ASTM F1043-10

(Specification)Standard Specification for Strength and Protective Coatings on Steel Industrial Chain Link Fence Framework

Standard Specification for Strength and Protective Coatings on Steel Industrial Chain Link Fence Framework

ABSTRACT

This specification covers the strength and protective coating requirements for industrial steel chain link fence framework. Maximum allowable heights of framework and post spacing are to be based on chain link fence fabric mesh size and gages, and specified wind loads. Coatings shall be classified as: external coatings (Type A, B, and C) and internal coatings (Type A, B, C, and D). Zinc used for coating shall be any grade of zinc conforming to the requirements and shall be applied by the hot-dip method. Strength test, tension test, adhesion test, and cross hatch test shall be performed to meet the specified requirements.

SCOPE

1.1 This specification covers the strength and protective coating requirements for industrial steel fence framework. The intended use is for all types of fence, including but not limited to, chain link, expanded metal, wire mesh both welded and woven, PVC and wood. Consult fencing product manufacturer for post spacing requirements. Post spacings for chain link fence are not to exceed 10 ft. (For additional information, see CLFMI Guide WLG2445.)

1.1.1 Caution Regarding Windload—If additives to the fence, such as windscreen, inserts, or signage are required, it is advisable to use stronger framework and fittings, to reduce the on-center spacing of posts, or to add back bracing. Factors to consider when determining windload include the type of screening material to be used, area of fence to be covered and local wind conditions.

1.2 Posts and rails may have any cross-sectional shape meeting the requirements herein. The shapes may be formed and welded, cold formed, hot rolled, or extruded.

1.3 The values in inch-pound units are to be regarded as the standard. The values stated in SI units are for information purposes only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1043 – 10

Standard Specification for

Strength and Protective Coatings on Steel Industrial Fence

1

Framework

This standard is issued under the fixed designation F1043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A924/A924M Specification for General Requirements for

Steel Sheet, Metallic-Coated by the Hot-Dip Process

1.1 This specification covers the strength and protective

A1011/A1011M Specification for Steel, Sheet and Strip,

coating requirements for industrial steel fence framework. The

Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy,

intended use is for all types of fence, including but not limited

High-Strength Low-Alloy with Improved Formability, and

to, chain link, expanded metal, wire mesh both welded and

Ultra-High Strength

woven, PVC and wood. Consult fencing product manufacturer

B6 Specification for Zinc

for post spacing requirements. Post spacings for chain link

D1499 Practice for Filtered Open-Flame Carbon-Arc Expo-

fence are not to exceed 10 ft. (For additional information, see

sures of Plastics

CLFMI Guide WLG2445.)

D3359 Test Methods for Measuring Adhesion by Tape Test

1.1.1 Caution Regarding Windload—If additives to the

E8 Test Methods for Tension Testing of Metallic Materials

fence, such as windscreen, inserts, or signage are required, it is

E376 Practice for Measuring Coating Thickness by

advisable to use stronger framework and fittings, to reduce the

Magnetic-FieldorEddy-Current(Electromagnetic)Exami-

on-center spacing of posts, or to add back bracing. Factors to

nation Methods

consider when determining windload include the type of

F552 Terminology Relating to Chain Link Fencing

screening material to be used, area of fence to be covered and

F934 Specification for Colors for Polymer-Coated Chain

local wind conditions.

Link Fence Materials

1.2 Posts and rails may have any cross-sectional shape

F1083 Specification for Pipe, Steel, Hot-Dipped Zinc-

meeting the requirements herein. The shapes may be formed

Coated (Galvanized) Welded, for Fence Structures

and welded, cold formed, hot rolled, or extruded.

F1553 Guide for Specifying Chain Link Fence

1.3 The values in inch-pound units are to be regarded as the

G155 PracticeforOperatingXenonArcLightApparatusfor

standard. The values stated in SI units are for information

Exposure of Non-Metallic Materials

purposes only.

2.2 Other Documents:

2. Referenced Documents

WLG2445 CLFMI Guide for the Selection of Line Post

3

2

Spacings

2.1 ASTM Standards:

A90/A90M Test Method for Weight [Mass] of Coating on

3. Terminology

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

3.1 Definitions:

A123/A123M Specification for Zinc (Hot-Dip Galvanized)

3.1.1 posts—vertical members of the fence.

Coatings on Iron and Steel Products

3.1.1.1 Discussion—End, corner, and pull posts are posts at

A653/A653M Specification for Steel Sheet, Zinc-Coated

which fencing material terminates. Gateposts are posts to

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

which gates are either attached or latched. Line posts are posts

by the Hot-Dip Process

that occur in a line of fence in which the fencing material

passes and to which it is secured.

1

This specification is under the jurisdiction ofASTM Committee F14 on Fences

3.1.2 rails—horizontal members of the fence.

and is the direct responsibility of Subcommittee F14.40 on Chain Link Fence and

3.1.2.1 Discussion—May be top, bottom, intermediate or

Wire Accessories.

brace rails.

Current edition approved Nov. 1, 2010. Published December 2010. Originally

approved in 1995. Last previous edition approved in 2008 as F1043 - 08. DOI:

3.1.3 The dimensional terminology is shown in Fig. 1.

10.1520/F1043-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AvailablefromChainLinkFenceManufacturersInstitute,10015OldColumbia

the ASTM website. Road, Suite B-215, Columbia, MD 21046, http://www.chainlinkinfo.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

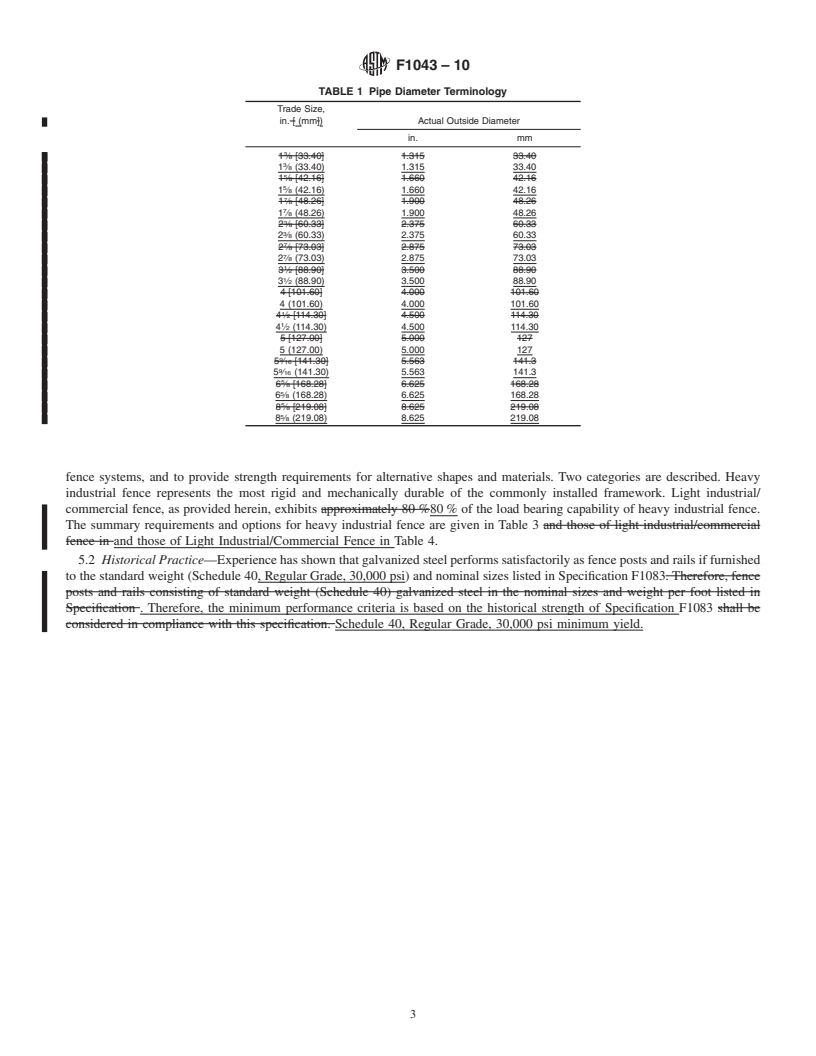

F1043 – 10

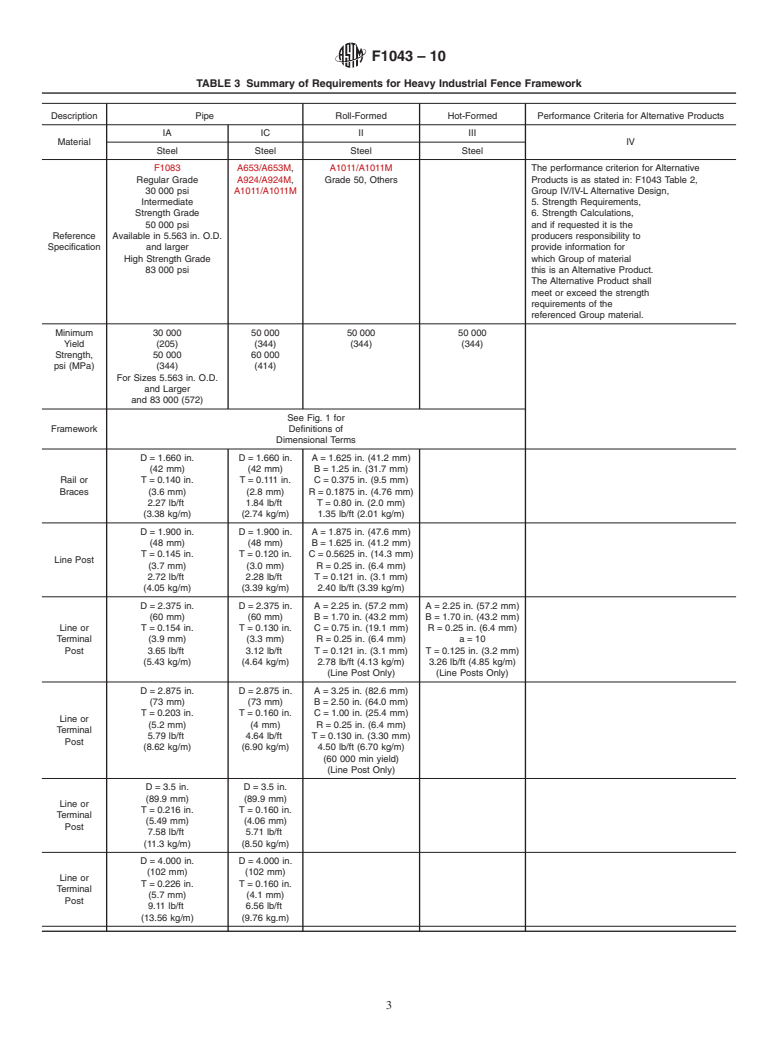

TABLE 2 Definitions of Fence Framework Materials Design

Material Description of Material

Group IA Steel pipe shall be produced to conform to Specification

Round Steel Pipe F1083, standard weight (Schedule 40). Weight shall not

vary more than 10 % 6 from that prescribed.

Group IC/IC-L Steel pipe shall be produced in accordance with

Round Steel

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F1043–08 Designation: F1043 – 10

Standard Specification for

Strength and Protective Coatings on Steel Industrial Chain

1

Link Fence Framework

This standard is issued under the fixed designation F1043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This specification covers the strength and protective coating requirements for industrial steel chain link fence framework.

Maximum allowable heights of framework and post spacing are to be based on chain link fence fabric mesh size and gages, and

specified wind loads. Post spacings are not to exceed 10 ft. (For additional information, see CLFMI Guide WLG2445

1.1 Thisspecificationcoversthestrengthandprotectivecoatingrequirementsforindustrialsteelfenceframework.Theintended

use is for all types of fence, including but not limited to, chain link, expanded metal, wire mesh both welded and woven, PVC and

wood. Consult fencing product manufacturer for post spacing requirements. Post spacings for chain link fence are not to exceed

10 ft. (For additional information, see CLFMI Guide WLG2445.)

1.1.1 Caution Regarding Windload—Ifadditivestothefence,suchaswindscreen,inserts,orsignagearerequired,itisadvisable

to use stronger framework and fittings, to reduce the on-center spacing of posts, or to add back bracing. Factors to consider when

determining windload include the type of screening material to be used, area of fence to be covered and local wind conditions.

1.2 Postsandrailsmayhaveanycross-sectionalshapemeetingtherequirementsherein.Theshapesmaybeformedandwelded,

cold formed, hot rolled, or extruded.

1.3 The values in inch-pound units are to be regarded as the standard.The values stated in SI units are for information purposes

only. Note1—For aluminum-alloy extruded structural pipe and tube please refer to Specification B429/B429M.

2. Referenced Documents

2

2.1 ASTM Standards:

A90/A90M Test Method for Weight [Mass] of Coating on Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

A123/A123M Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products

A653/A653M Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the

Hot-Dip Process

A875/A875MSpecification for Steel Sheet, Zinc-5 % Aluminum Alloy-Coated by the Hot-Dip Process 924/

A924M Specification for General Requirements for Steel Sheet, Metallic-Coated by the Hot-Dip Process

A1011/A1011M Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-

Strength Low-Alloy with Improved Formability, and Ultra-High Strength

B6 Specification for Zinc B429/B429MSpecification for Aluminum-Alloy Extruded Structural Pipe and Tube

B750Specification for GALFAN (Zinc-5 % Aluminum-Mischmetal) Alloy in Ingot Form for Hot-Dip Coatings

D1499 Practice for Filtered Open-Flame Carbon-Arc Exposures of Plastics

D3359 Test Methods for Measuring Adhesion by Tape Test

E8 Test Methods for Tension Testing of Metallic Materials

E376 Practice for Measuring Coating Thickness by Magnetic-Field or Eddy-Current (Electromagnetic) Examination Methods

F552 Terminology Relating to Chain Link Fencing

F934 Specification for Colors for Polymer-Coated Chain Link Fence Materials

F1083 Specification for Pipe, Steel, Hot-Dipped Zinc-Coated (Galvanized) Welded, for Fence Structures

F1553 Guide for Specifying Chain Link Fence

G23Practice for Operating Light-ExposureApparatus (Carbon-Arc Type) With and Without Water for Exposure of Nonmetallic

Materials (Discontinued 2001)

1

This specification is under the jurisdiction ofASTM Committee F14 on Fences and is the direct responsibility of Subcommittee F14.40 on Chain Link Fence and Wire

Accessories.

Current edition approvedAug.Nov. 1, 2008.2010. Published October 2008.December 2010. Originally approved in 1995. Last previous edition approved in 20062008 as

F1043 - 068. DOI: 10.1520/F1043-108.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1043 – 10

G26

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.