ASTM F2129-01

(Test Method)Standard Test Method for Conducting Cyclic Potentiodynamic Polarization Measurements to Determine the Corrosion Susceptibility of Small Implant Devices

Standard Test Method for Conducting Cyclic Potentiodynamic Polarization Measurements to Determine the Corrosion Susceptibility of Small Implant Devices

SCOPE

1.1 This test method assesses the corrosion susceptibility of small, metallic, implant medical devices, or components thereof, using cyclic (forward and reverse) potentiodynamic polarization. Examples of device types, which may be evaluated by this test method include, but are not limited to, vascular stents, filters, support segments of endovascular grafts, cardiac occluders, aneurysm or ligation clips, staples, and so forth.

1.2 This test method is used to assess a device in its final form and finish, as it would be implanted. These small devices should be tested in their entirety. The upper limit on device size is dictated by the electrical current delivery capability of the test apparatus (see Section 6). It is assumed that test methods, such as Test Methods G 5 and G 61 have been used for material screening.

1.3 Because of the variety of configurations and sizes of implants, this test method provides a variety of specimen holder configurations.

1.4 This test method is intended for use on implantable devices made from metals with a relatively high resistance to corrosion.

1.5This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 2129 – 01

Standard Test Method for

Conducting Cyclic Potentiodynamic Polarization

Measurements to Determine the Corrosion Susceptibility of

Small Implant Devices

This standard is issued under the fixed designation F 2129; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope G 61 Test Method for Conducting Cyclic Potentiodynamic

Polarization Measurements for Localized Corrosion Sus-

1.1 This test method assesses the corrosion susceptibility of

ceptibility of Iron-, Nickel-, or Cobalt-Based Alloys

small, metallic, implant medical devices, or components

G 102 Practice for Calculation of Corrosion Rates and

thereof, using cyclic (forward and reverse) potentiodynamic

Related Information from Electrochemical Measurements

polarization. Examples of device types, which may be evalu-

ated by this test method include, but are not limited to, vascular

3. Terminology

stents, filters, support segments of endovascular grafts, cardiac

3.1 Definitions:

occluders, aneurysm or ligation clips, staples, and so forth.

3.1.1 potentiostat, n—an instrument for automatically main-

1.2 This test method is used to assess a device in its final

taining an electrode in an electrolyte at a constant potential or

form and finish, as it would be implanted. These small devices

controlled potentials with respect to a suitable reference

should be tested in their entirety. The upper limit on device size

electrode (see Terminology G 15).

is dictated by the electrical current delivery capability of the

3.1.2 potentiodynamic cyclic polarization (forward and re-

test apparatus (see Section 6). It is assumed that test methods,

verse polarization), n—a technique in which the potential of

such as Test Methods G 5 and G 61 have been used for material

the test specimen is controlled and the corrosion current

screening.

measured by a potentiostat. The potential is scanned in the

1.3 Because of the variety of configurations and sizes of

positive or noble (forward) direction as defined in Practice G 3.

implants, this test method provides a variety of specimen

The potential scan is continued until a predetermined potential

holder configurations.

or current density is reached. Typically, the scan is run until the

1.4 This test method is intended for use on implantable

transpassive region is reached, and the specimen no longer

devices made from metals with a relatively high resistance to

demonstrates passivity, as defined in Practice G 3. The poten-

corrosion.

tial scan direction then is reversed until the specimen repassi-

1.5 This standard does not purport to address all of the

vates or the potential reaches a preset value.

safety concerns, if any, associated with its use. It is the

3.1.3 scan rate, n—the rate at which the controlling voltage

responsibility of the user of this standard to establish appro-

is changed.

priate safety and health practices and determine the applica-

3.2 Symbols:

bility of regulatory limitations prior to use.

3.2.1 E = Breakdown or Critical Pitting Potential—the

b

2. Referenced Documents least noble potential at which pitting or crevice corrosion or

both will initiate and propagate as defined in Terminology

2.1 ASTM Standards:

G 15. An increase in the resistance to pitting corrosion is

D 1193 Specification for Reagent Water

associated with an increase in E .

G 3 Practice for Conventions Applicable to Electrochemical b

3.2.2 E or OCP—the potential of a corroding surface in

corr

Measurements in Corrosion Testing

an electrolyte relative to a reference electrode measured under

G 5 Reference Test Method for Making Potentiostatic and

open-circuit conditions, as defined in Terminology G 15.

Potentiodynamic Anodic Polarization Measurements

3.2.3 E = Final Potential—a preset potential at which the

f

G 15 Terminology Relating to Corrosion and Corrosion

scan is stopped.

Testing

3.2.4 E = Initial Potential—the potential at which the

i

potentiostat begins the controlled potentiodynamic scan.

This test method is under the jurisdiction of ASTM Committee F04 on Medical

3.2.5 E = Protection Potential—the potential at which the

p

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

reverse scan intersects the forward scan at a value that is less

F04.15 on Material Test Methods.

noble than E . E cannot be determined if there is no

Current edition approved July 10, 2001. Published September 2001. b p

Annual Book of ASTM Standards, Vol 11.01.

breakdown. Whereas, pitting will occur on a pit-free surface

Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 2129

above E , it will occur only in the range of potentials between 6. Apparatus

b

E and E if the surface is already pitted. The severity of

p b

6.1 Potentiostat, capable of maintaining an electrode poten-

crevice corrosion susceptibility increases with increasing hys-

tial within 1 mV of a preset value over a wide range of

teresis of the polarization curve, the difference between E and

b

potentials, as described in Test Methods G 5 and G 61. The

E .

p

potential measuring circuit should have a high input imped-

3.2.6 E = Vertex Potential—a preset potential, at which the 11 14

v

ance, that is, on the order of 10 to 10 V. The current

scan direction is reversed.

measuring circuit should be capable of measuring current in the

3.2.7 i = Corrosion Current Density (mA/cm )—the 5

corr

range of 1.0 to 10 μA.

corrosion current density is extrapolated from the anodic and

6.2 Working Electrode, to be used as the test specimen. Its

cathodic Tafel regions to the OCP (in accordance with Practice

configuration and holder will depend on the type of specimen

G 102).

being tested, as described in Section 7. In all cases, the

3.2.8 i = Threshold Current Density (mA/cm )—a preset

t

metallurgical and surface condition of a specimen simulating a

current density, at which the scan direction is reversed.

device must be in the same condition as the device.

Typically, the scan is reversed when a current density two

6.2.1 An appropriate reference medical device in its final

decades higher than the current density at the breakdown

form and finish, as it would be implanted, should be used as a

potential (E ) is reached.

b

reference or control. Appropriate reference device shall consist

of a device, which is similar to the investigated device and has

4. Summary of Test Method

a history of good corrosion resistance in vivo, is used in a

4.1 The device is placed in an appropriate deaerated simu-

similar environment or location and is used to treat a similar

lated physiological solution and the corrosion potential (E )

corr

disease. Again, as for the working electrode, the configuration

is monitored for 1 h. The potentiodynamic scan is then started

and holder will depend on the type of reference specimen

at an initial potential (E ) 100 mV more negative than E , and

i corr

tested.

scanned in the positive or noble (forward) direction. The scan

6.3 Reference Electrode—A saturated calomel electrode

is reversed after the current density has reached a value

(SCE), as defined in Practice G 3, shall be used as a reference

approximately two decades greater than the current density

electrode.

measured at the breakdown potential. The reverse scan is

6.4 Salt Bridge, such as a Luggin probe, shall be used

stopped after the current has become less than that in the

between the working and reference electrode, such as the type

forward direction or the potential is 100 mV negative to E .

corr

shown in Test Method G 5.

The data is plotted with the current density in mA/cm on the

6.5 Auxiliary Electrodes:

x axis (logarithmic axis) versus the potential in mV on the y

axis (linear axis). Appropriate reference medical devices in 6.5.1 Two platinum auxiliary electrodes may be prepared

from high-purity rod stock. The surfaces may be platinized, as

their final form and finish, as they would be implanted, are used

as controls. per Test Method G 5.

6.5.2 Alternatively, high-purity graphite auxiliary electrodes

5. Significance and Use

may be used in accordance with Test Method G 5. Care should

5.1 Corrosion of implantable medical devices can have

be taken to insure that they do not get contaminated during a

deleterious effects on the device performance or may result in

test.

the release of corrosion products with harmful biological

6.5.3 The auxiliary electrode surface area should be at least

consequences; therefore, it is important to determine the

four times greater than the sample surface area. Use of

general corrosion behavior as well as the susceptibility of the

wire-mesh platinum might be more cost-effective than plati-

devices to localized corrosion.

num cylinders when testing larger specimens or whole devices.

5.2 The forming and finishing steps used to create an

6.6 Suitable Polarization Cell, with a volume of about 1000

implantable device may have significant effects on the corro-

cm , equivalent to or similar to that recommended in Test

sion resistance of the material out of which the device is

Method G 5.

fabricated. While testing the corrosion resistance of the mate-

6.7 Water Bath, or other heating appliance capable of

rials is essential in the process of selecting materials to be used,

maintaining the test solution temperature at 37 6 1°C.

it does not necessarily provide critical data regarding device

6.8 Purge Gas Delivery System, capable of delivering nitro-

performance.

gen gas at 150 cm /min.

5.3 To accommodate the wide variety of device shapes and

sizes encountered, a variety of holding devices can be used.

7. Specimen Holders

5.4 Note that the method is intentionally designed to reach

7.1 There are a variety of holders that may be used in this

conditions that are sufficiently severe to cause breakdown and

practice. Each is designed for a specific type or class of device.

deterioration of the medical devices and that these conditions

7.2 Short wire or coil specimens.

may not be necessarily encountered in vivo. The results of this

corrosion test conducted in artificial physiological electrolytes 7.2.1 Specimens can be held suspended from a clamping

can provide useful data for comparison of different device device. For example, the threaded end of a Test Method G 5

materials, designs, or manufacturing processes. However, note holder can be used to hold two stainless steel nuts. The wire

that this test method does not take into account the effects of test specimen is clamped between these nuts and bent so as to

cells, proteins, and so forth on the corrosion behavior in vivo. enter the test solution.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 2129

7.2.2 The surface area of the test specimen shall be calcu- the Committee on Analytical Reagents of the American Chemi-

cal Society.

lated based on the length of wire or coil immersed in the test

solution. 8.1.1 The water shall be distilled or deionized conforming

to the purity requirements of Specification D 1193, Type IV

7.2.3 This type of holder exposes the specimen to the

reagent water.

air-liquid interface, which is subject to localized crevice

8.1.2 The standard test solution should be prepared accord-

corrosion. Test specimens should be examined carefully after

ing to the specifications. As a reference, a list of common

testing to ensure that there is no localized corrosion at or just

physiological solutions and their composition is provided in

below the interface.

Appendix X2.

7.2.4 If specimens show evidence of localized corrosion at

8.1.3 The pH of the electrolyte should be adjusted based on

the air-liquid interface, then the portion of the specimen

the nature of the solution by the addition of NaOH or HCl.

passing across this interface shall be sealed with an impervious

8.1.4 High-purity nitrogen gas for purge should be used

coating.

when possible depending on the nature of the solution used.

7.3 Stents or cylindrical devices.

Gas purge may not be appropriate for simulated solutions that

7.3.1 Fixture for holding stents (1) or alternative methods

tend to foam excessively when agitated.

can be used to create an electrical connection.

9. Test Specimen

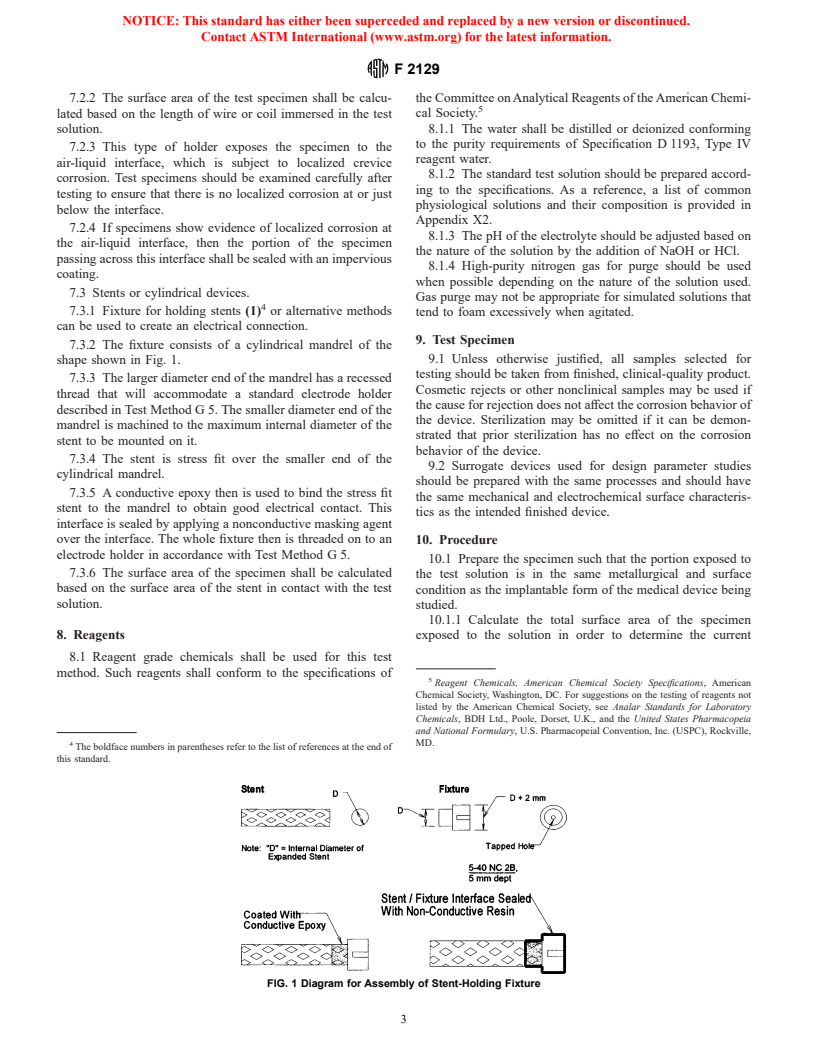

7.3.2 The fixture consists of a cylindrical mandrel of the

9.1 Unless otherwise justified, all samples selected for

shape shown in Fig. 1.

testing should be taken from finished, clinical-quality product.

7.3.3 The larger diameter end of the mandrel has a recessed

Cosmetic rejects or other nonclinical samples may be used if

thread that will accommodate a standard electrode holder

the cause for rejection does not affect the corrosion behavior of

described in Test Method G 5. The smaller diameter end of the

the device. Sterilization may be omitted if it can be demon-

mandrel is machined to the maximum internal diameter of the

strated that prior sterilization has no effect on the corrosion

stent to be mounted on it.

behavior of the device.

7.3.4 The stent is stress fit over the smaller end of the

9.2 Surrogate devices used for design parameter studies

cylindrical mandrel.

should be prepared with the same processes and should have

7.3.5 A conductive epoxy then is used to bind the stress fit

the same mechanical and electrochemical surface characteris-

stent to the mandrel to obtain good electrical contact. This

tics as the intended finished device.

interface is sealed by applying a nonconductive masking agent

over the interface. The whole fixture then is threaded on to an 10. Procedure

electrode holder in accordance with Test Method G 5.

10.1 Prepare the specimen such that the portion exposed to

7.3.6 The surface area of the specimen shall be calculated

the test solution is in the same metallurgical and surface

based on the surface area of the stent in contact with the test

condition as the implantable form of the medical device being

solution.

studied.

10.1.1 Calculate the total surface area of the specimen

8. Reagents exposed to the solution in order to determine the current

8.1 Reagent grade chemicals shall be used for this test

method. Such reagents shall conform to the specifications of

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For sugge

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.