EN 14350:2020+A1:2023

(Main)Child care articles - Drinking equipment - Safety requirements and test methods

Child care articles - Drinking equipment - Safety requirements and test methods

This document specifies safety requirements relating to the materials, construction, performance, packaging and product information for drinking equipment intended for children of 0 to 48 months (see B.2) of age:

- Re-usable containers and re-usable drinking accessories;

- Single-use containers and drinking accessories sold with these containers;

- Single-use feeding teats;

- Ready to use feeding teats.

This document does not include requirements for the cleanliness of ready to use and single use products.

This document does not apply to products designed for specialist clinical medical applications, e.g. those relating to cleft lip palates.

This document does not apply to drinking equipment made from ceramics.

This document does not apply to bags intended for storage only.

This document does not apply to drinking equipment which is supplied with fluids or food when purchased and to feeding accessories fixed to it.

This document is not applicable to soothers. Safety requirements and test methods for soothers are specified in EN 1400 [6].

This document is not applicable for cutlery and other feeding utensils. Safety requirements and test methods for Cutlery and other feeding equipment are specified in EN 14372 [7].

For drinking equipment excluded from the scope, consider the applicable requirements of this document whenever possible.

Artikel für Säuglinge und Kleinkinder - Artikel für flüssige Kindernahrung - Sicherheitstechnische Anforderungen und Prüfverfahren

Dieses Dokument legt sicherheitstechnische Anforderungen an die Materialien, Konstruktion, Ausführung, und Verpackung sowie an die Produktinformationen für Artikel für flüssige Kindernahrung fest, die für Kinder im Alter von 0 Monaten bis 48 Monaten (siehe B.2) vorgesehen sind:

wiederverwendbare Behälter und wiederverwendbare Trinkhilfen;

Behälter für den einmaligen Gebrauch und mit diesen Behältern verkaufte Trinkhilfen;

Ernährungssauger für den einmaligen Gebrauch;

gebrauchsfertige Ernährungssauger.

Dieses Dokument enthält keine Anforderungen an die Sauberkeit von gebrauchsfertigen Produkten und von Produkten für den einmaligen Gebrauch.

Dieses Dokument gilt nicht für Produkte, die für klinisch medizinische Spezialanwendungen vorgesehen sind, z. B. solche für den Einsatz im Falle einer Lippenkiefergaumenspalte.

Dieses Dokument gilt nicht für Artikel aus Keramik, die für flüssige Kindernahrung vorgesehen sind.

Dieses Dokument gilt nicht für nur zu Aufbewahrungszwecken vorgesehene Beutel.

Dieses Dokument gilt nicht für Artikel für flüssige Kindernahrung, die bereits beim Verkauf Flüssigkeiten oder Flüssignahrung enthalten, und nicht für an ihnen angebrachte Trinkhilfen.

Dieses Dokument gilt nicht für Schnuller. Sicherheitstechnische Anforderungen an Schnuller und entsprechende Prüfverfahren sind in EN 1400 [6] festgelegt.

Dieses Dokument ist nicht auf Besteck und Geschirr anwendbar. Sicherheitstechnische Anforderungen an Besteck und sonstige Ausrüstungsteile zum Füttern sowie entsprechende Prüfverfahren sind in EN 14372 [7] festgelegt.

Für Artikel für flüssige Kindernahrung, die nicht in den Anwendungsbereich fallen, sind nach Möglichkeit die anwendbaren Anforderungen dieses Dokuments zu berücksichtigen.

Articles de puériculture - Articles pour l'alimentation liquide - Exigences en matière de sécurité et méthodes d'essai

Le présent document spécifie les exigences de sécurité relatives aux matériaux constitutifs, à la construction, à la performance, à l’emballage et aux informations relatives au produit des articles destinés aux enfants âgés de 0 à 48 mois (voir B.2) :

- récipients réutilisables et accessoires pour l’alimentation liquide réutilisables ;

- récipients à usage unique et accessoires pour l’alimentation liquide vendus avec ;

- tétines pour l’alimentation liquide à usage unique ;

- tétines pour l’alimentation liquide prêtes à l’emploi.

Le présent document n’inclut pas les exigences relatives à la propreté des produits prêts à l’emploi et à usage unique.

Le présent document n’est pas applicable aux produits destinés à des applications médicales cliniques spécialisées, tels que ceux destinés aux fentes labiales et palatines.

Le présent document ne s’applique pas aux articles pour l’alimentation liquide fabriqués en céramique.

Le présent document ne s’applique pas aux sachets destinés à la conservation uniquement.

Le présent document ne s’applique pas aux articles pour l’alimentation liquide contenant des liquides ou des denrées alimentaires au moment de l’achat, ni aux accessoires pour l’alimentation liquide qui y sont fixés.

Le présent document ne s’applique pas aux sucettes. Les exigences en matière de sécurité et les méthodes d’essai relatives aux sucettes sont spécifiées dans l’EN 1400 [6].

Le présent document ne s’applique pas aux couverts et à la vaisselle. Les exigences en matière de sécurité et les méthodes d’essai relatives aux couverts et autres articles de vaisselle sont spécifiées dans l’EN 14372 [7].

En ce qui concerne les articles pour l’alimentation liquide exclus du domaine d’application du présent document, tenir compte, dans la mesure du possible, des exigences applicables du présent document.

Izdelki za otroke - Pripomočki za pitje - Varnostne zahteve in preskusne metode (vključuje dopolnilo A1)

Ta dokument določa varnostne zahteve v zvezi z materiali, sestavo, lastnostmi, pakiranjem in informacijami o izdelku za pripomočke za pitje, namenjene otrokom, starim od 0 do 48 mesecev (glej točko B.2):

– posode za pijačo in pripomočki za pitje za večkratno uporabo;

– posode za pijačo za enkratno uporabo in pripomočki za pitje, ki se prodajajo skupaj z njimi;

– cuclje za hranjenje za enkratno uporabo;

– cuclje za hranjenje, ki so že pripravljeni za uporabo.

Ta dokument ne vključuje zahtev za čistost izdelkov, že pripravljenih za uporabo, in izdelkov za enkratno uporabo.

Ta dokument se ne uporablja za izdelke, namenjene za specialistično klinično medicinsko uporabo, npr. v zvezi s prirojenim razcepom ustnice ali neba.

Ta dokument se ne uporablja za pripomočke za pitje iz keramike.

Ta dokument se ne uporablja za vrečke, namenjene samo za shranjevanje.

Ta dokument se ne uporablja za pripomočke za pitje, ki so ob nakupu dobavljeni s tekočino ali hrano, in pripomočke za hranjenje, pritrjene nanje.

Ta dokument se ne uporablja za dude. Varnostne zahteve in preskusne metode za dude so določene v standardu EN 1400 [6].

Ta dokument se ne uporablja za jedilni pribor in drugo posodo za hranjenje. Varnostne zahteve in preskusne metode za jedilni pribor in drugo opremo za hranjenje so določene v standardu EN 14372 [7].

Pri uporabi pripomočkov za pitje, ki ne spadajo na to področje uporabe, je treba upoštevati veljavne zahteve v tem dokumentu, kadar je to mogoče.

General Information

- Status

- Published

- Publication Date

- 08-Aug-2023

- Technical Committee

- CEN/TC 252 - Child use and care articles

- Drafting Committee

- CEN/TC 252/WG 5 - Feeding, drinking, sucking and similar functions

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Dec-2025

- Completion Date

- 02-Dec-2025

- Directive

- Not Harmonized2001/95/EC - General product safety

Relations

- Merged From

EN 14350:2020 - Child care articles - Drinking equipment - Safety requirements and test methods - Effective Date

- 17-May-2023

- Refers

ISO 188:2011 - Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14350:2020+A1:2023 - Child care articles: Drinking equipment - Safety requirements and test methods - is the European standard that defines safety, construction, performance, packaging and product information requirements for drinking equipment intended for children aged 0–48 months. It covers re‑usable and single‑use containers, drinking accessories, and feeding teats (ready‑to‑use and single‑use). The standard sets out mechanical and chemical test methods, labelling and warning requirements, and annexes with rationale and test procedures. Exclusions include ceramic products, soothers (EN 1400), cutlery (EN 14372), specialist clinical devices and bags intended for storage only.

Key Topics and Requirements

- Scope and definitions: Clear classification of containers, drinking accessories and teats for infants and toddlers (0–48 months).

- Construction & mechanical tests: Requirements and tests for small parts, sealing discs, lids, push‑pull valves, handles/clips, protective covers, protruding parts and finger‑trap hazards; sample preparation, pre‑treatment (e.g., boiling) and conditioning procedures are specified.

- Test equipment & tolerances: Standardised apparatus such as small parts cylinders, indentors, probes and templates to ensure repeatable mechanical testing.

- Chemical safety: Requirements and test methods for migration of elements, volatile compounds in silicone, N‑nitrosamines, MBT (2‑mercaptobenzothiazole), antioxidants, formaldehyde and colour fastness - tailored to likely exposure routes (food contact, mouthing, ingestion).

- Packaging & product information: Consumer packaging, purchase information, instructions for use and mandatory warnings (annexed warnings and visibility/legibility guidance).

- Normative and informative annexes: Methods (e.g., MBT determination), rationales, A‑deviations and good practice for warnings and multilingual labeling.

Practical Applications

- Ensures product safety and regulatory compliance for baby bottles, sippy cups, teats and related drinking accessories.

- Provides test methods for product development, quality control and third‑party testing laboratories.

- Guides packaging, labelling and user instructions to reduce misuse and hazards.

- Supports importers, retailers and conformity assessment bodies when evaluating products for the European market.

Who Should Use This Standard

- Manufacturers and product designers of infant drinking equipment

- Testing and certification laboratories

- Regulatory authorities, distributors and retailers

- Quality and compliance teams managing chemical and mechanical safety for nursery products

Related Standards

- EN 1400 - Soothers (pacifiers)

- EN 14372 - Cutlery and other feeding utensils

- CEN/TC 252 - Technical committee responsible for child care articles

SIST EN 14350 is essential for anyone responsible for the safety, testing and market compliance of drinking equipment for infants and toddlers.

Frequently Asked Questions

EN 14350:2020+A1:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Child care articles - Drinking equipment - Safety requirements and test methods". This standard covers: This document specifies safety requirements relating to the materials, construction, performance, packaging and product information for drinking equipment intended for children of 0 to 48 months (see B.2) of age: - Re-usable containers and re-usable drinking accessories; - Single-use containers and drinking accessories sold with these containers; - Single-use feeding teats; - Ready to use feeding teats. This document does not include requirements for the cleanliness of ready to use and single use products. This document does not apply to products designed for specialist clinical medical applications, e.g. those relating to cleft lip palates. This document does not apply to drinking equipment made from ceramics. This document does not apply to bags intended for storage only. This document does not apply to drinking equipment which is supplied with fluids or food when purchased and to feeding accessories fixed to it. This document is not applicable to soothers. Safety requirements and test methods for soothers are specified in EN 1400 [6]. This document is not applicable for cutlery and other feeding utensils. Safety requirements and test methods for Cutlery and other feeding equipment are specified in EN 14372 [7]. For drinking equipment excluded from the scope, consider the applicable requirements of this document whenever possible.

This document specifies safety requirements relating to the materials, construction, performance, packaging and product information for drinking equipment intended for children of 0 to 48 months (see B.2) of age: - Re-usable containers and re-usable drinking accessories; - Single-use containers and drinking accessories sold with these containers; - Single-use feeding teats; - Ready to use feeding teats. This document does not include requirements for the cleanliness of ready to use and single use products. This document does not apply to products designed for specialist clinical medical applications, e.g. those relating to cleft lip palates. This document does not apply to drinking equipment made from ceramics. This document does not apply to bags intended for storage only. This document does not apply to drinking equipment which is supplied with fluids or food when purchased and to feeding accessories fixed to it. This document is not applicable to soothers. Safety requirements and test methods for soothers are specified in EN 1400 [6]. This document is not applicable for cutlery and other feeding utensils. Safety requirements and test methods for Cutlery and other feeding equipment are specified in EN 14372 [7]. For drinking equipment excluded from the scope, consider the applicable requirements of this document whenever possible.

EN 14350:2020+A1:2023 is classified under the following ICS (International Classification for Standards) categories: 97.190 - Equipment for children. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14350:2020+A1:2023 has the following relationships with other standards: It is inter standard links to EN 14350:2020, ISO 188:2011, EN 60454-2:2007, EN ISO 3696:1995, EN 12868:2017, EN 71-11:2005, EN 71-3:2019+A1:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14350:2020+A1:2023 is associated with the following European legislation: EU Directives/Regulations: 2001/95/EC; Standardization Mandates: M/264. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14350:2020+A1:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2024

Nadomešča:

SIST EN 14350:2020

Izdelki za otroke - Pripomočki za pitje - Varnostne zahteve in preskusne metode

(vključuje dopolnilo A1)

Child care articles - Drinking equipment - Safety requirements and test methods

Artikel für Säuglinge und Kleinkinder - Artikel für flüssige Kindernahrung -

Sicherheitstechnische Anforderungen und Prüfverfahren

Articles de puériculture - Articles pour l'alimentation liquide - Exigences en matière de

sécurité et méthodes d'essai

Ta slovenski standard je istoveten z: EN 14350:2020+A1:2023

ICS:

97.190 Otroška oprema Equipment for children

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14350:2020+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2023

EUROPÄISCHE NORM

ICS 97.190 Supersedes EN 14350:2020

English Version

Child care articles - Drinking equipment - Safety

requirements and test methods

Articles de puériculture - Articles pour l’alimentation Artikel für Säuglinge und Kleinkinder - Artikel für

liquide - Exigences en matière de sécurité et méthodes flüssige Kindernahrung - Sicherheitstechnische

d’essai Anforderungen und Prüfverfahren

This European Standard was approved by CEN on 14 March 2020 and includes Amendment approved by CEN on 3 May 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14350:2020+A1:2023 E

worldwide for CEN national Members.

EN 14350:2020+A1:2023 (E)

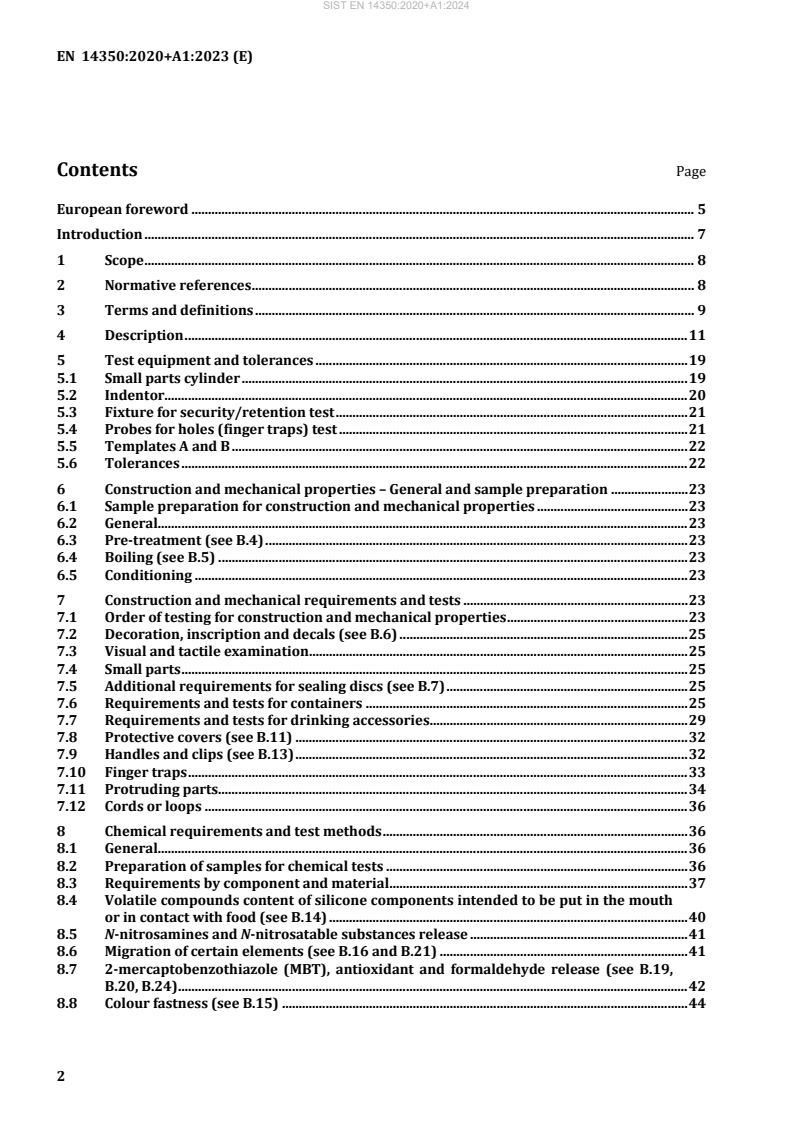

Contents Page

European foreword . 5

Introduction . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Description . 11

5 Test equipment and tolerances . 19

5.1 Small parts cylinder . 19

5.2 Indentor. 20

5.3 Fixture for security/retention test . 21

5.4 Probes for holes (finger traps) test . 21

5.5 Templates A and B . 22

5.6 Tolerances . 22

6 Construction and mechanical properties – General and sample preparation . 23

6.1 Sample preparation for construction and mechanical properties . 23

6.2 General. 23

6.3 Pre-treatment (see B.4) . 23

6.4 Boiling (see B.5) . 23

6.5 Conditioning . 23

7 Construction and mechanical requirements and tests . 23

7.1 Order of testing for construction and mechanical properties . 23

7.2 Decoration, inscription and decals (see B.6) . 25

7.3 Visual and tactile examination . 25

7.4 Small parts . 25

7.5 Additional requirements for sealing discs (see B.7) . 25

7.6 Requirements and tests for containers . 25

7.7 Requirements and tests for drinking accessories. 29

7.8 Protective covers (see B.11) . 32

7.9 Handles and clips (see B.13) . 32

7.10 Finger traps . 33

7.11 Protruding parts. 34

7.12 Cords or loops . 36

8 Chemical requirements and test methods . 36

8.1 General. 36

8.2 Preparation of samples for chemical tests . 36

8.3 Requirements by component and material . 37

8.4 Volatile compounds content of silicone components intended to be put in the mouth

or in contact with food (see B.14) . 40

8.5 N-nitrosamines and N-nitrosatable substances release . 41

8.6 Migration of certain elements (see B.16 and B.21) . 41

8.7 2-mercaptobenzothiazole (MBT), antioxidant and formaldehyde release (see B.19,

B.20, B.24). 42

8.8 Colour fastness (see B.15) . 44

EN 14350:2020+A1:2023 (E)

8.9 Migration of primary aromatic amines (see B.23) . 45

8.10 Migration of lead and cadmium from glass (see B.17) . 45

8.11 Migration of elements from metal (see B.18) . 45

9 Consumer packaging . 46

10 Product information . 46

10.1 General . 46

10.2 Purchase information . 46

10.3 Warnings . 47

10.4 Instructions for use . 48

10.5 Supply chain information for products that contain vulcanised rubber . 49

Annex A (normative) Warnings . 52

Annex B (informative) Rationales . 62

B.1 Introduction . 62

B.2 General . 62

B.3 Preparation of samples for construction and mechanical tests (see 6.1) . 62

B.4 Pre-treatment (see 6.3) . 63

B.5 Boiling (see 6.4) . 63

B.6 Decoration, inscription and decals (see 7.2) . 63

B.7 Additional requirements for sealing discs (see 7.5) . 63

B.8 Volumetric labelling and accuracy requirements (see 7.6.1. and 7.6.2) . 63

B.9 Tear resistance test (see 7.7.1) . 64

B.10 Print adhesion of markings and decorations (see 7.6.3) . 64

B.11 Protective covers (see 7.8) . 64

B.12 Push-pull valves (see 7.7.2) . 65

B.13 Handles and clips (see 7.9). 65

B.14 Volatile compounds content (see 8.4) . 65

B.15 Colourants (see 8.8) . 66

B.16 Migration of certain elements (see 8.6) . 66

B.17 Migration of lead and cadmium from glass (see 8.10) . 68

B.18 Migration of elements from metal (see 8.11) . 68

B.19 Antioxidant release (see 8.7) . 69

B.20 Formaldehyde release (see 8.7) . 71

B.21 Cr VI limit (see 8.6) . 71

B.22 Mercaptobenzothiazole (MBT) release (see 8.7) . 71

B.23 Migration of primary aromatic amines (see 8.9) . 71

B.24 Migration conditions for elastomeric materials . 72

EN 14350:2020+A1:2023 (E)

Annex C (informative) Method for the determination of 2-mercaptobenzothiazole (MBT)

and antioxidants specified in Table 7 . 73

C.1 Apparatus . 73

C.2 Procedure . 73

C.3 Column . 74

C.4 Detection . 74

C.5 Standards . 75

C.6 Preparation of standard solutions of MBT and antioxidants . 75

C.7 Retention times . 76

C.8 Calculation of MBT and antioxidants . 77

Annex D (informative) A-Deviations . 78

Annex E (informative) Good practice for visibility and legibility . 79

E.1 General. 79

E.2 Warnings . 79

E.3 Font . 79

E.4 Multi-languages . 79

Bibliography . 82

EN 14350:2020+A1:2023 (E)

European foreword

This document (EN 14350:2020+A1:2023) has been prepared by Technical Committee CEN/TC 252

“Child care articles”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2024, and conflicting national standards

shall be withdrawn at the latest by August 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 3 May 2023.

This document supersedes !EN 14350:2020".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !" .

The main changes compared to the previous edition are listed below:

— The standard has been completely renewed and a new structure was given. The former two parts

were joined together into one standard. A whole series of new aspects had to be considered,

following changes in the market and the regulatory background.

— Introduction: Completely reworded and references to European regulations were renewed.

— Clause 3: Completely restructured and partly described in more detail. Definitions for completely

new parts were added.

— Clause 4: Several completely new parts were added.

— Clause 5: This clause is completely new.

— Clause 6: This clause is completely new.

— Clause 7: The whole clause has been divided into several sub-paragraphs for individual

components of drinking equipment and the associated tests to improve the clarity of the sequence.

Several paragraphs for new items and their tests were added.

— Clause 8: This clause was completely restructured and subdivided. The requirements and test

conditions have been set with the consideration of the likely chemical exposure: food contact,

mouthing or ingestion. Chemical requirements and test methods were set for materials (like

rubber, silicon, TPE, metal, glass) and exposures (mouthing and swallowing) which are recently not

covered by harmonised legislations. Requirements for substances (e.g. Phthalates and BPA)

covered by harmonised regulation (like REACH, (EU) 10/2011 or its amendments) have not been

included.

— Clause 10: Revised and partly reworded.

— Clause 11: This clause on Test report is completely new.

— Annex A: This normative annex with translations of warnings into 24 languages is completely new.

EN 14350:2020+A1:2023 (E)

— Annex B: This informative annex with rationales is completely new.

— Annex C: This informative annex on Method for the determination of 2-mercaptobenzothiazole

(MBT) and antioxidants specified in Table 7 was revised and enlarged.

— Annex E: This informative annex on good practice for visibility and legibility is completely new.

!This document has been prepared under a standardization request addressed to CEN by the

European Commission. The Standing Committee of the EFTA States subsequently approves these

requests for its Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website."

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

EN 14350:2020+A1:2023 (E)

Introduction

This document harmonises minimum safety requirements and test methods for children’s drinking

equipment. Some of the provisions have been taken from other existing national and European

Standards and for these provisions the Technical Committee has relied on previous validation.

A significant choking hazard can arise if the component parts of drinking equipment become separated

during use. This hazard is addressed in this document by the inclusion of a security test. However, as

the fixing of such products to the container is user-dependent, the risk of an accident cannot be

completely eliminated. This document sets out labelling requirements stating that parents or carers

should not leave children unattended whilst being fed with a product containing a feeding teat or using

a container made of glass and that children should not be allowed to use feeding teats as a soother.

The Technical Committee considered the possibility of standardizing both sizes of feeding teats and

ranges of flow rates. However, it was decided that the many combinations of container systems

precluded being standardized. It is recommended that all container and drinking accessory

combinations are matched components. Providing meaningful flow rate information is difficult because

of several factors including hole diameter, teat thickness, hole shape/type of feed, and also how

individual infants suck the teat. Accordingly, it was decided not to include a test for flow rate but to

recommend that manufacturers provide information on flow rate and hole size that is appropriate to

their particular product.

This document sets chemical requirements and test methods for materials (like rubber, silicon, TPE etc)

and exposures (mouthing and swallowing) not covered by harmonised legislations. Where this

document sets migration limits for substances also covered by legislation, the requirements of this

document with stated test conditions must be regarded as additional.

Materials and chemical risks included in the standard (Table 3) do not present a definitive list but the

considered opinion of the Technical Committee based on current knowledge of likely risks.

All food contact materials and articles are regulated by Regulation (EC) No 1935/2004 [1], Regulation

(EC) No 2023/2006 [39] and relevant implementation measures, at European or national level.

All plastics components of drinking equipment intended to come into contact with food are specifically

regulated by the Regulation (EU) 10/2011 [2] on plastic materials and articles intended to come into

contact with food and its amendments.

Therefore, for example the Bisphenol A - requirement has not been included in this document. [40]

Phthalates in childcare articles are restricted by Annex XVII of the REACH Regulation [3] and have not

been included in this document.

Latex protein allergy risk has not been included in this document. There is no published information

that sensitization is caused by feeding teats and there is an extremely low incidence of latex protein

allergy among young children and babies. Nevertheless, provision for packaging information for feeding

teats made from natural rubber latex has been included in this document.

It is recommended that manufacturers and suppliers operate to EN ISO 9001 standard for quality

management systems [4]. It is also recommended that laboratories operate to EN ISO/IEC 17025,

General requirements for the competence of testing and calibration laboratories [5].

EN 14350:2020+A1:2023 (E)

1 Scope

This document specifies safety requirements relating to the materials, construction, performance,

packaging and product information for drinking equipment intended for children of 0 to 48 months (see

B.2) of age:

— Re-usable containers and re-usable drinking accessories;

— Single-use containers and drinking accessories sold with these containers;

— Single-use feeding teats;

— Ready to use feeding teats.

This document does not include requirements for the cleanliness of ready to use and single use

products.

This document does not apply to products designed for specialist clinical medical applications, e.g.

those relating to cleft lip palates.

This document does not apply to drinking equipment made from ceramics.

This document does not apply to bags intended for storage only.

This document does not apply to drinking equipment which is supplied with fluids or food when

purchased and to feeding accessories fixed to it.

This document is not applicable to soothers. Safety requirements and test methods for soothers are

specified in EN 1400 [6].

This document is not applicable for cutlery and other feeding utensils. Safety requirements and test

methods for Cutlery and other feeding equipment are specified in EN 14372 [7].

For drinking equipment excluded from the scope, consider the applicable requirements of this

document whenever possible.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

!EN 71-3:2019+A1:2021", Safety of toys — Part 3: Migration of certain elements

!EN 71-11:2005, Safety of toys — Part 11: Organic chemical compounds — Methods of analysis"

!EN 12868:2017", Child use and care articles — Method for determining the release of N-

nitrosamines and N-nitrosatable substances from elastomer or rubber teats and soothers

!EN 60454-2:2007", Pressure-sensitive adhesive tapes for electrical purposes — Part 2: Methods of

test (IEC 60454-2:2007)

!EN ISO 3696:1995, Water for analytical laboratory use — Specification and test methods (ISO

3696:1987)"

ISO 188:2011, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

EN 14350:2020+A1:2023 (E)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp/ui

3.1

matched components

components which are intended to be used together whilst feeding a child

Note 1 to entry: Their dimensions are matched to fit together and fulfil the relevant safety requirements.

Note 2 to entry: See definitions 3.2 to 3.9.

3.2

drinking accessory

device fitted to a container which permits a child to obtain fluid from it

3.2.1

feeding teat

elastic drinking accessory other than a straw

Note 1 to entry: there is no accepted scientific definition for the word “elastic”. The Technical Committee intended

to describe by "elastic"products made of silicone rubber, latex rubber, etc.

3.2.2

drinking spout

non-elastic drinking accessory other than a straw

3.2.3

push-pull valve

drinking accessory equipped with a valve designed to be manually operated by a push-pull, twist or

similar action

Note 1 to entry: A push-pull valve is also known as a “sports cup spout”.

3.2.4

straw

drinking accessory consisting of a cylindrical hollow tube which is in contact with the mouth and

through which fluid is sucked

3.2.5

protruding part

drinking accessory when assembled for its intended use on a container

3.3

container

feeding bottle, drinking cup or feeding bag

EN 14350:2020+A1:2023 (E)

3.3.1

feeding bottle

container which is capable of holding fluid incorporating a graduated scale suitable for visual

measurement and is intended for feeding a child through a suitable drinking accessory

3.3.2

drinking cup

container other than a feeding bottle or feeding bag capable of holding a fluid intended for feeding a

child

Note 1 to entry: Drinking cups are also known as “beakers” in the English language

3.3.3

feeding bag

bag capable of holding fluid and designed to be used with drinking accessories

Note 1 to entry: Feeding bags are also known as feeding liners.

3.3.4

feeding bag holder

support for a feeding bag

Note 1 to entry: see Figure 4 No 8.

3.4

locking ring

component used to secure a drinking accessory to a container

3.5

sealing disc

component used to create a seal between the container and the locking ring

3.6

protective cover

component to cover a drinking accessory

3.6.1

detachable protective cover

cover or parts of it intended to be detached when drinking or for cleaning

Note 1 to entry: After being detached they can be reassembled in the original state.

3.6.2

permanent protective cover

cover or parts of it intended to stay attached to the product during use/drinking

Note 1 to entry: It can only be detached by using a tool or force and is not intended to be reassembled afterwards.

3.7

handle

component designed to assist the handling of a container during drinking

EN 14350:2020+A1:2023 (E)

3.8

clip

component designed to assist the attachment of a container onto garments

3.9

cord or loop

flexible component designed to assist the handling of a container

3.10

graduations

markings which indicate the volume of fluid within the container, numbered or unnumbered

3.11

single-use product

product intended to be disposed of after first use

3.12

re-usable product

product intended to be used again after first use

3.13

ready to use product

product intended to be used without the need to clean before first use

3.14

outer packaging

any packaging used for storage of the product by a retailer, not including the packaging intended for the

consumer

4 Description

Figures 1 to 10 illustrate typical examples of different items of drinking equipment and their design

features.

Key

1 mouthpiece

2 feeding hole/holes

Figure 1 — Design features of a feeding teat

EN 14350:2020+A1:2023 (E)

Figure 2 — Examples of feeding teats

EN 14350:2020+A1:2023 (E)

Key

1 feeding spout including a locking ring

2 spout

3 straw

4 drinking accessory with mouthpiece in form of a spoon

Figure 3 — Examples of other drinking accessories

EN 14350:2020+A1:2023 (E)

Key

1 protective cover 5 feeding bottle

2 locking ring 6 feeding bag

3 feeding teat 7 graduations

4 sealing disc 8 feeding bag holder

Figure 4 — Examples of containers with feeding teats

EN 14350:2020+A1:2023 (E)

Key

1 drinking cup

2 drinking accessory

3 handle

Figure 5 — Example of container with drinking accessory

EN 14350:2020+A1:2023 (E)

a)

b)

Key

a closed position

b open position

Figure 6 — Example of a push-pull valve

EN 14350:2020+A1:2023 (E)

a)

b)

Key

a detachable protective cover in form of a cap

b permanent protective cover in form of a protective cap for straw

Figure 7 — Examples of protective covers

EN 14350:2020+A1:2023 (E)

Figure 8 — Examples of handles

Figure 9 — Example of a clip

EN 14350:2020+A1:2023 (E)

Figure 10 — Examples of loops

5 Test equipment and tolerances

5.1 Small parts cylinder

Dimensions in millimetres

Figure 11 — Small parts cylinder

EN 14350:2020+A1:2023 (E)

5.2 Indentor

The indentor is made from H13 high chrome tool steel or equivalent and hardened to a minimum of 50

Rockwell C and shall have dimensions as shown in Figure 12. All dimensions with a tolerance are

machined as ISO 1302 [8] to Ra 0,4 .The larger diameter of the indentor has not been specified, as it

hould be of a size to fit into the equipment for applying the necessary force specified in the test

methods.

Dimensions in millimetres

Key

Encircled is the tip of the indentor with the cutting blade.

a

This face is flat and has dimensions of (3,0 × 0,20) mm.

Figure 12 — Indentor

EN 14350:2020+A1:2023 (E)

5.3 Fixture for security/retention test

Key

A direction of tensile force

Figure 13 — Fixture for security/retention test

5.4 Probes for holes (finger traps) test

Key

1 tip radius equalling half the probe diameter

2 scribed line

0 +01,

diameter of probe 1: 5,5 mm, diameter of probe 2: 12 mm

−01,

Figure 14 — Probes for holes (finger traps) test method

EN 14350:2020+A1:2023 (E)

5.5 Templates A and B

Dimensions in millimetres

Figure 15 — Template A and B

5.6 Tolerances

Unless otherwise stated, the following tolerances apply:

— Forces: ± 5 % of the nominal force;

— Masses: ± 0,5 % of the nominal mass;

— Dimensions: ± 1,0 mm of the nominal dimension;

— Angles: ± 2° of the nominal angle;

— Duration of forces for durability tests: ± 1 s;

— Duration of forces for static load tests: ± 2 s.

Mechanical tests are often described in terms of the application of forces. Masses can however be used.

One kg mass may be used for 10 N force.

Unless otherwise specified, the test forces may be applied by any suitable device which does not affect

the results.

EN 14350:2020+A1:2023 (E)

6 Construction and mechanical properties – General and sample preparation

6.1 Sample preparation for construction and mechanical properties

Samples of single-use products shall be conditioned (6.5) before testing.

Samples of re-usable products shall be boiled (6.4) and conditioned (6.5) before testing.

Samples of any products containing vulcanized rubber shall be pre-treated (6.3) before being submitted

to the above sample preparation.

6.2 General

All samples shall be at least 3 days post-production (see B.3).

6.3 Pre-treatment (see B.4)

Parts made of vulcanised rubber (not silicone parts) taken directly from the manufacturer prior to

being shipped to a retailer, shall be artificially aged for (7 days) ± 2 h in an oven with forced air

circulation by means of a fan and a ventilation of three to ten changes per hour (as described as

Method B in ISO 188:2011) at a temperature of (70 ± 2) °C.

6.4 Boiling (see B.5)

All samples, excluding single-use products, shall be disassembled and immersed in boiling water, to the

requirements of !EN ISO 3696:1995", Grade 3, for (10 ± 1) min without touching the walls of the

container and removed. Afterwards allow the samples to cool to room temperature. Then after a

maximum of 2 h after boiling place in the conditioning room (see 6.5).

After boiling, there shall be no damage which causes the failure of any subsequent tests, or impairs the

assembly for the intended use and no graduation shall have been removed when assessed by visual

inspection.

6.5 Conditioning

All samples shall be conditioned for at least 40 h before the tests, at a temperature (23 ± 2) °C, and

relative humidity (50 ± 5) %. Samples shall remain in the conditioning atmosphere until the test is

carried out. The tests may be carried out in a non-conditioned room.

7 Construction and mechanical requirements and tests

7.1 Order of testing for construction and mechanical properties

The tests for construction and mechanical properties shall be carried out in the order given in Table 1,

after treatments according to Clause 6.

New samples, preferably from the same batch, shall be used for each test (i.e. samples used in one test

shall not be used in another test) unless otherwise stated.

When tensile tests are applied, clamps or other devices shall hold the components securely during the

test without causing damage which results in a test failure. Any failure due to such damage shall be

disregarded. If after a number of attempts using different methods secure holding is not possible due to

material weakness, the product fails.

NOTE If secure holding of the component causes problems, advice of the manufacturer should be considered.

EN 14350:2020+A1:2023 (E)

Table 1 — Order of testing for construction and mechanical properties

7.2 Decoration, inscription and decals

7.3 Visual and tactile examination

7.4 Small parts

7.5 Sealing discs

7.6 Containers

7.6.1 Volume labelling

7.6.2 Volumetric accuracy

7.6.3 Print adhesion of graduations (for re-

usable products)

7.6.4 Thermal shock (for re-usable products)

7.7 Drinking accessories

7.7.1 Resistance to tearing

7.7.2. Push-pull valves

7.8 Protective covers

7.8.1 Size of detachable protective cover

7.8.2 Size of permanent protective cover

7.8.3 Security of permanent protective cover

7.9 Handles and clips

7.10 Finger traps

7.11 Protruding parts

7.11.1 Maximum length of protruding parts

7.11.2 Flexibility of protruding parts

7.11.3 Security/retention test for protruding

parts

7.12 Cords and loops

EN 14350:2020+A1:2023 (E)

7.2 Decoration, inscription and decals (see B.6)

All areas of drinking equipment may be decorated or inscribed by techniques which do not apply

materials to their surface, e.g. by laser engraving. The manufacturer has to make sure that possible

contamination, e.g. from laser engraving combustion products, does not impair product safety.

Areas with intended food contact may only be printed or inmold labelled, if this printed or inmold

labelled area is completely covered by a functional barrier according to EU/10/2011 [2].

Areas of drinking accessories (3.2) that are intended or foreseeable to be mouthed shall not be printed,

also not when covered by a functional barrier including inmold labelling.

A drinking cup (3.3.2) which provides a drinking rim and is also intended to be used without a drinking

accessory (3.2) or a similar product where the child’s mouth can contact the outside of the cup shall not

be printed and / or inmold labelled on the area extending to 20 mm measured from the drinking rim.

Areas of drinking equipment that are not intended to contact food and/or to be mouthed may be

decorated or inscribed with techniques which apply colorant such as printing with printing inks.

Adhesive decals and labels intended to stay on the product during use are not allowed on any part of

drinking equipment. Decorations shall not be attached to any part of drinking equipment by glue.

7.3 Visual and tactile examination

All components of drinking equipment when assembled for use shall be free from any accessible sharp

points or edges and free of flash and burrs, which could cause injuries, and shall be assessed by visual

and tactile examination. In case of doubt apply test for sharp point and sharp edge according to

EN 71-1.

7.4 Small parts

All parts which are designed to be removed (e.g. for cleaning), or become separated after the tensile or

other mechanical tests shall not fit entirely within the small parts cylinder (see Figure 11) in any

orientation and without compression.

7.5 Additional requirements for sealing discs (see B.7)

The minimum diameter of a sealing disc shall be 35 mm.

7.6 Requirements and tests for containers

7.6.1 Volumetric labelling requirements (see B.8)

If containers are marked with graduations these shall include the nominated maximum capacity. The

volumes shall be given in millilitres and the letters “ml” or “mL” shall appear at least once. Additional

units for measurement can be used if applicable.

Drinking cups, feeding bags or holders for feeding bags may be marked with graduations. Feeding bags

with graduations shall not be used to prepare formula milk (see 10.3.3).

All feeding bottles shall be marked with graduations. The lowest numbered graduation shall not be

more than 60 ml and the highest graduation, numbered or unnumbered, shall be the nominal capacity

of the bottle. There shall be numbered or unnumbered graduations every 30ml starting from 60 ml. The

gap between numbered graduations shall not exceed 60 ml.

EN 14350:2020+A1:2023 (E)

7.6.2 Volumetric accuracy

7.6.2.1 Volumetric accuracy requirements (see B.8)

When tested in accordance with 7.6.2.2 the volumetric accuracy of all graduations, unnumbered and

numbered, on feeding bottles or if present on feeding cups shall be as follows:

— all graduations ≥ 100 ml: ± 5 %;

— all graduations < 100 ml: ± 5 ml.

For feeding bags and holders for feeding bags that have graduations their volumetric accuracy shall be

within ±15 % as measured according to 7.6.2.2 with the product set up by the method given in the

instructions for use.

7.6.2.2 Volumetric accuracy test procedure

Fill the container with distilled or preboiled water at (20 ± 5) °C to each of the numbered and

unnumbered graduations (where present).

Check the mass of the water using a balance, with an accuracy of ± 0,1 g.

Ensure that the base of the meniscus of the water is level with the middle of the graduation.

7.6.3 Print adhesion of graduations (see B.10)

7.6.3.1 Requirement

All containers with printed graduations intended for repeated use shall be tested. After being tested in

accordance to 7.6.3.3 all graduations required under 7.6.1, numbered and unnumbered, shall be

readable (see Figure 17).

7.6.3.2 Equipment

7.6.3.2.1 Adhesive tape

Adhesive tape with an adhesion strength of (10 ± 1) N per 25mm width when tested in accordance with

!EN 60454-2:2007".

7.6.3.2.2 Eraser

A non-abrasive eraser shall be used.

7.6.3.3 Test procedure

Carry out the test on the whole area of the container where the graduations are printed. Containers

which do not have numbered graduati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...