ASTM D6962-24

(Practice)Standard Practice for Operation of a Roller Chair Tester for Pile Yarn Floor Coverings

Standard Practice for Operation of a Roller Chair Tester for Pile Yarn Floor Coverings

SIGNIFICANCE AND USE

5.1 This practice is applicable for use in testing the durability of pile yarn floor covering of all types.

5.2 This practice is designed to simulate the stress on a pile yarn floor covering from the action of weighted roller chair castors over an extended period of time.

5.3 The specimen is tested under conditions that may simulate an actual flooring installation. This may include the pile yarn floor covering plus a specified underlayment cushion.

5.4 This practice is used to prepare specimens for additional testing, including but not limited to: visual assessment of delamination of the secondary backing, visual assessment of the pile surface, resistance to delamination measurement, tuft bind, and pile yarn raveling.

SCOPE

1.1 This practice covers a procedure for the operation of a weighted roller chair testing device that rotates and moves across a test specimen of pile yarn floor coverings.

1.2 This practice is applicable for testing unused pile yarn floor covering of all types.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6962 − 24

Standard Practice for

Operation of a Roller Chair Tester for Pile Yarn Floor

1

Coverings

This standard is issued under the fixed designation D6962; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 The following terms are relevant to this practice:

carpet, durability, finished, finished pile yarn floor covering,

1.1 This practice covers a procedure for the operation of a

floor covering, pile, pile yarn floor covering, practice, resis-

weighted roller chair testing device that rotates and moves

tance to delamination, secondary backing, textile floor

across a test specimen of pile yarn floor coverings.

covering, tufted fabric, underlay.

1.2 This practice is applicable for testing unused pile yarn

3.2 For all other terminology related to textiles, refer to

floor covering of all types.

Terminology D123.

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

4. Summary of Test Method

conversions to SI units that are provided for information only

4.1 The carpet test specimen is secured to a table with the

and are not considered standard.

pile surface exposed and is subjected to the action of three

1.4 This standard does not purport to address all of the

castors which produce an eccentric turning motion under a

safety concerns, if any, associated with its use. It is the

weighted roller chair device that moves across the test speci-

responsibility of the user of this standard to establish appro-

men for a specified number of cycles.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 5. Significance and Use

1.5 This international standard was developed in accor-

5.1 This practice is applicable for use in testing the dura-

dance with internationally recognized principles on standard-

bility of pile yarn floor covering of all types.

ization established in the Decision on Principles for the

5.2 This practice is designed to simulate the stress on a pile

Development of International Standards, Guides and Recom-

yarn floor covering from the action of weighted roller chair

mendations issued by the World Trade Organization Technical

castors over an extended period of time.

Barriers to Trade (TBT) Committee.

5.3 The specimen is tested under conditions that may

2. Referenced Documents

simulate an actual flooring installation. This may include the

2

2.1 ASTM Standards:

pile yarn floor covering plus a specified underlayment cushion.

D123 Terminology Relating to Textiles

5.4 This practice is used to prepare specimens for additional

D1776 Practice for Conditioning and Testing Textiles

testing, including but not limited to: visual assessment of

D2240 Test Method for Rubber Property—Durometer Hard-

delamination of the secondary backing, visual assessment of

ness

the pile surface, resistance to delamination measurement, tuft

D5684 Terminology Relating to Pile Floor Coverings

bind, and pile yarn raveling.

3. Terminology

6. Apparatus and Materials

3.1 For definitions of terms relating to Pile Floor Coverings,

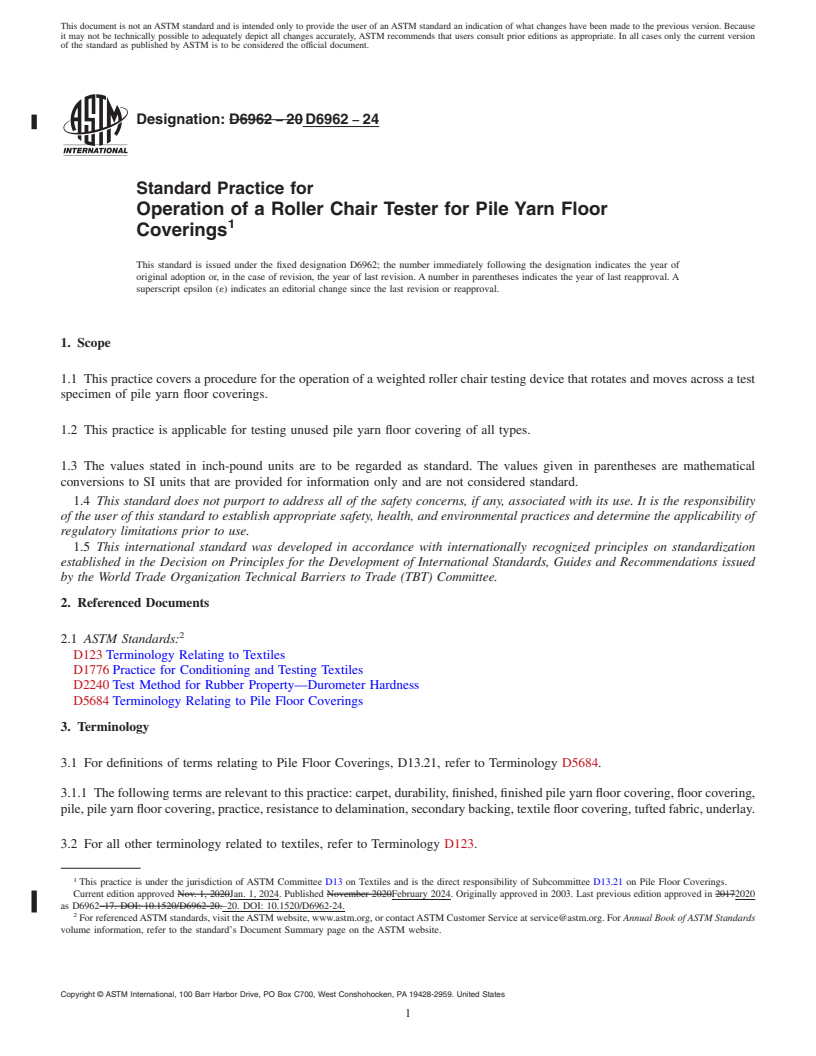

6.1 Roller Chair Tester is constructed of steel with a rotating

D13.21, refer to Terminology D5684.

circular table and a weighted roller fixture, rotating off-center

to the table. The apparatus also has electronic controls, a

1

This practice is under the jurisdiction of ASTM Committee D13 on Textiles and

protective cage, and a vacuum system to remove lint and dust.

is the direct responsibility of Subcommittee D13.21 on Pile Floor Coverings.

The area of contact between the rollers and the pile yarn wear

Current edition approved Jan. 1, 2024. Published February 2024. Originally

will be an annulus with an outside diameter of 23.6 6 0.6 in.

approved in 2003. Last previous edition approved in 2020 as D6962–20. DOI:

10.1520/D6962-24.

(600 6 15 mm) and inside diameter of 3.9 6 0.6 in. (100 6 15

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mm).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1.1 Rotating circular table is 31.3 in. 6 0.4 in. (795 mm 6

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 10 mm) diameter and 0.5 in. 6 0.1 in. (12 mm 6 1 mm) thick

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6962 − 20 D6962 − 24

Standard Practice for

Operation of a Roller Chair Tester for Pile Yarn Floor

1

Coverings

This standard is issued under the fixed designation D6962; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers a procedure for the operation of a weighted roller chair testing device that rotates and moves across a test

specimen of pile yarn floor coverings.

1.2 This practice is applicable for testing unused pile yarn floor covering of all types.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

D2240 Test Method for Rubber Property—Durometer Hardness

D5684 Terminology Relating to Pile Floor Coverings

3. Terminology

3.1 For definitions of terms relating to Pile Floor Coverings, D13.21, refer to Terminology D5684.

3.1.1 The following terms are relevant to this practice: carpet, durability, finished, finished pile yarn floor covering, floor covering,

pile, pile yarn floor covering, practice, resistance to delamination, secondary backing, textile floor covering, tufted fabric, underlay.

3.2 For all other terminology related to textiles, refer to Terminology D123.

1

This practice is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.21 on Pile Floor Coverings.

Current edition approved Nov. 1, 2020Jan. 1, 2024. Published November 2020February 2024. Originally approved in 2003. Last previous edition approved in 20172020

as D6962–17. DOI: 10.1520/D6962-20.–20. DOI: 10.1520/D6962-24.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6962 − 24

4. Summary of Test Method

4.1 The carpet test specimen is secured to a table with the pile surface exposed and is subjected to the action of three castors which

produce an eccentric turning motion under a weighted roller chair device that moves across the test specimen for a specified

number of cycles.

5. Significance and Use

5.1 This practice is applicable for use in testing the durability of pile yarn floor covering of all types.

5.2 This practice is designed to simulate the stress on a pile yarn floor covering from the action of weighted roller chair castors

over an extended period of time.

5.3 The specimen is tested under conditions that may simulate an actual flooring installation. This may include the pile yarn floor

covering plus a specified underlayment cushion.

5.4 This practice is used to prepare specimens for additional testing, including but not limited to: visual assessment of

delamination of the secondary backing, visual assessment of the pile surface, resistance to delamination measurement, tuft bind,

and pile yarn raveling.

6. Apparatus and Materials

6.1 Roller Chair Tester is constructed of steel with a rotating circular table and a weighted roller fixture, rotating off-center to the

table. The apparatus also has electronic controls, a protective cage, and a vacuum system to remove lint and dust. The area of

contact between the rollers and the pile yarn wear will be an annulus with an outside diameter of 23

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.