ASTM E1127-91(1997)

(Guide)Standard Guide for Depth Profiling in Auger Electron Spectroscopy

Standard Guide for Depth Profiling in Auger Electron Spectroscopy

SCOPE

1.1 This guide covers procedures used for depth profiling in Auger electron spectroscopy.

1.2 Guidelines are given for depth profiling by the following: Section Ion Sputtering 6 Angle Lapping and Cross-Sectioning 7 Mechanical Cratering 8 Nondestructive Depth Profiling 9

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1127 – 91 (Reapproved 1997)

Standard Guide for

Depth Profiling in Auger Electron Spectroscopy

This standard is issued under the fixed designation E 1127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.3 In mechanical cratering, a spherical or cylindrical crater

is created in the surface using a rotating ball or wheel. The

1.1 This guide covers procedures used for depth profiling in

sloping sides of the crater are used to improve the depth

Auger electron spectroscopy.

resolution as in angle lapping.

1.2 Guidelines are given for depth profiling by the follow-

4.4 In nondestructive techniques, different methods of vary-

ing:

ing the electron information depth are involved.

Section

Ion Sputtering 6

5. Significance and Use

Angle Lapping and Cross-Sectioning 7

Mechanical Cratering 8

5.1 Auger electron spectroscopy yields information con-

Nondestructive Depth Profiling 9

cerning the chemical and physical state of a solid surface in the

1.3 This standard does not purport to address all of the

near surface region. Nondestructive depth profiling is limited

safety problems, if any, associated with its use. It is the

to this near surface region.

responsibility of the user of this standard to establish appro-

5.2 Ion sputtering is primarily used for depths of less than

priate safety and health practices and determine the applica-

the order of 1 μm.

bility of regulatory limitations prior to use.

5.3 Angle lapping or mechanical cratering is primarily used

for depths greater than the order of 1 μm.

2. Referenced Documents

5.4 The choice of depth profiling methods for investigating

2.1 ASTM Standards:

an interface depends on surface roughness, interface rough-

E 673 Terminology Relating to Surface Analysis 3

ness, and film thickness (1).

E 684 Practice for Approximate Determination of Current

Density of Large-Diameter Ion Beams for Sputter Depth 6. Ion Sputtering

Profiling of Solid Surfaces

6.1 First introduce the specimen into a vacuum chamber

E 827 Practice for Elemental Identification by Auger Elec-

equipped with an Auger analyzer and an ion sputtering gun.

tron Spectroscopy

Align the ion beam using a sputtering target or a Faraday cup,

E 996 Practice for Reporting Data in Auger Electron Spec-

paying careful attention to the relative spot size of the electron

troscopy and X-Ray Photoelectron Spectroscopy

beam, ion beam, and Faraday cup and their respective orien-

tations to ensure accurate convergence of the two beams at the

3. Terminology

specimen surface.

3.1 Definitions:

6.1.1 Place the specimen in front of the Auger analyzer and

3.1.1 For definitions of terms used in this guide, refer to

direct the ion gun towards the analysis area. If the ion beam is

Terminology E 673.

not normal to the specimen surface then possible shadowing of

the analysis area from the ion beam must be considered.

4. Summary of Guide

6.2 Choose the elements to be investigated from previous

4.1 In ion sputtering, the surface layers are removed by ion

experience or from an initial Auger electron spectrum or an

bombardment in conjunction with Auger analysis.

energy-dispersive X-ray spectrum since the latter spectrum can

4.2 In angle lapping, the surface is lapped or polished at a

reveal additional elements present at depths greater than those

small angle to improve the depth resolution as compared to a

that contribute to the Auger electron spectrum (2). Select a

cross section.

specific transition for each element. During the depth profiling,

record the peak-to-peak heights for Auger derivative data, or

peak heights or peak areas for N(E) data. The data may be

This guide is under the jurisdiction of ASTM Committee E-42 on Surface

Analysis and is the direct responsibility of Subcommittee E42.03 on Auger Electron

Spectroscopy and XPS.

Current edition approved Jan. 25, 1991. Published May 1991. Originally

published as E 1127 – 86. Last previous edition E 1127 – 86. The boldface numbers in parentheses refer to the list of references at the end of

Annual Book of ASTM Standards, Vol 03.06. this guide.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1127 – 91 (1997)

gathered during continuous sputtering or between timed sputter modelling of these and other ion-induced phenomena has been

segments. Results may vary between the two techniques. extensively studied and has provided new insights into this

field (21 and 22).

6.2.1 One source of their difference is due to the presence of

6.8.1 It should be determined for each specimen if compo-

ion-induced electrons during continuous sputter depth profil-

sitional changes or other sputter effects are likely to occur. It

ing, especially at low-electron kinetic energies, that can be-

may be possible to minimize these effects in some instances by

come comparable in intensity to the electrons induced by the

adjusting the sputtering parameters.

probing incident electron beam. Unless one or the other of the

6.9 Ion guns used in Auger analysis are normally self-

excitation beams is modulated and detected synchronously

contained units capable of producing a focused beam of ions.

these two types of emitted electrons are difficult to distinguish.

The specimen is not used as an anode for the gun. Many ion

These ion-induced electrons usually form a featureless back-

guns are able to raster the ion beam. A rastered ion beam will

ground that rises steeply as their kinetic energy decreases, but

produce a more uniform ion current distribution on the

sometimes ion-induced Auger peaks might be present whose

specimen surface in the region of analysis.

lineshape may be different from those produced by the electron

6.10 If the ion gun is equipped with a restricted orifice for

beam (3). As a result, care must be taken during continuous

the sputter gas flow, then the vacuum pumps may be left on

sputtering to ensure reliable results. Another source of differ-

during sputtering, removing most of the sputtered gases. If not,

ence is due to the buildup of adsorbed species during the data

then the chamber must be back filled with gas and provisions

acquisition time in the discontinuous sputter depth profile

for removing the sputtered active gases must be considered.

mode (4). If portions of the ion-eroded surface expose very

Titanium sublimation is effective in removing these gases.

reactive phases, then Auger peaks due to adsorbed species, for

6.11 Noble gas ions are normally used in sputtering and the

example, oxygen or carbon, or both, will appear in the spectra

most commonly used gas is argon. Xenon is occasionally used

and mask the actual depth distribution.

with high beam energies when rapid sputtering is needed.

6.2.2 It is advisable when analyzing an unknown specimen

Active gases such as oxygen and metal ions are used in special

to periodically examine survey scans to detect any new

circumstances.

elements that were not present in the initial survey scan and to

6.11.1 Ion energies commonly used for depth profiling

determine if any of the Auger peaks have been displaced

using noble gases are in the range from 1 to 5 keV where lower

outside of their analysis windows (5).

ion energies are usually preferred for improved depth resolu-

6.3 Crater-edge profiling of the sputter-formed crater by

tion. Higher ion energies usually can be obtained with higher

using Auger line scans is a technique similar to the analysis of

ion currents and less preferential sputtering.

the mechanically formed craters in Section 8 (6). Forming the

6.11.2 Ion beam current density can be measured by a

crater by sputtering may introduce the additional complications

Faraday cup or by following Practice E 684.

of ion-induced damage and asymmetric crater dimensions.

6.11.3 The sputter rate is needed to calibrate the depth scale

6.4 If specimen rotation is used to reduce ion-induced when depth profiling using ion sputtering. Several reference

roughness, then the rotational speed, rotation axis runout

standards are available for this purpose. One reference material

relative to ion beam sputtered area or wobble and data consists of 30 and 100-nm thick tantalum pentoxide films

acquisition rate should be reported (7 and 8).

(23). Another reference material is an alternating nickel and

chromium thin film structure; each layer is nominally 50-nm

6.5 Identify the elements in the survey scans using Practice

thick.

E 827.

6.6 The Auger data and the sputtering conditions should be

7. Angle Lapping and Cross-Sectioning

reported as described in Practice E 996.

7.1 In cross-sectioning, polish the specimen perpendicular

6.7 There is extensive information available in the literature

to the interface, while in angle lapping, polish the specimen at

on the effects of ion bombardment on solid surfaces (9-14).

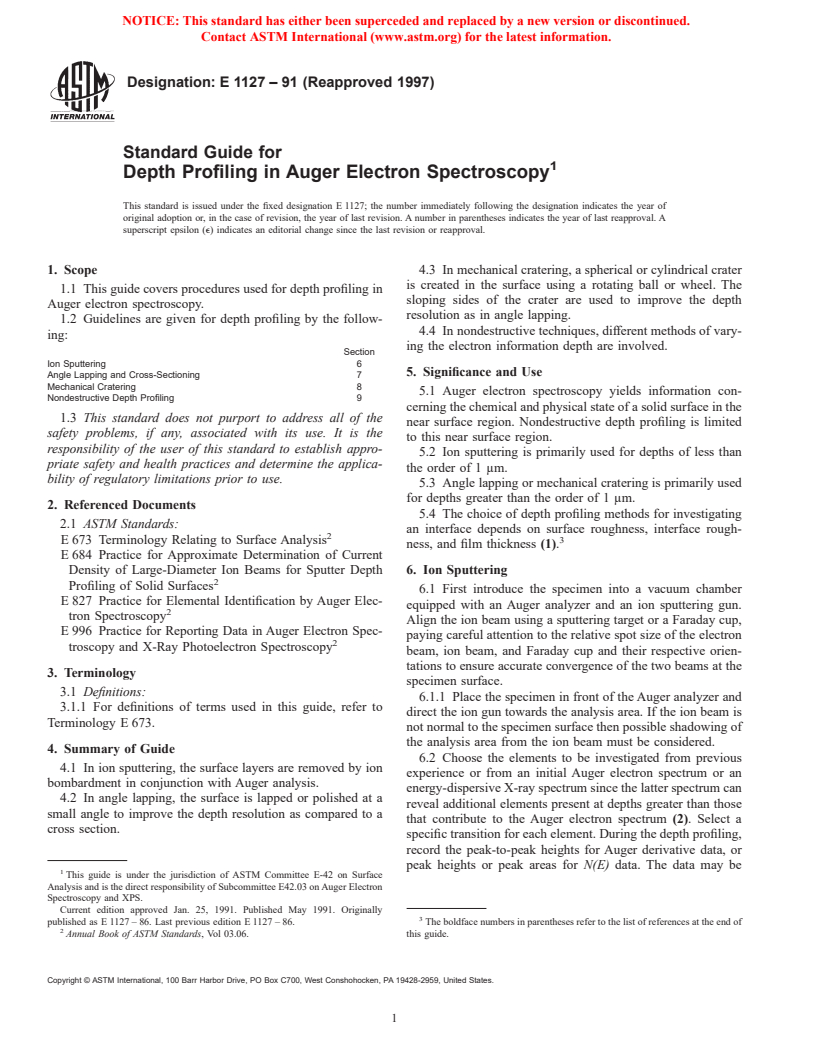

an angle to increase the depth resolution as shown in Fig. 1

6.8 Special care must be exercised whenever specimen

(24). Polishing usually includes the use of silicon carbide

temperature changes are present because effects due to surface

papers, diamond paste, and alumina. Use progressively finer

diffusion, surface segregation or diffusion limited bulk pro-

polishing particles to obtain the desired surface finish. Possible

cesses such as point defect migration can occur and dramati-

limitations of the techniques include smearing of material

cally alter the specimen composition, even over depths larger

across the interface, surface roughness, and the electron probe

than the ion beam penetration depth which is typically a few

diameter limiting the spatial resolution.

nanometers (15 and 16). The concept of preferential sputtering

7.2 In angle lapping mount the specimen on a flat gage

in multielement, single-phase specimens has altered signifi-

block and measure the angle with a collimator. The accuracy

cantly so that chemical effects such as surface segregation are

depends on the flatness of the specimen. In practice an angle of

considered to be at least as important as physical effects such

0.1° can be accurately measured.

as mass differences in the evolution of the near surface

composition during sputter depth profiling (17-20). Since the

Available from the National Physical Laboratory, Teddington, Middlesex,

probing depths in Auger electron spectroscopy are usually

England. Listed as Certified Reference Material NPL No. S7B83, BCR No. 261.

smaller than the ion-penetration depth these effects are very

Available from the National Institute of Standards and Technology, U.S.

important in any interpretation of Auger signal intensity in

Department of Commerce, Gaithersburg, MD 20899. Listed as NIST Standard

terms of composition during ion-beam profiling. Computer Reference Material 2135.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1127 – 91 (1997)

NOTE 1—In practice, the angle u is much smaller than shown, being of

the order of 1°

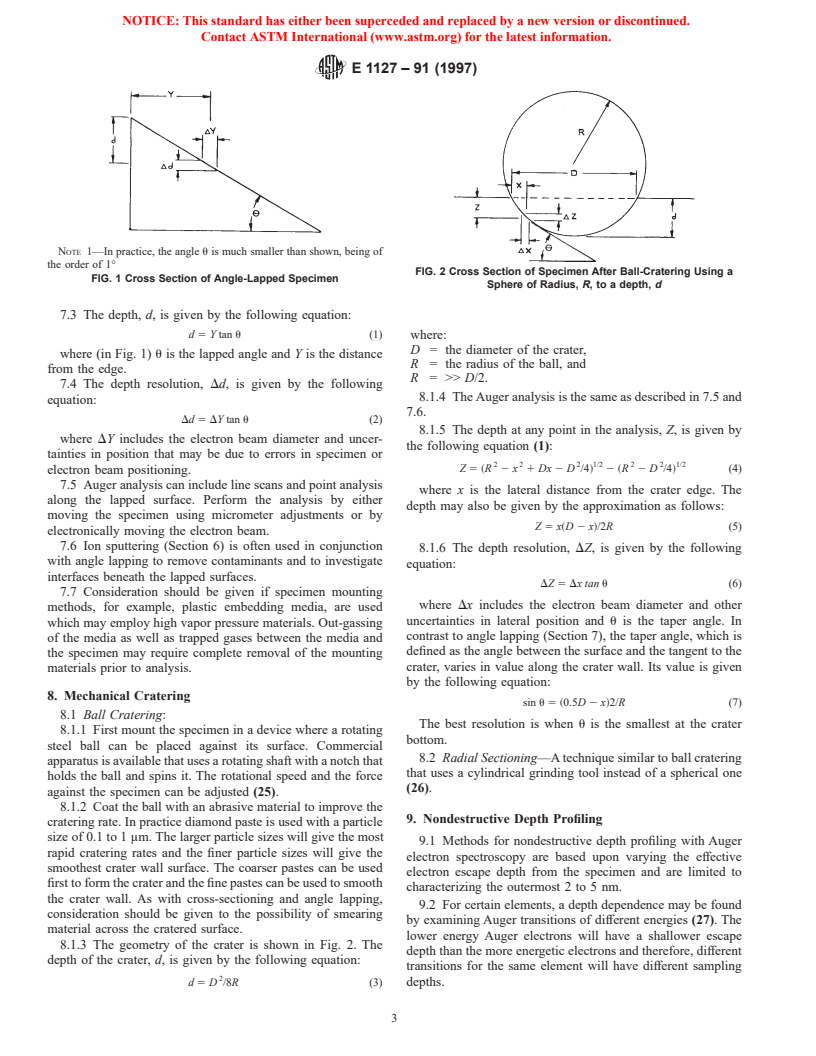

FIG. 2 Cross Section of Specimen After Ball-Cratering Using a

FIG. 1 Cross Section of Angle-Lapped Specimen

Sphere of Radius, R, to a depth, d

7.3 The depth, d, is given by the following equation:

d 5 Y tan u (1)

where:

D = the diameter of the crater,

where (in Fig. 1) u is the lapped angle and Y is the distance

R = the radius of the ball, and

from the edge.

R =>> D/2.

7.4 The depth resolution, Dd, is given by the following

8.1.4 The Auger analysis is the same as described in 7.5 and

equation:

7.6.

Dd5DY tan u (2)

8.1.5 The depth at any point in the analysis, Z, is given by

where DY includes the electron beam diameter and uncer-

the following equation (1):

tainties in position that may be due to errors in specimen or

2 2 2 1/2 2 2 1/2

Z 5 ~R 2 x 1 Dx 2 D /4! 2 ~R 2 D /4! (4)

electron beam positioning.

7.5 Auger analysis can include line scans and point analysis

where x is the lateral distance from the crater edge. The

along the lapped surface. Perform the analysis by either

depth may also be given by the approximation as follows:

moving the specimen using micrometer adjustments or by

Z 5 x~D 2 x!/2R (5)

electronically moving the electron beam.

7.6 Ion sputtering (Section 6) is often used in conjunction

8.1.6 The depth resolution, DZ, is given by the following

with angle lapping to remove contaminants and to investigate

equation:

interfaces beneath the lapped surfaces.

DZ5Dx tan u (6)

7.7 Consideration should be given if specimen mounting

where Dx includes the electron beam diameter and other

methods, for example, plastic embedding media, are used

uncertainties in lateral position and u is the taper angle. In

which may employ high vapor pressure materials. Out-gassing

contrast to angle lapping (Section 7), the taper angle, which is

of the media as well as trapped gases between the media and

defined as the angle between the surface and the tangent to the

the specimen may require complete removal of the mounting

crater, varies in value along the crater wall. Its value is given

materials prior to analysis.

by the following equation:

8. Mechanical Cratering

sinu5 ~0.5D 2 x!2/R (7)

8.1 Ball Cratering:

The best resolution is when u is the smallest at the crater

8.1.1 First mount the specimen in a device where a rotating

bottom.

steel ball can be placed against its surface. Commercial

8.2 Radial Sectioning—A technique similar to ball cratering

apparatus is available that uses a rotating shaft with a notch that

that uses a cylindrical grinding tool instead of a spherical one

holds the ball and spins it. The rotational speed and the force

(26).

against the specimen can be adjusted (25).

8.1.2 Coat the ball with an abrasive material to improve the

9. Nondestructive Depth Profiling

cratering rate. In practice diamond paste is used with a particle

size of 0.1 to 1 μm. The larger particle sizes will give the most

9.1 Methods for nondestructive depth profiling with Auger

rapid cratering rates and the finer particle sizes will give the

electron spectroscopy are based upon varying the effective

smoothest crater wall surface. The coarser pastes can be used

electron escape depth from the specimen and are limited to

first to form the crater and the fine pastes can be used to smooth

characterizing the outermost 2 to 5 nm.

the crater wall. As with cross-sectioning and angle lapping,

9.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.