ASTM F1829-16

(Test Method)Standard Test Method for Static Evaluation of Anatomic Glenoid Locking Mechanism in Shear

Standard Test Method for Static Evaluation of Anatomic Glenoid Locking Mechanism in Shear

SIGNIFICANCE AND USE

4.1 This test method can be used to describe the effects of materials, manufacturing, and design variables on the performance of metal or composite-backed anatomic glenoid prostheses’ locking mechanisms to resist static shear loading.

4.2 The glenoid component is used in shoulder replacements and should conform to the criteria specified in Specification F1378.

4.3 The loading of metal or composite-backed anatomic glenoid prostheses in vivo will, in general, differ from the loading defined in this test method. The results obtained here cannot be used to directly predict in vivo performance. However, this test method is designed to allow for comparisons between different metal or composite-backed anatomic glenoid locking mechanism designs, when tested under similar circumstances.

4.4 This test method may not be appropriate for all types of implant applications. The user is cautioned to consider the appropriateness of the method in view of the materials being tested and their potential application.

4.5 In order for the test data on metal or composite-backed anatomic glenoid components to be comparable, reproducible, and capable of being correlated among laboratories, it is essential that uniform procedures be established.

SCOPE

1.1 This test method covers a method for determining the static shear disassembly force of modular anatomic glenoid components used in anatomic total shoulder arthroplasty prostheses.

1.2 Although the methodology described does not replicate all physiological force conditions, it is a means of in vitro comparison of modular anatomic glenoid component designs and the strength of the retention mechanism between the articular insert and glenoid backing under the stated test conditions.

1.3 This test method covers modular glenoid components comprised of a separate articular insert and backing. The insert and backing can be fabricated from any combination of the following materials: metal alloys, polymeric materials, composite materials.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1829 − 16

Standard Test Method for

Static Evaluation of Anatomic Glenoid Locking Mechanism

1

in Shear

This standard is issued under the fixed designation F1829; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers a method for determining the 3.1 Definitions:

static shear disassembly force of modular anatomic glenoid 3.1.1 anatomic total shoulder arthroplasty system,

components used in anatomic total shoulder arthroplasty pros- n—shoulder implant system that has a concave glenoid com-

theses. ponent and a convex humeral component design.

3.1.2 glenoid component, n—the prosthetic portion that

1.2 Although the methodology described does not replicate

replaces the glenoid fossa of the scapula and articulates with

all physiological force conditions, it is a means of in vitro

the natural humeral head or a prosthetic replacement.

comparison of modular anatomic glenoid component designs

and the strength of the retention mechanism between the

3.2 Definitions of Terms Specific to This Standard:

articular insert and glenoid backing under the stated test

3.2.1 articular insert, n—the concave prosthetic portion of a

conditions.

multi-piece glenoid component that articulates with the hu-

meral head. This articular insert is most often polymeric.

1.3 This test method covers modular glenoid components

comprised of a separate articular insert and backing. The insert

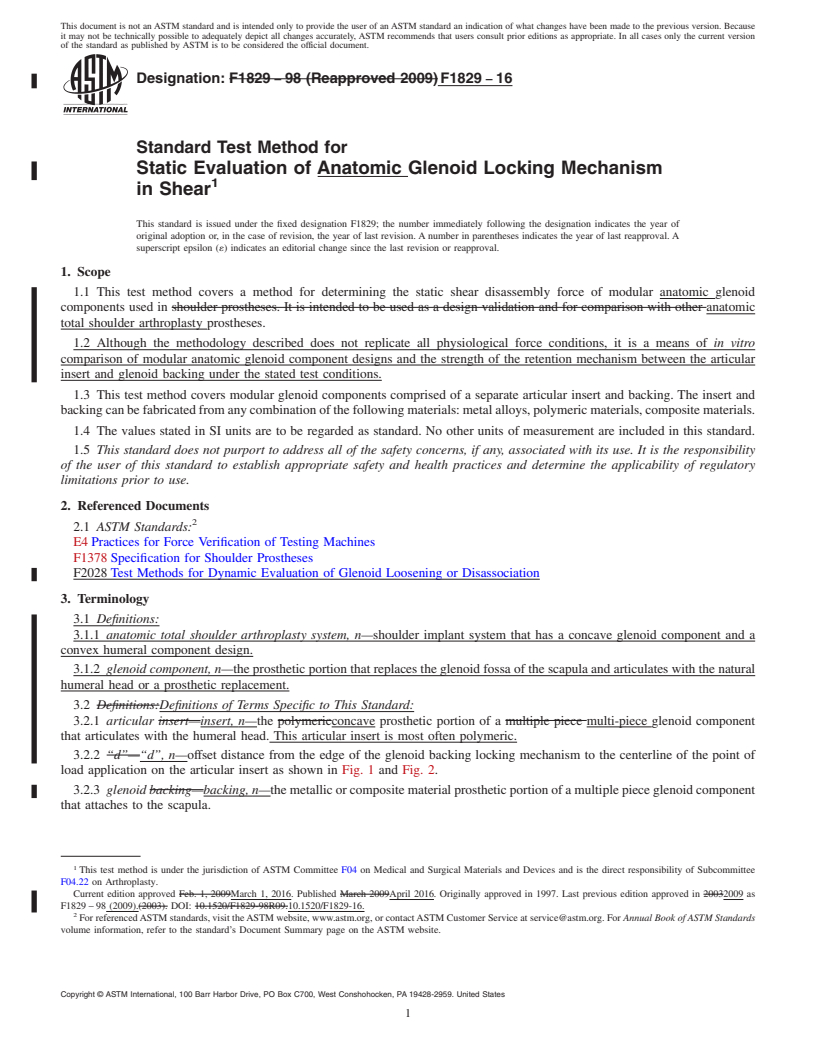

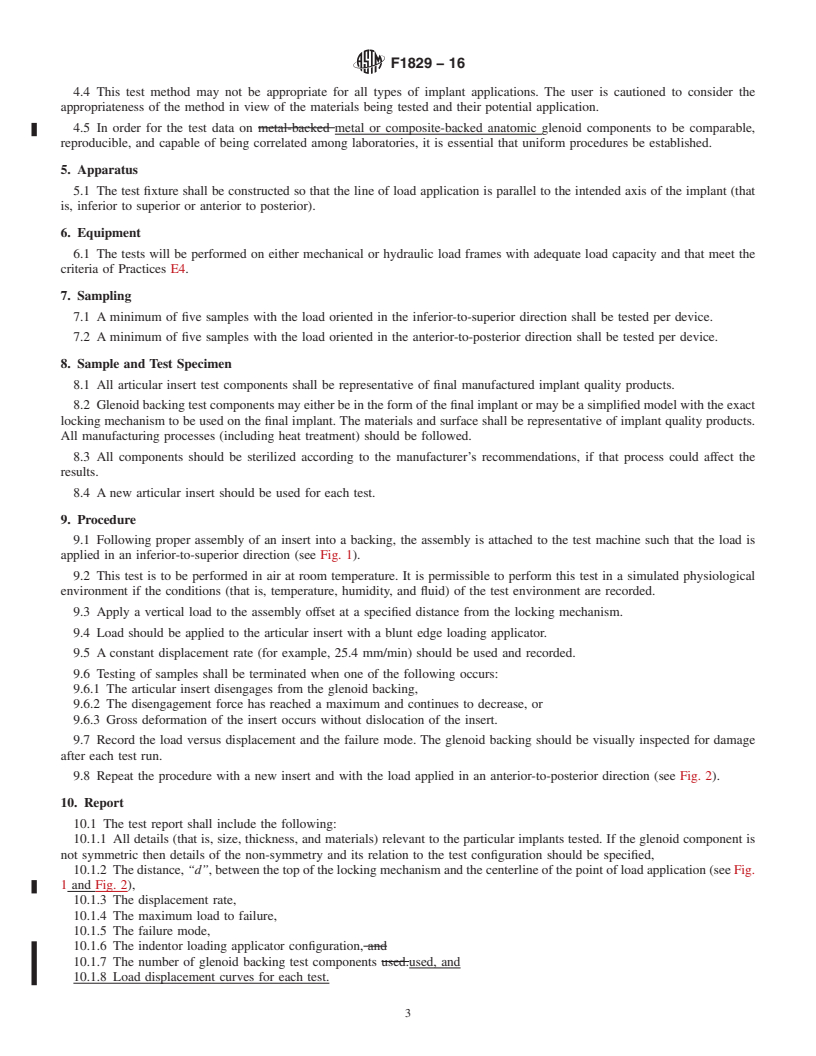

3.2.2 “d”, n—offset distance from the edge of the glenoid

and backing can be fabricated from any combination of the

backing locking mechanism to the centerline of the point of

following materials: metal alloys, polymeric materials, com-

load application on the articular insert as shown in Fig. 1 and

posite materials.

Fig. 2.

1.4 The values stated in SI units are to be regarded as

3.2.3 glenoid backing, n—the metallic or composite mate-

standard. No other units of measurement are included in this

rial prosthetic portion of a multiple piece glenoid component

standard.

that attaches to the scapula.

1.5 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 This test method can be used to describe the effects of

priate safety and health practices and determine the applica-

materials, manufacturing, and design variables on the perfor-

bility of regulatory limitations prior to use.

mance of metal or composite-backed anatomic glenoid pros-

theses’ locking mechanisms to resist static shear loading.

2. Referenced Documents

4.2 The glenoid component is used in shoulder replace-

2

2.1 ASTM Standards:

ments and should conform to the criteria specified in Specifi-

E4 Practices for Force Verification of Testing Machines

cation F1378.

F1378 Specification for Shoulder Prostheses

4.3 The loading of metal or composite-backed anatomic

F2028 Test Methods for Dynamic Evaluation of Glenoid

glenoid prostheses in vivo will, in general, differ from the

Loosening or Disassociation

loading defined in this test method. The results obtained here

cannot be used to directly predict in vivo performance.

However,thistestmethodisdesignedtoallowforcomparisons

1

This test method is under the jurisdiction ofASTM Committee F04 on Medical

between different metal or composite-backed anatomic glenoid

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.22 on Arthroplasty.

locking mechanism designs, when tested under similar circum-

Current edition approved March 1, 2016. Published April 2016. Originally

stances.

approved in 1997. Last previous edition approved in 2009 as F1829 – 98 (2009).

DOI: 10.1520/F1829-16.

4.4 This test method may not be appropriate for all types of

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

implant applications. The user is cautioned to consider the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

appropriateness of the method in view of the materials being

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tested and their potential application.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1829 − 16

FIG. 1 Schematic of Static Glenoid Locking Strength Inferior-to-Superior Direction

FIG. 2 Schematic of Static Glenoid Locking Strength Anterior-to-Posterior Direction

4.5 In order for the test data on metal or

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1829 − 98 (Reapproved 2009) F1829 − 16

Standard Test Method for

Static Evaluation of Anatomic Glenoid Locking Mechanism

1

in Shear

This standard is issued under the fixed designation F1829; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a method for determining the static shear disassembly force of modular anatomic glenoid

components used in shoulder prostheses. It is intended to be used as a design validation and for comparison with other anatomic

total shoulder arthroplasty prostheses.

1.2 Although the methodology described does not replicate all physiological force conditions, it is a means of in vitro

comparison of modular anatomic glenoid component designs and the strength of the retention mechanism between the articular

insert and glenoid backing under the stated test conditions.

1.3 This test method covers modular glenoid components comprised of a separate articular insert and backing. The insert and

backing can be fabricated from any combination of the following materials: metal alloys, polymeric materials, composite materials.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

F1378 Specification for Shoulder Prostheses

F2028 Test Methods for Dynamic Evaluation of Glenoid Loosening or Disassociation

3. Terminology

3.1 Definitions:

3.1.1 anatomic total shoulder arthroplasty system, n—shoulder implant system that has a concave glenoid component and a

convex humeral component design.

3.1.2 glenoid component, n—the prosthetic portion that replaces the glenoid fossa of the scapula and articulates with the natural

humeral head or a prosthetic replacement.

3.2 Definitions:Definitions of Terms Specific to This Standard:

3.2.1 articular insert—insert, n—the polymericconcave prosthetic portion of a multiple piece multi-piece glenoid component

that articulates with the humeral head. This articular insert is most often polymeric.

3.2.2 “d”—“d”, n—offset distance from the edge of the glenoid backing locking mechanism to the centerline of the point of

load application on the articular insert as shown in Fig. 1 and Fig. 2.

3.2.3 glenoid backing—backing, n—the metallic or composite material prosthetic portion of a multiple piece glenoid component

that attaches to the scapula.

1

This test method is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.22 on Arthroplasty.

Current edition approved Feb. 1, 2009March 1, 2016. Published March 2009April 2016. Originally approved in 1997. Last previous edition approved in 20032009 as

F1829 – 98 (2009).(2003). DOI: 10.1520/F1829-98R09.10.1520/F1829-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1829 − 16

FIG. 1 Schematic of Static Glenoid Locking Strength Inferior-to-Superior Direction

FIG. 2 Schematic of Static Glenoid Locking Strength Anterior-to-Posterior Direction

3.1.4 glenoid component—the prosthetic portion that replaces the glenoid fossa of the scapula and articulates with the natural

humeral head or a prosthetic replacement.

4. Significance and Use

4.1 This test method can be used to describe the effects of materials, manufacturing, and design variables on the performance

of metal-backed glenoid prosthesesmetal or composite-backed anatomic glenoid prostheses’ locking mechanisms to resist static

shear loading.

4.2 The glenoid component is used in shoulder replacements and should conform to the criteria specified in Specifica

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.