ASTM D8021-23

(Guide)Standard Guide for Blast Furnace and Steel Furnace Slag as Produced During the Manufacture of Iron and Steel

Standard Guide for Blast Furnace and Steel Furnace Slag as Produced During the Manufacture of Iron and Steel

SIGNIFICANCE AND USE

4.1 This guide provides guidance as to the appropriate/typical mineralogy observed when iron and steel slag is produced during a variety of processes in the manufacture of iron and steel.

4.2 Slag can be considered a product based on the mineralogy of samples that are tested using X-ray diffraction, phase recognition and characterization, powdered XRD-Rietveld analysis, and SEM-PARC results, using this guide.

SCOPE

1.1 This standard is intended to provide guidance as to the appropriate/typical mineralogy observed when iron and steel slag, produced during the manufacture of iron and steel, is designated as a product. The included information covers the mineral properties of blast furnace slag and steel slag when they are manufactured in conjunction with the production of iron or steel, or both (Note 1).

Note 1: This guide is not intended to be used to determine the applicability of iron or steel slag, or both, for various applications. Terminology D8 designates steel slag as a product, while Terminology C125 designates blast furnace slag as a product. Its sole intent is to provide guidance as to the typical mineralogy when the iron or steel slag, or both, is designated as a product.

1.2 The values stated in SI units are to be regarded as standard. No other units are utilized in this standard.

1.3 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) should not be considered as requirements of the specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

- Status

- Published

- Publication Date

- 31-Oct-2023

- Technical Committee

- D04 - Road and Paving Materials

- Drafting Committee

- D04.99 - Sustainable Asphalt Pavement Materials and Construction

- Current Stage

Relations

- Effective Date

- 01-Nov-2023

- Effective Date

- 01-Feb-2024

- Effective Date

- 01-Jul-2022

- Effective Date

- 01-Nov-2023

ASTM D8021-23 - Standard Guide for Blast Furnace and Steel Furnace Slag as Produced During the Manufacture of Iron and Steel

REDLINE ASTM D8021-23 - Standard Guide for Blast Furnace and Steel Furnace Slag as Produced During the Manufacture of Iron and Steel

Frequently Asked Questions

ASTM D8021-23 is a guide published by ASTM International. Its full title is "Standard Guide for Blast Furnace and Steel Furnace Slag as Produced During the Manufacture of Iron and Steel". This standard covers: SIGNIFICANCE AND USE 4.1 This guide provides guidance as to the appropriate/typical mineralogy observed when iron and steel slag is produced during a variety of processes in the manufacture of iron and steel. 4.2 Slag can be considered a product based on the mineralogy of samples that are tested using X-ray diffraction, phase recognition and characterization, powdered XRD-Rietveld analysis, and SEM-PARC results, using this guide. SCOPE 1.1 This standard is intended to provide guidance as to the appropriate/typical mineralogy observed when iron and steel slag, produced during the manufacture of iron and steel, is designated as a product. The included information covers the mineral properties of blast furnace slag and steel slag when they are manufactured in conjunction with the production of iron or steel, or both (Note 1). Note 1: This guide is not intended to be used to determine the applicability of iron or steel slag, or both, for various applications. Terminology D8 designates steel slag as a product, while Terminology C125 designates blast furnace slag as a product. Its sole intent is to provide guidance as to the typical mineralogy when the iron or steel slag, or both, is designated as a product. 1.2 The values stated in SI units are to be regarded as standard. No other units are utilized in this standard. 1.3 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) should not be considered as requirements of the specification. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 4.1 This guide provides guidance as to the appropriate/typical mineralogy observed when iron and steel slag is produced during a variety of processes in the manufacture of iron and steel. 4.2 Slag can be considered a product based on the mineralogy of samples that are tested using X-ray diffraction, phase recognition and characterization, powdered XRD-Rietveld analysis, and SEM-PARC results, using this guide. SCOPE 1.1 This standard is intended to provide guidance as to the appropriate/typical mineralogy observed when iron and steel slag, produced during the manufacture of iron and steel, is designated as a product. The included information covers the mineral properties of blast furnace slag and steel slag when they are manufactured in conjunction with the production of iron or steel, or both (Note 1). Note 1: This guide is not intended to be used to determine the applicability of iron or steel slag, or both, for various applications. Terminology D8 designates steel slag as a product, while Terminology C125 designates blast furnace slag as a product. Its sole intent is to provide guidance as to the typical mineralogy when the iron or steel slag, or both, is designated as a product. 1.2 The values stated in SI units are to be regarded as standard. No other units are utilized in this standard. 1.3 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) should not be considered as requirements of the specification. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D8021-23 is classified under the following ICS (International Classification for Standards) categories: 91.100.15 - Mineral materials and products. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D8021-23 has the following relationships with other standards: It is inter standard links to ASTM D8021-20, ASTM C989/C989M-24, ASTM C989/C989M-22, ASTM D8418-21. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM D8021-23 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8021 − 23

Standard Guide for

Blast Furnace and Steel Furnace Slag as Produced During

the Manufacture of Iron and Steel

This standard is issued under the fixed designation D8021; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This standard is intended to provide guidance as to the 2.1 ASTM Standards:

appropriate/typical mineralogy observed when iron and steel C125 Terminology Relating to Concrete and Concrete Ag-

slag, produced during the manufacture of iron and steel, is gregates

designated as a product. The included information covers the C595/C595M Specification for Blended Hydraulic Cements

mineral properties of blast furnace slag and steel slag when C702/C702M Practice for Reducing Samples of Aggregate

they are manufactured in conjunction with the production of to Testing Size

iron or steel, or both (Note 1). C989/C989M Specification for Slag Cement for Use in

Concrete and Mortars

NOTE 1—This guide is not intended to be used to determine the

C1252 Test Methods for Uncompacted Void Content of Fine

applicability of iron or steel slag, or both, for various applications.

Aggregate (as Influenced by Particle Shape, Surface

Terminology D8 designates steel slag as a product, while Terminology

C125 designates blast furnace slag as a product. Its sole intent is to

Texture, and Grading)

provide guidance as to the typical mineralogy when the iron or steel slag,

D8 Terminology Relating to Materials for Roads and Pave-

or both, is designated as a product.

ments

1.2 The values stated in SI units are to be regarded as

D75/D75M Practice for Sampling Aggregates

standard. No other units are utilized in this standard.

3. Terminology

1.3 The text of this standard references notes and footnotes

3.1 Definitions—For the definitions of terms used in this

that provide explanatory material. These notes and footnotes

standard, refer to Terminology D8.

(excluding those in tables and figures) should not be considered

as requirements of the specification.

3.2 Definitions of Terms Specific to This Standard:

1.4 This standard does not purport to address all of the 3.2.1 blast furnace slag, n—see Terminology C125.

3.2.1.1 Discussion—Slag, ferrous metal, blast furnace

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- (granulated, GBS or air-cooled, ABFS or ABF)—Blast furnace

slag is formed in a continuous process by the fusion of

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. limestone (or dolomite, or a combination thereof) and other

fluxes with the residues from the carbon source and the

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard- non-metallic components of the iron-bearing materials (for

example, iron ore, iron sinter). Blast furnace slag is generated

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- at temperatures above 1500 °C. Dependent on the manner of

cooling of the liquid slag, it can be distinguished between

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. crystalline, air-cooled blast furnace slag and glassy, granulated

blast furnace slag. Various cooling processes are defined in

Terminology C125.

This guide is under the jurisdiction of ASTM Committee D04 on Road and

Paving Materials and is the direct responsibility of Subcommittee D04.99 on

Sustainable Asphalt Pavement Materials and Construction. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2023. Published December 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2020. Last previous edition approved in 2020 as D8021 – 20. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D8021-23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D8021 − 23

3.2.2 slag, steelmaking, n—steelmaking slags (SMS) are recognition and characterization, powdered XRD-Rietveld

generated as products during the refining/modification of steel analysis, and SEM-PARC results, using this guide.

in the production process.

5. Classification

3.2.2.1 Discussion—Steelmaking slag is formed (for

5.1 Slag, ferrous metal, blast furnace (granulated, GBS or

example, from the conversion of hot metal to steel) from the

melting of scrap in an electric arc furnace or from the air-cooled, ABFS).

subsequent treatments of various refinements/modifications of

5.2 Slag, steelmaking, and converter—BOF.

the crude steel, or both. The composition of the slags varies

5.3 Slag, steelmaking, and electric arc furnace—EAF C

depending on the process step in which they are produced. The

(carbon steel production).

molten slag which has tapping temperatures of around 1600 °C

5.4 Slag, steelmaking, electric arc furnace—EAF S

is discharged into pots or pits where it cools and solidifies to

provide an artificial aggregate having a crystalline structure. (stainless/high-alloy steel production).

They are sometimes referred to as ladle modification or caster

5.5 Slag, steelmaking—SMS.

slags.

6. Properties

3.2.3 steel slag, BOF/converter, n—a product of the conver-

sion of liquid iron (hot metal) into steel during a batch process 6.1 Mineral Constituents:

in a basic oxygen furnace. 6.1.1 Granulated blast furnace slag (GBS) typically contains

up to 100 w ⁄w% of glassy (vitreous) material (Specification

3.2.3.1 Discussion—BOF/converter slag is generated by the

C989/C989M). In some cases where a minor mineral compo-

addition of fluxes, such as limestone, dolomite, or both, during

nent is detected, it is usually in the form of melilite (calcium-

the blowing of oxygen into the melt. Due to the oxidizing

magnesium-silicate). Since the mineral component is usually

conditions, some elements (like Fe and Mn) are partly oxidized

minor, no characteristic mineral constituents can be given.

and contribute to the formation of the slag. Furthermore, some

6.1.2 All other iron and steel slags exist predominantly in a

components are either oxidized to gas (like carbon) or are

crystalline form. Many are considered air cooled, although the

chemically bound in the slag (like silicon or phosphorus). The

process does allow for a water addition during cooling. The

liquid slag which has tapping temperatures of around 1600 °C

typical tables for ABFS, BOF, and EAF C include major

is air cooled under controlled conditions in pits forming

primary mineral constituents which are characteristic for the

crystalline slag.

fresh slag. The table for EAF S contains typical major mineral

3.2.4 steel slag, EAF C, n—electric arc furnace slag gener-

constituents (primary and secondary), and for SMS slags the

ated during carbon steel production is a product of melting

most common mineral constituents are listed. Other mineral

steel scrap in an electric arc furnace. 3

phases can occur, because the slags are UVCB substances.

3.2.4.1 Discussion—Steel slag, EAF C (carbon steel pro-

The XRD diagrams of all slags can show secondary mineral

duction) is generated by the addition of fluxes, such as

phases, for example hydroxides and carbonates, which are a

limestone, dolomite, or both. Furthermore, some elements of

result of weathering and aging of the slags. This is the case

the melt are oxidized and contribute to the formation of the

especially for EAF S slags and a large quantity of SMS slags,

slag. The liquid slag which has tapping temperatures of around

which are mostly soaked directly after the production.

1600 °C is typically air cooled (possibly applying small

6.1.3 Sometimes impurities, for example sand (quartz), can

amounts of water) under controlled conditions in pots or pits

occur due to sampling, processing, or loading. In that case the

forming crystalline slag.

quartz is not a fine-grained respirable crystalline silica, but

granules, and therefore is considered to have no adverse health

3.2.5 steel slag, EAF S, n—electric arc furnace slag gener-

effects. The slag itself generally does not include crystalline

ated during stainless steel or high-alloy steel production.

quartz.

3.2.5.1 Discussion—Steel slag, EAF S (stainless/high-alloy

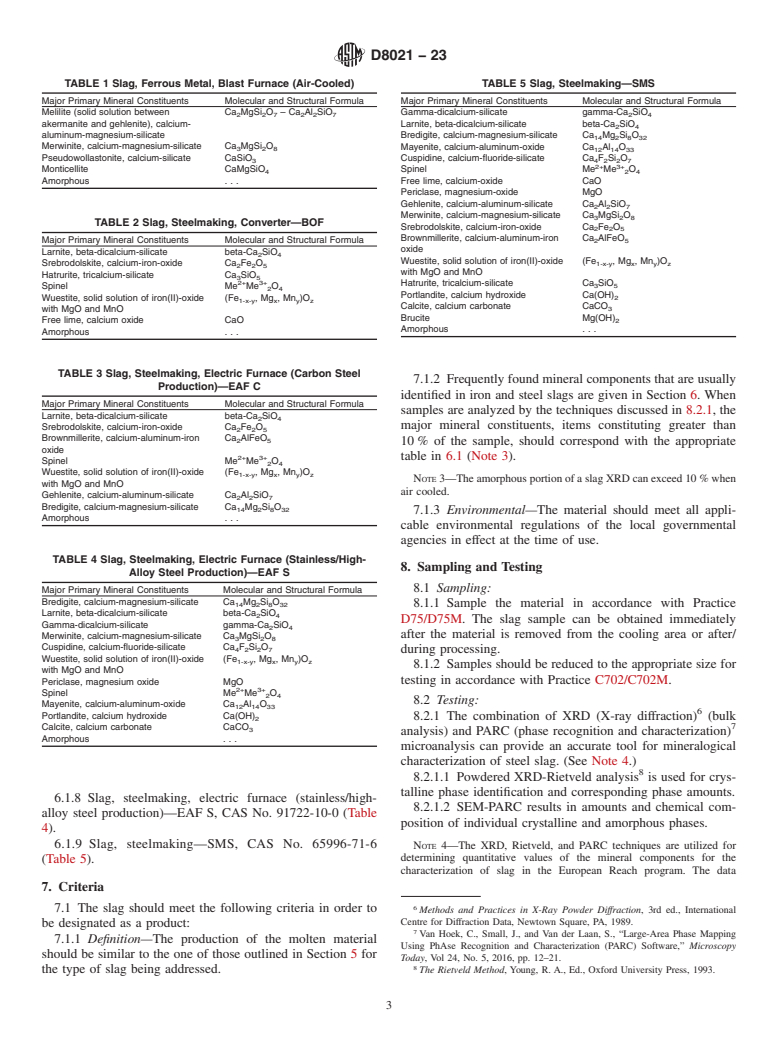

6.1.4 Slag, ferrous metal, blast furnace (granulated)—GBS,

steel production) is generated by the addition of fluxes and

CAS No. 65996-69-2. Mineral constituents: glass (amor-

reducing agents, for example lime or dolomite (or a combina-

phous).

tion thereof), silicon compounds, or aluminum. The liquid slag

6.1.5 Slag, ferrous metal, blast furnace (air-cooled)—ABS,

which has tapping temperatures of around 1600 °C is con-

CAS No. 65996-69-2 (Table 1, Note 2).

trolled and treated, if necessary, to improve the properties of

the slag. Then, the slag is cooled under controlled conditions in

NOTE 2—Air-cooled blast furnace slag from some steel plants may also

pots or pits forming crystalline slag. contain a certain amount of glass.

6.1.6 Slag, steelmaking, converter—BOF, CAS No. 91722-

4. Significance and Use

09-7 (Table 2).

6.1.7 Slag, steelmaking, electric furnace (carbon steel

4.1 This guide provides guidance as to the appropriate/

production)—EAF C, CAS No. 91722-10-0 (Table 3).

typical mineralogy observed when iron and steel slag is

produced during a variety of processes in the manufacture of

iron and steel.

UVCB: unknown or variable composition, complex reaction products, and

biological materials.

4.2 Slag can be considered a product based on the mineral-

XRD: X-ray powder diffraction.

ogy of samples that are tested using X-ray diffraction, phase CAS: Chemical Abstracts Service.

D8021 − 23

TABLE 1 Slag, Ferrous Metal, Blast Furnace (Air-Cooled) TABLE 5 Slag, Steelmaking—SMS

Major Primary Mineral Constituents Molecular and Structural Formula Major Primary Mineral Constituents Molecular and Structural Formula

Melilite (solid solution between Ca MgSi O – Ca Al SiO Gamma-dicalcium-silicate gamma-Ca SiO

2 2 7 2 2 7 2 4

akermanite and gehlenite), calcium- Larnite, beta-dicalcium-silicate beta-Ca SiO

2 4

aluminum-magnesium-silicate Bredigite, calcium-magnesium-silicate Ca Mg Si O

14 2 8 32

Merwinite, calcium-magnesium-silicate Ca MgSi O Mayenite, calcium-aluminum-oxide Ca Al O

3 2 8

12 14 33

Pseudowollastonite, calcium-silicate CaSiO

Cuspidine, calcium-fluoride-silicate Ca F Si O

3 4 2 2 7

2+ 3+

Monticellite CaMgSiO Spinel Me Me O

4 2 4

Amorphous . . . Free lime, calcium-oxide CaO

Periclase, magnesium-oxide MgO

Gehlenite, calcium-aluminum-silicate Ca Al SiO

2 2 7

Merwinite, calcium-magnesium-silicate Ca MgSi O

3 2 8

TABLE 2 Slag, Steelmaking, Converter—BOF

Srebrodolskite, calcium-iron-oxide Ca Fe O

2 2 5

Brownmillerite, calcium-aluminum-iron Ca AlFeO

Major Primary Mineral Constituents Molecular and Structural Formula 2 5

oxide

Larnite, beta-dicalcium-silicate beta-Ca SiO

2 4

Wuestite, solid solution of iron(II)-oxide (Fe , Mg , Mn )O

1-x-y x y z

Srebrodolskite, calcium-iron-oxide Ca Fe O

2 2 5

with MgO and MnO

Hatrurite, tricalcium-silicate Ca SiO

3 5

2+ 3+

Hatrurite, tricalcium-silicate Ca SiO

3 5

Spinel Me Me O

2 4

Portlandite, calcium hydroxide Ca(OH)

Wuestite, solid solution of iron(II)-oxide (Fe , Mg , Mn )O 2

1-x-y x y z

Calcite, calcium carbonate CaCO

with MgO and MnO

Brucite Mg(OH)

Free lime, calcium oxide CaO 2

Amorphous . . .

Amorphous . . .

TABLE 3 Slag, Steelmaking, Electric Furnace (Carbon Steel

7.1.2 Frequently found mineral components that are usually

Production)—EAF C

identified in iron and steel slags are given in Section 6. When

Major Primary Mineral Constituents Molecular and Structural Formula

samples are analyzed by the techniques discussed in 8.2.1, the

Larnite, beta-dicalcium-silicate beta-Ca SiO

2 4

Srebrodolskite, calcium-iron-oxide Ca Fe O major mineral constituents, items constituting greater than

2 2 5

Brownmillerite, calcium-aluminum-iron Ca AlFeO

2 5

10 % of the sample, should correspond with the appropriate

oxide

2+ 3+ table in 6.1 (Note 3).

Spinel Me Me O

2 4

Wuestite, solid solution of iron(II)-oxide (Fe , Mg , Mn )O

1-x-y x y z

NOTE 3—The amorphous portion of a slag XRD can exceed 10 % when

with MgO and MnO

air cooled.

Gehlenite, calcium-aluminum-silicate Ca Al SiO

2 2 7

Bredigite, calcium-magnesium-silicate Ca Mg Si O

14 2 8 32

7.1.3 Environmental—The material should meet all appli-

Amorphous . . .

cable environmental regulations of the local governmental

agencies in effect at the time of use.

TABLE 4 Slag, Steelmaking, Electric Furnace (Stainless/High-

8. Sampling and Testing

Alloy Steel Production)—EAF S

8.1 Sampling:

Major Primary Mineral Constituents Molecular and Structural Formula

Bredigite, calcium-magnesium-silicate Ca Mg Si O

14 2 8 32 8.1.1 Sample the material in accordance with Practice

Larnite, beta-dicalcium-silicate beta-Ca SiO

2 4

D75/D75M. The slag sample can be obtained immediately

Gamma-dicalcium-silicate gamma-Ca SiO

2 4

after the material is removed from the cooling area or after/

Merwinite, calcium-magnesium-silicate Ca MgSi O

3 2 8

Cuspidine, calcium-fluoride-silicate Ca F Si O

4 2 2 7

during processing.

Wuestite, solid solution of iron(II)-oxide (Fe , Mg , Mn )O

1-x-y x y z

8.1.2 Samples should be reduced to the appropriate size for

with MgO and MnO

Periclase, magnesium oxide MgO testing in accordance with Practice C702/C702M.

2+ 3+

Spinel Me Me O

2 4

8.2 Testing:

Mayenite, calcium-aluminum-oxide Ca Al O

12 14 33

Portlandite, calcium hydroxide Ca(OH)

8.2.1 The combination of XRD (X-ray diffraction) (bulk

Calcite, calcium carbonate CaCO

analysis) and PARC (phase recognition and characterization)

Amorphous . . .

microanalysis can provide an accurate tool for mineralogical

characterization of steel slag. (See Note 4.)

8.2.1.1 Powdered XRD-Rietveld analysis is used for crys-

talline phase identification and corresponding phase amounts.

6.1.8 Slag, steelmaking, electric furnace (stainless/high-

8.2.1.2 SEM-PARC results in amounts and chemical com-

alloy steel production)—EAF S, CAS No. 91722-10-0 (Table

position of individual crystalline and amorphous phases.

4).

6.1.9 Slag, steelmaking—SMS, CAS No. 65996-71-6

NOTE 4—The XRD, Rietveld, and PARC techniques are utilized for

determining quantitative values of the mineral components for the

(Table 5).

characterization of slag in the European Reach program. The data

7. Criteria

7.1 The slag should meet the following criteria in order to

Methods and Practices in X-Ray Powder Diffraction, 3rd ed., International

Centre for Diffraction Data, Newtown Square, PA, 1989.

be designated as a product:

Van Hoek, C., Small, J., and Van der Laan, S., “Large-Area Phase Mapping

7.1.1 Definition—The production of the molten material

Using PhAse Recognition and Characterization (PARC) Software,” Microscopy

should be similar to the one of those outlined in Section 5 for

Today, Vol 24, No. 5, 2016, pp. 12–21.

the type of slag being addressed. The Rietveld Method, Young, R. A., Ed., Oxford University Press, 1993.

D8021 − 23

presented in this guide was determined using these techniques as well as

ICP (inductively coupled plasma) and XRF (X-ray fluorescence).

9. Keywords

9.1 ACBF slag; blast furnace; BOF slag; EAF slag; electric

furnace; slag; slag composition; steel furnace

APPENDIX

(Nonmandatory Information)

X1. TERMINOLOGY (DESCRIPTIONS)

(for reference purposes only)

X1.1 International Glossary of Terms – World of Iron X1.2.1.4 air-cooled blast furnace slag (ABS)—after separat-

and Steel Network 2020

ing from the heavier iron, the slag is typically tapped or poured

onto ground bays to air cool to form a crystalline aggregate.

X1.1.1 This glossary contains terms and phrases that are

commonly used by those who are involved with the

X1.2.1.5 air cooling—process where the slag is allowed to

production, handling, management, storage, value add

cool down slowly by leaving it in contact with ambient

applications, and use of iron and steel slags (ISS) across the

temperature air.

globe.

X1.2.1.6 AOD process—AOD stands for Argon Oxygen

X1.1.2 Stakeholders within the iron and steel slags value

Decarburization, a refining process associated with the produc-

chain have used these terms for many years, with other modern

tion of stainless steel. Most stainless steel is initially produced

terms, for example, co-product, have been included over time

in an electric arc furnace before being transferred to a separate

which better define the essential role of slag production to the

ladle furnace for refining to achieve the precise metallurgical

primary products of iron and steel.

content required, a process known as secondary metallurgy. In

X1.1.3 The acronym ISS was first used in 2010 and subse-

the AOD process, a mixture of argon and oxygen is blown

quently globally adopted and encouraged through the World of

through the molten steel in the ladle furnace, and the oxygen

Iron and Steel Slag Network (WoISS).

achieves the main objective of oxidizing unwanted carbon in

X1.1.4 This glossary of terms is an attempt to aid in future

the steel melt. But because the vital and expensive chromium

standardization, and reflect these terms in common usage

contained in all stainless steels is also prone to oxidation and

across the industry. Additionally, some ASTM, allied products,

subsequent loss with the process slag, the argon is introduced

environmental, and regulatory terms associated with ISS are

to inhibit this reaction.

included for comparison purposes. The ASTM terms and

X1.2.1.7 ash—the solid residue from combustion processes.

definitions utilized are related to Terminologies C125 and D8.

Industrial combustion processes mostly aim to extract energy

X1.1.5 Contributions, suggestions, corrections, and/or im-

from coal, oil, or even domestic waste. The primary aim is

provements to this living document are welcome. Please

therefore not to obtain valuable materials, as it is in metallur-

submit these to the Australasian (Iron & Steel) Slag Associa-

gical processes, where the focus is on obtaining a metal.

tion (asa-inc.org.au), the National Slag Association

(nationalslag.org), or EuroSlag (euroslag.com).

X1.2.1.8 basic oxygen furnace (BOF)—also known as LD

converter or Basic Oxygen System (BOS), is a steel making

X1.2 Terminology

furnace in which hot metal from the blast furnace, with some

X1.2.1 Definitions:

amounts of steel scrap, is converted into steel. High-purity

X1.2.1.1 aggregate—material complying with the specified

oxygen is blown through the molten bath to lower the carbon

grading requirements for fine and coarse aggregates. It may be

content. Fluxes are used to reduce other unwanted elements.

produced from rock, gravel, metallurgical slag, or artificial

Those fluxes combine with silicates and oxides to form liquid

stone.

slag that floats on the surface of the hot metal. Also see Guide

X1.2.1.2 aggregate—a granular material used as a construc-

D8021 for further information.

tion material, meeting the requirements of road and paving

X1.2.1.9 basic oxygen furnace slag (BOF slag)—also

applications. D8

X1.2.1.2.1 Discussion—Examples of aggregate include known as LD converter slag or Basic Oxygen System Slag

sand, gravel, shell, slag, and crushed stone. See coarse aggre- (BOS) are slags from a steel making furnace which are defined

gate and fine aggregate for more information.

as co-products. The slag is removed from the vessel after the

exothermic refinement of molten iron and recycled steel in the

X1.2.1.3 aggregate—granular material such as sand, gravel,

presence of fluxes and oxygen. The slag is typically dark gray

crushed stone, or iron blast-furnace slag, used with a cementing

medium to form hydraulic-cement concrete or mortar. C125 in color and characteristically harder than blast furnace slag

D8021 − 23

(BFS) with a density approximately 20 to 25 % greater than penetration of a standard plunger into the sample to the load

natural quarried aggregates or BFS. Also see Guide D8021 for required to produce the same penetration of same plunger into

further information. a standard aggregate sample. It is expressed as a percentage

and is broadly used in design of the base and the sub-base

X1.2.1.10 blast furnace (BF)—a furnace used in the inte-

material for pavement.

grated metallurgical process in which iron ore, sinter, or pellets

are melted down under a hot air flow (enriched with oxygen),

X1.2.1.19 cement—a hydraulic binding agent, that is, upon

using carbon in the form of coal and coke as a heating and contact with water, it immediately produces strength-forming

reducing agent in the chemical process. As a result, as well a

reaction products that are durable both above water and

liquid hot metal (“pig iron”) as a liquid slag are produced. Also underwater. Cement is used for manufacturing concrete,

see Guide D8021 for further information.

mortar, and other construction products. Globally, there are

many different types of cement which differ in terms of their

X1.2.1.11 blast furnace lime (BFL)—product from blast

composition, fineness, and technical suitability for different

furnace slag obtained by milling the slag. As essential ingre-

applications. For example, EN 197-1 for “standard cements”

dients it contain

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D8021 − 20 D8021 − 23

Standard Guide for

Blast Furnace and Steel Furnace Slag as Produced During

the Manufacture of Iron and Steel

This standard is issued under the fixed designation D8021; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard is intended to provide guidance as to the appropriate/typical mineralogy observed when iron and steel slag,

produced during the manufacture of iron and steel, is designated as a product. The included information covers the mineral

properties of blast furnace slag and steel slag when they are manufactured in conjunction with the production of iron or steel, or

both (Note 1).

NOTE 1—This guide is not intended to be used to determine the applicability of iron or steel slag, or both, for various applications. Terminology D8

designates steel slag as a product, while Terminology C125 designates blast furnace slag as a product. Its sole intent is to provide guidance as to the typical

mineralogy when the iron or steel slag, or both, is designated as a product.

1.2 The values stated in SI units are to be regarded as standard. No other units are utilized in this standard.

1.3 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes

(excluding those in tables and figures) should not be considered as requirements of the specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Aggregates

C595/C595M Specification for Blended Hydraulic Cements

C702/C702M Practice for Reducing Samples of Aggregate to Testing Size

C989/C989M Specification for Slag Cement for Use in Concrete and Mortars

C1252 Test Methods for Uncompacted Void Content of Fine Aggregate (as Influenced by Particle Shape, Surface Texture, and

Grading)

This guide is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.99 on Sustainable

Asphalt Pavement Materials and Construction.

Current edition approved Nov. 1, 2020Nov. 1, 2023. Published November 2020December 2023. Originally approved in 2020. Last previous edition approved in 2020 as

D8021 – 20. DOI: 10.1520/D8021-20.10.1520/D8021-23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D8021 − 23

D8 Terminology Relating to Materials for Roads and Pavements

D75/D75M Practice for Sampling Aggregates

3. Terminology

3.1 Definitions—For the definitions of terms used in this standard, refer to Terminology D8.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 blast furnace slag, n—see Terminology C125.

3.2.1.1 Discussion—

Slag, ferrous metal, blast furnace (granulated, GBS or air-cooled, ABFS or ABF)—Blast furnace slag is formed in a continuous

process by the fusion of limestone (or dolomite, or a combination thereof) and other fluxes with the residues from the carbon source

and the non-metallic components of the iron-bearing materials (for example, iron ore, iron sinter). Blast furnace slag is generated

at temperatures above 1500 °C. Dependent on the manner of cooling of the liquid slag, it can be distinguished between crystalline,

air-cooled blast furnace slag and glassy, granulated blast furnace slag. Various cooling processes are defined in Terminology C125.

3.2.2 slag, steelmaking, n—steelmaking slags (SMS) are generated as products during the refining/modification of steel in the

production process.

3.2.2.1 Discussion—

Steelmaking slag is formed (for example, from the conversion of hot metal to steel) from the melting of scrap in an electric arc

furnace or from the subsequent treatments of various refinements/modifications of the crude steel, or both. The composition of the

slags varies depending on the process step in which they are produced. The molten slag which has tapping temperatures of around

1600 °C is discharged into pots or pits where it cools and solidifies to provide an artificial aggregate having a crystalline structure.

They are sometimes referred to as ladle modification or caster slags.

3.2.3 steel slag, BOF/converter, n—a product of the conversion of liquid iron (hot metal) into steel during a batch process in a

basic oxygen furnace.

3.2.3.1 Discussion—

BOF/converter slag is generated by the addition of fluxes, such as limestone, dolomite, or both, during the blowing of oxygen into

the melt. Due to the oxidizing conditions, some elements (like Fe and Mn) are partly oxidized and contribute to the formation of

the slag. Furthermore, some components are either oxidized to gas (like carbon) or are chemically bound in the slag (like silicon

or phosphorus). The liquid slag which has tapping temperatures of around 1600 °C is air cooled under controlled conditions in pits

forming crystalline slag.

3.2.4 steel slag, EAF C, n—electric arc furnace slag generated during carbon steel production is a product of melting steel scrap

in an electric arc furnace.

3.2.4.1 Discussion—

Steel slag, EAF C (carbon steel production) is generated by the addition of fluxes, such as limestone, dolomite, or both.

Furthermore, some elements of the melt are oxidized and contribute to the formation of the slag. The liquid slag which has tapping

temperatures of around 1600 °C is typically air cooled (possibly applying small amounts of water) under controlled conditions in

pots or pits forming crystalline slag.

3.2.5 steel slag, EAF S, n—electric arc furnace slag generated during stainless steel or high-alloy steel production.

3.2.5.1 Discussion—

Steel slag, EAF S (stainless/high-alloy steel production) is generated by the addition of fluxes and reducing agents, for example

lime or dolomite (or a combination thereof), silicon compounds, or aluminum. The liquid slag which has tapping temperatures of

around 1600 °C is controlled and treated, if necessary, to improve the properties of the slag. Then, the slag is cooled under

controlled conditions in pots or pits forming crystalline slag.

4. Significance and Use

4.1 This guide provides guidance as to the appropriate/typical mineralogy observed when iron and steel slag is produced during

a variety of processes in the manufacture of iron and steel.

4.2 Slag can be considered a product based on the mineralogy of samples that are tested using X-ray diffraction, phase recognition

and characterization, powdered XRD-Rietveld analysis, and SEM-PARC results, using this guide.

D8021 − 23

5. Classification

5.1 Slag, ferrous metal, blast furnace (granulated, GBS or air-cooled, ABFS).

5.2 Slag, steelmaking, and converter—BOF.

5.3 Slag, steelmaking, and electric arc furnace—EAF C (carbon steel production).

5.4 Slag, steelmaking, electric arc furnace—EAF S (stainless/high-alloy steel production).

5.5 Slag, steelmaking—SMS.

6. Properties

6.1 Mineral Constituents:

6.1.1 Granulated blast furnace slag (GBS) typically contains up to 100 w ⁄w% of glassy (vitreous) material (Specification

C989/C989M). In some cases where a minor mineral component is detected, it is usually in the form of melilite (calcium-

magnesium-silicate). Since the mineral component is usually minor, no characteristic mineral constituents can be given.

6.1.2 All other iron and steel slags exist predominantly in a crystalline form. Many are considered air cooled, although the process

does allow for a water addition during cooling. The typical tables for ABFS, BOF, and EAF C include major primary mineral

constituents which are characteristic for the fresh slag. The table for EAF S contains typical major mineral constituents (primary

and secondary), and for SMS slags the most common mineral constituents are listed. Other mineral phases can occur, because the

3 4

slags are UVCB substances. The XRD diagrams of all slags can show secondary mineral phases, for example hydroxides and

carbonates, which are a result of weathering and aging of the slags. This is the case especially for EAF S slags and a large quantity

of SMS slags, which are mostly soaked directly after the production.

6.1.3 Sometimes impurities, for example sand (quartz), can occur due to sampling, processing, or loading. In that case the quartz

is not a fine-grained respirable crystalline silica, but granules, and therefore is considered to have no adverse health effects. The

slag itself generally does not include crystalline quartz.

6.1.4 Slag, ferrous metal, blast furnace (granulated)—GBS, CAS No. 65996-69-2. Mineral constituents: glass (amorphous).

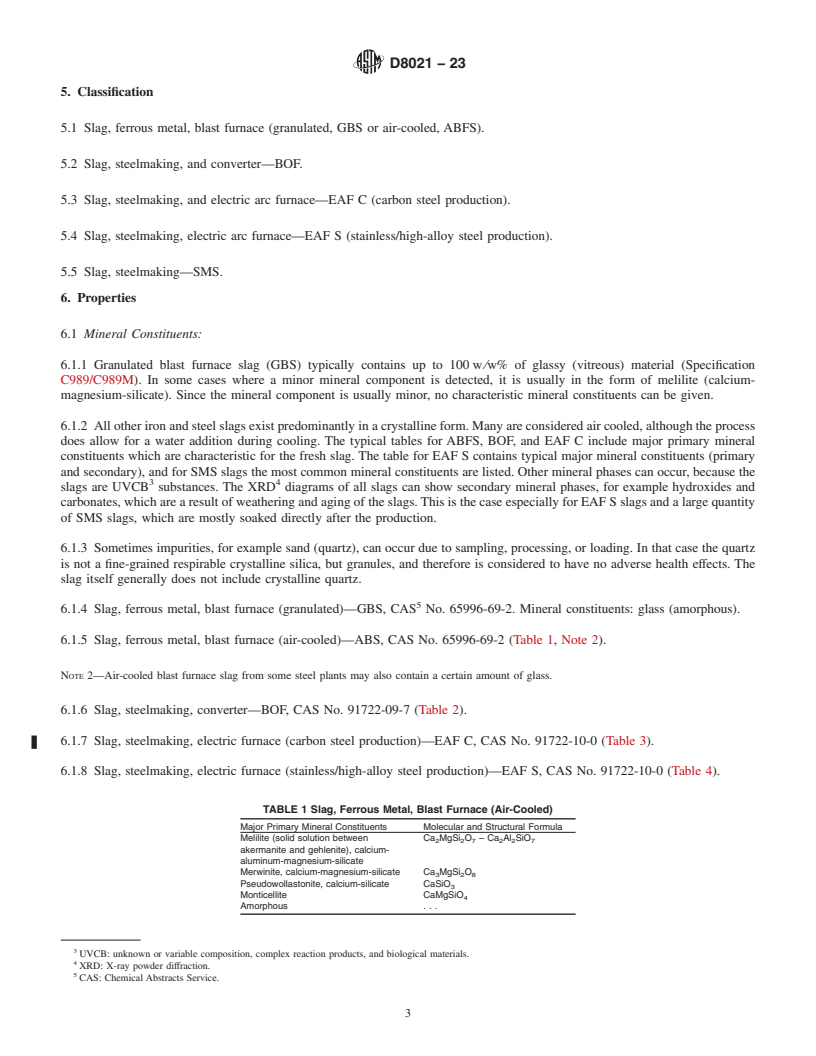

6.1.5 Slag, ferrous metal, blast furnace (air-cooled)—ABS, CAS No. 65996-69-2 (Table 1, Note 2).

NOTE 2—Air-cooled blast furnace slag from some steel plants may also contain a certain amount of glass.

6.1.6 Slag, steelmaking, converter—BOF, CAS No. 91722-09-7 (Table 2).

6.1.7 Slag, steelmaking, electric furnace (carbon steel production)—EAF C, CAS No. 91722-10-0 (Table 3).

6.1.8 Slag, steelmaking, electric furnace (stainless/high-alloy steel production)—EAF S, CAS No. 91722-10-0 (Table 4).

TABLE 1 Slag, Ferrous Metal, Blast Furnace (Air-Cooled)

Major Primary Mineral Constituents Molecular and Structural Formula

Melilite (solid solution between Ca MgSi O – Ca Al SiO

2 2 7 2 2 7

akermanite and gehlenite), calcium-

aluminum-magnesium-silicate

Merwinite, calcium-magnesium-silicate Ca MgSi O

3 2 8

Pseudowollastonite, calcium-silicate CaSiO

Monticellite CaMgSiO

Amorphous . . .

UVCB: unknown or variable composition, complex reaction products, and biological materials.

XRD: X-ray powder diffraction.

CAS: Chemical Abstracts Service.

D8021 − 23

TABLE 2 Slag, Steelmaking, Converter—BOF

Major Primary Mineral Constituents Molecular and Structural Formula

Larnite, beta-dicalcium-silicate beta-Ca SiO

2 4

Srebrodolskite, calcium-iron-oxide Ca Fe O

2 2 5

Hatrurite, tricalcium-silicate Ca SiO

3 5

2+ 3+

Spinel Me Me O

2 4

Wuestite, solid solution of iron(II)-oxide (Fe , Mg , Mn )O

1-x-y x y z

with MgO and MnO

Free lime, calcium oxide CaO

Amorphous . . .

TABLE 3 Slag, Steelmaking, Electric Furnace (Carbon Steel

Production)—EAF C

Major Primary Mineral Constituents Molecular and Structural Formula

Larnite, beta-dicalcium-silicate beta-Ca SiO

2 4

Srebrodolskite, calcium-iron-oxide Ca Fe O

2 2 5

Brownmillerite, calcium-aluminum-iron Ca AlFeO

2 5

oxide

2+ 3+

Spinel Me Me O

2 4

Wuestite, solid solution of iron(II)-oxide (Fe , Mg , Mn )O

1-x-y x y z

with MgO and MnO

Gehlenite, calcium-aluminum-silicate Ca Al SiO

2 2 7

Bredigite, calcium-magnesium-silicate Ca Mg Si O

14 2 8 32

Amorphous . . .

TABLE 4 Slag, Steelmaking, Electric Furnace (Stainless/High-

Alloy Steel Production)—EAF S

Major Primary Mineral Constituents Molecular and Structural Formula

Bredigite, calcium-magnesium-silicate Ca Mg Si O

14 2 8 32

Larnite, beta-dicalcium-silicate beta-Ca SiO

2 4

Gamma-dicalcium-silicate gamma-Ca SiO

2 4

Merwinite, calcium-magnesium-silicate Ca MgSi O

3 2 8

Cuspidine, calcium-fluoride-silicate Ca F Si O

4 2 2 7

Wuestite, solid solution of iron(II)-oxide (Fe , Mg , Mn )O

1-x-y x y z

with MgO and MnO

Periclase, magnesium oxide MgO

2+ 3+

Spinel Me Me O

2 4

Mayenite, calcium-aluminum-oxide Ca Al O

12 14 33

Portlandite, calcium hydroxide Ca(OH)

Calcite, calcium carbonate CaCO

Amorphous . . .

6.1.9 Slag, steelmaking—SMS, CAS No. 65996-71-6 (Table 5).

TABLE 5 Slag, Steelmaking—SMS

Major Primary Mineral Constituents Molecular and Structural Formula

Gamma-dicalcium-silicate gamma-Ca SiO

2 4

Larnite, beta-dicalcium-silicate beta-Ca SiO

2 4

Bredigite, calcium-magnesium-silicate Ca Mg Si O

14 2 8 32

Mayenite, calcium-aluminum-oxide Ca Al O

12 14 33

Cuspidine, calcium-fluoride-silicate Ca F Si O

4 2 2 7

2+ 3+

Spinel Me Me O

2 4

Free lime, calcium-oxide CaO

Periclase, magnesium-oxide MgO

Gehlenite, calcium-aluminum-silicate Ca Al SiO

2 2 7

Merwinite, calcium-magnesium-silicate Ca MgSi O

3 2 8

Srebrodolskite, calcium-iron-oxide Ca Fe O

2 2 5

Brownmillerite, calcium-aluminum-iron Ca AlFeO

2 5

oxide

Wuestite, solid solution of iron(II)-oxide (Fe , Mg , Mn )O

1-x-y x y z

with MgO and MnO

Hatrurite, tricalcium-silicate Ca SiO

3 5

Portlandite, calcium hydroxide Ca(OH)

Calcite, calcium carbonate CaCO

Brucite Mg(OH)

Amorphous . . .

D8021 − 23

7. Criteria

7.1 The slag should meet the following criteria in order to be designated as a product:

7.1.1 Definition—The production of the molten material should be similar to the one of those outlined in Section 5 for the type

of slag being addressed.

7.1.2 Frequently found mineral components that are usually identified in iron and steel slags are given in Section 6. When samples

are analyzed by the techniques discussed in 8.2.1, the major mineral constituents, items constituting greater than 10 % of the

sample, should correspond with the appropriate table in 6.1 (Note 3).

NOTE 3—The amorphous portion of a slag XRD can exceed 10 % when air cooled.

7.1.3 Environmental—The material should meet all applicable environmental regulations of the local governmental agencies in

effect at the time of use.

8. Sampling and Testing

8.1 Sampling:

8.1.1 Sample the material in accordance with Practice D75/D75M. The slag sample can be obtained immediately after the material

is removed from the cooling area or after/during processing.

8.1.2 Samples should be reduced to the appropriate size for testing in accordance with Practice C702/C702M.

8.2 Testing:

6 7

8.2.1 The combination of XRD (X-ray diffraction) (bulk analysis) and PARC (phase recognition and characterization)

microanalysis can provide an accurate tool for mineralogical characterization of steel slag. (See Note 4.)

8.2.1.1 Powdered XRD-Rietveld analysis is used for crystalline phase identification and corresponding phase amounts.

8.2.1.2 SEM-PARC results in amounts and chemical composition of individual crystalline and amorphous phases.

NOTE 4—The XRD, Rietveld, and PARC techniques are utilized for determining quantitative values of the mineral components for the characterization

of slag in the European Reach program. The data presented in this guide was determined using these techniques as well as ICP (inductively coupled

plasma) and XRF (X-ray fluorescence).

9. Keywords

9.1 ACBF slag; blast furnace; BOF slag; EAF slag; electric furnace; slag; slag composition; steel furnace

APPENDIX

(Nonmandatory Information)

X1. TERMINOLOGY (DESCRIPTIONS)

(for reference purposes only)

X1.1 International Glossary of Terms – World of Iron and Steel Network 2020

Methods and Practices in X-Ray Powder Diffraction, 3rd ed., International Centre for Diffraction Data, Newtown Square, PA, 1989.

Van Hoek, C., Small, J., and Van der Laan, S., “Large-Area Phase Mapping Using PhAse Recognition and Characterization (PARC) Software,” Microscopy Today, Vol

24, No. 5, 2016, pp. 12–21.

The Rietveld Method, Young, R. A., Ed., Oxford University Press, 1993.

D8021 − 23

X1.1.1 This glossary contains terms and phrases that are commonly used by those who are involved with the production, handling,

management, storage, value add applications, and use of iron and steel slags (ISS) across the globe.

X1.1.2 Stakeholders within the iron and steel slags value chain have used these terms for many years, with other modern terms,

for example, co-product, have been included over time which better define the essential role of slag production to the primary

products of iron and steel.

X1.1.3 The acronym ISS was first used in 2010 and subsequently globally adopted and encouraged through the World of Iron and

Steel Slag Network (WoISS).

X1.1.4 This glossary of terms is an attempt to aid in future standardization, and reflect these terms in common usage across the

industry. Additionally, some ASTM, allied products, environmental, and regulatory terms associated with ISS are included for

comparison purposes. The ASTM terms and definitions utilized are related to Terminologies C125 and D8.

X1.1.5 Contributions, suggestions, corrections, and/or improvements to this living document are welcome. Please submit these to

the Australasian (Iron & Steel) Slag Association (asa-inc.org.au), the National Slag Association (nationalslag.org), or EuroSlag

(euroslag.com).

X1.2 Terminology

X1.2.1 Definitions:

X1.2.1.1 aggregate—material complying with the specified grading requirements for fine and coarse aggregates. It may be

produced from rock, gravel, metallurgical slag, or artificial stone.

X1.2.1.2 aggregate—a granular material used as a construction material, meeting the requirements of road and paving

applications. D8

X1.2.1.2.1 Discussion—

Examples of aggregate include sand, gravel, shell, slag, and crushed stone. See coarse aggregate and fine aggregate for more

information.

X1.2.1.3 aggregate—granular material such as sand, gravel, crushed stone, or iron blast-furnace slag, used with a cementing

medium to form hydraulic-cement concrete or mortar. C125

X1.2.1.4 air-cooled blast furnace slag (ABS)—after separating from the heavier iron, the slag is typically tapped or poured onto

ground bays to air cool to form a crystalline aggregate.

X1.2.1.5 air cooling—process where the slag is allowed to cool down slowly by leaving it in contact with ambient temperature

air.

X1.2.1.6 AOD process—AOD stands for Argon Oxygen Decarburization, a refining process associated with the production of

stainless steel. Most stainless steel is initially produced in an electric arc furnace before being transferred to a separate ladle furnace

for refining to achieve the precise metallurgical content required, a process known as secondary metallurgy. In the AOD process,

a mixture of argon and oxygen is blown through the molten steel in the ladle furnace, and the oxygen achieves the main objective

D8021 − 23

of oxidizing unwanted carbon in the steel melt. But because the vital and expensive chromium contained in all stainless steels is

also prone to oxidation and subsequent loss with the process slag, the argon is introduced to inhibit this reaction.

X1.2.1.7 ash—the solid residue from combustion processes. Industrial combustion processes mostly aim to extract energy from

coal, oil, or even domestic waste. The primary aim is therefore not to obtain valuable materials, as it is in metallurgical processes,

where the focus is on obtaining a metal.

X1.2.1.8 basic oxygen furnace (BOF)—also known as LD converter or Basic Oxygen System (BOS), is a steel making furnace

in which hot metal from the blast furnace, with some amounts of steel scrap, is converted into steel. High-purity oxygen is blown

through the molten bath to lower the carbon content. Fluxes are used to reduce other unwanted elements. Those fluxes combine

with silicates and oxides to form liquid slag that floats on the surface of the hot metal. Also see Guide D8021 for further

information.

X1.2.1.9 basic oxygen furnace slag (BOF slag)—also known as LD converter slag or Basic Oxygen System Slag (BOS) are slags

from a steel making furnace which are defined as co-products. The slag is removed from the vessel after the exothermic refinement

of molten iron and recycled steel in the presence of fluxes and oxygen. The slag is typically dark gray in color and characteristically

harder than blast furnace slag (BFS) with a density approximately 20 to 25 % greater than natural quarried aggregates or BFS. Also

see Guide D8021 for further information.

X1.2.1.10 blast furnace (BF)—a furnace used in the integrated metallurgical process in which iron ore, sinter, or pellets are melted

down under a hot air flow (enriched with oxygen), using carbon in the form of coal and coke as a heating and reducing agent in

the chemical process. As a result, as well a liquid hot metal (“pig iron”) as a liquid slag are produced. Also see Guide D8021 for

further information.

X1.2.1.11 blast furnace lime (BFL)—product from blast furnace slag obtained by milling the slag. As essential ingredients it

contains calcium and magnesium silicates as well as oxides and is used as fertilizer.

X1.2.1.12 blast furnace slag (BFS)—a co-product of the iron-making process. Formed within a blast furnace with molten iron

from iron ore in the reducing presence of heated air, coke/coal, and additions like limestone. The resulting molten slag and iron,

once removed from the furnace, are subjected to further processing to form a crystalline aggregate (air-cooled blast furnace slag,

ABS) or a glassy granulate (granulated blast furnace slag, GBS). See Guide D8021 for additional information on the process.

X1.2.1.13 blast furnace slag—the nonmetallic product, consisting essentially of silicates and alumino-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...