ASTM C506-15

(Specification)Standard Specification for Reinforced Concrete Arch Culvert, Storm Drain, and Sewer Pipe

Standard Specification for Reinforced Concrete Arch Culvert, Storm Drain, and Sewer Pipe

ABSTRACT

This specification covers reinforced arch-shaped concrete pipe to be used for the conveyance of sewage, industrial wastes, storm water, and for the construction of culverts. Pipe manufactured according to this specification shall be of three classes identified as Class A-II, A-III, and A-IV. The reinforced concrete shall consist of cementitious materials, mineral aggregates, and water, in which steel has been embedded in such a manner that the steel and concrete act together. The pipe shall be designed to meet both the 0.01 in. crack and ultimate strength requirements determined by conducting plant load bearing tests, material tests, and inspection of manufactured pipe for visual defects and imperfections. The reinforcement, joint, and manufacture are detailed.

SCOPE

1.1 This specification covers reinforced arch-shaped concrete pipe to be used for the conveyance of sewage, industrial wastes, storm water, and for the construction of culverts.

1.2 This specification is the inch-pound companion to C506M; therefore, no SI equivalents are presented in the specification.

Note 1: This specification is a manufacturing and purchase specification only, and does not include requirements for bedding, backfill, or the relationship between field load condition and the strength classification of pipe. However, experience has shown that the successful performance of this product depends upon the proper selection of the class of pipe, type of bedding and backfill, and care that the installation conforms to the construction specifications. The owner of the reinforced concrete pipe specified herein is cautioned that he must correlate the field requirements with the class of pipe specified and provide inspection at the construction site.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C506 −15

StandardSpecification for

Reinforced Concrete Arch Culvert, Storm Drain, and Sewer

Pipe

This standard is issued under the fixed designation C506; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope C309 Specification for Liquid Membrane-Forming Com-

pounds for Curing Concrete

1.1 This specification covers reinforced arch-shaped con-

C494/C494M Specification for Chemical Admixtures for

crete pipe to be used for the conveyance of sewage, industrial

Concrete

wastes, storm water, and for the construction of culverts.

C497 Test Methods for Concrete Pipe, Manhole Sections, or

1.2 This specification is the inch-pound companion to

Tile

C506M; therefore, no SI equivalents are presented in the

C595 Specification for Blended Hydraulic Cements

specification.

C618 Specification for Coal Fly Ash and Raw or Calcined

Natural Pozzolan for Use in Concrete

NOTE 1—This specification is a manufacturing and purchase specifica-

tion only, and does not include requirements for bedding, backfill, or the C822 Terminology Relating to Concrete Pipe and Related

relationship between field load condition and the strength classification of

Products

pipe. However, experience has shown that the successful performance of

C989 Specification for Slag Cement for Use in Concrete and

this product depends upon the proper selection of the class of pipe, type

Mortars

of bedding and backfill, and care that the installation conforms to the

C1017/C1017M Specification for Chemical Admixtures for

construction specifications. The owner of the reinforced concrete pipe

specified herein is cautioned that he must correlate the field requirements

Use in Producing Flowing Concrete

with the class of pipe specified and provide inspection at the construction

C1116 Specification for Fiber-Reinforced Concrete and

site.

Shotcrete

C1602/C1602M Specification for Mixing Water Used in the

2. Referenced Documents

Production of Hydraulic Cement Concrete

2.1 ASTM Standards:

A36/A36M Specification for Carbon Structural Steel

3. Terminology

A615/A615M SpecificationforDeformedandPlainCarbon-

3.1 Definitions—For definitions of terms relating to con-

Steel Bars for Concrete Reinforcement

crete pipe, see Terminology C822.

A706/A706M Specification for Deformed and Plain Low-

Alloy Steel Bars for Concrete Reinforcement

4. Classification

A1064/A1064M Specification for Carbon-Steel Wire and

4.1 Pipe manufactured according to this specification shall

Welded Wire Reinforcement, Plain and Deformed, for

beofthreeclassesidentifiedasClassA-II,A-III,andA-IV.The

Concrete

strength requirements are prescribed in Table 1.

C33 Specification for Concrete Aggregates

C150 Specification for Portland Cement

5. Basis of Acceptance

C260 Specification for Air-Entraining Admixtures for Con-

5.1 Unlessotherwisedesignatedbytheowneratthetimeof,

crete

or before placing an order, there are two separate and alterna-

tive bases of acceptance. Independent of the method of

This specification is under the jurisdiction of ASTM Committee C13 on

acceptance, the pipe shall be designed to meet both the 0.01-in.

Concrete Pipe and is the direct responsibility of Subcommittee C13.02 on

crack and ultimate strength requirements.

Reinforced Sewer and Culvert Pipe.

5.1.1 Acceptance on Basis of Plant Load Bearing Tests,

Current edition approved Jan. 1, 2015. Published January 2015. Originally

Material Tests, and Inspection of Manufactured Pipe for Visual

approved in 1963. Last previous edition approved in 2014 as C506 – 14. DOI:

10.1520/C0506-15.

Defects and Imperfections—Acceptability of the pipe in all

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

diameters and classes produced in accordance with 7.1 or 7.2,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

shall be determined by the results of the three-edge-bearing

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tests as defined in 11.3.1; by such material tests as are required

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C506−15

A

TABLE 1 Strength Requirements for Reinforced Concrete Pipe

C

Double Line Reinforcement

B

f'c, MPA

Continuous Basic

D

Additional Reinforcement = A Single Line

Approx- D s

Reinforcement = A

Mini- Mini- s

Reinforcement

imate

T, mum mum

“U” “V”

Equivalent

Class Inner Cage Outer Cage

in. Rise, Span,

(Inner Cage) (Outer Cage)

Round

in. in.

Size, in. Dimen- Dimen-

A-II A-III A-IV A-II A-III A-IV A-II A-III A-IV sion, A-II A-III A-IV sion, A-II A-III A-IV A-II A-III A-IV

in. in.

15 2 ⁄4 11 18 4 4 4 . . . . . . . . . . . . . . 0.08 0.12 0.17

1 1

18 2 ⁄2 13 ⁄2 22 4 4 4 . . . . . . . . . . . . . . 0.11 0.14 0.26

3 1

21 2 ⁄8 15 ⁄2 26 4 4 4 . . . . . . . . . . . . . . 0.12 0.17 0.29

24 3 18 28 ⁄2 4 4 4 . . . . . . . . . . . . . . 0.16 0.21 0.32

1 1 1

30 3 ⁄2 22 ⁄2 36 ⁄4 4 4 4 0.09 0.12 0.18 0.07 0.09 0.14 26 0.09 0.12 0.18 29 0.07 0.09 0.12 0.18 0.24 0.36

5 3

36 4 26 ⁄8 43 ⁄8 4 4 4 0.11 0.15 0.21 0.09 0.12 0.17 30 0.11 0.15 0.21 34 0.09 0.12 0.16 0.21 0.30 0.44

1 5 1

42 4 ⁄2 31 ⁄16 51 ⁄8 4 4 4 0.12 0.18 0.27 0.10 0.14 0.21 34 0.12 0.18 0.27 39 0.10 0.14 0.21 0.26 0.36 0.54

48 5 36 58 ⁄2 4 4 . 0.15 0.21 . 0.12 0.17 . 42 0.15 0.21 . 43 0.12 0.17 . 0.30 0.44 .

54 5 ⁄2 40 65 4 4 . 0.18 0.24 . 0.14 0.19 . 48 0.18 0.24 . 49 0.14 0.19 . 0.36 0.48 .

60 6 45 73 4 4 . 0.21 0.27 . 0.17 0.21 . 52 0.21 0.27 . 55 0.17 0.21 . 0.42 0.56 .

72 7 54 88 4 5 . 0.26 0.36 . 0.20 0.27 . 60 0.26 0.36 . 67 0.20 0.27 . 0.52 0.72 .

84 8 62 102 4 5 . 0.32 0.44 . 0.24 0.34 . 68 0.32 0.44 . 77 0.24 0.34 . 0.64 0.88 .

90 8 ⁄2 72 115 . . . . . . . . . . . . . . . . . . . .

96 9 77 ⁄2 122 . . . . . . . . . . . . . . . . . . . .

108 10 87 ⁄8 138 . . . . . . . . . . . . . . . . . . . .

120 11 96 ⁄8 154 . . . . . . . . . . . . . . . . . . . .

1 3

132 10 106 ⁄2 168 ⁄4 . . . . . . . . . . . . . . . . . . . .

D-Loads for 3-Edge-Bearing Method

Class 0.01-in. Ultimate

Crack

II 1000 1500

III 1350 2000

IV 2000 3000

Note—Test load in pounds per linear foot

equals D-load × inside span in feet.

A

For modified or special designs, see 7.3.

B

f'c, ksi = minimum compressive strength of concrete in thousands of pounds-force per square inch.

C

As an alternative to designs requiring double line reinforcement, the reinforcement may be positioned and proportioned so that the total reinforcement of the inner cage

plus the middle cage shall not be less than that specified for the inner cage continuous basic reinforcement, and the additional reinforcement “U” and the total reinforcement

of the outer cage plus the middle cage shall not be less than that specified for the outer cage continuous basic reinforcement and the additional reinforcement “V.”

D

A = circumferential steel area in square inches per longitudinal foot of pipe barrel in each continuous basic cage and additional cages in area denoted “U” and “V.”

s

Dimensions “U” and “V” are measured on the center line of the culvert wall.

in accordance with 6.2, 6.3, 6.5, and 6.6, by an absorption test 5.2 Age for Acceptance—Pipe shall be considered ready for

of the concrete from the wall of the pipe as required in 11.9; acceptancewhentheyconformtotherequirementsasindicated

and by visual inspection of the finished pipe to determine its by the specified tests.

conformance with the accepted design and its freedom from

defects.

6. Materials

5.1.2 Acceptance on Basis of Material Tests and Inspection

6.1 The aggregate shall be so sized, graded, proportioned,

of Manufactured Pipe for Defects and Imperfections—

and mixed with such proportions of portland cement, blended

Acceptability of the pipe in all diameters and classes produced

hydraulic cement, or portland cement and supplementary

in accordance with 7.1 or 7.2 shall be determined by the results

cementing materials, or admixtures, or a combination thereof,

of such material tests as are required in 6.2, 6.3, 6.5, and 6.6;

if used, and water to produce a homogeneous concrete mixture

bycrushingtestsonconcretecoresorcuredconcretecylinders;

of such quality that the pipe will conform to the test and design

by an absorption test of the concrete from the wall of the pipe

requirements of this specification. In no case, however, shall

for each mix design that is used on an order; and by inspection

the proportion of portland cement, blended hydraulic cement,

of the finished pipe, including amount and placement of

or a combination of portland cement and supplementary

reinforcement, to determine its conformance with the accepted

cementing materials be less than 470 lb/yd .

design and its freedom from defects.

6.2 Cementitious Materials:

5.1.3 Whenagreeduponbytheownerandthemanufacturer,

any portion or any combination of the tests itemized in 5.1.1 or 6.2.1 Cement—Cementshallconformtotherequirementsof

5.1.2 may form the basis of acceptance. Specification C150, or shall be portland blast-furnace slag

C506−15

cement, or slag modified portland cement, or portland- 6.4.1 Air-entraining admixture conforming to Specification

pozzolan cement conforming to the requirements of Specifica- C260;

tion C595, except that the pozzolan constituent in the Type IP

6.4.2 Chemical admixture conforming to Specification

portland-pozzolan cement shall be fly ash.

C494/C494M;

6.2.2 Ground Granulated Blast-Furnace Slag (GGBFS)—

6.4.3 Chemical admixture for use in producing flowing

GGBFS shall conform to the requirements of Grade 100 or 120

concrete conforming to Specification C1017/C1017M; and

of Specification C989.

6.4.4 Chemical admixture or blend approved by the owner.

6.2.3 Fly Ash—Fly ash shall conform to the requirements of

6.5 Steel Reinforcement—Reinforcement shall conform to

Class F or Class C of Specification C618.

the requirements of Specification A1064/A1064M, or bars

6.2.4 Allowable Combinations of Cementitious Materials—

conforming to Specification A36/A36M, Specification A615/

Thecombinationofcementitiousmaterialsusedintheconcrete

A615M Grade 40 or 60, or Specification A706/A706M Grade

shall be one of the following:

60. For helically wound cages only, weld shear tests are not

6.2.4.1 Portland cement only,

required.

6.2.4.2 Portland blast furnace slag cement only,

6.2.4.3 Portland pozzolan cement only,

6.6 Synthetic Fibers—Collated fibrillated virgin polypropyl-

6.2.4.4 A combination of portland cement and ground

ene fibers may be used, at the manufacturer’s option, in

granulated blast-furnace slag,

concrete pipe as a nonstructural manufacturing material. Only

6.2.4.5 A combination of portland cement and fly ash,

Type III synthetic fibers designed and manufactured specifi-

6.2.4.6 A combination of portland cement, ground granu-

cally for use in concrete and conforming to the requirements of

lated blast-furnace slag, and fly ash, or

Specification C1116 shall be accepted.

6.2.4.7 A combination of portland pozzolan cement and fly

ash.

7. Design

6.3 Aggregates—Aggregates shall conform to Specification

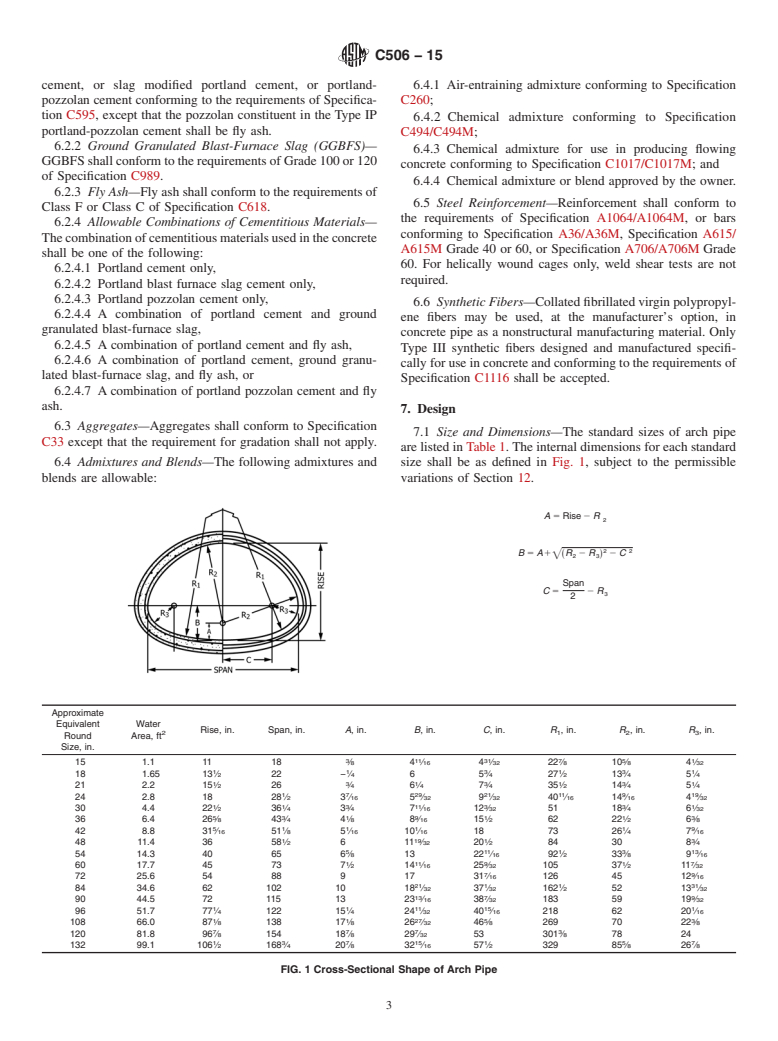

7.1 Size and Dimensions—The standard sizes of arch pipe

C33 except that the requirement for gradation shall not apply.

are listed in Table 1. The internal dimensions for each standard

6.4 Admixtures and Blends—The following admixtures and size shall be as defined in Fig. 1, subject to the permissible

blends are allowable: variations of Section 12.

A5 Rise2 R

2 2

B5 A1 sR 2 R d 2 C

œ 2 3

Span

C5 2 R

Approximate

Equivalent Water

Rise, in. Span, in. A,in. B,in. C,in. R ,in. R ,in. R ,in.

2 1 2 3

Round Area, ft

Size, in.

3 11 31 7 5 1

15 1.1 11 18 ⁄8 4 ⁄16 4 ⁄32 22 ⁄8 10 ⁄8 4 ⁄32

1 1 3 1 3 1

18 1.65 13 ⁄2 22 − ⁄4 65 ⁄4 27 ⁄2 13 ⁄4 5 ⁄4

1 3 1 3 1 3 1

21 2.2 15 ⁄2 26 ⁄4 6 ⁄4 7 ⁄4 35 ⁄2 14 ⁄4 5 ⁄4

1 7 29 21 11 9 19

24 2.8 18 28 ⁄2 3 ⁄16 5 ⁄32 9 ⁄32 40 ⁄16 14 ⁄16 4 ⁄32

1 1 3 11 3 3 1

30 4.4 22 ⁄2 36 ⁄4 3 ⁄4 7 ⁄16 12 ⁄32 51 18 ⁄4 6 ⁄32

5 3 1 9 1 1 3

36 6.4 26 ⁄8 43 ⁄4 4 ⁄8 8 ⁄16 15 ⁄2 62 22 ⁄2 6 ⁄8

5 1 1 1 1 9

42 8.8 31 ⁄16 51 ⁄8 5 ⁄16 10 ⁄16 18 73 26 ⁄4 7 ⁄16

1 19 1 3

48 11.4 36 58 ⁄2 611 ⁄32 20 ⁄2 84 30 8 ⁄4

5 11 1 3 13

54 14.3 40 65 6 ⁄8 13 22 ⁄16 92 ⁄2 33 ⁄8 9 ⁄16

1 11 9 1 7

60 17.7 45 73 7 ⁄2 14 ⁄16 25 ⁄32 105 37 ⁄2 11 ⁄32

7 9

72 25.6 54 88 9 17 31 ⁄16 126 45 12 ⁄16

21 1 1 31

84 34.6 62 102 10 18 ⁄32 37 ⁄32 162 ⁄2 52 13 ⁄32

13 7 9

90 44.5 72 115 13 23 ⁄16 38 ⁄32 183 59 19 ⁄32

1 1 11 15 1

96 51.7 77 ⁄4 122 15 ⁄4 24 ⁄32 40 ⁄16 218 62 20 ⁄16

1 1 27 5 3

108 66.0 87 ⁄8 138 17 ⁄8 26 ⁄32 46 ⁄8 269 70 22 ⁄8

7 7 7 3

120 81.8 96 ⁄8 154 18 ⁄8 29 ⁄32 53 301 ⁄8 78 24

1 3 7 15 1 5 7

132 99.1 106 ⁄2 168 ⁄4 20 ⁄8 32 ⁄16 57 ⁄2 329 85 ⁄8 26 ⁄8

FIG. 1Cross-Sectional Shape of Arch Pipe

C506−15

7.2 Design Tables—The wall thickness, compressive 8.1.2 Where two lines of reinforcement of arch shape

strength of concrete, and the area of circumferential reinforce- corresponding to the contour of the pipe are used, each line

ment shall be as prescribed in Table 1, subject to the provisions shall be so placed that the covering of concrete over the

of 7.3 and Sections 11 and 12. reinforcement is 1 in.

7.2.1 Footnotes to the tables herein are intended to be

8.1.3 The location of the reinforcement shall be subject to

amplifications of the tabulated requirements and are to be the permissible variations in dimensions given in 12.5. Re-

considered applicable and binding as if they were contained in

quirements for placement and protective covering of the

the body of the specification. concrete from the inner or outer surface of the pipe do not

apply to that portion of a cage which is flared so as to extend

7.3 Modified and Special Designs:

into the bell or reduced in diameter so as to extend into the

7.3.1 If permitted by the owner, the manufacturer may

spigot.

request approval by the owner of modified designs that differ

8.1.3.1 Where the wall reinforcement does not extend into

from the designs in this Section 7 or special designs for sizes

the joint, the maximum longitudinal distance to the last

andloadsbeyondthoseshowninTable1,orspecialdesignsfor

circumferential from the inside shoulder of the bell o

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C506 − 14 C506 − 15

Standard Specification for

Reinforced Concrete Arch Culvert, Storm Drain, and Sewer

Pipe

This standard is issued under the fixed designation C506; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers reinforced arch-shaped concrete pipe to be used for the conveyance of sewage, industrial wastes,

storm water, and for the construction of culverts.

1.2 This specification is the inch-pound companion to C506M; therefore, no SI equivalents are presented in the specification.

NOTE 1—This specification is a manufacturing and purchase specification only, and does not include requirements for bedding, backfill, or the

relationship between field load condition and the strength classification of pipe. However, experience has shown that the successful performance of this

product depends upon the proper selection of the class of pipe, type of bedding and backfill, and care that the installation conforms to the construction

specifications. The owner of the reinforced concrete pipe specified herein is cautioned that he must correlate the field requirements with the class of pipe

specified and provide inspection at the construction site.

2. Referenced Documents

2.1 ASTM Standards:

A36/A36M Specification for Carbon Structural Steel

A615/A615M Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement

A706/A706M Specification for Deformed and Plain Low-Alloy Steel Bars for Concrete Reinforcement

A1064/A1064M Specification for Carbon-Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete

C33 Specification for Concrete Aggregates

C150 Specification for Portland Cement

C260 Specification for Air-Entraining Admixtures for Concrete

C309 Specification for Liquid Membrane-Forming Compounds for Curing Concrete

C494/C494M Specification for Chemical Admixtures for Concrete

C497 Test Methods for Concrete Pipe, Manhole Sections, or Tile

C595 Specification for Blended Hydraulic Cements

C618 Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete

C822 Terminology Relating to Concrete Pipe and Related Products

C989 Specification for Slag Cement for Use in Concrete and Mortars

C1017/C1017M Specification for Chemical Admixtures for Use in Producing Flowing Concrete

C1116 Specification for Fiber-Reinforced Concrete and Shotcrete

C1602/C1602M Specification for Mixing Water Used in the Production of Hydraulic Cement Concrete

3. Terminology

3.1 Definitions—For definitions of terms relating to concrete pipe, see Terminology C822.

4. Classification

4.1 Pipe manufactured according to this specification shall be of three classes identified as Class A-II, A-III, and A-IV. The

strength requirements are prescribed in Table 1.

This specification is under the jurisdiction of ASTM Committee C13 on Concrete Pipe and is the direct responsibility of Subcommittee C13.02 on Reinforced Sewer

and Culvert Pipe.

Current edition approved May 1, 2014Jan. 1, 2015. Published May 2014January 2015. Originally approved in 1963. Last previous edition approved in 20132014 as

C506 – 13a.C506 – 14. DOI: 10.1520/C0506-14.10.1520/C0506-15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C506 − 15

A

TABLE 1 Strength Requirements for Reinforced Concrete Pipe

C

Double Line Reinforcement

B

f 'c, MPA

Continuous Basic

D

Additional Reinforcement = A Single Line

Approx- D s

Reinforcement = A

Mini- Mini- s

Reinforcement

imate

T, mum mum

“U” “V”

Equivalent

Class Inner Cage Outer Cage

in. Rise, Span,

(Inner Cage) (Outer Cage)

Round

in. in.

Size, in. Dimen- Dimen-

A-II A-III A-IV A-II A-III A-IV A-II A-III A-IV sion, A-II A-III A-IV sion, A-II A-III A-IV A-II A-III A-IV

in. in.

15 2 ⁄4 11 18 4 4 4 . . . . . . . . . . . . . . 0.08 0.12 0.17

1 1

18 2 ⁄2 13 ⁄2 22 4 4 4 . . . . . . . . . . . . . . 0.11 0.14 0.26

3 1

21 2 ⁄8 15 ⁄2 26 4 4 4 . . . . . . . . . . . . . . 0.12 0.17 0.29

24 3 18 28 ⁄2 4 4 4 . . . . . . . . . . . . . . 0.16 0.21 0.32

1 1 1

30 3 ⁄2 22 ⁄2 36 ⁄4 4 4 4 0.09 0.12 0.18 0.07 0.09 0.14 26 0.09 0.12 0.18 29 0.07 0.09 0.12 0.18 0.24 0.36

5 3

36 4 26 ⁄8 43 ⁄8 4 4 4 0.11 0.15 0.21 0.09 0.12 0.17 30 0.11 0.15 0.21 34 0.09 0.12 0.16 0.21 0.30 0.44

1 5 1

42 4 ⁄2 31 ⁄16 51 ⁄8 4 4 4 0.12 0.18 0.27 0.10 0.14 0.21 34 0.12 0.18 0.27 39 0.10 0.14 0.21 0.26 0.36 0.54

48 5 36 58 ⁄2 4 4 . 0.15 0.21 . 0.12 0.17 . 42 0.15 0.21 . 43 0.12 0.17 . 0.30 0.44 .

54 5 ⁄2 40 65 4 4 . 0.18 0.24 . 0.14 0.19 . 48 0.18 0.24 . 49 0.14 0.19 . 0.36 0.48 .

60 6 45 73 4 4 . 0.21 0.27 . 0.17 0.21 . 52 0.21 0.27 . 55 0.17 0.21 . 0.42 0.56 .

72 7 54 88 4 5 . 0.26 0.36 . 0.20 0.27 . 60 0.26 0.36 . 67 0.20 0.27 . 0.52 0.72 .

84 8 62 102 4 5 . 0.32 0.44 . 0.24 0.34 . 68 0.32 0.44 . 77 0.24 0.34 . 0.64 0.88 .

90 8 ⁄2 72 115 . . . . . . . . . . . . . . . . . . . .

96 9 77 ⁄2 122 . . . . . . . . . . . . . . . . . . . .

108 10 87 ⁄8 138 . . . . . . . . . . . . . . . . . . . .

120 11 96 ⁄8 154 . . . . . . . . . . . . . . . . . . . .

1 3

132 10 106 ⁄2 168 ⁄4 . . . . . . . . . . . . . . . . . . . .

D-Loads for 3-Edge-Bearing Method

Class 0.01-in. Ultimate

Crack

II 1000 1500

III 1350 2000

IV 2000 3000

Note—Test load in pounds per linear foot

equals D-load × inside span in feet.

A

ForFor modified or special designs, see 7.3.

B

f 'c, ksi = minimum compressive strength of concrete in thousands of pounds-force per square inch.

C

AsAs an alternative to designs requiring double line reinforcement, the reinforcement may be positioned and proportioned so that the total reinforcement of the inner cage

plus the middle cage shall not be less than that specified for the inner cage continuous basic reinforcement, and the additional reinforcement “U ”” and the total

reinforcement of the outer cage plus the middle cage shall not be less than that specified for the outer cage continuous basic reinforcement and the additional reinforcement

“V.”

D

A = circumferential steel area in square inches per longitudinal foot of pipe barrel in each continuous basic cage and additional cages in area denoted “U ”” and “V.”

s

Dimensions “U ”” and “V ”” are measured on the center line of the culvert wall.

5. Basis of Acceptance

5.1 Unless otherwise designated by the owner at the time of, or before placing an order, there are two separate and alternative

bases of acceptance. Independent of the method of acceptance, the pipe shall be designed to meet both the 0.01-in. crack and

ultimate strength requirements.

5.1.1 Acceptance on Basis of Plant Load Bearing Tests, Material Tests, and Inspection of Manufactured Pipe for Visual Defects

and Imperfections—Acceptability of the pipe in all diameters and classes produced in accordance with 7.1 or 7.2, shall be

determined by the results of the three-edge-bearing tests as defined in 11.3.1; by such material tests as are required in accordance

with 6.2, 6.3, 6.5, and 6.6, by an absorption test of the concrete from the wall of the pipe as required in 11.9; and by visual

inspection of the finished pipe to determine its conformance with the accepted design and its freedom from defects.

5.1.2 Acceptance on Basis of Material Tests and Inspection of Manufactured Pipe for Defects and Imperfections—Acceptability

of the pipe in all diameters and classes produced in accordance with 7.1 or 7.2 shall be determined by the results of such material

tests as are required in 6.2, 6.3, 6.5, and 6.6; by crushing tests on concrete cores or cured concrete cylinders; by an absorption test

of the concrete from the wall of the pipe for each mix design that is used on an order; and by inspection of the finished pipe,

including amount and placement of reinforcement, to determine its conformance with the accepted design and its freedom from

defects.

5.1.3 When agreed upon by the owner and the manufacturer, any portion or any combination of the tests itemized in 5.1.1 or

5.1.2 may form the basis of acceptance.

5.2 Age for Acceptance—Pipe shall be considered ready for acceptance when they conform to the requirements as indicated by

the specified tests.

C506 − 15

6. Materials

6.1 The aggregate shall be so sized, graded, proportioned, and mixed with such proportions of portland cement, blended

hydraulic cement, or portland cement and supplementary cementing materials, or admixtures, or a combination thereof, if used,

and water to produce a homogeneous concrete mixture of such quality that the pipe will conform to the test and design

requirements of this specification. In no case, however, shall the proportion of portland cement, blended hydraulic cement, or a

combination of portland cement and supplementary cementing materials be less than 470 lb/yd .

6.2 Cementitious Materials:

6.2.1 Cement—Cement shall conform to the requirements of Specification C150, or shall be portland blast-furnace slag cement,

or slag modified portland cement, or portland-pozzolan cement conforming to the requirements of Specification C595, except that

the pozzolan constituent in the Type IP portland-pozzolan cement shall be fly ash.

6.2.2 Ground Granulated Blast-Furnace Slag (GGBFS)—GGBFS shall conform to the requirements of Grade 100 or 120 of

Specification C989.

6.2.3 Fly Ash—Fly ash shall conform to the requirements of Class F or Class C of Specification C618.

6.2.4 Allowable Combinations of Cementitious Materials—The combination of cementitious materials used in the concrete shall

be one of the following:

6.2.4.1 Portland cement only,

6.2.4.2 Portland blast furnace slag cement only,

6.2.4.3 Portland pozzolan cement only,

6.2.4.4 A combination of portland cement and ground granulated blast-furnace slag,

6.2.4.5 A combination of portland cement and fly ash,

6.2.4.6 A combination of portland cement, ground granulated blast-furnace slag, and fly ash, or

6.2.4.7 A combination of portland pozzolan cement and fly ash.

6.3 Aggregates—Aggregates shall conform to Specification C33 except that the requirement for gradation shall not apply.

6.4 Admixtures and Blends—The following admixtures and blends are allowable:

6.4.1 Air-entraining admixture conforming to Specification C260;

6.4.2 Chemical admixture conforming to Specification C494/C494M;

6.4.3 Chemical admixture for use in producing flowing concrete conforming to Specification C1017/C1017M; and

6.4.4 Chemical admixture or blend approved by the owner.

6.5 Steel Reinforcement—Reinforcement shall conform to the requirements of Specification A1064/A1064M, or bars

conforming to Specification A36/A36M, Specification A615/A615M Grade 40 or 60, or Specification A706/A706M Grade 60. For

helically wound cages only, weld shear tests are not required.

6.6 Synthetic Fibers—Collated fibrillated virgin polypropylene fibers may be used, at the manufacturer’s option, in concrete

pipe as a nonstructural manufacturing material. Only Type III synthetic fibers designed and manufactured specifically for use in

concrete and conforming to the requirements of Specification C1116 shall be accepted.

7. Design

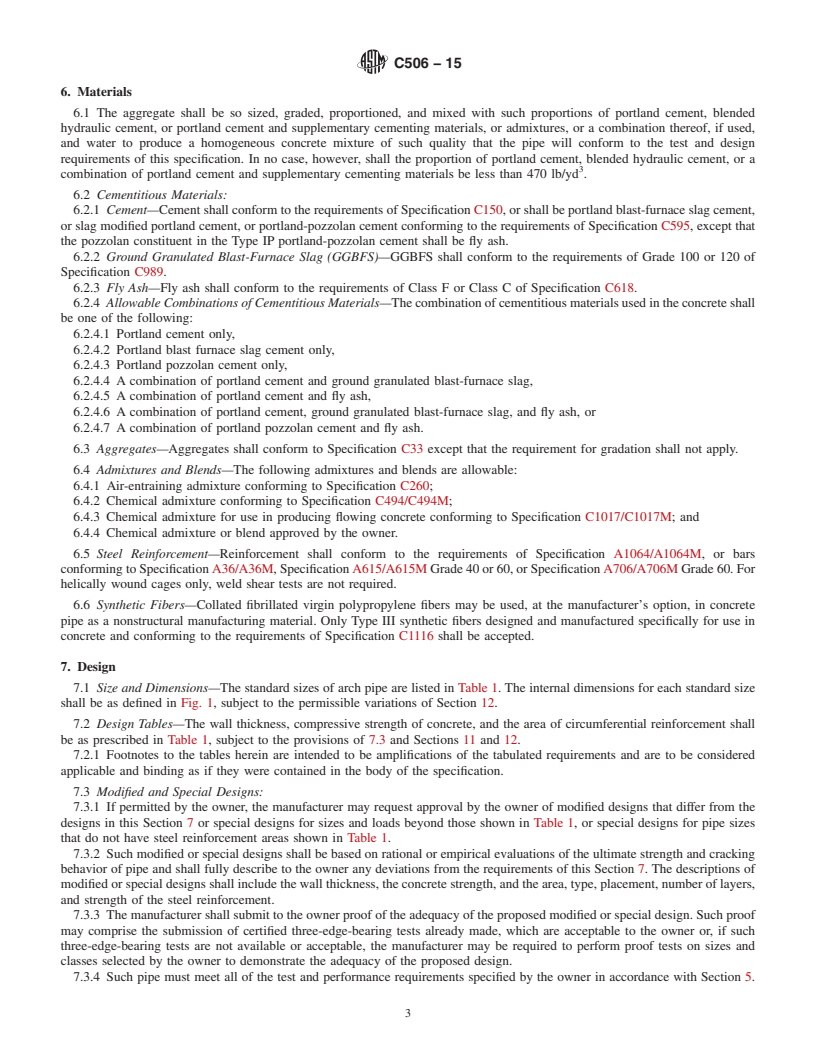

7.1 Size and Dimensions—The standard sizes of arch pipe are listed in Table 1. The internal dimensions for each standard size

shall be as defined in Fig. 1, subject to the permissible variations of Section 12.

7.2 Design Tables—The wall thickness, compressive strength of concrete, and the area of circumferential reinforcement shall

be as prescribed in Table 1, subject to the provisions of 7.3 and Sections 11 and 12.

7.2.1 Footnotes to the tables herein are intended to be amplifications of the tabulated requirements and are to be considered

applicable and binding as if they were contained in the body of the specification.

7.3 Modified and Special Designs:

7.3.1 If permitted by the owner, the manufacturer may request approval by the owner of modified designs that differ from the

designs in this Section 7 or special designs for sizes and loads beyond those shown in Table 1, or special designs for pipe sizes

that do not have steel reinforcement areas shown in Table 1.

7.3.2 Such modified or special designs shall be based on rational or empirical evaluations of the ultimate strength and cracking

behavior of pipe and shall fully describe to the owner any deviations from the requirements of this Section 7. The descriptions of

modified or special designs shall include the wall thickness, the concrete strength, and the area, type, placement, number of layers,

and strength of the steel reinforcement.

7.3.3 The manufacturer shall submit to the owner proof of the adequacy of the proposed modified or special design. Such proof

may comprise the submission of certified three-edge-bearing tests already made, which are acceptable to the owner or, if such

three-edge-bearing tests are not available or acceptable, the manufacturer may be required to perform proof tests on sizes and

classes selected by the owner to demonstrate the adequacy of the proposed design.

7.3.4 Such pipe must meet all of the test and performance requirements specified by the owner in accordance with Section 5.

C506 − 15

A 5Rise 2R

2 2

B 5A1 sR 2R d 2C

œ 2 3

Span

C 5 2R

Approximate

Equivalent Water

Rise, in. Span, in. A, in. B, in. C, in. R , in. R , in. R , in.

2 1 2 3

Round Area, ft

Size, in.

3 11 31 7 5 1

15 1.1 11 18 ⁄8 4 ⁄16 4 ⁄32 22 ⁄8 10 ⁄8 4 ⁄32

1 1 3 1 3 1

18 1.65 13 ⁄2 22 − ⁄4 6 5 ⁄4 27 ⁄2 13 ⁄4 5 ⁄4

1 3 1 3 1 3 1

21 2.2 15 ⁄2 26 ⁄4 6 ⁄4 7 ⁄4 35 ⁄2 14 ⁄4 5 ⁄4

1 7 29 21 11 9 19

24 2.8 18 28 ⁄2 3 ⁄16 5 ⁄32 9 ⁄32 40 ⁄16 14 ⁄16 4 ⁄32

1 1 3 11 3 3 1

30 4.4 22 ⁄2 36 ⁄4 3 ⁄4 7 ⁄16 12

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.