ASTM F2182-02

(Test Method)Standard Test Method for Measurement of Radio Frequency Induced Heating Near Passive Implants During Magnetic Resonance Imaging

Standard Test Method for Measurement of Radio Frequency Induced Heating Near Passive Implants During Magnetic Resonance Imaging

SCOPE

1.1 This test method covers measurement of Radio Frequency (RF) induced heating near a passive medical implant and its surroundings during Magnetic Resonance Imaging (MRI).

1.2 This test method is one of those required to determine if the presence of a passive implant may cause injury to the person with the implant during an MRI procedure. Other safety issues that should be addressed include magnetically induced displacement force and torque.

1.3 The amount of RF-induced temperature rise for a given specific absorption rate (SAR) will depend on the RF frequency, which is proportional to the static magnetic field strength. Because of possible additional heating, particularly when device dimensions exceed a quarter wavelength, conclusions from measurements made at one frequency may not apply to other frequencies.

1.4 This test method assumes that testing is done on devices that will be entirely inside the body.

1.5 This test method applies to whole body magnetic resonance equipment, as defined in section 2.2.103 of the IEC Standard 60601-2-33 with a whole body RF transmit coil as defined in section 2.2.100. The RF coil is assumed to have quadrature excitation.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 2182 – 02

Standard Test Method for

Measurement of Radio Frequency Induced Heating Near

Passive Implants During Magnetic Resonance Imaging

This standard is issued under the fixed designation F 2182; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Magnetic Resonance Environment

F 2119 Test Method for Evaluation of MR Image Artifacts

1.1 This test method covers measurement of Radio Fre-

from Passive Implants

quency (RF) induced heating near a passive medical implant

2.2 IEC Standard:

and its surroundings during Magnetic Resonance Imaging

60601-2-33 Medical Electrical Equipment—Part 2: Particu-

(MRI).

lar Requirements for the Safety of Magnetic Resonance

1.2 This test method is one of those required to determine if

Equipment for Medical Diagnosis, 2001

the presence of a passive implant may cause injury to the

person with the implant during an MRI procedure. Other safety

3. Terminology

issues that should be addressed include magnetically induced

3.1 Definitions—For the purposes of this test method, the

displacement force and torque.

definitions in 3.1.1-3.1.8 shall apply.

1.3 The amount of RF-induced temperature rise for a given

3.1.1 isocenter—geometric center of the gradient coil sys-

specific absorption rate (SAR) will depend on the RF fre-

tem, which generally is the geometric center of a scanner with

quency, which is proportional to the static magnetic field

a cylindrical bore.

strength. Because of possible additional heating, particularly

3.1.2 magnetic resonance imaging (MRI)—diagnostic im-

when device dimensions exceed a quarter wavelength, conclu-

aging technique that uses static and time varying magnetic

sions from measurements made at one frequency may not

fields to provide images of tissue by the magnetic resonance of

apply to other frequencies.

nuclei.

1.4 This test method assumes that testing is done on devices

3.1.3 medical implant—a structure or device that is placed

that will be entirely inside the body.

within the body of the patient for medical diagnostic or

1.5 This test method applies to whole body magnetic

therapeutic purposes.

resonance equipment, as defined in section 2.2.103 of the IEC

3.1.4 MR safe—the device, when used in the MR environ-

Standard 60601-2-33 with a whole body RF transmit coil as

ment, has been demonstrated to present no additional risk to

defined in section 2.2.100. The RF coil is assumed to have

the patient or other individuals, but may affect the quality of

quadrature excitation.

the diagnostic information. The MR conditions in which the

1.6 This standard does not purport to address all of the

device was tested should be specified in conjunction with the

safety concerns, if any, associated with its use. It is the

terms MR safe and MR compatible since a device which is safe

responsibility of the user of this standard to establish appro-

or compatible under one set of conditions may not be found to

priate safety and health practices and determine the applica-

be so under more extreme MR conditions.

bility of regulatory limitations prior to use.

3.1.5 MR compatible—the device, when used in the MR

2. Referenced Documents environment, is MR safe and has been demonstrated to neither

significantly affect the quality of the diagnostic information nor

2.1 ASTM Standards:

have its operations affected by the MR device. The MR

A 340 Terminology of Symbols and Definitions Relating to

conditions in which the device was tested should be specified

Magnetic Testing

in conjunction with the terms MR safe and MR compatible

F 2052 Test Method for Measurement of Magnetically In-

since a device which is safe or compatible under one set of

duced Displacement Force on Passive Implants in the

conditions may not be found to be so under more extreme MR

conditions.

3.1.6 passive implant—an implant that serves its function

This test method is under the jurisdiction of ASTM Committee F04 on Medical

without supply of electrical power.

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.15 on Material Test Methods.

Current edition approved Apr. 10, 2002. Published June 2002. Annual Book of ASTM Standards, Vol 13.01.

2 4

Annual Book of ASTM Standards, Vol 03.04. Available from the International Electrotechnical Commission (IEC), 3 rue de

Varembe, Case postale 131, CH-1211 Geneva 20, Switzerland.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 2182

NOTE 1—The device does not have to be sterile at the time of testing.

3.1.7 radio frequency (RF) magnetic field—the magnetic

However, it should have been subjected to all processing, packaging, and

field in MRI that is used to flip the magnetic moments. The

sterilization steps before testing because any of these steps may affect the

frequency of the RF field is gB where g is the gyromagnetic

magnetic properties of the device.

constant, 42.56 MHz/T for protons, and B is the static

7.2 For purposes of device qualification, implant devices

magnetic field in Tesla.

shall not be altered in any manner prior to testing.

3.1.8 specific absorption rate (SAR)—the mass normalized

7.3 This test method may be used on prototype devices

rate at which RF energy is deposited in biological tissue. SAR

during product development.

is typically indicated in W/kg.

8. Procedure

4. Summary of Test Method

8.1 Phantom Morphology—Use a phantom geometry that

4.1 The implant to be tested is placed in a phantom material

reflects how the implant is placed in the body. The phantom

that simulates the electrical and thermal properties of the

container needs to be large enough to allow the device to be

human body. The phantom material will include saline solution

placed in a position representative of where it would be in the

and a gelling agent. Fiber optic temperature probes are placed

body. The container and all its parts should be made of material

at locations where the induced heating is expected to be

that is an electrical insulator and is non-magnetic. A whole

greatest. The phantom is placed in an MR system with a

body phantom should simulate the RF loading that would occur

cylindrical bore or an apparatus that reproduces the RF field of

with a patient. The phantom should have the general shape of

this type of system. An RF field with SAR of at least 1 W/kg

a patient (Fig. 1) but a rectangular phantom (Fig. 2) is also

averaged over the volume of the phantom is applied. The

acceptable. For application of RF by the body coil, the

temperature rise at the sensors is measured during the approxi-

phantom should contain at least 30 kg of phantom material. For

mately 15 min of RF application, or other appropriate period,

an implant inserted entirely in the head, a spherical phantom

depending on the mass and thermal conductivity of critical

with dimensions similar to those of the human head may be

parts of the device. Temperature measurements at one or more

appropriate. Generally, a homogeneous phantom will suffice,

locations away from the device serve as the control.

but in certain cases it may be appropriate to incorporate

materials of different conductivity within the phantom.

5. Significance and Use

8.2 Phantom Material—Phantom materials simulating tis-

5.1 This test method describes a test procedure for evaluat-

sue for the RF heating test during MRI shall meet the following

ing the RF-induced temperature rise in MRI in the vicinity of

criteria.

an implanted medical device. The actual temperature rise in the

8.2.1 Conductivity—Conductivity shall be 0.4 to 0.8 S/m at

patient will depend on a variety of factors beyond the SAR and

64 MHz, depending on the tissue to be modeled. (See Stuchly

time of RF application. The conditions and results of the

et al. (1) for data on tissue electrical properties and Athey et

testing should be included in the device labeling so that the

al. (2) for procedures for measurement of electrical properties.)

attending physician can make the decision of whether to allow

Electrical conductivity at low frequency will be less than at 64

the patient with the implant to undergo an MRI procedure.

MHz. The phantom conductivity should be 0.2 to 0.4 S/m for

6. Apparatus measurements made at a frequency of 1 kHz. (Stuchly and

Stuchly (3)).

6.1 Test Apparatus—The test apparatus consists of a suit-

8.2.2 Dielectric Constant—Dielectric constant shall be 60

able phantom and an MR imager for production of the RF field.

to 100 at 64 MHz.

The phantom, implant and MR imager are to simulate the

8.2.3 Thermal Parameters—The phantom material shall

electrical and physical environment that the patient and device

have thermal properties similar to those of the body which has

experience during an MRI procedure.

-7 2

diffusivity of about 1.3 3 10 m /s and heat capacity close to

6.2 Temperature Sensor—A suitable temperature measuring

that of water, 4184 J/kg °C.

device, usually a fiber optic probe, is used to measure tempera-

8.2.4 Viscosity—The viscosity shall be sufficient so that the

ture versus time of RF exposure in the vicinity of the implant.

phantom material does not allow bulk transport or convection

The temperature sensor will have a resolution of 0.1°C and a

currents. Generally, this is achieved by inclusion of a gelling

sensitive volume not to exceed 1 mm in radius. Fluoroptic

agent.

temperature probes have been found to be satisfactory for this

8.3 Phantom Formulation—A suitable gelled phantom

purpose.

(Rezai (4)) can be made with 0.8 g/L NaCl and 5.85 g/L

7. Test Specimens

Polyacrylic acid into distilled water. This formulation has a

room temperature conductivity of about 0.25 S/m and a

7.1 For purposes of device qualification, the implant or

viscosity sufficient to prevent convective heat transport. A

device evaluated according to this test method shall be repre-

number of other phantom formulations may be appropriate and

sentative of a finished sterilized device. For the purposes of

some are described in the rationale.

device qualification, the device evaluated according to this test

method should be a finished sterilized device.

The phantom in Fig. 2 may be purchased from Fab Lab Inc., Suite 1501325

Armstrong Rd., Northfield, MN 55057, tel. +1-507-645-2815, cbenson@fablab.net.

5 7

Particularly suitable are the Luxtron (Luxtron Corporation, Santa Clara, CA, The boldface numbers in parentheses refer to the list of references at the end of

USA) Models 790, 3000, and 3100 Fluoroptic Thermometer Systems and the 0.6 this standard.

mm diameter SFF-10 probe. Catalog 43,636-4, Aldrich Chemical Company, Inc., Milwaukee, WI, USA.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 2182

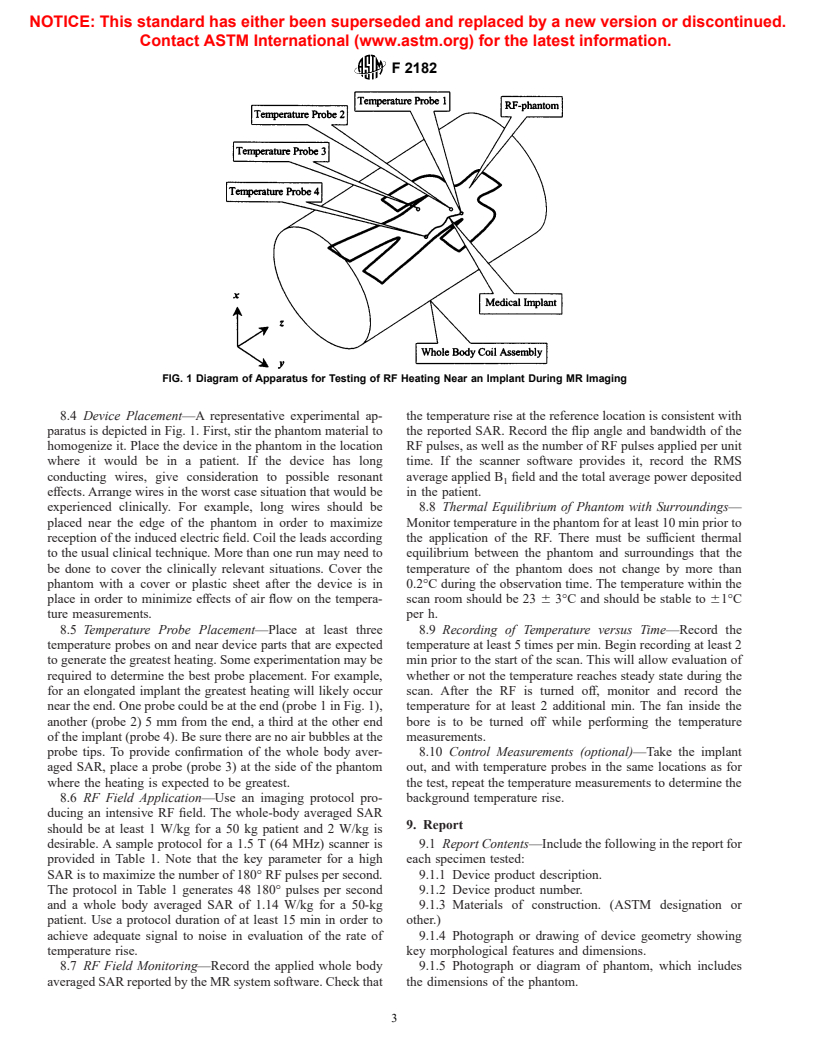

FIG. 1 Diagram of Apparatus for Testing of RF Heating Near an Implant During MR Imaging

8.4 Device Placement—A representative experimental ap- the temperature rise at the reference location is consistent with

paratus is depicted in Fig. 1. First, stir the phantom material to the reported SAR. Record the flip angle and bandwidth of the

homogenize it. Place the device in the phantom in the location RF pulses, as well as the number of RF pulses applied per unit

where it would be in a patient. If the device has long time. If the scanner software provides it, record the RMS

conducting wires, give consideration to possible resonant average applied B field and the total average power deposited

effects. Arrange wires in the worst case situation that would be in the patient.

experienced clinically. For example, long wires should be 8.8 Thermal Equilibrium of Phantom with Surroundings—

placed near the edge of the phantom in order to maximize Monitor temperature in the phantom for at least 10 min prior to

reception of the induced electric field. Coil the leads according the application of the RF. There must be sufficient thermal

to the usual clinical technique. More than one run may need to equilibrium between the phantom and surroundings that the

be done to cover the clinically relevant situations. Cover the temperature of the phantom does not change by more than

phantom with a cover or plastic sheet after the device is in 0.2°C during the observation time. The temperature within the

place in order to minimize effects of air flow on the tempera- scan room should be 23 6 3°C and should be stable to 61°C

ture measurements. per h.

8.5 Temperature Probe Placement—Place at least three 8.9 Recording of Temperature versus Time—Record the

temperature probes on and near device parts that are expected temperature at least 5 times per min. Begin recording at least 2

to generate the greatest heating. Some experimentation may be min prior to the start of the scan. This will allow evaluation of

required to determine the best probe placement. For example, whether or not the temperature reaches steady state during the

for an elongated implant the greatest heating will likely occur scan. After the RF is turned off, monitor and record the

near the end. One probe could be at the end (probe 1 in Fig. 1), temperature for at least 2 additional min. The fan inside the

another (probe 2) 5 mm from the end, a third at the other end bore is to be turned off while performing the temperature

of the implant (probe 4). Be sure there are no air bubbles at the measurements.

probe tips. To provide confirmation of the whole body aver- 8.10 Control Measurements (optional)—Take the implant

aged SAR, place a probe (probe 3) at the side of the phantom out, and with temperature probes in the same locations as for

where the heating is expected to be greatest. the test, repeat the temperature measurements to determine the

8.6 RF Field Application—Use an imaging protocol pro- background temperature rise.

ducing an intensive RF field. The whole-body averaged SAR

9. Report

should be at least 1 W/kg for a 50 kg patient and 2 W/kg is

desirable. A sample protocol for a 1.5 T (64 MHz) scanner is 9.1 Report Contents—Include the following in the report for

provided in Table 1. Note that the key parameter for a high each specimen tested:

SAR is to maximize the number of 180° RF pulses per second. 9.1.1 Device product description.

The protocol in Table 1 generates 48 180° pulses per second 9.1.2 Device product number.

and a whole body

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.