ASTM F558-98

(Test Method)Standard Test Method for Measuring Air Performance Characteristics of Vacuum Cleaners

Standard Test Method for Measuring Air Performance Characteristics of Vacuum Cleaners

SCOPE

1.1 This test method covers procedures for determining air performance characteristics of household upright, canister, and combination-type vacuum cleaners having provisions for attaching a hose. This test method does not apply to the carpet cleaning mode of operation.

1.2 These tests and calculations include determination of suction, air flow, air power, maximum air power, and input power under standard conditions.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only. Note 1-For more information on air performance characteristics, see Ref (1) through (6).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. A specific precautionary statement is given in Note 2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 558 – 98

Standard Test Method for

Measuring Air Performance Characteristics of Vacuum

1

Cleaners

This standard is issued under the fixed designation F 558; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers procedures for determining air 3.1 Definitions:

performance characteristics of commercial and household 3.1.1 air power, AP, W, n— in a vacuum cleaner, the net

upright, canister, stick, hand-held, utility, and combination- time rate of work performed by an air stream while expending

type vacuum cleaners having provisions for attaching a hose energy to produce an airflow by a vacuum cleaner under

and incorporating a series universal motor. This test method specified air resistance conditions.

does not apply to the carpet cleaning mode of operation. 3.1.2 automatic bleed valve, n—any device a part of a

1.2 These tests and calculations include determination of vacuum cleaner’s design which automatically introduces an

suction, airflow, air power, maximum air power, and input intentional leak within the vacuum cleaner’s system when

power under standard operating conditions (see Note 1). manufacturer specified conditions are met.

3.1.3 corrected airflow, Q, cfm, n—in a vacuum cleaner, the

NOTE 1—For more information on air performance characteristics, see

volume of air movement per unit of time under standard

2

Refs (1-6).

atmospheric conditions.

1.3 The foot-pound-inch system of units is used in this

3.1.4 input power, W, n—the rate at which electrical energy

standard. The values in parentheses are given for information

is absorbed by a vacuum cleaner.

only.

3.1.5 model, n—the designation of a group of vacuum

1.4 This standard may involve hazardous materials, opera-

cleaners having the same mechanical and electrical construc-

tions, and equipment. This standard does not purport to

tion with only cosmetic or nonfunctional differences.

address all of the safety concerns, if any, associated with its

3.1.6 population, n—the total of all units of a particular

use. It is the responsibility of the user of this standard to

model vacuum cleaner being tested.

establish appropriate safety and health practices and deter-

3.1.7 repeatability limit (r), n—the value below which the

mine the applicability of regulatory limitations prior to use. A

absolute difference between two individual test results obtained

specific precautionary statement is given in Note 2.

under repeatability condition may be expected to occur with a

probability of approximately 0.95 (95 %).

2. Referenced Documents

3.1.8 repeatability standard deviation (S ), n—the standard

r

2.1 ASTM Standards:

deviation of test results obtained under repeatability condi-

3

E 1 Specification for ASTM Thermometers

tions.

4

F 395 Terminology Relating to Vacuum Cleaners

3.1.9 reproducibility limit (R), n—the value below which

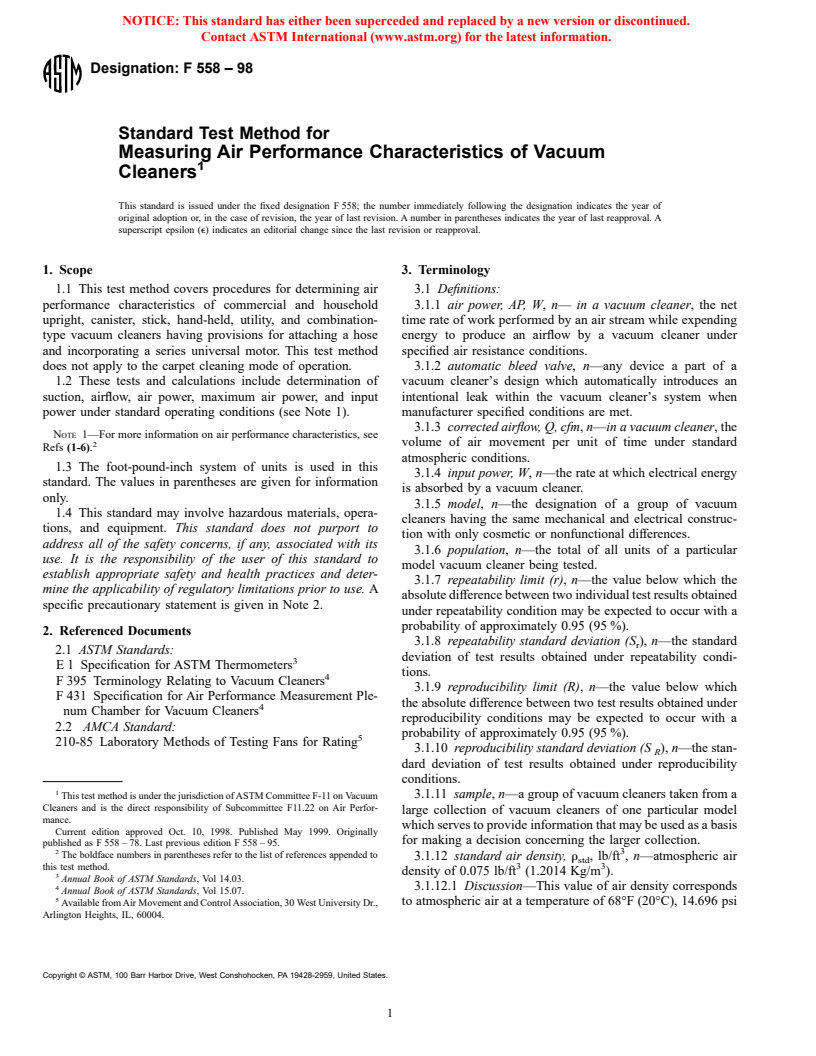

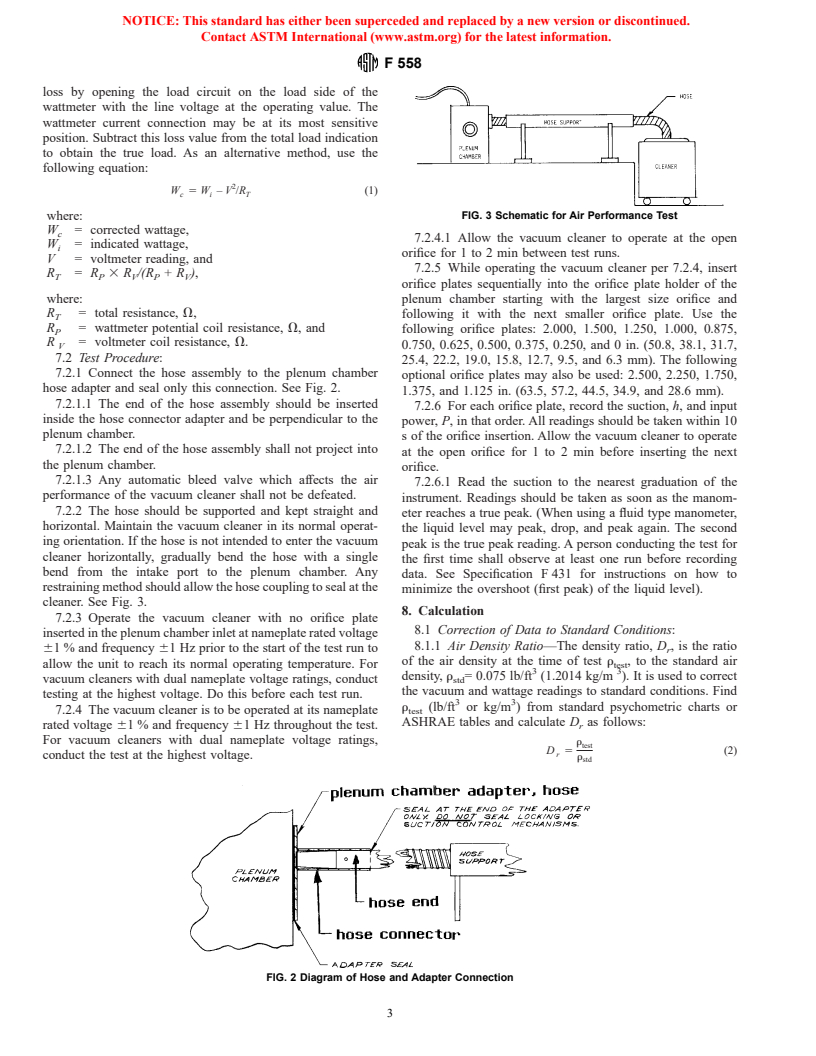

F 431 Specification for Air Performance Measurement Ple-

the absolute difference between two test results obtained under

4

num Chamber for Vacuum Cleaners

reproducibility conditions may be expected to occur with a

2.2 AMCA Standard:

probability of approximately 0.95 (95 %).

5

210-85 Laboratory Methods of Testing Fans for Rating

3.1.10 reproducibility standard deviation (S ), n—the stan-

R

dard deviation of test results obtained under reproducibility

conditions.

1

This test method is under the jurisdiction of ASTM Committee F-11 on Vacuum 3.1.11 sample, n—a group of vacuum cleaners taken from a

Cleaners and is the direct responsibility of Subcommittee F11.22 on Air Perfor-

large collection of vacuum cleaners of one particular model

mance.

which serves to provide information that may be used as a basis

Current edition approved Oct. 10, 1998. Published May 1999. Originally

for making a decision concerning the larger collection.

published as F 558 – 78. Last previous edition F 558 – 95.

2 3

The boldface numbers in parentheses refer to the list of references appended to

3.1.12 standard air density, r , lb/ft , n—atmospheric air

std

3 3

this test method.

density of 0.075 lb/ft (1.2014 Kg/m ).

3

Annual Book of ASTM Standards, Vol 14.03.

4 3.1.12.1 Discussion—This value of air density corresponds

Annual Book of ASTM Standards, Vol 15.07.

5

Available from Air Movement and Control Association, 30 West University Dr., to atmospheric air at a temperature of 68°F (20°C), 14.696 psi

Arlington Heights, IL, 60004.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.