 16800:2020 has the following relationships with other standards: It is inter standard links to CEN/TS 16800:2015, ISO/IEC Guide 99:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TS 16800:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2021

Nadomešča:

SIST-TS CEN/TS 16800:2016

Smernica za validacijo fizikalno-kemijskih analiznih metod

Guideline for the validation of physico-chemical analytical methods

Anleitung zur Validierung physikalisch-chemischer Analysenverfahren

Lignes directrices pour la validation des méthodes d'analyse physico-chimiques

Ta slovenski standard je istoveten z: CEN/TS 16800:2020

ICS:

13.060.50 Preiskava vode na kemične Examination of water for

snovi chemical substances

13.080.10 Kemijske značilnosti tal Chemical characteristics of

soils

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TS 16800

TECHNICAL SPECIFICATION

SPÉCIFICATION TECHNIQUE

December 2020

TECHNISCHE SPEZIFIKATION

ICS 13.060.50 Supersedes CEN/TS 16800:2015

English Version

Guideline for the validation of physico-chemical analytical

methods

Lignes directrices pour la validation des méthodes Anleitung zur Validierung physikalisch-chemischer

d'analyse physico-chimiques Analysenverfahren

This Technical Specification (CEN/TS) was approved by CEN on 9 November 2020 for provisional application.

The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to

submit their comments, particularly on the question whether the CEN/TS can be converted into a European Standard.

CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS

available promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in

parallel to the CEN/TS) until the final decision about the possible conversion of the CEN/TS into an EN is reached.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TS 16800:2020 E

worldwide for CEN national Members.

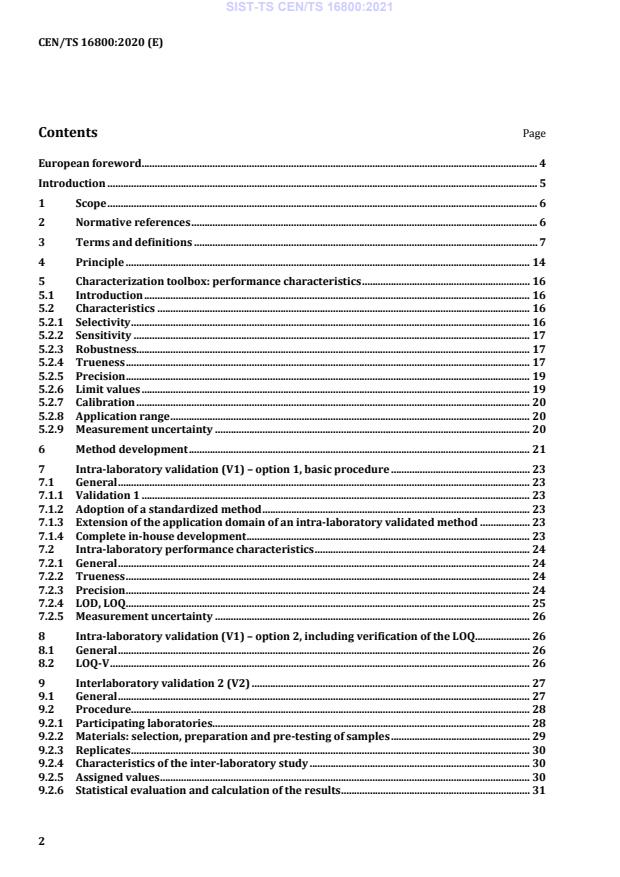

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Principle . 14

5 Characterization toolbox: performance characteristics . 16

5.1 Introduction . 16

5.2 Characteristics . 16

5.2.1 Selectivity . 16

5.2.2 Sensitivity . 17

5.2.3 Robustness. 17

5.2.4 Trueness . 17

5.2.5 Precision . 19

5.2.6 Limit values . 19

5.2.7 Calibration . 20

5.2.8 Application range . 20

5.2.9 Measurement uncertainty . 20

6 Method development . 21

7 Intra-laboratory validation (V1) – option 1, basic procedure . 23

7.1 General . 23

7.1.1 Validation 1 . 23

7.1.2 Adoption of a standardized method . 23

7.1.3 Extension of the application domain of an intra-laboratory validated method . 23

7.1.4 Complete in-house development . 23

7.2 Intra-laboratory performance characteristics . 24

7.2.1 General . 24

7.2.2 Trueness . 24

7.2.3 Precision . 24

7.2.4 LOD, LOQ . 25

7.2.5 Measurement uncertainty . 26

8 Intra-laboratory validation (V1) – option 2, including verification of the LOQ . 26

8.1 General . 26

8.2 LOQ-V . 26

9 Interlaboratory validation 2 (V2) . 27

9.1 General . 27

9.2 Procedure. 28

9.2.1 Participating laboratories. 28

9.2.2 Materials: selection, preparation and pre-testing of samples . 29

9.2.3 Replicates . 30

9.2.4 Characteristics of the inter-laboratory study . 30

9.2.5 Assigned values . 30

9.2.6 Statistical evaluation and calculation of the results . 31

10 Validation report . 32

10.1 General . 32

10.2 Module A: Test method definition, documentation and general requirements . 32

10.3 Module B: Applicability domain validation . 33

10.4 Module C: Intra-laboratory performance . 33

10.5 Inter-laboratory validation . 33

10.5.1 General . 33

10.5.2 Documentation, publication and standardization . 34

Annex A (normative) Intra-laboratory validation . 35

A.1 Module A: Test method definition, documentation and general requirements . 35

A.2 Module B: Application range and pre-validation . 38

Annex B (normative) Module C: Intra-laboratory performance . 40

Annex C (normative) Module D: Requirements on the study for inter-laboratory validation . 41

Annex D (informative) Structure and content of a validation study documentation (V2) . 44

Annex E (informative) Robustness testing by systematic variation of influencing factors . 49

E.1 Design of experiment [21], [22] . 49

E.2 Calculation. 50

Annex F (informative) Protocol for spiking of solid matrices . 51

Bibliography . 52

European foreword

This document (CEN/TS 16800:2020) has been prepared by Technical Committee CEN/TC 444

“Environmental characterization of solid matrices”, the secretariat of which is held by NEN.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes CEN/TS 16800:2015.

The main changes compared to the previous edition are listed below:

— the scope has been extended from water only to water and environmental solid matrices, thus the

document has been modified accordingly;

— a protocol for spiking of solid matrices has been added in an informative annex.

According to the CEN/CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to announce this Technical Specification: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

Environmental monitoring of chemical substances is increasingly carried out within a European

framework, and there is concern about the comparability of data at the European level. Methods used for

the monitoring of substances with recent interest have often not been properly validated either in-house

(i.e. within a single laboratory) or at the international level.

These issues may be addressed by adopting a harmonized approach towards method development and

validation. The main objective of this document is to provide a common European approach to the

validation of chemical methods for the respective monitoring of chemical substances in a broad range of

matrices. Although the development of this approach was triggered by the needs for monitoring of

emerging pollutants, it is of general nature and can be applied to the measurement of the concentration

of a wide range of substances in a variety of matrices.

This guidance considers the different requirements for the level of method maturity and validation at

different stages of the investigation or regulation of chemical substances.

This protocol will guide the user through the following steps:

— classification of existing methods with respect to their status towards validation, and the selection of

the appropriate validation approach;

— development of a method to extend its application; for example, if a method for determining a

required target compound in a selected matrix is available, but is not suitable for the same compound

in a different matrix of interest;

— the validation procedures to be undertaken to effectively demonstrate the validation status of a

selected method according to the approach adopted.

To agree on the use of one method, or several similar methods, in a trans-border or a multi-metrological

context, and allow comparison of the results reported by several data producers on the same location

(water quality measured on both bank of the same river, or soil composition measured on both sides of a

border, or continuity of quality assessment of waste after measurement provider, e.g.), the procedure of

establishing the LOQ of the measurement method must be clearly published.

The LOQ may result of:

— statistical evaluation of repeated measurements of a blank sample or a sample with a low

concentration of the compound of interest (LOQ);

— experimental verification with a spike matched matrix that the LOQ meets accuracy validation

criteria (LOQ-V).

Many (national and international) standards currently contain in their scope a statement like “this

method is applicable from a concentration level of xx µg/l or yy mg/kg dry matter”, without any

statement how this concentration level was established. When the limit of quantification is evaluated

(LOQ) or verified (LOQ-V) using the procedure of this guideline, there is a possibility that it does not meet

the lower limit of the claimed range.

Also, the LOQ and LOQ-V might be different depending on the analytical method. Therefore, if criteria are

set to the LOQ of a method, it is necessary to clarify if LOQ or LOQ-V is meant.

1 Scope

This document describes an approach for the validation of physico-chemical analytical methods for

environmental solid matrices and water.

The guidance in this document addresses the initial description of the method and two different

validation approaches, in increasing order of complexity. These are:

a) method development, if the method is developed by the laboratory, or conditions of adoption, if the

method is a standardized protocol adopted by the laboratory;

b) validation at the level of single laboratories (within-laboratory validation);

c) method validation at the level of several laboratories (between-laboratory or inter-laboratory

validation), with a focus on methods that are sufficiently mature and robust to be applied not only by

a few expert laboratories but by laboratories operating at the routine level.

The concept is strictly hierarchical, i.e. a method shall fulfil all criteria of within-laboratory validation

before it can enter the validation protocol of the between-laboratory.

This document is applicable to the validation of a broad range of quantitative physico-chemical test

methods for the analysis of water (including drinking water, surface water, groundwater, waste water,

marine water), and of solid environmental matrices, such as soil, sludge, liquid and solid waste, sediment

and biota. It is intended for standardized protocols adopted by a laboratory, and either for test methods

aiming at substances that have recently become of interest or for test methods applying recently

developed technologies.

The minimal requirements that are indispensable for the characterization of the fitness for the intended

purpose of an analytical method are: selectivity, precision, trueness, performances characteristics and

measurement uncertainty. The aim of validation is to prove that these requirements are met.

In this document after the definitions (Clause 3) and description of the principles (Clause 4) a toolbox is

given describing the relevant performance characteristics in the validation process.

Clause 7 and 8 focus on the within laboratory validation process (V1) and Clause 9 on the interlaboratory

validation process (V2). Clause 7 and 8 describe largely the same processes, but differ in approach for

establishing the LOQ.

Reporting of the results of the validation studies is addressed in Clause 10.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO/IEC Guide 99:2007, International vocabulary of metrology — Basic and general concepts and

associated terms (VIM)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO/IEC Guide 99:2007 (VIM) and

the following apply.

3.1

accepted reference value

value that serves as an agreed-upon reference for comparison, and which is derived as:

a) a theoretical or established value, based on scientific principles;

b) an assigned or certified value, based on experimental work of some national or international

organization;

c) a consensus or certified value, based on collaborative experimental work under the auspices of a

scientific or engineering group;

d) when a), b) and c) are not available, the expectation of the (measurable) quantity, i.e. the mean of a

specified population of measurements

[SOURCE: ISO 3534-2:2006, definition 3.2.7]

3.2

accuracy

closeness of agreement between a test result and the accepted reference value

Note 1 to entry: The term accuracy, when applied to a set of test results, involves a combination of random

components (usually expressed by a precision measure) and a common systematic error or bias component (usually

expressed by a measure for trueness).

Note 2 to entry: The technical term “accuracy” should not be confused with the term ‘trueness’ (see definition of

“trueness”).

[SOURCE: ISO 3534-2:2006, definition 3.3.1]

3.3

analyte

substance to be analysed (chemical species or physical parameter)

Note 1 to entry: The quantity of an analyte is the measurand (3.15).

3.4

bias

difference between the expectation of a test result or measurement result and a true value

Note 1 to entry: Bias is the total systematic error as contrasted to random error. There may be one or more

systematic error components contributing to the bias. A larger systematic difference from the accepted reference

value is reflected by a larger bias value.

Note 2 to entry: The bias of a measuring instrument is normally estimated by averaging the error of indication

over an appropriate number of repeated measurements. The error of indication is the: “indication of a measuring

instrument minus a true value of the corresponding input quantity”.

Note 3 to entry: In practice, accepted reference value is substituted for the true value.

[SOURCE: ISO 3534-2:2006, definition 3.3.2]

3.5

blank

sample or test scheme without the analyte known to produce the measured signal

Note 1 to entry: Use of various types of blanks enable assessment of which proportion of the measured signal is

attributable to the measurand and which proportion to other causes. Various types of blank are available (see

definition of Reagent Blank and Sample Blank).

3.6

calibration

operation that, under specified conditions, in a first step, establishes a relation between the quantity

values with measurement uncertainties provided by measurement standards and corresponding

indications with associated measurement uncertainties and, in a second step, uses this information to

establish a relation for obtaining a measurement result from an indication

Note 1 to entry: A calibration may be expressed by a statement, calibration function, calibration diagram,

calibration curve, or calibration table. In some cases, it may consist of an additive or multiplicative correction of the

indication with associated measurement uncertainty.

Note 2 to entry: Calibration should not be confused with adjustment of a measuring system, often mistakenly

called “self-calibration”, nor with verification of calibration.

[SOURCE: ISO/IEC Guide 99:2007, definition 2.39]

3.7

certified reference material

CRM

reference material, accompanied by documentation issued by an authoritative body and providing one

or more specified property values with associated uncertainties and traceabilities, using valid procedures

[SOURCE: ISO/IEC Guide 99:2007, definition 5.14]

3.8

fitness for purpose

degree to which data produced by a measurement process enables a user to make technically and

administratively correct decisions for a stated purpose

3.9

intermediate precision

precision under intermediate precision conditions

[SOURCE: ISO 3534-2:2006, definition 3.3.15]

3.10

intermediate precision conditions

conditions where test results or measurement results are obtained with the same method, on identical

test/measurement items in the same test or measurement facility, under some different operating

conditions

Note 1 to entry: There are four elements to the operating condition: time, calibration, operator and equipment.

[SOURCE: ISO 3534-2:2006, definition 3.3.16 and ISO 11352:2012, definition 3.10]

3.11

limit of detection

LOD

measured quantity value, obtained by a given measurement procedure, for which the probability of

falsely claiming the absence of a component in a material is β, given a probability α of falsely claiming its

presence

Note 1 to entry: IUPAC recommends default values for α and β equal to 0,05.

Note 2 to entry: The abbreviation LOD is sometimes used.

Note 3 to entry: The term “sensitivity” is discouraged for ‘detection limit’.

Note 4 to entry: The LOD is the lowest concentration of measurand in a sample that can be detected, but not

necessarily quantitated under the stated conditions of the test.

[SOURCE: ISO/IEC Guide 99:2007, definition 4.18]

3.12

limit of quantification

LOQ

lowest concentration of a measurand that can be determined with acceptable precision under the stated

conditions of the test

Note 1 to entry: as such defined, LOQ is based on evaluation of precision. This does not encompass neither any

eventual bias, nor laboratory measurement uncertainty at LOQ level.

3.13

Verified LOQ

LOQ-V

lowest concentration of a measurand that can be determined with acceptable accuracy under the stated

conditions of the test

Note 1 entry: LOQ-V is based on the check of a defined level of accuracy of the method at LOQ-V level. Bias and

precision have been considered to verify LOQ-V

3.14

reporting limit

RL

specific concentration at or above the limit of quantification that is reported to the client with a certain

degree of confidence

Note 1 to entry: The reporting limit is often defined on a project-specific basis. If the reporting limit is set below

the limit of quantification by the client, method modification is required

[SOURCE: ISO/TS 13530:2009, 4.4.7]

3.15

linearity

ability of the method to obtain test results proportional to the concentration of measurand

Note 1 to entry: The linear range is by inference the range of measurand concentrations over which the method

gives test results proportional to the concentration of the measurand.

[SOURCE: EURACHEM Guide]

3.16

measurand

quantity intended to be measured

Note 1 to entry: The specification of a measurand requires knowledge of the kind of quantity, description of the

state of the phenomenon, body, or substance carrying the quantity, including any relevant component, and the

chemical entities involved.

Note 2 to entry: In chemistry, “analyte”, or the name of a substance or compound, are terms sometimes used for

“measurand”. This usage is erroneous because these terms do not refer to quantities.

[SOURCE: ISO/IEC Guide 99:2007, definition 2.3]

3.17

measurement

process of experimentally obtaining one or more quantity values that can reasonably be attributed to a

quantity

[SOURCE: ISO/IEC Guide 99:2007, definition 2.1]

3.18

measurement uncertainty

non-negative parameter characterizing the dispersion of the quantity values being attributed to a

measurand, based on the information used

[SOURCE: ISO/IEC Guide 99:2007, definition 2.26]

3.19

outlier

member of a set of values which is inconsistent with the other members of that set

Note 1 to entry: ISO 5725-2 specifies the statistical tests and the significance level to be used to identify outliers

in trueness and precision experiments.

[SOURCE: ISO 5725-1:1994, definition 3.21]

3.20

precision

closeness of agreement between independent test results obtained under stipulated conditions

Note 1 to entry: Precision depends only on the distribution of random errors and does not relate to the true value

or the specified value.

Note 2 to entry: The measure of precision is usually expressed in terms of imprecision and computed as a

standard deviation of the test results. Less precision is reflected by a larger standard deviation.

Note 3 to entry: “Independent test results” means results obtained in a manner not influenced by any previous

result on the same or similar test object. Quantitative measures of precision depend critically on the stipulated

conditions. Repeatability and reproducibility conditions are particular sets of extreme conditions.

[SOURCE: ISO 3534-2:2006, definition 3.3.4]

3.21

proficiency testing

evaluation of participant performance against pre-established criteria by means of interlaboratory

comparisons

[SOURCE: EN ISO/IEC 17043:2010, definition 3.7]

3.22

quality assurance

part of quality management focused on providing confidence that quality requirements will be fulfilled

Note 1 to entry: A major part of quality assurance is quality control.

[SOURCE: EN ISO 9000:2015, definition 3.3.6]

3.23

quality control

part of quality management focused on fulfilling quality requirements

[SOURCE: EN ISO 9000:2015, definition 3.3.7]

3.24

quantity

property of a phenomenon, body, or substance, where the property has a magnitude that can be

expressed as a number and a reference

[SOURCE: ISO/IEC Guide 99:2007, definition 1.1]

3.25

working range

interval, being experimentally established and statistically proved by the calibration of the method,

between the lowest and highest quantity possibly measured by the method

Note 1 to entry: The lowest possible limit of a working range is the limit of quantification of an analytical method.

3.26

reagent blank

all reagents used during the analytical process (including solvents used for extraction or dissolution) are

analysed in isolation in order to check whether they contribute to the measurement signal

Note 1 to entry: The measurement signal arising from the measurand can then be corrected accordingly.

3.27

Analytical recovery

extent to which a known, added quantity of analyte (3.3) in a sample can be measured by an analytical

system

Note 1 to entry: Recovery is calculated from the difference between results obtained from a spiked and an

unspiked aliquot of sample and is usually expressed as a percentage.

[SOURCE: Adapted from ISO 5667-14:2014, definition 3.8]

3.28

reference material

RM

material, sufficiently homogeneous and stable with respect to one or more specified properties, which

has been established to be fit for its intended use in a measurement process

Note 1 to entry: RM is a generic term.

Note 2 to entry: Properties can be quantitative or qualitative, e.g. identity of substances or species.

Note 3 to entry: Uses may include the calibration of a measurement system, assessment of a measurement

procedure, assigning values to other materials, and quality control.

Note 4 to entry: ISO/IEC Guide 99:2007[1] has an analogous definition (5.13), but restricts the term

“measurement” to apply to quantitative values. However, Note 3 of ISO/IEC Guide 99:2007, 5.13 (VIM), specifically

includes qualitative properties, called “nominal properties”.

[SOURCE: ISO Guide 30:2015, definition 2.1]

3.29

repeatability

precision under repeatability conditions, i.e. conditions where independent test results are obtained with

the same method on identical test items in the same laboratory by the same operator using the same

equipment within short intervals of time

[SOURCE: ISO 3534-2:2006, combination of definition 3.3.5 and definition 3.3.6]

3.30

reproducibility

precision under reproducibility conditions, i.e. conditions where test results are obtained with the same

method on identical test items in different laboratories with different operators using different

equipment

[SOURCE: ISO 3534-2:2006, combination of definition 3.3.10 and definition 3.3.11]

3.31

residual

difference between the observed response and that predicted by a calibration function

3.32

robustness

measure of capacity of a procedure to remain unaffected by small, but deliberate variations in method

parameters and provides an indication of its reliability during normal usage

3.33

sample

totality of a homogeneous analysis material with an identical composition or quality (similar to term

batch)

[SOURCE: ISO/TS 20612:2007, definition 3.3]

3.34

blank sample

matrix with no measurand

Note 1 to entry: They are difficult to obtain but such materials are necessary to give a realistic estimate of

interferences that would be encountered in the analysis of test samples.

3.35

selectivity

ability of a method to determine accurately and specifically the measurand of interest in the presence of

other components in a sample matrix under the stated conditions of the test

3.36

sensitivity

change in the response of a measurand divided by the corresponding change in the stimulus

3.37

traceability

property of a measurement result whereby the result can be related to a reference through a documented

unbroken chain of calibrations, each contributing to the measurement uncertainty

[SOURCE: ISO/IEC Guide 99:2007, definition 2.41]

3.38

trueness

closeness of agreement between the average value obtained from a large series of test results and an

accepted reference value

Note 1 to entry: In the present document, trueness will be expressed in terms of bias.

Note 2 to entry: Trueness should not be confused with the term ‘accuracy’ (see definition of “accuracy”).

3.39

validation

verification, where the specified requirements are adequate for an intended use

Note 1 to entry: This process is used to asses that a method is fit for its intended purpose. It includes:

— establishing the performance characteristics, advantages and limitations of a method and the

identification of the influences which may change these characteristics, and the extent of such changes;

— a comprehensive evaluation of the outcome of this process with respect to the fitness for purpose of the

method.

[SOURCE: ISO/IEC Guide 99:2007, definition 2.45]

3.40

verification

provision of objective evidence that a given item fulfils specified requirements

EXAMPLE 1 Confirmation that a given reference material as claimed is homogeneous for the quantity value and

measurement procedure concerned, down to a measurement portion having a mass of 10 mg.

EXAMPLE 2 Confirmation that performance properties or legal requirements of a measuring system are

achieved.

EXAMPLE 3 Confirmation that a target measurement uncertainty can be met.

Note 1 to entry: When applicable, measurement uncertainty should be taken into consideration.

Note 2 to entry: The item may be, e.g. a process, measurement procedure, material, compound, or measuring

system.

Note 3 to entry: The specified requirements may be, e.g. that a manufacturer's specifications are met.”

[SOURCE: ISO/IEC Guide 99:2007, definition 2.44]

3.41

application range

range of concentrations routinely measured by a method

[SOURCE: ISO 6107-2:2006, 8]

4 Principle

The goal of any validation activity is to demonstrate the applicability of the method to the intended

purpose for which it is to be used. Any laboratory performing analytical measurement shall provide

reliable and comparable data when carried out on similar samples, whatever the modifications of the

operating conditions, e.g. operators. This fitness-for-purpose shall be demonstrated through

experimental, well documented evidences. This comprises a set of general principles and criteria that are

applicable to physico-chemical test methods.

The requirements for methods used for determination of chemical measurands depend on:

— the extent of the intended or requested measurement activity; and

— the potential of the available methods that may be used for monitoring a specific substance (group).

In some cases, fully developed methods usable by routine laboratories may already exist. In the case of

new substances or newly developed technics there will be a lack of information on the extent to which

the methods have been fully developed and validated, which is concretely a default of publicity of the

performance characteristics of the method, and/or the way used to establish these performances.

To cover most eventualities, two distinct (and hierarchical) levels of method validation, V1 (7, 8), resp.

V2 (9), are described in this document. The validation levels are organized as shown in Figure 1.

Performance characteristics relevant for the demonstration of the fitness-for-purpose of a method are,

among others, selectivity, sensitivity, robustness, application range, measurement uncertainty. They

constitute the toolbox of the validation process, where method characteristics and their quantification

protocols are selected for the demonstration.

Figure 1 — Flow chart of a method validation

5 Characterization toolbox: performance characteristics

5.1 Introduction

An analytical method is characterized by performance criteria, limitations where existing, and influences

that may change them. The usual performance characteristics are:

— Selectivity (3.35);

— Sensitivity (3.36);

— Robustness (3.32);

— Trueness (3.37), bias (3.4) and method recovery (3.27), if applicable;

— Precision (3.20);

— Limit values: detection limit (3.11), quantification limit (3.12), verified quantification limit (3.13) and

if necessary, reporting limit (3.14);

— Calibration (3.6);

— Application range (3.40);

— Measurement uncertainty (3.18).

These characteristics should be determined for all validation levels. The experimental design may vary

depending on the level. The suitability of the method documented according to Annex A is investigated

on the whole scope. When an extension of the scope of a validated test method is to be investigated,

validation shall entirely be carried out on the additional parts of the new scope.

The design of experiment at validation level V1 and at level V2 is the same. This design of experiment is

detailed in Table A.2.

5.2 Characteristics

5.2.1 Selectivity

Selectivity should be taken into consideration, albeit more in qualitative terms of the attention that has

been paid to possible interferences than in terms of quantification.

Selectivity is a performance characteristic that is difficult to quantify. It is necessary to establish that the

signal produced by the measurement system, or other measured property, is unambiguously attributed

to the measurand, and not produced by accident or coincidence or due to the presence of chemically or

physically similar compounds. The selectivity of a method can usually be investigated by studying its

ability to measure the substance of interest compared to selected interferences which have been

introduced in the sample (i.e. those interferences thought likely to be present in samples or which from

expert knowledge are known to be likely interferences for the method). Another indirect way is checking

the bias of a method (e.g. by analysing a CRM). However, often a CRM is not available for chemicals of

recent interest, and a possible interference should also be present in the CRM. If a bias consistent with

the fitness for purpose of the method cannot be demonstrated by analysis of CRMs that also contain

representative amounts of interfering compounds, then the method is considered as selective.

Analyses of spiked and non-spiked samples with and without interfering substances allow to distinguish

between matrix effects (change of sensitivity) and background interferences.

5.2.2 Sensitivity

Sensitivity (3.35) is related to the response of a measurand along with the change of its concentration in

the sample. Sensitivity should be established via the calibration function of the method.

5.2.3 Robustness

Robustness for routine use can be regarded as multiple:

a) robustness toward sample variation in one laboratory (matrix);

b) robustness towards small variations in environmental and/or operational conditions (3.32);

c) robustness toward variability in implementation by several different laboratories.

Robustness of the method toward sample variation shall be investigated during method development, in

any case before any collaborative trials. This approach helps also in saving costs by avoiding running

costly trials on insufficiently investigated methods.

For intra-laboratory validation, only a) and b) shall be considered.

The capacity of an analytical method to remain unaffected by small variations in environmental and/or

operational conditions provides an indication of its reliability during normal usage. This can be tested

using a systematic set of experiments that introduce small but deliberate changes to the experimental

conditions of the method, and by observing (either in a qualitative or quantitative way) how these

changes affect the final result by determining the relative standard deviations of e.g. the spike sample.

About the deliberate changes that are introduced, these can be different instrumental settings, reagents,

materials, amounts of sample material, exposure times, etc. Eventually, this approach should provide

information about the most critical conditions that affect the performance and reliability of the method.

To examine the effect of the variation in the environmental conditions on the results, a “factorial design”

approach could be applied as described in Annex F. The advantage of this approach is that information

can be provided on which environmental/operational conditions significantly affect the results.

For interlaboratory validation, robustness as in c) should be considered. Organization of such trials is

described in Annex C.

5.2.4 Trueness

5.2.4.1 Bias

The trueness of the method shall be evaluated to investigate the potential for bias in the method.

x

The method bias b can be estimated by comparing the mean of analytical results (with uncertainty

u x u

) with the assigned value (uncertainty )

x av av

b xx−

(1)

av

The standard uncertainty of the bias results from the combination of the above-mentioned uncertainties:

2 2

u uu+ (2)

b x av

With the coverage factor k = 2 (for about 95 % confidence) the expanded uncertainty is

Uu2×

(3)

bb

=

=

=

As long as the bias b is lower than its expanded uncertainty U the bias may be regarded as not significant.

b

5.2.4.2 Method recovery

To evaluate a method recovery, an accepted reference value (often referred to as “conventional true

value”) is essential. Ideally, the accepted reference value is established for a so-called certified reference

material (CRM). For pollutants with recent interest that are to be measured using methods validated at

the V1 level, the availability of CRMs is unlikely. In the absence of a suitable CRM, consensus mean, or

median values of ring test samples are often used as an estimate of accepted reference values. At the V1-

level, neither CRMs nor ring test results may be available.

As an alternative, spiking a sample with a known amount of measurand and analysing the sample before

and after spiking offers a means of determining recovery. The recovery shall be calculated on at least 2

levels, as described in e.g. ISO 11352:2012, 8.3.2 or 8.3.4.

NOTE 1 The spiking level can influence the bias of the method when using this approach. Lower spike

concentrations might give a larger relative bias.

A homogeneous bat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...