ASTM B317-02

(Specification)Standard Specification for Aluminum-Alloy Extruded Bar, Rod, Tube, Pipe, and Structural Profiles for Electrical Purposes (Bus Conductor)

Standard Specification for Aluminum-Alloy Extruded Bar, Rod, Tube, Pipe, and Structural Profiles for Electrical Purposes (Bus Conductor)

SCOPE

1.1 This specification covers 6101 aluminum-alloy extruded bar, rod, tube, pipe (Schedules 40 and 80), and structural profiles (channels and angles) in selected tempers for use as electric conductors as follows:

1.1.1 Type B—Hot-finished bar, rod, tube, pipe and structural profiles in T6, T61, T63, T64, T65, and H111 tempers with Type B tolerances, as shown in the "List of ANSI Tables of Dimensional Tolerances."

1.1.2 Type C—Hot-finished rectangular bar in T6, T61, T63, T64, T65, and H111 tempers with Type C tolerances as listed in the tolerances and permissible variations tables.

1.2 Alloy and temper designations are in accordance with ANSI H35.1. The equivalent Unified Numbering System alloy designation in accordance with Practice E 527 is A96101 for Alloy 6101.

Note 1—Type A material, last covered in the 1966 issue of this specification, is no longer available; therefore, requirements for cold-finished rectangular bar have been deleted.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: B 317 – 02

Standard Specification for

Aluminum-Alloy Extruded Bar, Rod, Tube, Pipe, and

1

Structural Profiles for Electrical Purposes (Bus Conductor)

This standard is issued under the fixed designation B 317; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B 557 Test Methods of Tension Testing Wrought and Cast

4

Aluminum- and Magnesium-Alloy Products

1.1 Thisspecificationcovers6101aluminum-alloyextruded

B 660 Practices for Packaging/Packing of Aluminum and

bar, rod, tube, pipe (Schedules 40 and 80), and structural

4

Magnesium Products

profiles (channels and angles) in selected tempers for use as

B 666/B 666M Practice for Identification Marking of Alu-

electric conductors as follows:

4

minum and Magnesium Products

1.1.1 Type B—Hot-finished bar, rod, tube, pipe and struc-

B 807 Practice for Extrusion Press Solution Heat Treatment

tural profiles in T6, T61, T63, T64, T65, and H111 tempers

4

of Aluminum Alloys

with Type B tolerances, as shown in the “List of ANSI Tables

B 918 Practice for Heat Treatment of Wrought Aluminum

of Dimensional Tolerances.”

4

Alloys

1.1.2 Type C—Hot-finishedrectangularbarinT6,T61,T63,

E 29 Practice for Using Significant Digits in Test Data to

T64, T65, and H111 tempers with Type C tolerances as listed

5

Determine Conformance with Specifications

in the tolerances and permissible variations tables.

E 34 Test Methods for ChemicalAnalysis ofAluminum and

1.2 Alloy and temper designations are in accordance with

6

Aluminum Base Alloys

ANSI H35.1. The equivalent Unified Numbering System alloy

E 55 PracticeforSamplingWroughtNonferrousMetalsand

designation in accordance with Practice E 527 is A96101 for

6

Alloys for Determination of Chemical Composition

Alloy 6101.

E 227 Test Method for Optical Emission Spectrometric

NOTE 1—Type A material, last covered in the 1966 issue of this

Analysis of Aluminum and Aluminum Alloys by the

specification, is no longer available; therefore, requirements for cold-

6

Point-to-Plane Technique

finished rectangular bar have been deleted.

E 290 Test Methods for Bend Testing of Material for

1.3 For acceptance criteria for inclusion of new aluminum 7

Ductility

8

and aluminum alloys in this specification, see Annex A2.

E 527 Practice for Numbering Metals and Alloys (UNS)

1.4 The values stated in inch-pound units are to be regarded

E 607 Test Method for Atomic Emission Spectrometric

as the standard. The values given in parentheses are for

Analysis of Aluminum and Aluminum Alloys by the

information only. 6

Point-to-Plane Technique, Nitrogen Atmosphere

E 716 Practices for Sampling Aluminum and Aluminum

2. Referenced Documents

6

Alloys for Spectrochemical Analysis

2.1 The following documents of the issue in effect on the

E 1004 Practice for Determining Electrical Conductivity

date of material purchase form a part of this specification to the 9

Using the Electromagnetic (Eddy-Current) Method

extent referenced herein:

E 1251 Test Method for Optical Emission Spectrometric

2.2 ASTM Standards:

Analysis ofAluminum andAluminumAlloys by theArgon

B 193 Test Method for Resistivity of Electrical Conductor

Atmosphere, Point-to-Plane, Unipolar Self-Initiating Ca-

2

6

Materials

pacitor Discharge

B 253 Guide for Preparation of Aluminum Alloys for Elec- 4

2.3 ANSI Standards:

3

troplating

H35.1 Alloy and Temper Designation Systems for Alumi-

num

1

This specification is under the jurisdiction of ASTM Committee B07 on Light

4

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on Annual Book of ASTM Standards, Vol 02.02.

5

Aluminum-Alloy Wrought Products. Annual Book of ASTM Standards, Vol 14.02.

6

Current edition approved Oct. 10, 2002. Published January 2003. Originally Annual Book of ASTM Standards, Vol 03.05.

7

approved in 1957. Last previous edition approved in 2000 as B 317–00. Annual Book of ASTM Standards, Vol 03.01.

2 8

Annual Book of ASTM Standards, Vol 02.03. Annual Book of ASTM Standards, Vol 01.01.

3 9

Annual Book of ASTM Standards, Vol 02.05. Annual Book of ASTM Standards, Vol 03.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

B317–02

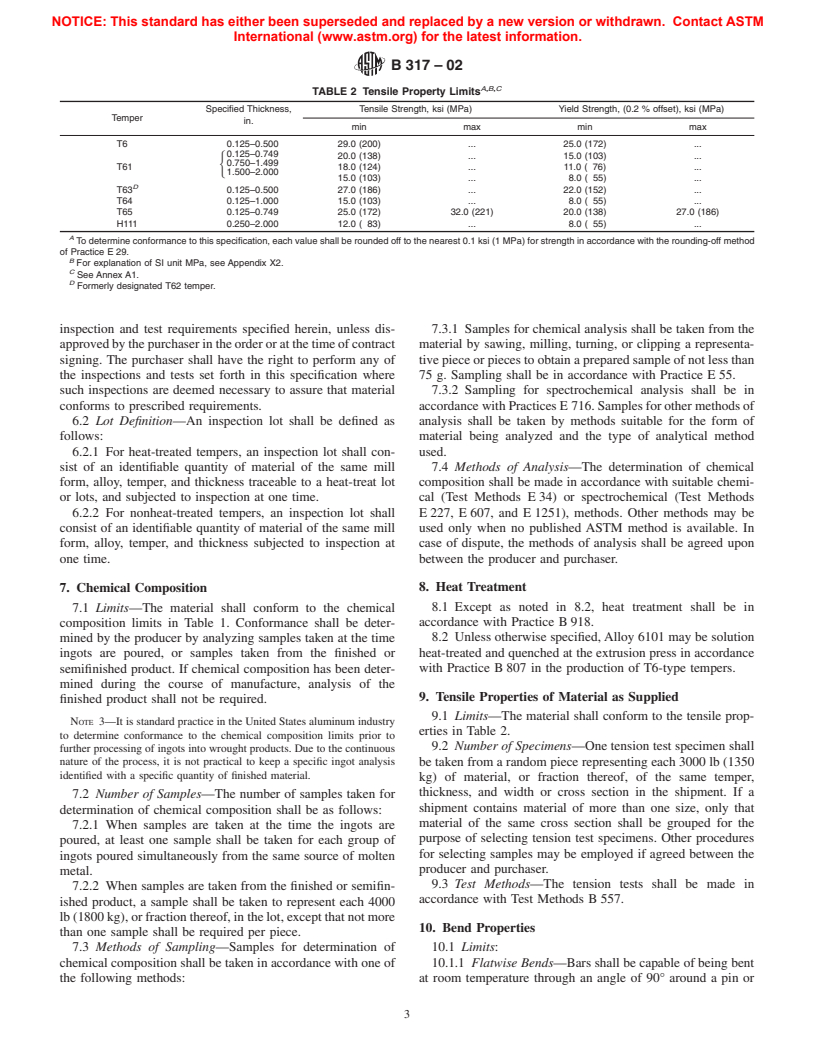

A,B,C

TABLE 1 Chemical Composition Limits

H35.2 DimensionalToleranc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.