ASTM G13/G13M-21

(Test Method)Standard Test Method for Impact Resistance of Pipeline Coatings(Limestone Drop Test)

Standard Test Method for Impact Resistance of Pipeline Coatings<brk/>(Limestone Drop Test)

SIGNIFICANCE AND USE

4.1 This test method is intended to simulate the effects of backfilling after pipe has been placed in the trench. The backfill is often rocky soil and, if it is unscreened and the coated pipe is unshielded by sand or other protective padding, the falling rocks may seriously damage the coating.

SCOPE

1.1 This test method covers the determination of the relative resistance of pipeline coatings to impact by observing the effects of falling stones on coated pipe specimens.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G13/G13M − 21

Standard Test Method for

Impact Resistance of Pipeline Coatings

1

(Limestone Drop Test)

This standard is issued under the fixed designation G13/G13M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 AASHTO Standard:

M80–51 (No. 67) Specification for Coarse Aggregate for

1.1 This test method covers the determination of the relative

Portland Cement Concrete

resistance of pipeline coatings to impact by observing the

effects of falling stones on coated pipe specimens.

3. Summary of Test Method

1.2 The values stated in either SI units or inch-pound units

3.1 The impact resistance of pipeline coatings is determined

are to be regarded separately as standard. The values stated in

by dropping weighed amounts of a specified type of limestone

each system are not necessarily exact equivalents; therefore, to

through a chute onto a coated pipe specimen. Results are

ensure conformance with the standard, each system shall be

reported as the number of drops required to pierce through the

used independently of the other, and values from the two

coating to bare metal, as determined visually and electrically.

systems shall not be combined.

4. Significance and Use

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 4.1 This test method is intended to simulate the effects of

responsibility of the user of this standard to establish appro- backfillingafterpipehasbeenplacedinthetrench.Thebackfill

priate safety, health, and environmental practices and deter- is often rocky soil and, if it is unscreened and the coated pipe

is unshielded by sand or other protective padding, the falling

mine the applicability of regulatory limitations prior to use.

rocks may seriously damage the coating.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

5. Apparatus

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

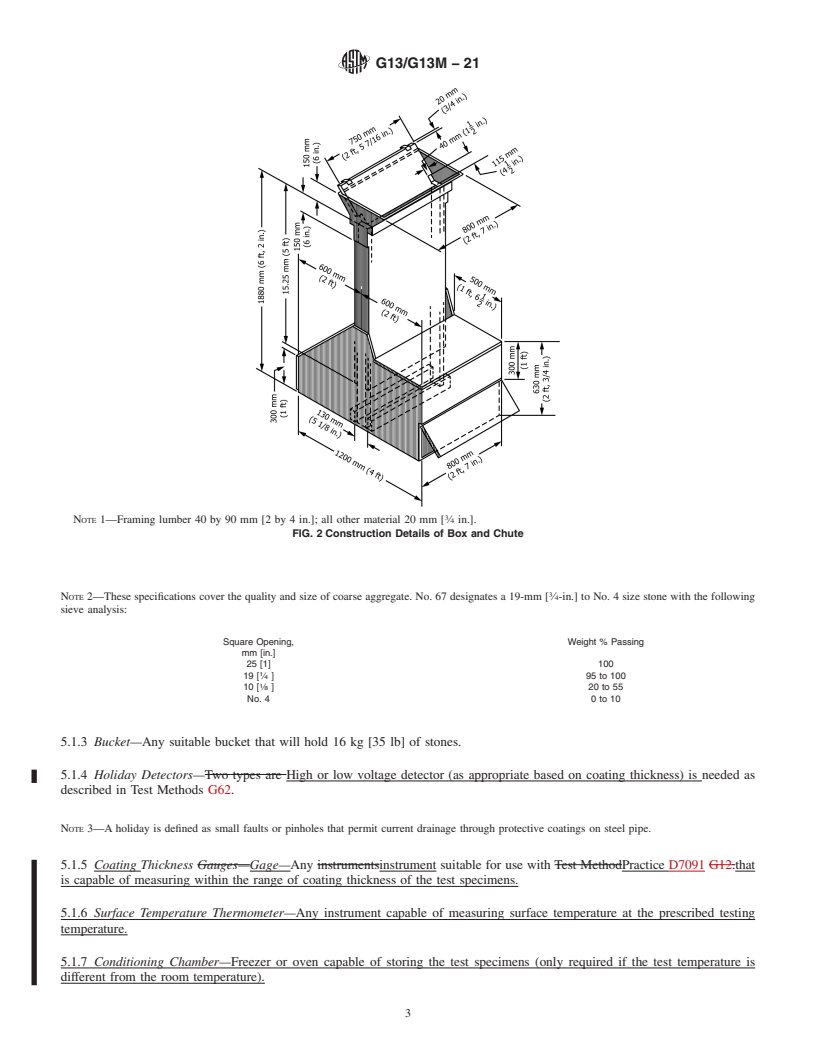

5.1 The impact apparatus shall be essentially as shown in

mendations issued by the World Trade Organization Technical

Fig. 1 and shall include the following:

Barriers to Trade (TBT) Committee.

5.1.1 BoxwithChute, providing a means of dropping stones

from a height of 1830 mm [6.0 ft] measured to the top of a

2. Referenced Documents piece of coated pipe under test. Construction details are shown

in Fig. 2.

2

2.1 ASTM Standards:

NOTE 1—The box and chute described in Fig. 2 are designed for testing

D7091 Practice for Nondestructive Measurement of Dry

coatings on 100-mm [4-in.] and 150-mm [6-in.] pipe specimens. Smaller

Film Thickness of Nonmagnetic Coatings Applied to

diameter pipe may be used by inserting woodV-blocks in the trough in the

Ferrous Metals and Nonmagnetic, Nonconductive Coat-

box below the chute.

ings Applied to Non-Ferrous Metals

5.1.2 Stones, hard, coarse, limestone aggregate, conforming

G62 Test Methods for Holiday Detection in Pipeline Coat-

to AASHTO Designation: M80-51 (No. 67) which is taken

ings

from America Association of State Highway and Transporta-

tion Officials “Standard Specifications for Coarse Aggregate

for Portland Cement Concrete.”

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

NOTE 2—These specifications cover the quality and size of coarse

and Related Coatings, Materials, andApplications and is the direct responsibility of

3

aggregate. No. 67 designates a 19-mm [ ⁄4-in.] to No. 4 size stone with the

Subcommittee D01.48 on Durability of Pipeline Coating and Linings.

CurrenteditionapprovedJune1,2021.PublishedJuly2021.Originallyapproved following sieve analysis:

in 1989. Last previous edition approved in 2013 as G13/G13M – 13. DOI:

10.1520/G0013_G0013M-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Association of State Highway and Transportation

Standards volume information, refer to the standard’s Document Summary page on Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

the ASTM website. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G13/G13M − 21

NOTE 1—Framing lumber 40 by 90

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G13/G13M − 13 G13/G13M − 21

Standard Test Method for

Impact Resistance of Pipeline Coatings

1

(Limestone Drop Test)

This standard is issued under the fixed designation G13/G13M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the relative resistance of pipeline coatings to impact by observing the effects of

falling stones on coated pipe specimens.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

G12D7091 Test Method Practice for Nondestructive Measurement of Dry Film Thickness of Pipeline Coatings on SteelNon-

magnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals

(Withdrawn 2013)

G62 Test Methods for Holiday Detection in Pipeline Coatings

3

2.2 AASHTO Standard:

M80–51 (No. 67) Specification for Coarse Aggregate for Portland Cement Concrete

3. Summary of Test Method

3.1 The impact resistance of pipeline coatings is determined by dropping weighed amounts of a specified type of limestone

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.48 on Durability of Pipeline Coating and Linings.

Current edition approved Nov. 1, 2013June 1, 2021. Published November 2013July 2021. Originally approved in 1989. Last previous edition approved in 19962013 as

ε1

G13G13/G13M – 13. – 89 (1996) which was withdrawn December 2003 and reinstated in November 2013. DOI: 10.1520G0013_G0013M-13.DOI: 10.1520/G0013_

G0013M-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Association of State Highway and Transportation Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G13/G13M − 21

through a chute onto a coated pipe specimen. Results are reported as the number of drops required to pierce through the coating

to bare metal, as determined visually orand electrically.

4. Significance and Use

4.1 This test method is intended to simulate the effects of backfilling after pipe has been placed in the trench. The backfill is often

rocky soil and, if it is unscreened and the coated pipe is unshielded by sand or other protective padding, the falling rocks may

seriously damage the coating.

5. Apparatus

5.1 The impact apparatus shall be essentially as shown in Fig. 1 and shall include the following:

5.1.1 Box with Chute, providing a means of dropping stones from a height of 1830 mm [6.0 ft] measured to the top of a piece

of coated pipe under test. Construction details are shown in Fig. 2.

NOTE 1—The box and chute described in Fig. 2 are designed for testing coatings on 100-mm [4-in.] and 150-mm [6-in.] pipe specimens. Smaller diameter

pipe may be used by inserting wood V-blocks in the trough in the box below the chute.

NOTE 1—The box and chute described in Fig. 2 are designed for testing coatings on 100-mm [4-in.] a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.