ASTM F1985-99(2011)

(Specification)Standard Specification for Pneumatic-Operated, Globe-Style, Control Valves

Standard Specification for Pneumatic-Operated, Globe-Style, Control Valves

ABSTRACT

This specification covers the design, construction, testing, and operating requirements for pneumatic-operated, globe-style, control valves complete with actuators for various fluid systems (steam, gas, and liquid applications). The control valves with actuators may be procured under this specification complete with all associated pneumatic instrumentation necessary for the valve to function in the system application. Valves shall be of following material grades: Grade A; Grade B; Grade C; and Grade D. Valves shall be of following pressure rating types: Type 1; Type 2; Type 3; and Type 4. The inherent flow characteristics of the valve shall be specified as quick-opening, linear-opening, equal-percentage opening, or as specified. Visual examination, hydrostatic shell test, nondestructive examination, seat leakage test, and functional test shall be performed to conform with the specified requirements.

SCOPE

1.1 This specification covers the design, construction, testing, and operating requirements for pneumatic-operated, globe-style, control valves complete with actuators for various fluid systems (steam, gas, and liquid applications). The control valves with actuators may be procured under this specification complete with all associated pneumatic instrumentation necessary for the valve to function in the system application; however, complete and detailed requirements for air instrumentation are beyond the scope of this specification and thus are not included here. This specification is not intended to cover quarter-turn or multi-turn stem valves.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1985 −99 (Reapproved 2011) An American National Standard

Standard Specification for

Pneumatic-Operated, Globe-Style, Control Valves

This standard is issued under the fixed designation F1985; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 Manufacturers Standardization Society of the Valve and

Fitting Industry:

1.1 This specification covers the design, construction,

MSS SP-25Standard Marking System for Valves, Fittings,

testing, and operating requirements for pneumatic-operated,

Flanges and Unions

globe-style, control valves complete with actuators for various

2.4 Fluid Controls Institute Standard:

fluid systems (steam, gas, and liquid applications).The control

FCI 70-2Control Valve Seat Leakage

valves with actuators may be procured under this specification

2.5 Military Standards and Specifications:

complete with all associated pneumatic instrumentation neces-

MIL-STD-798 Nondestructive Testing, Welding Quality

sary for the valve to function in the system application;

Control Material Control and Identification and Hi-Shock

however, complete and detailed requirements for air instru-

Test Requirements for Piping System Components for

mentation are beyond the scope of this specification and thus

Naval Ship Use

are not included here. This specification is not intended to

MIL-S-901Shock Tests, H.I. (High Impact); Shipboard

cover quarter-turn or multi-turn stem valves.

Machinery, Equipment and Systems, Requirements for

MIL-STD-167-1 Mechanical Vibrations of Shipboard

1.2 The values stated in SI units are to be regarded as the

Equipment (Type I– Environmental and Type II – Inter-

standard. The values given in parentheses are for information

nally Excited)

only.

MS-16142Boss Gasket-Seal Straight Thread Tube Fitting,

Standard Dimensions for

2. Referenced Documents

MIL-F-1183Fittings, Pipe, Cast Bronze, Silver Brazing,

2.1 The most recent edition or revision of the following

General Specification for

standards or specifications shall, to the extent specified in this

MIL-F-20042Flanges, Pipe and Bulkhead, Bronze (Silver

specification, form a part of this specification.

Brazing)

2.6 Government Drawings and Publications:

2.2 ASME Standards: 5

Naval Sea Systems Command (NAVSEA):

B1.1Unified Screw Threads (UN and UNR Thread Form)

803-1385946Unions, Bronze, Silver Brazing Alloy. For

B1.20.1Pipe Threads, General Purpose (Inch)

Water, Oil, and Gas

B16.1CastIronPipeFlangesandFlangedFittings,Class25,

803-1385943Unions, Silver Brazing, 3000 lb/in. , WOG,

125, 250 and 800

NPS, for UT Inspection

B16.5Pipe Flanges and Flanged Fittings

803-1385884Unions, Butt and SocketWelding, 6000 lb/in.

B16.11Forged Steel Fittings, Socket-Welding andThreaded

WOG, NPS, For UT Inspections

B16.25Buttwelding Ends

2.7 ISA Standard:

B16.24Bronze Pipe Flanges and Flanged fittings, Class 150

ISA-S75.05Standard for Control Valve Terminology

and 300

3. Terminology

B16.34Valves - Flanged and Buttwelding End Steel, Nickel

Alloy, and Other Special Allows

3.1 Definitions of Terms Specific to This Standard:

AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

This specification is under the jurisdiction of ASTM committee F25 on Ships Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on hq.com.

Machinery and Piping Systems. Available from Fluid Controls Institute, 1300 Sumner Ave., Cleveland, OH

Current edition approved Nov. 1, 2011. Published November 2011. Originally 44115.

approved in 1999. Last previous edition approved in 2005 as F1985–99(2005). AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

DOI: 10.1520/F1985-99R11. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

Available from American Society of Mechanical Engineers (ASME), ASME www.access.gpo.gov.

International Headquarters, Three Park Ave., New York, NY 10016-5990, http:// Available from International Society for Measurement and Control, 67 Alex-

www.asme.org. ander Dr., PO Box 12277, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1985−99 (2011)

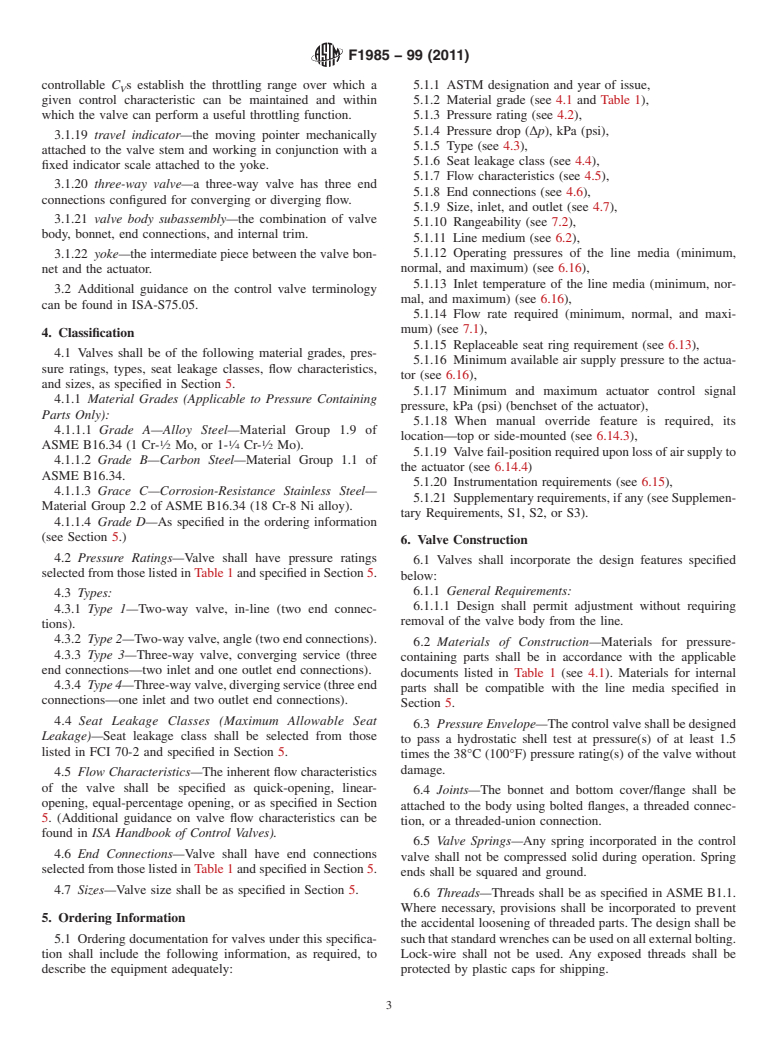

TABLE 1 Pressure Ratings for Control Valves

3.1.1 actuator—the unit that converts a pneumatic pressure

signal into a force to position the valve plug. Applicable Documents for

Type of

Pressure Rating Dimensional Details of End

End Connection

3.1.2 bonnet—the upper portion of the valve body subas-

Connections

sembly to which the yoke attaches. The bonnet contains the

Butt-welded ASME B16.34 ASME B16.25

valve stem packing. Class 150, 300, 400, 600,

900, 1500, 2500, or 4500

3.1.3 dead band—the range through which input signal can

Socket-welded ASME B16.34 ASME B16.11

be varied, upon reversal of direction, without an observable

Class 150, 300, 400, 600,

change in the value stem position.

900, 1500, 2500, or 4500

3.1.4 equal-percentage opening—an equal-percentage flow

Flanged ASME B16.34 ASME B16.5

characteristicofacontrolvalveprovidesachangeinflow,with

Class 150, 300, 400, 600,

thechangeinvalvelift,thatisaconstantpercentageoftheflow

900, 1500, 2500

before the change was made.

Flanged ASME B16.1 ASME B16.1

3.1.5 flow coeffıcient (C )—A basic capacity rating for

(cast iron valves only) Class 125, 250

V

valves that relates flow rate to the inlet and outlet pressure for

Flanged ASME B16.24 ASME B16.24

a particular fluid in the full-open position of the valve. It is

(bronze) Class 150, and 300

defined as the number of litres per seconds (gallons/min) of

Flanged-navy MIL-F-20042 MIL-F-20042

16°C (60°F) water that will flow through the valve with a 6.9

(bronze) Class 150, 250, 400

kPa (1 psi) pressure drop (∆p) across the valve.

Threaded ASME B16.34 ASME B1.20.1

3.1.6 globe-style valve—a basic control valve type that gets

(tapered pipe thread) Class 150, 300, 400, 600, and ASME B16.11

its name from the globular shape of its body. It normally uses

900, 1500, or 2500

a basic rising stem/plug for the closure member.

A

Union-end , MIL-F-1183 MIL-F-1183

3.1.7 hydrostatic shell test pressure—the hydrostatic test silver-brazed

(O-ring type) (O-ring type)

2 2

400 lb/in. 400 lb/in.

pressure that the valve body is required to withstand without

damage or leakage. Valve operation is not required during

A

Union-end, 803-1385946 803-1385946

2 2

application of this test pressure, but the valve shall meet all

silver-brazed

1500 lb/in. 1500 lb/in.

performancerequirementsafterthepressurehasbeenremoved.

A

Union-end, 803-1385943 803-1385943

2 2

3.1.8 hysteresis—the maximum difference in output value silver-brazed

3000 lb/in. 3000 lb/in.

for any single input value during a calibration cycle, excluding

A

Union-end, 803-1385884 803-1385884

errors as a result of dead band.

2 2

butt/socket weld

6000 lb/in. 6000 lb/in.

3.1.9 instrumentation—theterminstrumentation,whenused

Other, as specified as specified as specified

in this specification, refers to any instrumentation, that is, pilot

A

Forunioninletandoutletendconnections,onlythepertinentdimensionslisted

controllers, transmitters, relays, selectors, positioners, instru-

intheapplicabledocuments(MilitarySpecificationorNAVSEArequirements)shall

ment air reducing valves, and strainers/filters required for

apply.UnlessotherwisespecifiedintheorderingdataSection5,thetailpiecesand

the union-nuts shall not be furnished—only the thread-pieces shall be furnished. If

operation of the control valve in the system.

tailpieces and union-nuts are required, their materials of construction shall be in

3.1.10 internal trim—internal parts of the control valve, accordance with the applicable documents listed above and shall be specified in

the ordering data Section 5.

including seat rings, plug, stem, guide bushings, cage, pistons,

and so forth.

3.1.11 linear-opening—a linear-opening flow characteristic

of a control valve provides a change in flow that is linearly

ratings (also called pressure-temperature ratings) establish the

proportional with valve lift.

maximum allowable working (service) pressures of a compo-

3.1.12 linearity—the measure of how close a plot of the nent (valve, end connections, and so forth) at various tempera-

valvestemtravel(inresponsetoanincreasingandadecreasing

tures.

input signal) conforms to a straight line. Linearity is normally

3.1.16 quick change cage trim—agasketoranO-ringsealed

expressed as the ratio (in percentage) of the maximum devia-

seat ring held in position by a cage, which may be either

tion from a straight line connecting the end points of the full

separate from or integral with the seat ring.The cage is held in

operational valve stem stroke.

position by either the bonnet or bottom flange. This design

3.1.13 manual override—the manual override allows valve shall permit the rapid replacement of all internal trim by

operationmanually.Themanualoverridefeaturehastheability

avoiding the use of any threads located within the valve body,

to oppose and overcome an opening or closing pneumatic such as seat ring threads.

control signal in controlling valve position.

3.1.17 quick-opening—a quick-opening flow characteristic

3.1.14 pneumatic-operated control valve—a valve installed of a control valve provides large changes in flow for small

directlyinthefluidsystem,whichtranslatesapneumaticsignal

changes in valve lift.

into a change in flow resistance for the system fluid.

3.1.18 rangeability—a measure of the usable range of a

3.1.15 pressurerating—thepressureratingofthevalveshall control valve and defined as the ratio of the maximum to the

be as defined in the documents listed in Table 1. The pressure minimum controllable C . These maximum and minimum

V

F1985−99 (2011)

controllable C s establish the throttling range over which a 5.1.1 ASTM designation and year of issue,

V

given control characteristic can be maintained and within 5.1.2 Material grade (see 4.1 and Table 1),

which the valve can perform a useful throttling function. 5.1.3 Pressure rating (see 4.2),

5.1.4 Pressure drop (∆p), kPa (psi),

3.1.19 travel indicator—the moving pointer mechanically

5.1.5 Type (see 4.3),

attached to the valve stem and working in conjunction with a

5.1.6 Seat leakage class (see 4.4),

fixed indicator scale attached to the yoke.

5.1.7 Flow characteristics (see 4.5),

3.1.20 three-way valve—a three-way valve has three end

5.1.8 End connections (see 4.6),

connections configured for converging or diverging flow.

5.1.9 Size, inlet, and outlet (see 4.7),

3.1.21 valve body subassembly—the combination of valve

5.1.10 Rangeability (see 7.2),

body, bonnet, end connections, and internal trim.

5.1.11 Line medium (see 6.2),

3.1.22 yoke—the intermediate piece between the valve bon- 5.1.12 Operating pressures of the line media (minimum,

normal, and maximum) (see 6.16),

net and the actuator.

5.1.13 Inlet temperature of the line media (minimum, nor-

3.2 Additional guidance on the control valve terminology

mal, and maximum) (see 6.16),

can be found in ISA-S75.05.

5.1.14 Flow rate required (minimum, normal, and maxi-

mum) (see 7.1),

4. Classification

5.1.15 Replaceable seat ring requirement (see 6.13),

4.1 Valves shall be of the following material grades, pres-

5.1.16 Minimum available air supply pressure to the actua-

sure ratings, types, seat leakage classes, flow characteristics,

tor (see 6.16),

and sizes, as specified in Section 5.

5.1.17 Minimum and maximum actuator control signal

4.1.1 Material Grades (Applicable to Pressure Containing

pressure, kPa (psi) (benchset of the actuator),

Parts Only):

5.1.18 When manual override feature is required, its

4.1.1.1 Grade A—Alloy Steel—Material Group 1.9 of

location—top or side-mounted (see 6.14.3),

1 1 1

ASME B16.34 (1 Cr- ⁄2 Mo, or 1- ⁄4 Cr- ⁄2 Mo).

5.1.19 Valvefail-positionrequireduponlossofairsupplyto

4.1.1.2 Grade B—Carbon Steel—Material Group 1.1 of

the actuator (see 6.14.4)

ASME B16.34.

5.1.20 Instrumentation requirements (see 6.15),

4.1.1.3 Grace C—Corrosion-Resistance Stainless Steel—

5.1.21 Supplementaryrequirements,ifany(seeSupplemen-

Material Group 2.2 of ASME B16.34 (18 Cr-8 Ni alloy).

tary Requirements, S1, S2, or S3).

4.1.1.4 Grade D—As specified in the ordering information

(see Section 5.)

6. Valve Construction

4.2 Pressure Ratings—Valve shall have pressure ratings

6.1 Valves shall incorporate the design features specified

selectedfromthoselistedinTable1andspecifiedinSection5.

below:

6.1.1 General Requirements:

4.3 Types:

6.1.1.1 Design shall permit adjustment without requiring

4.3.1 Type 1—Two-way valve, in-line (two end connec-

removal of the valve body from the line.

tions).

4.3.2 Type 2—Two-wayvalve,angle(twoendconnections).

6.2 Materials of Construction—Materials for pressure-

4.3.3 Type 3—Three-way valve, converging service (three

containing parts shall be in accordance with the applicable

end connections—two inlet and one outlet end connections).

documents listed in Table 1 (see 4.1). Materials for internal

4.3.4 Type4—Three-wayvalve,divergingservice(threeend

parts shall be compatible with the line media specified in

connections—one inlet and two outlet end connections).

Section 5.

4.4 Seat Leakage Classes (Maximum Allowable Seat

6.3 Pressure Envelope—Thecontrolvalveshallbedesigned

Leakage)—Seat leakage class shall be selected from those

to pass a hydrostatic shell test at pressure(s) of at least 1.5

listed in FCI 70-2 and specified in Section 5.

times the 38°C (100°F) pressure rating(s) of the valve without

damage.

4.5 Flow Characteristics—The inherent flow characteristics

of the valve shall be specified as quick-opening, linear-

6.4 Joints—The bonnet and bottom cover/flange shall be

opening, equal-percentage opening, or as specified in Section

attached to the body using bolted flanges, a threaded connec-

5. (Additional guidance on valve flow characteristics can be

tion, or a threaded-union connection.

found in ISA Handbook of Control Valves).

6.5 Valve Springs—Any spring incorporated in the control

4.6 End Connections—Valve shall have end connections

valve shall not be compressed solid during operation. Spring

selectedfromthoselistedinTable1andspecifiedinSection5.

ends shall be squared and ground.

4.7 Sizes—Valve size shall be as specified in Section 5.

6.6 Threads—Threads shall be as specified in ASME B1.1.

Where necessary, provisions shall be incorporated to prevent

5. Ordering Information

the accidental loosening of threaded parts. The design shall be

5.1 Ordering documentation for valves under this specifica- suchthatstandardwrench

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.