ASTM F897-84(1997)e1

(Test Method)Standard Test Method for Measuring Fretting Corrosion of Osteosynthesis Plates and Screws

Standard Test Method for Measuring Fretting Corrosion of Osteosynthesis Plates and Screws

SCOPE

1.1 This test method provides a screening test for determining the amount of metal loss from plates and screws used for osteosynthesis (internal fixation of broken bones) due to fretting corrosion in the contact area between the screw head and the plate hole countersink area. The implants are used in the form they would be used clinically. The machine described generates a relative motion between plates and screws which simulates one type of motion pattern that can occur when these devices are used clinically.

1.2 Since the environmental and stress conditions used in this test may not be identical to those experienced by bone plates in the human body, this test may produce fretting corrosion rates that are lower or higher than those experienced in practice. The recommended axial load of 400 N was selected as being in a range where the amount of fretting corrosion is not sensitive to small changes in axial load (1). The combination of the recommended load and angular displacement are such that a measurable amount of fretting corrosion of surgical alloys occurs in a comparatively short period of time (7 to 14 days). (1-3)

1.3 The device is designed so as to facilitate sterilization of the test specimens and test chambers to permit testing with proteinaceous solutions that would become contaminated with microbial growth in nonsterile conditions.

1.4 The specimens used can be standard osteosynthesis implants or can be materials fabricated into the appropriate shapes.

1.5 This test method may be used for testing the fretting corrosion of metal plates and screws of similar or different alloy compositions, or it may be used for testing the fretting corrosion of metal-nonmetal combinations. This test method may also be used for wear or degradation studies of nonmetallic materials. This test may be used as a screening test to rank the corrosivities of saline or proteinaceous solutions, or to rank metal-to-metal couples for resistance to fretting corrosion, or to study other material combinations.

1.6 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

e1

Designation: F 897 – 84 (Reapproved 1997)

Standard Test Method for

Measuring Fretting Corrosion of Osteosynthesis Plates and

Screws

This standard is issued under the fixed designation F 897; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Sections 2.1, 4.3, and 7.1.2 were corrected editorially in October 2002.

1. Scope rank metal-to-metal couples for resistance to fretting corrosion,

or to study other material combinations.

1.1 This test method provides a screening test for determin-

1.6 This standard may involve hazardous materials, opera-

ing the amount of metal loss from plates and screws used for

tions, and equipment. This standard does not purport to

osteosynthesis (internal fixation of broken bones) due to

address all of the safety concerns associated with its use. It is

fretting corrosion in the contact area between the screw head

the responsibility of whoever uses this standard to consult and

and the plate hole countersink area. The implants are used in

establish appropriate safety and health practices and deter-

the form they would be used clinically. The machine described

mine the applicability of regulatory limitations prior to use.

generates a relative motion between plates and screws which

simulates one type of motion pattern that can occur when these

2. Referenced Documents

devices are used clinically.

2.1 ASTM Standards:

1.2 Since the environmental and stress conditions used in

D 1886 Test Methods for Nickel in Water

this test may not be identical to those experienced by bone

F 86 Practice for Surface Preparation and Marking of Me-

plates in the human body, this test may produce fretting

tallic Surgical Implants

corrosion rates that are lower or higher than those experienced

F 382 Specification and Test Method for Metallic Bone

in practice. The recommended axial load of 400 N was selected

Plates

as being in a range where the amount of fretting corrosion is

F 543 Specification for Cortical Bone Screws

not sensitive to small changes in axial load (1). The combi-

G 1 Practice for Preparing, Cleaning, and Evaluating Cor-

nation of the recommended load and angular displacement are

rosion Test Specimens

such that a measurable amount of fretting corrosion of surgical

alloys occurs in a comparatively short period of time (7 to 14

3. Summary of Test Method

days). (1-3)

3.1 A two-hole plate is attached to two plastic rods with

1.3 The device is designed so as to facilitate sterilization of

bone screws, with flexible spacers between the plate and the

the test specimens and test chambers to permit testing with

rods, placed in a glass beaker, and the beaker sealed with a

proteinaceous solutions that would become contaminated with

flexible rubber cover. This assembly is steam sterilized, and

microbial growth in nonsterile conditions.

then a sterile solution is injected through the rubber cover into

1.4 The specimens used can be standard osteosynthesis

the beaker. This assembly is then mounted in the fretting

implants or can be materials fabricated into the appropriate

apparatus which, when set in motion, produces a rocking

shapes.

motion and, therefore, a small cyclic displacement between the

1.5 This test method may be used for testing the fretting

mating surfaces of the plate and screws. The amount of fretting

corrosion of metal plates and screws of similar or different

corrosion is determined at the end of the test by measurement

alloy compositions, or it may be used for testing the fretting

of the weight loss of the plates and screws and by chemical

corrosion of metal-nonmetal combinations. This test method

analysis of the solutions.

may also be used for wear or degradation studies of nonme-

tallic materials. This test may be used as a screening test to

4. Significance and Use

rank the corrosivities of saline or proteinaceous solutions, or to

4.1 It is well known from examination of implants after use

that plates and screws used for osteosynthesis are subjected to

This test method is under the jurisdiction of ASTM Committee F04 on Medical metal loss due to corrosion at the plate-screw interfaces. One of

and Surgical Materials and Devicesand is the direct responsibility of Subcommittee

F04.15 on Material Test Methods.

Current edition approved Sept. 28, 1984. Published February 1985. Annual Book of ASTM Standards, Vol 11.01.

2 4

The boldface numbers in parentheses refer to the list of references at the end Annual Book of ASTM Standards, Vol 13.01.

of this standard. Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

F 897 – 84 (1997)

the mechanisms of this corrosive attack is fretting corrosion (250 6 4°F), and equipped with a thermometer, pressure gage,

due to relative motion (micromotion) between the screw heads vent cock, and a rack to hold the test assemblies above the

and plate-hole countersinks. water level.

4.2 It is also known that release of corrosion products into

5.2 Microbalance, with a 0.01-mg scale.

the tissues surrounding an implant may have adverse effects on 5.3 Fretting Apparatus, as described in 5.3.1-5.3.4 and

local tissue or have systemic effects. Thus, it is important to

illustrated in Fig. 1.

minimize the amount of tissue exposure to corrosion products. 5.3.1 The fretting apparatus is driven by a slow speed gear

4.3 Screws and plates are available in different configura-

motor connected to a horizontal rotating shaft. Round disks

tions in accordance with Specifications F 543 and F 382. This with machined flats (cams) are mounted on the shaft as shown

test method may be used to evaluate the effects of different

in Fig. 1. For multiple specimen testing, there may be more

combinations of screw and plate designs. As new materials and than one cam on the drive shaft.

device designs are developed for use in the treatment of

5.3.2 The flats on the cams are machined so as to produce 2°

fractured bones, it is important to determine the effects these of relative motion between the posts of the test assemblies.

developments have on the amount of metal loss due to fretting

NOTE 1—A suggested combination of short post length and plunger

corrosion.

displacement is a 5-cm post with a 1.9-mm displacement.

4.4 This test method provides a standardized screening test

5.3.3 The shaft rotation rate and the number of machined

for ranking metal plates and screws in terms of resistance to

flats shall be such that the flats produce one oscillation of the

fretting corrosion and for determining the influence of different

plunger per second.

solutions on fretting corrosion rates.

5.3.4 Test assembly holding and driving frames are mounted

4.5 This test method may also be used to generate corrosion

symmetrically on each side of the rotating cams. The oscillat-

products either for chemical analysis of the products or for

ing plunger is springloaded and held in the guide sleeve. The

testing for biological reactions to corrosion products using

hole in the top plate is slotted to permit adjustment of the

animal or cell culture methods.

position of the test assemblies.

4.6 It is well known that fretting corrosion rates depend on

5.4 Test Assemblies, consisting of two plastic rods, and two

normal load or pressure, frequency, sliding amplitude, materi-

flexible spacers, the two-hole plate, two bone screws, one

als, surface treatments, and environmental factors. (4) There-

beaker, and the rubber cover.

fore, when determining the effect of changing one of these

5.4.1 The longer rod is threaded at one end to mate with a

parameters (for example, material or environment), all others

mounting screw, while the other end is threaded to mate with

must be kept constant to facilitate interpretation of the results.

the bone screw.

5. Apparatus

5.4.2 The shorter rod has a reduced diameter at one end to

5.1 Steam Autoclave, capable of maintaining 121 6 2°C mate with the oscillating horizontal plunger, while the other

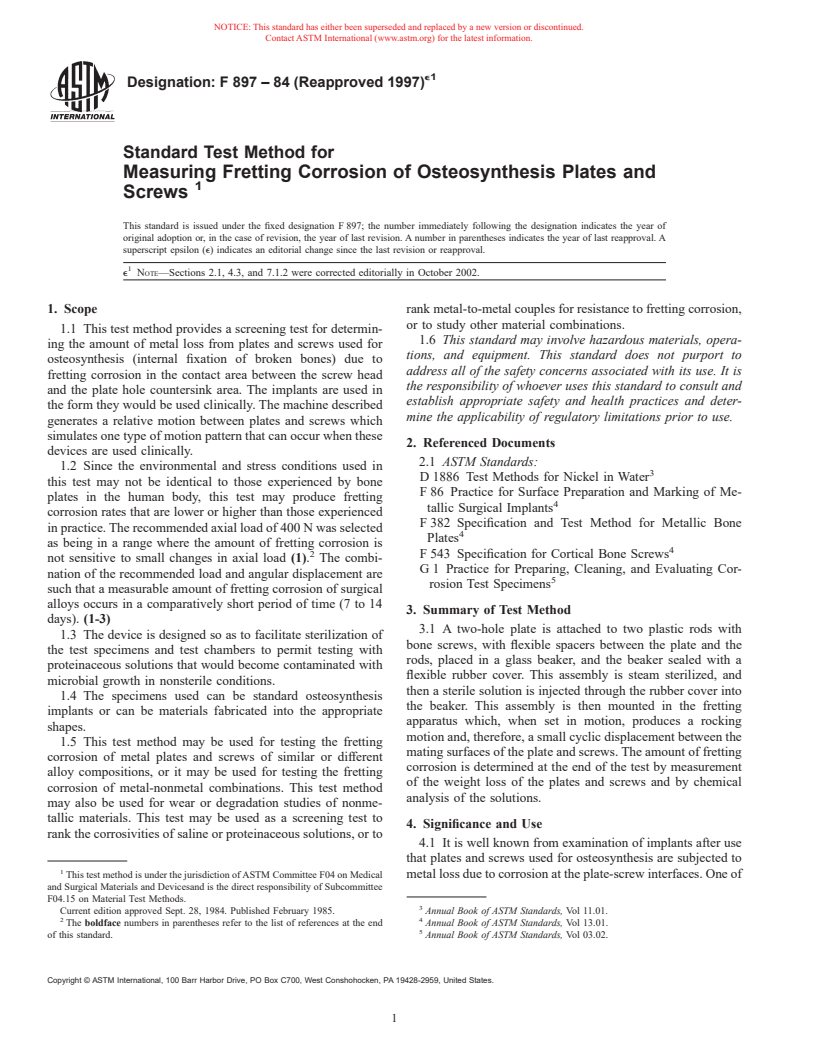

NOTE 1—Figure shows assembly drawings of one pair of test positions on each side of a cam, and of the relationships between the screws, plate,

spacers, and polyacetal rods.

FIG. 1 Two-Hole Plate Fretting (THPF) Testing System

e1

F 897 – 84 (1997)

able bone screws. Heads should be spherical, although other

shapes may be used.

7.2.2 Screws may be fabricated from rod stock in accor-

dance with Specification F 543.

7.3 Test specimens may be used in the condition as received

from the implant manufacturer; custom fabricated specimens

should be prepared in accordance with Practice F 86.

8. Procedure

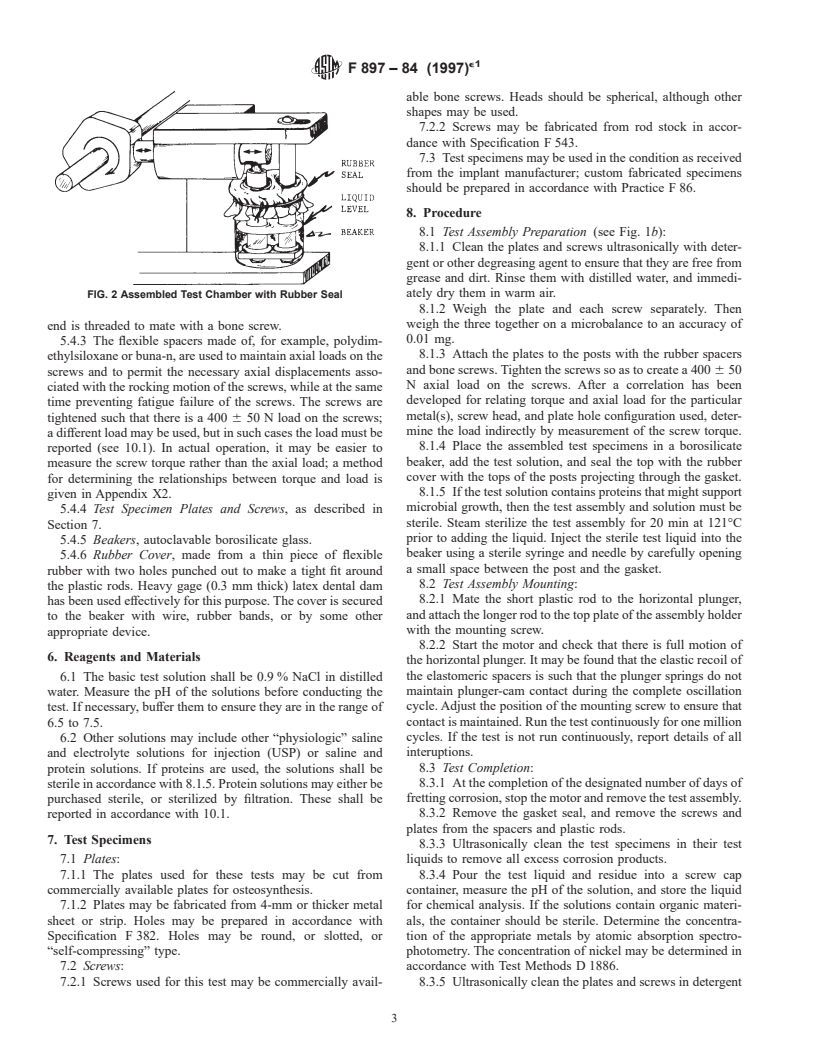

8.1 Test Assembly Preparation (see Fig. 1b):

8.1.1 Clean the plates and screws ultrasonically with deter-

gent or other degreasing agent to ensure that they are free from

grease and dirt. Rinse them with distilled water, and immedi-

ately dry them in warm air.

FIG. 2 Assembled Test Chamber with Rubber Seal

8.1.2 Weigh the plate and each screw separately. Then

weigh the three together on a microbalance to an accuracy of

end is threaded to mate with a bone screw.

0.01 mg.

5.4.3 The flexible spacers made of, for example, polydim-

8.1.3 Attach the plates to the posts with the rubber spacers

ethylsiloxane or buna-n, are used to maintain axial loads on the

and bone screws. Tighten the screws so as to create a 400 6 50

screws and to permit the necessary axial displacements asso-

N axial load on the screws. After a correlation has been

ciated with the rocking motion of the screws, while at the same

developed for relating torque and axial load for the particular

time preventing fatigue failure of the screws. The screws are

metal(s), screw head, and plate hole configuration used, deter-

tightened such that there is a 400 6 50 N load on the screws;

mine the load indirectly by measurement of the screw torque.

a different load may be used, but in such cases the load must be

8.1.4 Place the assembled test specimens in a borosilicate

reported (see 10.1). In actual operation, it may be easier to

beaker, add the test solution, and seal the top with the rubber

measure the screw torque rather than the axial load; a method

cover with the tops of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.