ASTM D5965-19

(Test Method)Standard Test Methods for Density of Coating Powders

Standard Test Methods for Density of Coating Powders

SIGNIFICANCE AND USE

4.1 Test Method A is a straight-forward method using readily available laboratory equipment and glassware. Test Method A may only be used with powder that does not contain metallic pigments.

4.2 Test Method B provides better precision at higher cost and includes metallics, although different models produced different grand averages for each of the three samples tested.

4.3 Test Method C may be used when the formulation is known, and the density of each raw material is available.

SCOPE

1.1 These standard test methods cover three procedures for determining the density of coating powders, as follows:

1.2 Test Method A, for testing coating powders, excluding metallics, is a method that uses readily available laboratory equipment (for example, analytical balance, volumetric flask, etc.).

1.3 Test Method B requires the use of a pycnometer.

1.4 Test Method C is a method that calculates the density of a powder based upon the formula ingredients and their amounts and densities.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5965 − 19

Standard Test Methods for

1

Density of Coating Powders

This standard is issued under the fixed designation D5965; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 These standard test methods cover three procedures for

determining the density of coating powders, as follows:

3. Terminology

1.2 Test Method A, for testing coating powders, excluding

3.1 Definitions:

metallics, is a method that uses readily available laboratory

3.1.1 coating powder, n—finely divided particles of resin,

equipment (for example, analytical balance, volumetric flask,

either thermoplastic or thermosetting, generally incorporating

etc.).

pigments, fillers, and additives and remaining finely divided

1.3 Test Method B requires the use of a pycnometer.

during storage under suitable conditions, which, after fusing

1.4 Test Method C is a method that calculates the density of and possibly curing, give a continuous film.

apowderbasedupontheformulaingredientsandtheiramounts

3.1.2 density, n—the mass per unit volume of a material,

3

and densities.

usually expressed in g/cm .

1.5 The values stated in SI units are to be regarded as the

3.1.2.1 Discussion—In this standard, a volumetric flask

standard. The values given in parentheses are for information

capacity is expressed—by convention—in mL. However, con-

only.

3

vention also states density in terms of mass per cm . Since

3

1.6 This standard does not purport to address all of the

1mL=1cm , terms will be interchanged—by convention—

safety concerns, if any, associated with its use. It is the

but will not affect any of the calculations.

responsibility of the user of this standard to establish appro-

3.1.3 meniscus, n—curved upper surface of a liquid column

priate safety, health, and environmental practices and deter-

that is concave when the containing walls are wetted by the

mine the applicability of regulatory limitations prior to use.

liquid.

1.7 This international standard was developed in accor-

3.1.4 powder coating, n—coatings which are protective or

dance with internationally recognized principles on standard-

decorative, or both, formed by the application of a coating

ization established in the Decision on Principles for the

powder to a substrate and fused into continuous films by the

Development of International Standards, Guides and Recom-

application of heat or radiant energy.

mendations issued by the World Trade Organization Technical

3.1.5 pycnometer, n—instrument designed to measure the

Barriers to Trade (TBT) Committee.

volume of solid materials usingArchimedes’ principle of fluid

2. Referenced Documents

displacement. The displaced fluid is a helium gas.

2

2.1 ASTM Standards: 3.1.6 wetting liquid, n—an organic solvent used to wet-out

D3924 Specification for Standard Environment for Condi- the powder and displace the air that is trapped between the

tioning and Testing Paint, Varnish, Lacquer, and Related powder particles.

3

Materials (Withdrawn 2016)

4. Significance and Use

1

4.1 Test Method A is a straight-forward method using

These test methods are under the jurisdiction of ASTM Committee D01 on

Paint and Related Coatings, Materials, and Applications and are the direct

readily available laboratory equipment and glassware. Test

responsibility of Subcommittee D01.51 on Powder Coatings.

MethodAmay only be used with powder that does not contain

Current edition approved July 1, 2019. Published July 2019. Originally approved

metallic pigments.

in 1996. Last previous edition approved in 2013 as D5965 – 02 (2013). DOI:

10.1520/D5965-19.

4.2 Test Method B provides better precision at higher cost

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and includes metallics, although different models produced

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on different grand averages for each of the three samples tested.

the ASTM website.

3

4.3 Test Method C may be used when the formulation is

The last approved version of this historical standard is referenced on

www.astm.org. known, and the density of each raw material is available.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 -------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5965 − 02 (Reapproved 2013) D5965 − 19

Standard Test Methods for

1

Specific Gravity Density of Coating Powders

This standard is issued under the fixed designation D5965; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These standard test methods cover three procedures for determining the specific gravity (see definition) density of coating

powders, as follows:

TEST METHOD A—For Testing Coating Powders, Excluding Metallics

TEST METHOD B—For Tests Requiring Greater Precision than Test Method A,

Including Metallics, Using Helium Pycnometry

TEST METHOD C—For Theoretical Calculation Based on Raw Material Specific

Gravities

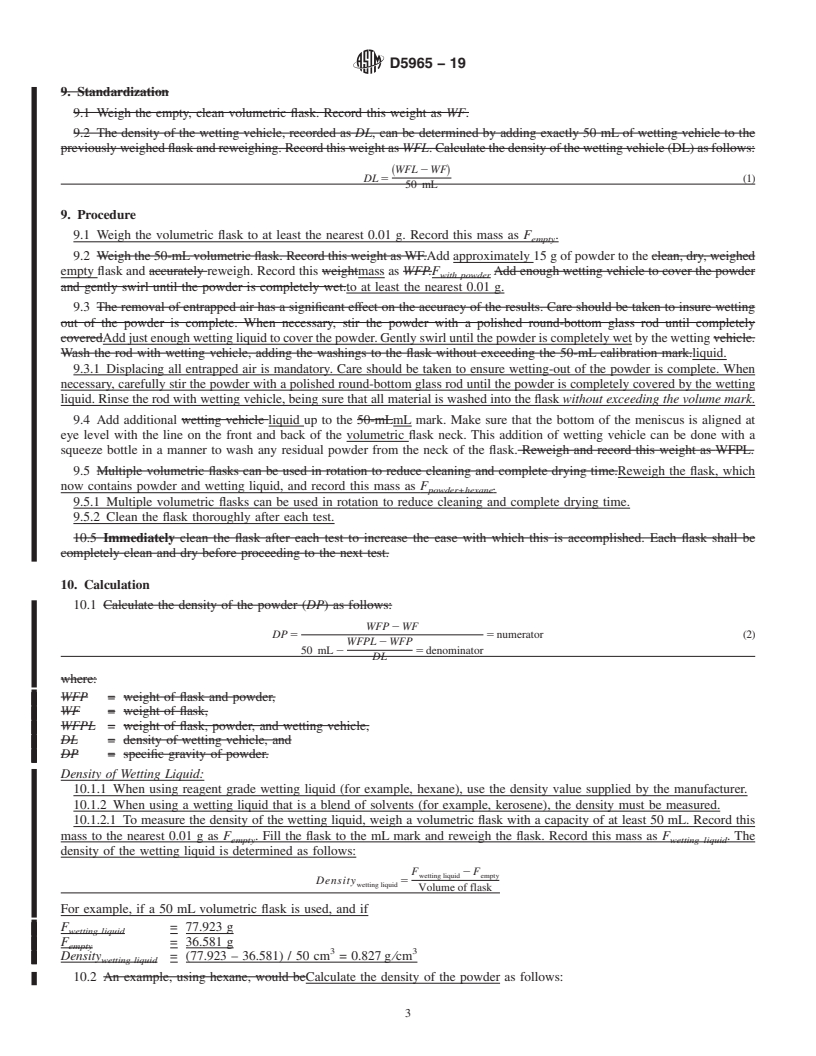

1.2 Test Method A can be used as a less expensive method with reduced accuracy for determining the specific gravity of coating

powders, excluding metallics.A, for testing coating powders, excluding metallics, is a method that uses readily available laboratory

equipment (for example, analytical balance, volumetric flask, etc.).

1.3 The ideal gas law forms the basis for all calculations used in the Test Method B determination of density of coating powders.

1.4 Test Method B includes procedures that provided acceptable results for samples analyzed during round robin testing.

1.3 Test Method B uses SI units as standard. State all numerical values in terms of SI units unless specific instrumentation

3

software reports surface area using alternate units. Many instruments report density as g/cmrequires the use of a pycnometer. ,

3

instead of using SI units (kg/m ).

1.4 Test Method C is a method that calculates the density of a powder based upon the formula ingredients and their amounts

and densities.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D3924 Specification for Standard Environment for Conditioning and Testing Paint, Varnish, Lacquer, and Related Materials

3

(Withdrawn 2016)

D5382 Guide to Evaluation of Optical Properties of Powder Coatings

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 Definitions 3.1.1 and 3.1.3 are from Guide D5382.

1

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.51 on Powder Coatings.

Current edition approved June 1, 2013July 1, 2019. Published July 2013July 2019. Originally approved in 1996. Last previous edition approved in 20072013 as D5965 – 02

(2007).(2013). DOI: 10.1520/D5965-02R13.10.1520/D5965-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5965 − 19

3.1.1 coating powder, n—finely divided particles of resin, either thermoplastic or thermosetting, generally incorporating

pigments, fillers, and additives and remaining finely divided during storage under suitable conditions, which, after fusing and

possibly curing, give a continuous film.

3

3.1.2 density, n—the mass per unit volume of a material, usually expressed in g/cm .

3.1.2.1 Discussion—

In this standard, a volumetric flask capacity is expressed—by convention—in mL. However, convention als

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.