ASTM E2242-02

(Test Method)Standard Test Method for Column Percolation Extraction of Mine Rock by the Meteoric Water Mobility Procedure

Standard Test Method for Column Percolation Extraction of Mine Rock by the Meteoric Water Mobility Procedure

SCOPE

1.1 This test method provides a procedure for the column percolation extraction of mine rock in order to determine the potential for dissolution and mobility of certain constituents by meteoric water.

1.2 This test method is intended to describe the procedure for performing column percolation extractions only. It does not describe all types of sampling and analytical requirements that may be associated with its application.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2242–02

Standard Test Method for

Column Percolation Extraction of Mine Rock by the

Meteoric Water Mobility Procedure

This standard is issued under the fixed designation E 2242; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 877 Practice for Sampling and Analysis of Iron Ores and

Related Materials

1.1 This test method provides a procedure for the column

E 882 Guide for Accountability and Quality Control in the

percolation extraction of mine rock in order to determine the

Chemical Analysis Laboratory

potential for dissolution and mobility of certain constituents by

E 1601 Practice for Conducting an Interlaboratory Study to

meteoric water.

Evaluate the Performance of an Analytical Method

1.2 This test method is intended to describe the procedure

2.2 Other References:

for performing column percolation extractions only. It does not

Meteoric Water Mobility Procedure, Bureau of Mining

describe all types of sampling and analytical requirements that

Regulation and Reclamation, Nevada Division of Envi-

may be associated with its application.

ronmental Protection, 9/19/90

1.3 The values stated in SI units are to be regarded as the

Standard Methods for the Examination of Water and

standard.

Wastewater, 18th edition, APHA/AWWA/WEF, 1992

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions—For definitions of terms used in this test

priate safety and health practices and determine the applica-

method, see Terminology E 135.

bility of regulatory limitations prior to use.

3.1.1 meteoric water—rainfall that has the potential to

2. Referenced Documents contact materials and mobilize soluble constituents from mine

rock at a mining or mineral processing site.

2.1 ASTM Standards:

3.1.2 mine rock—ore, waste rock or overburden excavated

D 1193 Specification for Reagent Water

inordertorecovermetalsormineralsduringminingoperations

D 1293 Test Methods for pH of Water

or coarse processed ore such as heap leach spoils.

D 6234 Test Method for Shake Extraction of Mining Waste

by the Synthetic Precipitation Leaching Procedure

4. Summary of Test Method

E 50 Practices for Apparatus, Reagents, and Safety Precau-

4.1 The test material is placed in a plastic column and

tions for Chemical Analysis of Metals

contacted with an equal weight of water during a 24 h leaching

E 135 Terminology Relating to Analytical Chemistry for

period. The extract is collected and preserved for analysis of

Metals, Ores and Related Materials

inorganic constituents.

E 389 Method for Particle Size or ScreenAnalysis at No. 4

(4.75-mm) Sieve and Coarser for Metal-Bearing Ores and

5. Significance and Use

Related Materials

5.1 This test method is intended as a means for obtaining an

E 691 Practice for Conducting an Interlaboratory to Deter-

extract from mine rock samples. The extract may be used to

mine the Precision of a Test Method

estimate the final pH and release of certain constituents of the

test sample under the laboratory conditions described in this

test method.

This test method is under the jurisdiction of ASTM Committee E01 on

5.2 The pH of the extraction fluid used in this test method

Analytical Chemistry of Metals, Ores and Related Materials and is the direct

should reflect the pH of precipitation in the geographic region

responsibility of Subcommittee E01.02 on Ores, Concentrates, and Related Metal-

in which the mine rock is being evaluated.

lurgical Materials.

Current edition approved Oct. 10, 2002. Published July 2003.

5.3 This test method is designed to mobilize potential

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contaminants present in the solids, so that the resulting extract

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

can be used to assess leachate that could potentially be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. produced from mine rock in the field.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2242–02

5.4 This test method has not been demonstrated to simulate 7.9 Water Metering Device, a metering pump or constant

actual site leaching conditions. head device to insure constant rate extraction fluid application

5.5 This test method produces extracts that are amenable to during column percolation.

the determination of both major and minor (trace) constituents.

8. Reagents and Materials

When minor constituents are being determined, it is especially

important that precautions be taken in sample preservation, 8.1 Purity of Reagents—Reagent grade chemicals shall be

storage and handling to avoid possible contamination of the

used in all tests. Unless otherwise indicated, it is intended that

extracts. all reagents shall conform to the specifications of the Commit-

5.6 This test method is a comparative method intended for tee onAnalytical Reagents of theAmerican Chemical Society,

use as a routine method for monitoring mine rock. It is where such specifications are available. Other grades may be

assumed that all who use this method will be trained analysts

used, provided it is first ascertained that the reagent is of

capable of performing skillfully and safely. It is expected that sufficiently high purity to permit its use without lessening the

work will be performed in a properly equipped laboratory

accuracy of the determination.

under appropriate quality control practices such as those 8.2 Purity of Water—Unless otherwise indicated, references

described in Guide E 882.

to water shall be understood to mean Type II reagent water at

18 to 27°C conforming to Specification D 1193.

6. Interferences

9. Hazards

6.1 This test method may not be suitable for obtaining

9.1 For precautions to be observed in the use of analytical

extracts from finely divided solids (such as: finely crushed drill

methods associated with this standard, refer to Practices E 50.

cuttings, clays, sludges, mill tailings, etc.), due to difficulty in

obtainingarepresentativeextractsolution.Ifittakesmorethan

10. Sampling and Sample Preparation

48 h for the column to produce an extract which has a mass

10.1 Theamountofgrosssampletobesenttothelaboratory

equivalent to 70 % of the dry test sample weight, use of an

shouldhesufficienttoperformthesolidscontentdetermination

alternate extraction procedure may be required, such as

as specified in 10.3, and to provide at least 5 kg of test sample

Method D 6234.

on a dry weight basis for extraction. Gross sample weights in

the range of 7 to 25 kg are appropriate.

7. Apparatus

NOTE 1—Information on obtaining representative samples can also be

7.1 Drying Pans or Dishes, for moisture content determina-

found in Pierre Gy’s Sampling Theory and Sampling Practice and in

tions, 1 kg capacity.

Practice E 877.

7.2 Extraction Column, PVC column of 15-cm (6-in.) O.D.

10.2 In order to prevent sample contamination or constitu-

ofsufficientheighttocontainaminimumof5kgoftestsample

withafeedparticlesizethatjustpassesa5-cm(2-in.)sieveand ent loss prior to extraction, keep the samples in closed

sufficient additional height to contain applied water volume containers appropriate to sample type and desired analysis.

10.3 Moisture Determination—Remove the gross sample

should poor percolation occur. Fora5kg test sample, a 15 cm

O.D. 3 45 cm high column is recommended. Additional from the container and blend by coning or rolling to obtain a

sample for feed moisture content with a minimum of 500 g dry

column height will be required for test sample quantities

greaterthan5kg.Thebottomofthecolumnmustbesealedand weight.

10.3.1 Weigh the moisture test sample and dry to constant

a solution discharge outlet situated above the sealed bottom of

the column and below a perforated support plate.Adrawing of weight (6 0.05 %) at 105 6 2°C and record the weight.

10.3.2 Calculate the moisture content of the test sample as

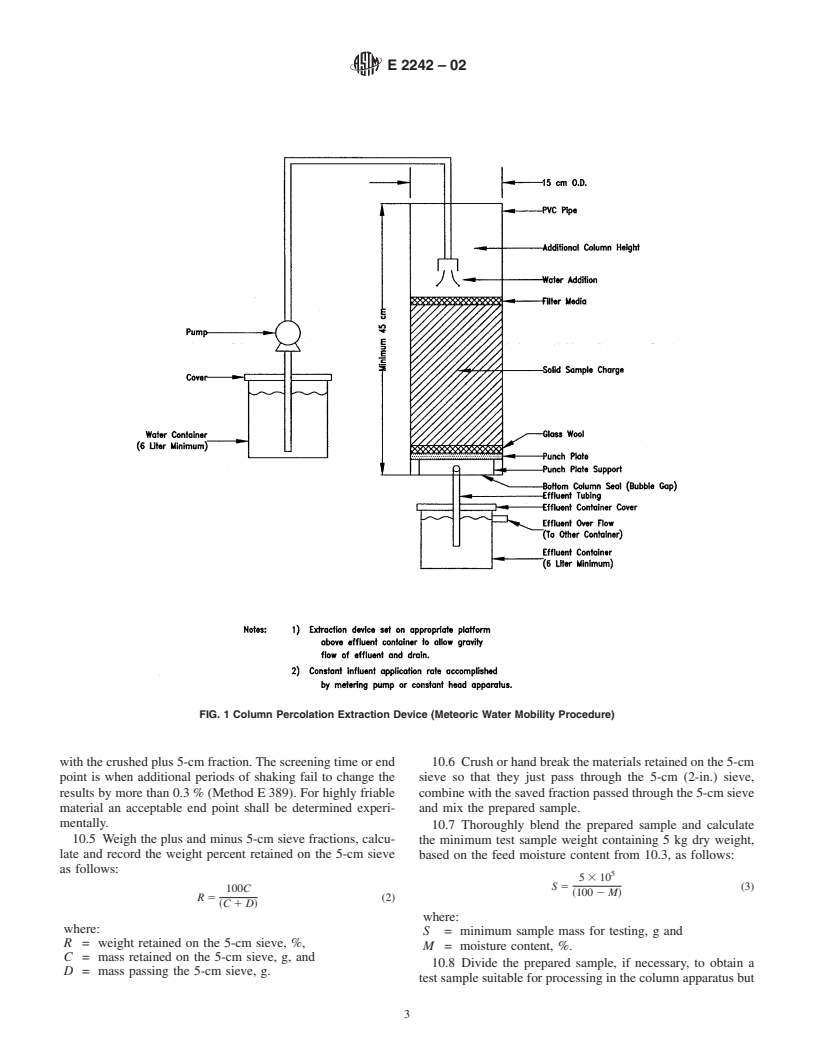

a suitable extraction column is shown in Fig. 1.

follows:

7.3 Filtration Device, of a composition suitable to the

nature of the analyses to be performed and equipped with a

100~B 2 A!

M 5 (1)

0.45 µm pore size filter. An assembly for pre-filtration or a

B

centrifuge may be required if 0.45 µm filtration is difficult.

where:

7.4 Filter Media, glass wool (inert) or a plastic fiber pad is

A = mass of sample after drying, g,

placed onto the support plate before loading the laboratory

B = wet mass of sample, g, and

sample into the column, to minimize fines migration, and onto

M = moisture content, %.

the top of the test sample after column loading, to aid in

10.4 Separate the remaining laboratory sample on a 5-cm

making an even water distribution.

(2-in.) sieve. Save the minus 5-cm fraction for recombination

7.5 Laboratory Balance, capable of weighing to 1.0 g.

7.6 pH Meter, with a readability of 0.01 units and an

accuracy of at least 60.05 units at 25°C.

Reagent Chemicals, American Chemical Society Specifications, American

7.7 Tubing, surgical or synthetic tubing sufficient in diam-

Chemical Society, Washington. DC. For suggestions on the testing of reagents not

eter and length for the extraction column assembly (pump,

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

column outlet).

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

7.8 Water and Extract Containers, sufficient in size to

MD.

contain the water added during extraction. Containers must be

Pitard, F., Pierre Gy’s Sampling Theory and Sampling Practice, Vols. I and II,

covered to avoid contamination. CRC Press, 1989.

E2242–02

FIG. 1 Column Percolation Extraction Device (Meteoric Water Mobility Procedure)

with the crushed plus 5-cm fraction. The screening time or end 10.6 Crush or hand break the materials retained on the 5-cm

point is when additional periods of shaking fail to change the sieve so that they just pass through the 5-cm (2-in.) sieve,

results by more than 0.3 % (Method E 389). For highly friable combine with the saved fraction passed through the 5-cm sieve

material an acceptable end point shall be determined experi- and mix the prepared sample.

mentally.

10.7 Thoroughly blend the prepared sample and calculate

10.5 Weigh the plus and minus 5-cm sieve fractions, calcu-

the minimum test sample weight containing 5 kg dry weight,

late and record the weight percent retained on the 5-cm sieve

based on the feed moisture content from 10.3, as follows:

as follows:

5 3 10

S 5 (3)

100C

~100 2 M!

R 5 (2)

~C 1 D!

where:

where:

S = minimum sample mass for testing, g and

R = weight retained on the 5-cm sieve, %,

M = moisture content, %.

C = mass retained on the 5-cm sieve, g, and

10.8 Divide the prepared sample, if necessary, to obtain a

D = mass passing the 5-cm sieve, g.

test sample suitable for processing in the column apparatus but

E2242–02

notlessthantheminimumsampleweightfrom10.7.andweigh some difficult to filter effluents. Immediately measure and

to 61g.Labelandreserveanyexcesspreparedsampleforany record the final pH of the extract in accordance with Test

additional testing which may be required. Methods D 1293. Record the final effluent and extract weights.

10.9 Calculate the dry weight of the test sample as follows: 11.8.1 Retain a 250-mL portion of the extract for metals

analysis with its pH adjusted to less than 2 with nitric acid.

E~100 2 M!

L 5 (4)

11.8.2 Retain a 250-mL portion of the extract for nutrients

analysis with its pH adjusted to less than 2 with sulfuric acid.

where:

11.8.3 Retain a 1-L portion of the extract for cyanide

L = dry mass of the test sample, g,

analysis with its pH adjusted to between 12 and 12.5 with

E = gross mass of the test sample, g, and

sodium hydroxide. Store in a dark bottle at 4 6 2°C, if the

M = moisture content of the gross sample, %.

cyanide analysis is not performed immediately.

11.8.4 Refrigerate the remaining extract at 4 6 2°C for

11. Procedure

mineral analyses.

11.1 Place filter media (7.4) in the bottom of the extraction 11.9 Analyze the unfiltered effluent for specific constituents

column and load the laboratory sample incrementally (~1-kg/ or properties, or use for biological testing procedures as

necessary.

increment) into the column. To minimize particle segregation

and compaction during column loading, the sample portions 11.10 Analyses should be performed using appropriate

ASTM test methods. Where no appropriate ASTM test meth-

shall be dropped from no more than 0.6 m (24 in.) when

introduced from the top of the column, and no tamping, ods exist, other test methods may be used, such as Standard

Methods for the Examination of Water and Wastewater, and

shaking, or other methods to compact the sample will be

employed. Place filter media over the test sample in the record the methods used in the report. Whether visible phase

separation during storage of the extract or effluent occurs or

column.

11.2 Use a water addition rate of 3.5 mL/min for minimum not, appropriate mixing should be used to ensure the homoge-

neity of the extract and effluent prior to their use in such

weight samples in the range of 5 to 5.5 kg dry weight.

11.2.1 For samples greater than 5.5 kg dry weight, calculate analyses or testing.

11.11 Allow the remaining column effluent to drain until at

the rate of water addition to the column to pass a weight of

water equal to the dry weight of the test sample during the 24 least two minutes elapses between drops of effluent from the

test column. There should be no apparent free water phase in

h test period as follows:

the column at the end of the draining period. Record any visual

L

F 5 (5)

changes in the column residue, extract or effluent which

occurred during the test period.

where:

11.12 Remove the test residue from the column and blend

F = water addition rate, mL/min, and

by coning or rolling and obtain a sample of at least 500 g for

L = dry mass of the laboratory sample, g.

residual moisture content. Determine the residual moisture as

11.3 Measure and record the initial temperature and pH of

in 10.3 and record the results. Reserve the residue for any

the leaching water in accordance with Test Methods D 1293.

additional testing required.

Record the time and date that water addition

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.