ASTM D1336-97(2003)

(Test Method)Standard Test Method for Distortion of Yarn in Woven Fabrics

Standard Test Method for Distortion of Yarn in Woven Fabrics

SCOPE

1.1 This test method covers the measurement of yarn distortion of one set of yarns over the other in woven cloth following the application of surface friction. This test method especially is applicable to open-weave fabrics, such as nettings, marquisettes, gauzes, chiffons, and heavier fabrics made from slippery surface yarns.

Note 1—For the determination of yarn slippage in woven fabrics, refer to Test Method D 434.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1336–97 (Reapproved 2003)

Standard Test Method for

Distortion of Yarn in Woven Fabrics

This standard is issued under the fixed designation D 1336; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 yarn distortion, n—in woven fabrics, a condition in

which the symmetrical surface appearance of a fabric is altered

1.1 This test method covers the measurement of yarn

by the shifting or sliding of warp or filling yarns.

distortion of one set of yarns over the other in woven cloth

following the application of surface friction. This test method

4. Summary of Test Method

especiallyisapplicabletoopen-weavefabrics,suchasnettings,

4.1 A specimen is subjected to a specified shearing force

marquisettes, gauzes, chiffons, and heavier fabrics made from

acting in the plane of the fabric. The degree to which the force

slippery surface yarns.

causes yarns to shift distorting the original symmetry of the

NOTE 1—For the determination of yarn slippage in woven fabrics, refer

weave is taken as a measure of ease of yarn distortion in the

to Test Method D 434.

fabric. The degree of distortion is reported in terms of the

1.2 The values stated in SI units are to be regarded as the

widest opening, measured in hundredths of an inch.

standard. The inch-pound units given in parentheses are

5. Significance and Use

provided for information only.

1.3 This standard does not purport to address all of the 5.1 This test method is considered satisfactory for accep-

safety concerns, if any, associated with its use. It is the

tance testing of commercial shipments because current esti-

responsibility of the user of this standard to establish appro- mates of between-laboratory precision are acceptable and the

priate safety and health practices and determine the applica-

method has been used extensively in the trade for acceptance

bility of regulatory limitations prior to use. testing.

5.2 In cases of dispute, the statistical bias, if any, between

2. Referenced Documents

the laboratory of the purchaser and the laboratory of the seller

2.1 ASTM Standards:

should be determined, with each comparison being based on

D 123 Terminology Relating to Textiles

testing randomized specimens from one sample of fabric.

D 434 Test Method for Resistance of Slippage of Yarns in

5.3 This test method is used as an indication of the propen-

Woven Fabrics Using a Standard Seam

sity of yarns to shift or distort in a fabric. Such distortions are

D 1776 Practice for Conditioning Textiles for Testing

objectionable due to the resulting changes in appearance.

2.2 Federal Standard:

These appearance changes are sometimes referred to as “finger

Federal Test Method Standard 191–Method 5410 Slippage

marks” or “shift marks.”

Resistance of Yarns in Cloth, Yarn Distortion Method

5.4 It is recommended that fabrics be tested in their original

condition and also after laundering or drycleaning, or both,

3. Terminology

depending upon the intended use of the material.

3.1 Definitions—For definitions of terms used in this test

6. Apparatus

method, refer to Terminology D 123.

3.2 Definitions of Terms Specific to This Standard:

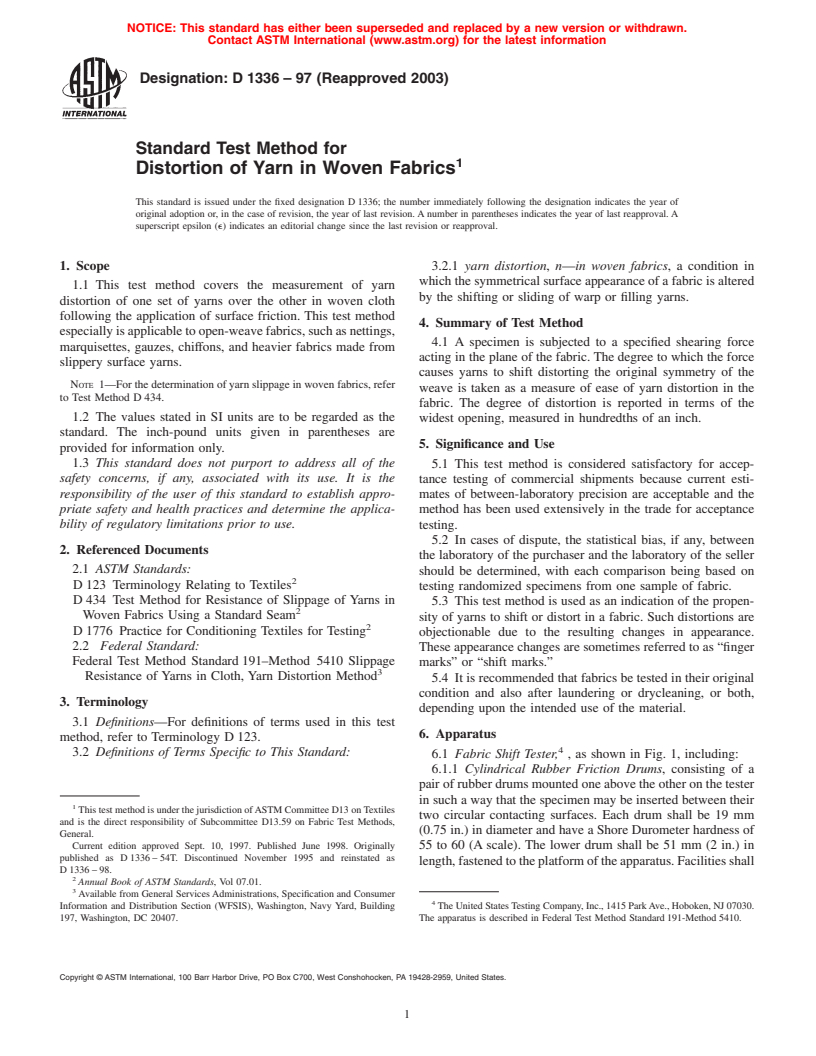

6.1 Fabric Shift Tester, , as shown in Fig. 1, including:

6.1.1 Cylindrical Rubber Friction Drums, consisting of a

pair of rubber drums mounted one above the other on the tester

in such a way that the specimen may be inserted between their

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

two circular contacting surfaces. Each drum shall be 19 mm

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

(0.75 in.) in diameter and have a Shore Durometer hardness of

General.

Current edition approved Sept. 10, 1997. Published June 1998. Originally

55 to 60 (A scale). The lower drum shall be 51 mm (2 in.) in

published as D 1336 – 54T. Discontinued November 1995 and reinstated as

length,fastenedtotheplatformoftheapparatus.Facilitiesshall

D 1336 – 98.

Annual Book of ASTM Standards, Vol 07.01.

Available from General ServicesAdministrations, Specification and Consumer

Information and Distribution Section (WFSIS), Washington, Navy Yard, Building The United StatesTesting Company, Inc., 1415 ParkAve., Hoboken, NJ 07030.

197, Washington, DC 20407. The apparatus is described in Federal Test Method Standard 191-Method 5410.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

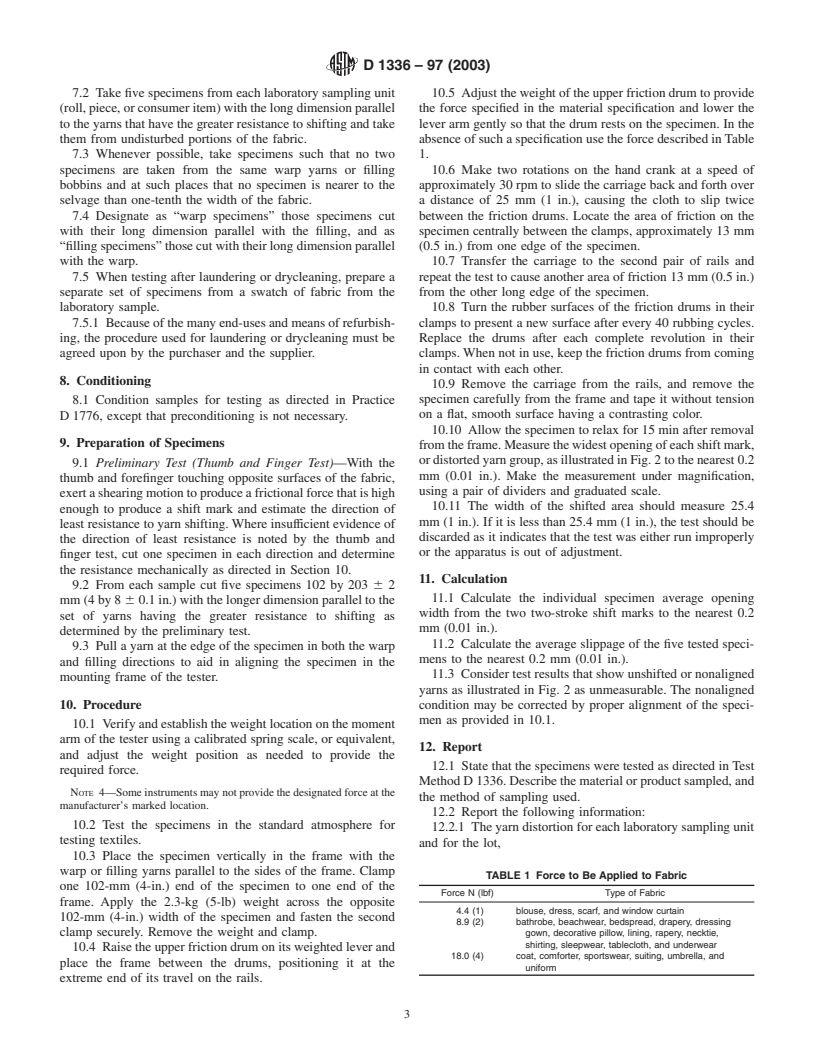

D1336–97 (2003)

FIG. 1 Fabric Shift Tester

be provided for rotation of the drums in the mounting frame 6.1.4 Rails,twosets,fixedandspacedontheplatformofthe

betweentests.Theupperdrumshallbe25mm(1in.)inlength, tester, for supporting the carriage.

have the same provisions for rotation as the lower one, and

6.2 Jig, for mounting the specimen in the frame under

shall be so mounted that a total force of 4.5 to 18 N (1 to 4 lbf)

tension of 22.2 6 0.22 N (5 6 0.05 lbf). A suitable device

can be exerted upon the specimen by means of a lever arm and

consists of a clamp and weight (Fig. 1) having a total mass of

movable weight.

2.3 kg (5 lb).

NOTE 2—The term “weight” is used temporarily in this test method 6.3 Steel Scale, graduated in a 0.2 mm (0.01 in.).

becauseofestablishedtradeusage.Thewordweightisusedtomeanboth“

6.4 Dividers.

force” and “mass,” and care must be taken to determine which is meant in

6.5 Magnifying Device,53 power.

each case (SI unit for force = newton and for mass = kilogram).

6.1.2 Mounting Frame or Bracket, designed to hold the

7. Sampling, Selection and Number of Specimens

specimen under uniform tension. The frame shall consist of a

rectangle whose inside dimensions are 102 by 153 mm (4 by 6 7.1 Take a lot sample and a laboratory sample as directed in

in.). The 153-mm (4-in.) sides shall be rectangular screw the applicable material specification or as agreed upon by the

clamps 10 mm (0.375 in.) wide, with the gripping surfaces purchaser and the supplier. In the absence of such a specifica-

suitably grooved, taped, or otherwise designed or modified to

tionoragreement,takeonerepresentativesamplefromeachlot

minimize slipping of the specimen in the clamps during the of rolls, pieces, or consumer items.

test. The frame, when placed in the test position on the rails,

NOTE 3—A realistic specification or other agreement between the

shall be free to slide as a carriage in a plane perpendicular to

purchaser and the supplier requires taking into account the variability

the plane of the areas of the friction drums.

between primary sampling units and within primary sampling units so as

6.1.3 Hand-Crank Arrangement, for 25 mm (1 in.) recipro-

to provide a sampling plan, which has a meaningful producer’s risk,

cating motion of the carriage. This device, or reciprocating

consumer’s risk, acceptable quality level, and limiting quality level.Alot

arm, shall have a cam attachment that lifts the upper drum in

sample normally consists of a very small fraction of the total primary

the return motion. sampling units.

D1336–97 (2003)

7.2 Take five specimens from each laboratory sampling unit 10.5 Adjust the weight of the upper friction drum to provide

(roll,piece,orconsumeritem)withthelongdimensionparallel the force specified in the material specification and lower the

to the yarns that have the greater resistance to shifting and take lever arm gently so that the drum rests on the specimen. In the

them from undisturbed portions of the fabric. absence of such a specification use the force described inTable

7.3 Whenever possible, take specimens such that no two 1.

specimens are taken from the same warp yarns or filling 10.6 Make two rotations on the hand crank at a speed of

bobbins and at such places that no specimen is nearer to the approximately 30 rpm to slide the carriage back and forth over

selvage than one-tenth the width of the fabric. a distance of 25 mm (1 in.), causing the cloth to slip twice

7.4 Designate as “warp specimens” those specimens cut between the friction drums. Locate the area of friction on the

with their long dimension parallel with the filling, and as specimen centrally between the clamps, approximately 13 mm

“fillingspecimens”thosecutwiththeirlongdimensionparallel (0.5 in.) from one edge of the specimen.

with the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.