EN 751-3:2022

(Main)Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hot water - Part 3: Unsintered PTFE tapes and PTFE strings

Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hot water - Part 3: Unsintered PTFE tapes and PTFE strings

This document specifies requirements and test methods for unsintered polytetrafluorethylene (PTFE) tapes and polytetrafluorethylene (PTFE) strings (PTFE tapes or PTFE strings, for short) which are suitable for sealing threaded metallic joints as specified in EN 10226-1:2004.

This document covers two classes of PTFE tapes and PTFE strings suitable for fine (F) and coarse (G) threads.

The PTFE tapes and PTFE strings are used as sealing materials for metallic threaded joints in contact with 1st family gases (town gas), 2nd family gases (natural gas) and 3rd family gases (liquefied petroleum gases (LPG)) up to 500 kPa, up to 700 kPa for hot water of heating systems, and up to 20 kPa in gas appliances and their auxiliary equipment. The maximum working pressure covered in this document is 2000 kPa which is relevant to LPG storage. The temperature range is limited to −20 °C to 125 °C.

Dichtmittel für metallene Gewindeverbindungen in Kontakt mit Gasen der 1., 2. und 3. Familie und Heißwasser - Teil 3: Ungesinterte PTFE-Bänder und -Fäden

Dieses Dokument legt Anforderungen und Prüfverfahren für ungesinterte Polytetrafluorethylen-(PTFE)-Bänder und Polytetrafluorethylen-(PTFE)-Fäden (im weiteren als PTFE-Bänder oder PTFE-Fäden bezeichnet) fest, die geeignet sind metallene Gewindeverbindungen abzudichten, wie sie in EN 10226-1:2004 festgelegt sind.

Dieses Dokument behandelt zwei Klassen von PTFE-Bändern und PTFE-Fäden, die für feine (F) und grobe (G) Gewinde geeignet sind.

Die PTFE-Bänder und PTFE-Fäden werden als Dichtmittel für metallene Gewindeverbindungen verwendet, die für den Einsatz in Installationen bis zu einem Druck von 500 kPa bei Gasen der 1. Familie (Stadtgas), der 2. Familie (Erdgas) und der 3. Familie (Flüssiggas) und bis zu einem Druck von 700 kPa bei Heißwasser von Heizungsanlagen vorgesehen sind, außerdem für den Einsatz in Gasgeräten und deren Zusatzeinrichtungen bis zu einem Druck von 20 kPa. Der maximale durch dieses Dokument abgedeckte Betriebsdruck von 2000 kPa betrifft die Flüssiggaslagerung. Der Temperaturbereich ist begrenzt auf-20 °C bis 125 °C.

Matériaux d'étanchéité pour raccords filetés en contact des gaz de la 1ère, 2ème et 3ème famille et de l'eau chaude - Partie 3 : Bandes et cordons en PTFE non fritté

Le présent document prescrit les exigences et les méthodes d'essai auxquelles les bandes en polytétrafluoroéthylène (PTFE) et cordons en polytétrafluoroéthylène (PTFE) non frittés (appelées dans le reste du document bandes PTFE ou cordons PTFE) doivent satisfaire pour étanchéiser les raccords filetés métalliques conformes à l'EN 10226-1 :2004.

Le présent document couvre les deux classes de bandes et cordons en PTFE adaptées aux filetages à pas fins (F) et aux filetages à pas gros (G).

Les bandes et cordons en PTFE sont utilisés sur les installations de gaz de la 1ère famille (gaz de ville), de la 2ème famille (gaz naturel) et de la 3ème famille (gaz de pétrole liquéfiés (GPL)) jusqu'à 500 kPa et jusqu'à 700 kPa pour l'eau chaude des systèmes de chauffage, et jusqu'à 20 kPa pour les appareils à gaz et leur équipement auxiliaire. La pression maximale de fonctionnement couverte par le présent document est de 2000 kPa pour ce qui concerne le stockage du GPL. La plage de température est comprise entre −20 °C & 125 °C.

Tesnilni materiali za kovinske navojne zveze v stiku s plini 1., 2. in 3. družine ter vročo vodo - 3. del: Nesintrani PTFE trakovi in vrvice

Ta dokument določa zahteve in preskusne metode za nesintrane trakove in vrvice iz politetrafluoroetilena (na kratko: PTFE trakovi oz. vrvice), ki so primerni za tesnjenje kovinskih navojnih zvez, kot je določeno v standardu EN 10226-1:2004. Ta dokument zajema dva razreda PTFE trakov in vrvic, primerna za drobne (F) in grobe (G) navoje. PTFE trakovi in vrvice se uporabljajo kot tesnilni materiali za kovinske navojne zveze, ki so v stiku s plini iz 1. in 2. skupine (mestni plin), plini iz 2. skupine (zemeljski plin) ter plini iz 3. skupine (utekočinjeni naftni plin (LPG)) do največ 500 kPa, do 700 kPa za vročo vodo ogrevalnih sistemov ter do 20 kPa v plinskih napravah in njihovi dodatni opremi. Največji delovni tlak, obravnavan v tem dokumentu, je 2000 kPa, kar je relevantno za hranjenje utekočinjenega naftnega plina (LPG). Temperaturno območje je omejeno na −20 °C do 125 °C.

General Information

- Status

- Withdrawn

- Publication Date

- 07-Jun-2022

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 208 - Elastomeric seals for joints in pipework and pipelines

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Dec-2023

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 15-Jun-2022

- Effective Date

- 25-May-2022

- Effective Date

- 18-Oct-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 751-3:2022 is a standard published by the European Committee for Standardization (CEN). Its full title is "Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hot water - Part 3: Unsintered PTFE tapes and PTFE strings". This standard covers: This document specifies requirements and test methods for unsintered polytetrafluorethylene (PTFE) tapes and polytetrafluorethylene (PTFE) strings (PTFE tapes or PTFE strings, for short) which are suitable for sealing threaded metallic joints as specified in EN 10226-1:2004. This document covers two classes of PTFE tapes and PTFE strings suitable for fine (F) and coarse (G) threads. The PTFE tapes and PTFE strings are used as sealing materials for metallic threaded joints in contact with 1st family gases (town gas), 2nd family gases (natural gas) and 3rd family gases (liquefied petroleum gases (LPG)) up to 500 kPa, up to 700 kPa for hot water of heating systems, and up to 20 kPa in gas appliances and their auxiliary equipment. The maximum working pressure covered in this document is 2000 kPa which is relevant to LPG storage. The temperature range is limited to −20 °C to 125 °C.

This document specifies requirements and test methods for unsintered polytetrafluorethylene (PTFE) tapes and polytetrafluorethylene (PTFE) strings (PTFE tapes or PTFE strings, for short) which are suitable for sealing threaded metallic joints as specified in EN 10226-1:2004. This document covers two classes of PTFE tapes and PTFE strings suitable for fine (F) and coarse (G) threads. The PTFE tapes and PTFE strings are used as sealing materials for metallic threaded joints in contact with 1st family gases (town gas), 2nd family gases (natural gas) and 3rd family gases (liquefied petroleum gases (LPG)) up to 500 kPa, up to 700 kPa for hot water of heating systems, and up to 20 kPa in gas appliances and their auxiliary equipment. The maximum working pressure covered in this document is 2000 kPa which is relevant to LPG storage. The temperature range is limited to −20 °C to 125 °C.

EN 751-3:2022 is classified under the following ICS (International Classification for Standards) categories: 23.040.80 - Seals for pipe and hose assemblies. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 751-3:2022 has the following relationships with other standards: It is inter standard links to EN 751-3:1996, EN 751-3:1996/AC:1997, EN 751-3:2022+A1:2023, EN ISO 11358-1:2014, EN 10226-3:2005, EN 10242:1994/A1:1999, EN 10242:1994/A2:2003, EN 12164:2016, EN ISO 11357-3:2018, EN 10242:1994, EN 10255:2004+A1:2007, EN 10226-1:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 751-3:2022 is associated with the following European legislation: EU Directives/Regulations: 2016/426, 305/2011; Standardization Mandates: M/131, M/BC/CEN/89/6. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 751-3:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2022

Nadomešča:

SIST EN 751-3:1997

SIST EN 751-3:1997/AC:1999

Tesnilni materiali za kovinske navojne zveze v stiku s plini 1., 2. in 3. družine ter

vročo vodo - 3. del: Nesintrani PTFE trakovi in vrvice

Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family

gases and hot water - Part 3: Unsintered PTFE tapes and PTFE strings

Dichtmittel für metallene Gewindeverbindungen in Kontakt mit Gasen der 1., 2. und 3.

Familie und Heißwasser - Teil 3: Ungesinterte PTFE-Bänder und -Fäden

Matériaux d'étanchéité pour raccords filetés en contact des gaz du 1ère, 2ème et 3ème

groupe et de l'eau chaude - Partie 3 : Bandes et cordons en PTFE non fritté

Ta slovenski standard je istoveten z: EN 751-3:2022

ICS:

23.040.80 Tesnila za cevne zveze Seals for pipe and hose

assemblies

83.140.50 Tesnila Seals

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 751-3

EUROPEAN STANDARD

NORME EUROPÉENNE

June 2022

EUROPÄISCHE NORM

ICS 23.040.80 Supersedes EN 751-3:1996

English Version

Sealing materials for metallic threaded joints in contact

with 1st, 2nd and 3rd family gases and hot water - Part 3:

Unsintered PTFE tapes and PTFE strings

Matériaux d'étanchéité pour raccords filetés en contact Dichtmittel für metallene Gewindeverbindungen in

des gaz de la 1ère, 2ème et 3ème famille et de l'eau Kontakt mit Gasen der 1., 2. und 3. Familie und

chaude - Partie 3 : Bandes et cordons en PTFE non Heißwasser - Teil 3: Ungesinterte PTFE-Bänder und -

fritté Fäden

This European Standard was approved by CEN on 27 April 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 751-3:2022 E

worldwide for CEN national Members.

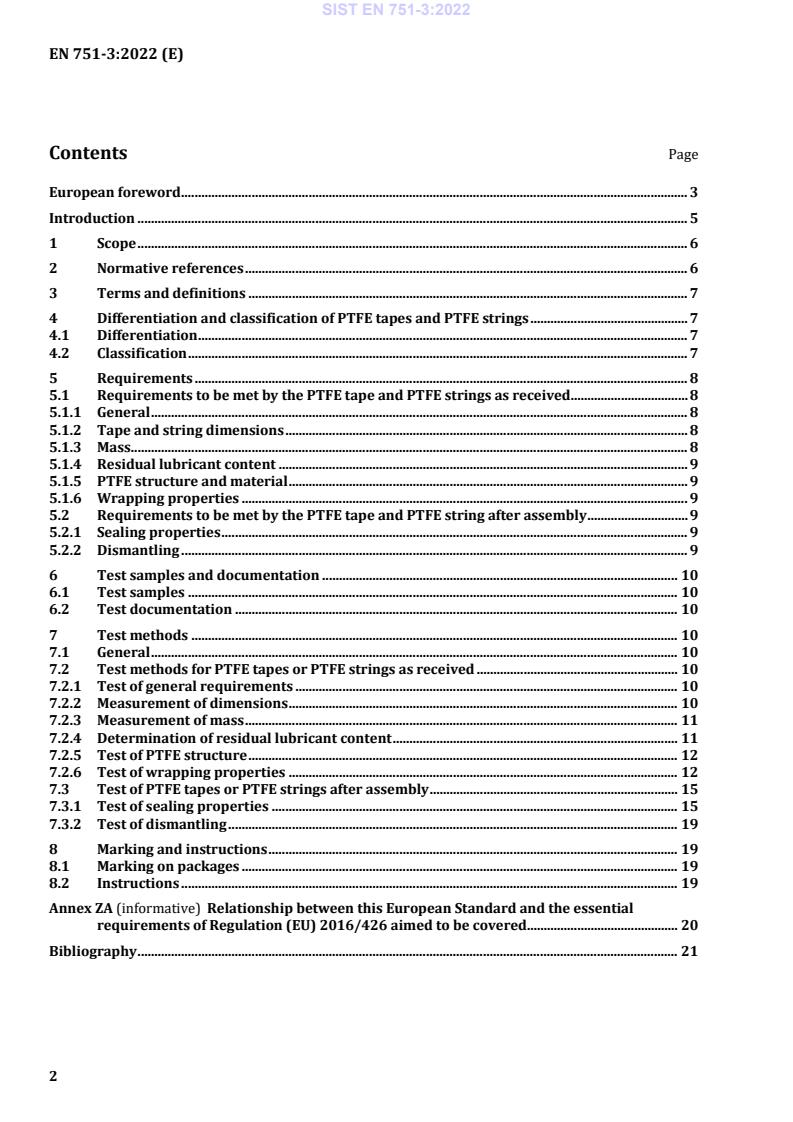

Contents Page

European foreword . 3

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Differentiation and classification of PTFE tapes and PTFE strings . 7

4.1 Differentiation . 7

4.2 Classification . 7

5 Requirements . 8

5.1 Requirements to be met by the PTFE tape and PTFE strings as received . 8

5.1.1 General . 8

5.1.2 Tape and string dimensions . 8

5.1.3 Mass . 8

5.1.4 Residual lubricant content . 9

5.1.5 PTFE structure and material . 9

5.1.6 Wrapping properties . 9

5.2 Requirements to be met by the PTFE tape and PTFE string after assembly . 9

5.2.1 Sealing properties . 9

5.2.2 Dismantling . 9

6 Test samples and documentation . 10

6.1 Test samples . 10

6.2 Test documentation . 10

7 Test methods . 10

7.1 General . 10

7.2 Test methods for PTFE tapes or PTFE strings as received . 10

7.2.1 Test of general requirements . 10

7.2.2 Measurement of dimensions . 10

7.2.3 Measurement of mass . 11

7.2.4 Determination of residual lubricant content . 11

7.2.5 Test of PTFE structure . 12

7.2.6 Test of wrapping properties . 12

7.3 Test of PTFE tapes or PTFE strings after assembly . 15

7.3.1 Test of sealing properties . 15

7.3.2 Test of dismantling . 19

8 Marking and instructions . 19

8.1 Marking on packages . 19

8.2 Instructions . 19

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Regulation (EU) 2016/426 aimed to be covered . 20

Bibliography . 21

European foreword

This document (EN 751-3:2022) has been prepared by Technical Committee CEN/TC 208 “Elastomeric

seals for joints in pipework and pipelines”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by December 2022, and conflicting national standards shall

be withdrawn at the latest by December 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 751-3:1996.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

The following main technical changes have been made compared to EN 751-3:1996:

a) normative references have been updated;

b) definitions have been added;

c) requirements and tests for strings have been added;

d) differentiation between PTFE tapes and PTFE strings has been added;

e) restriction of use of APFO and PFOA has been added;

f) requirements and testing of mass per area and mass per length have been specified and added;

g) requirements and testing for the PTFE structure and material have been added;

h) wrapping properties have been specified;

i) possibility of adjustment has been deleted;

j) for the determination of residual lubricant content, a thermogravimetric method has been added;

k) for the determination of residual lubricant content, the quantities and associated vessel volumes

were reduced in the analytical method;

l) for the determination of structure and material, DSC method has been added;

m) testing of wrapping properties has been added and specified;

n) requirements for the test samples and their assembly have been added and specified;

o) evaluation of failed samples after assembly has been added;

p) temperature cycling test has been revised and specified;

q) vibration test has been deleted;

r) marking has been clarified;

s) Annex ZA has been added.

The EN 751 series comprises the listed parts:

— Part 1: Anaerobic jointing compounds;

— Part 2: Non-hardening jointing compounds;

— Part 3: Unsintered PTFE tapes and strings.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document specifies requirements and test methods for tapes and strings produced from virgin

unsintered polytetrafluorethylene (PTFE) for use with metallic threaded joints. It specifies two classes of

PTFE tapes and PTFE strings – mainly differing in thickness and mass per area – for fine (F) and coarse

(G) threads.

A universally applicable PTFE tape or PTFE string may be used for all gas, potable water and hot water

installation.

In respect of potential adverse effects of the jointing compounds covered by this document on the quality

of water intended for human consumption this document provides no information as to whether the

jointing compounds may be used without restriction in any of the Member States of the EU or EFTA. The

use and characteristics of the jointing compounds should comply with current regulations, where they

exist, depending the acceptance of verifiable European criteria.

Compared to previous standard EN 751-3:1996, this document does not include an assessment of the

turning back properties. It has been determined in practice and during periodic tests that these

properties can only be reproduced to a limited extent. Turning back during installation should be avoided.

Should a connection made with PTFE tapes or threads nevertheless (have to) be turned back during

installation, this is the responsibility of the user. It is common sense that installations are checked for

tightness after completion.

Although PTFE natural colour is white and most common for PTFE tapes and PTFE strings, other colours

may be used as well.

Test practice since the standard was published has shown that the vibration test has not provided any

additional information about the tightness of the threaded connections. Therefore, the test was removed

from the test schedule of the standard.

1 Scope

This document specifies requirements and test methods for unsintered polytetrafluorethylene (PTFE)

tapes and polytetrafluorethylene (PTFE) strings (PTFE tapes or PTFE strings, for short) which are

suitable for sealing threaded metallic joints as specified in EN 10226-1:2004.

This document covers two classes of PTFE tapes and PTFE strings suitable for fine (F) and coarse (G)

threads.

The PTFE tapes and PTFE strings are used as sealing materials for metallic threaded joints in contact with

st nd rd

1 family gases (town gas), 2 family gases (natural gas) and 3 family gases (liquefied petroleum gases

(LPG)) up to 500 kPa, up to 700 kPa for hot water of heating systems, and up to 20 kPa in gas appliances

and their auxiliary equipment. The maximum working pressure covered in this document is 2000 kPa

which is relevant to LPG storage. The temperature range is limited to −20 °C to 125 °C.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 10242:1994, Threaded pipe fittings in malleable cast iron

EN 10255:2004+A1:2007, Non-alloy steel tubes suitable for welding and threading — Technical delivery

conditions

EN 12164:2016, Copper and copper alloys — Rod for free machining purposes

EN 10226-1:2004, Pipe threads where pressure tight joints are made on the threads — Part 1: Taper

external threads and parallel internal threads — Dimensions, tolerances and designation

EN 10226-3:2005, Pipes threads where pressure tight joints are made on the threads — Part 3: Verification

by means of limit gauges

EN ISO 11357-3:2018, Plastics — Differential scanning calorimetry (DSC) — Part 3: Determination of

temperature and enthalpy of melting and crystallization (ISO 11357-3:2018)

EN ISO 11358-1:2014, Plastics — Thermogravimetry (TG) of polymers — Part 1: General principles

(ISO 11358-1:2014)

This document is currently impacted by the stand-alone amendments EN 10242:1994/A1:1999 and

EN 10242:1994/A2:2003.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

PTFE tape

thread sealing tape manufactured from virgin unsintered polytetraflourethylene (PTFE) without fillers

or additives

3.2

PTFE string

thread sealing string manufactured from virgin unsintered polytetraflourethylene (PTFE) without fillers

or additives

Note 1 to entry: PTFE strings are also known as “PTFE cords”.

3.3

gas family

group of gaseous fuels with similar burning behaviour linked together by a range of Wobbe indices

Note 1 to entry: For further information on types of gases see EN 437:2021.

3.4

batch

any quantity of PTFE-tapes or PTFE strings manufactured in a single mix at one time

4 Differentiation and classification of PTFE tapes and PTFE strings

4.1 Differentiation

Tapes and strings differ in their geometry, weight per unit area and application. Both have a rectangular

geometry, whereby the tapes are thin and wide, while the strings are thick and narrow. Therefore, tapes

have to be wrapped overlapping, while strings are wrapped crosswise with a larger number of windings.

In addition, the strings have a greater weight per unit area.

NOTE 1 Typical tape dimensions; 12 mm × 0,10 mm.

NOTE 2 String dimensions; e.g. 2 mm × 0,5 mm, other cross sections are possible.

4.2 Classification

There are two classes of PTFE tapes and PTFE strings suitable only for fine (F) and for fine and coarse (G)

threads in accordance with Table 1.

Table 1 — Classification of PTFE tapes and PTFE strings

Class Thread Nominal size

a

F EN 10226-1:2004 taper/parallel DN ≤ 10

G EN 10226-1:2004 taper/parallel DN ≤ 50

a

Class F tapes and strings may also be used for other dimensions when the number of turns of the thread is

-1

≥ 7,5 cm .

5 Requirements

5.1 Requirements to be met by the PTFE tape and PTFE strings as received

5.1.1 General

PTFE shall be produced without using APFO (ammonium perfluorooctanoate) and PFOA

(perfluorooctanoic acid).

The PTFE tape and PTFE string shall be free from inclusions or imperfections visible to the naked eye and

shall be free from any surface or edge defects, when tested in accordance with 7.2.1.

5.1.2 Tape and string dimensions

5.1.2.1 Length

The actual length of the PTFE tape and PTFE string, when tested in accordance with 7.2.2.1, shall not be

less than that marked on the spool/ dispenser.

5.1.2.2 Width

The actual width of the PTFE tape, when tested in accordance with 7.2.2.2, shall not differ from that

marked on the spool by more than ±0,5 mm.

The actual width of the PTFE string, when tested in accordance with 7.2.2.2, shall not differ from that

marked on the dispenser by more than ±10 %.

5.1.2.3 Thickness

The thickness of the PTFE tape and PTFE string, when tested in accordance with 7.2.2.3, shall not differ

from the stated value by more than ±10 %.

5.1.3 Mass

5.1.3.1 Mass per area for PTFE tapes

The mass per area of the PTFE tape, when tested in accordance with 7.2.3.1, shall be greater than 90 %

of the value declared by the manufacturer, but not less than:

— 60 g/m for class F;

— 100 g/m for class G.

5.1.3.2 Mass per length for PTFE strings

The mass per length of the PTFE string, when tested in accordance with 7.2.3.2, shall be greater than 90 %

of the value declared by the manufacturer, but not less than 0,3 g/m for both classes.

5.1.4 Residual lubricant content

The residual lubricant content of the PTFE tape and PTFE string, when tested in accordance with 7.2.4.1

or 7.2.4.2, shall not exceed 0,1 % by mass.

5.1.5 PTFE structure and material

Using DSC (differential scanning calorimetry) method. The conditions during manufacture shall be such

that the tape or string remains in the unsintered state, during the test in accordance with 7.2.5 a shift or

change in the peak temperature of the initial melting peak shall be given. The enthalpy for the first heating

shall be significantly higher than for the second one. The following peak temperatures shall be met:

— (345 ± 5) °C during heating up from ambient temperature to (380 ± 5) °C;

— (312 ± 5) °C during cooling down from (380 ± 5) °C to (50 ± 5) °C;

— (327 ± 5) °C during heating up from (50 ± 5) °C to (380 ± 5) °C.

NOTE Experience shows that these requirements only can be met by use of virgin materials.

PTFE tapes or PTFE strings shall be manufactured from virgin consistent PTFE that does not contain any

filler (exception of colour) and is free of APFO and/or PFOA.

5.1.6 Wrapping properties

When wrapped around the specified thread in accordance with 7.2.6.1 or 7.2.6.2, the PTFE tape shall

conform to and hold the thread form. The finishing end of the PTFE tape shall remain in position with no

tendency to unwind. During wrapping the PTFE tape shall not break, tear, or split.

When wrapped around the specified thread in accordance with 7.2.6.3 or 7.2.6.4, the PTFE string shall

conform to and hold the thread form. The finishing end of the PTFE string shall remain in position with

no tendency to unwind. During wr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...