ASTM E3320-21

(Test Method)Standard Test Method for Measurement of Retroreflective Pavement Marking Materials Using a Mobile Retroreflectometer Unit (MRU)

Standard Test Method for Measurement of Retroreflective Pavement Marking Materials Using a Mobile Retroreflectometer Unit (MRU)

SIGNIFICANCE AND USE

5.1 The quality of the pavement marking is determined by the coefficient of retroreflected luminance, RL, and depends on the materials used, age, wear pattern, application method, pavements surface, and other conditions.

5.2 Under the same conditions of illumination and viewing, larger values of RL correspond to higher levels of visual performance in dark conditions.

5.3 Retroreflectivity of pavement (road) markings degrades with traffic wear and requires periodic measurement to ensure that sufficient line visibility is provided to drivers.

5.4 MRUs are used to measure RL values of road markings while moving at traffic speed, and can be used for longer stretches of road than portable instruments and in cases where the use of portable instruments require extensive precautions, in particular on motorways.

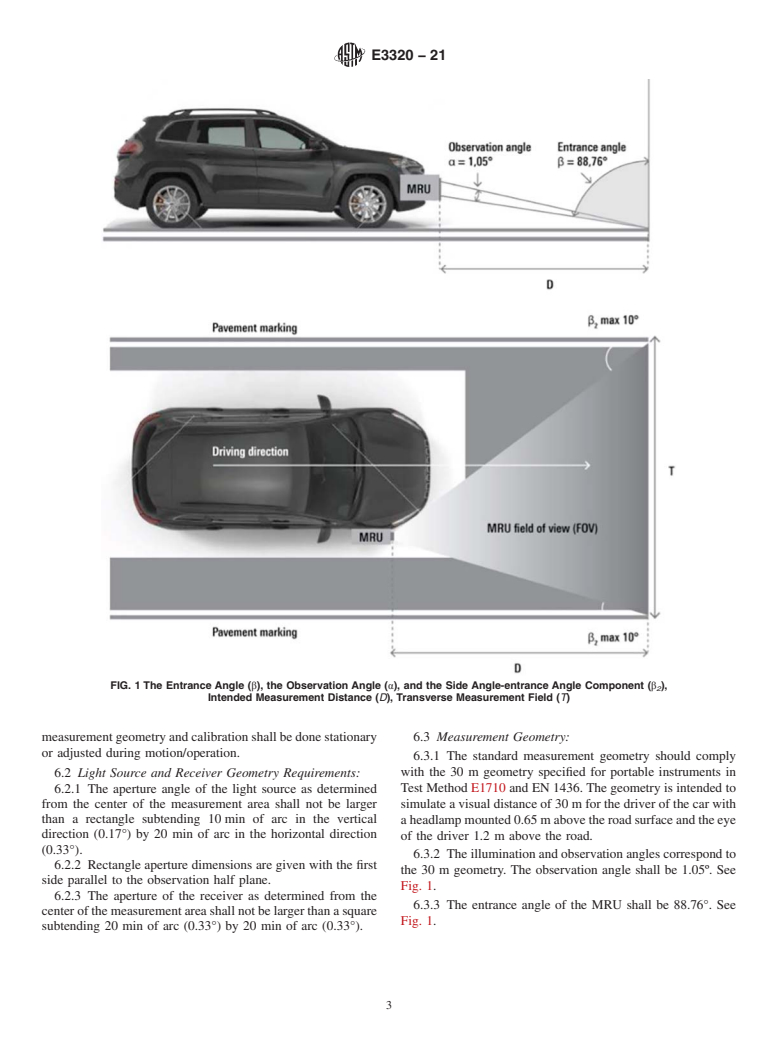

5.5 The measurement geometry of the MRU is based on a viewing distance of 30 m, a headlight mounting height of 0.65 m directly over the stripe, and an eye height of 1.2 m directly over the marking according to CEN 1436 and Test Method E1710.

5.6 MRUs are to be calibrated, maintained, and operated according to instructions by the instrument supplier or manufacturer.

5.7 It shall be the responsibility of the user to employ an MRU fulfilling the required specifications in this standard.

SCOPE

1.1 This test method covers measurement of the retroreflective properties of horizontal pavement marking materials containing retroreflecting optics, such as traffic stripes and surface symbols, using a mobile retroreflectometer unit that can be operated at traffic speed, mounted on a vehicle to measure the retroreflection at a prescribed geometry.

1.2 The entrance and observation angles of the MRU affect the readings. As specified by the European Committee for Standardization (CEN) and in Test Method E1710, the entrance and observation angles shall be 88.76° and 1.05°, respectively.

1.3 This test method is intended to be used for field measurement of pavement markings at traffic speed.

1.4 This test method is intended to be used for retroreflectivity measurement of dry pavement markings.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.6 This standard does not purport to address regulatory and safety regulations of the MRU and its use. It is the responsibility of the manufacturer to fulfill regulatory standards. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3320 −21

Standard Test Method for

Measurement of Retroreflective Pavement Marking Materials

1

Using a Mobile Retroreflectometer Unit (MRU)

This standard is issued under the fixed designation E3320; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers measurement of the retroreflec-

tive properties of horizontal pavement marking materials D7585Practice for Evaluating Retroreflective Pavement

containing retroreflecting optics, such as traffic stripes and Markings Using Portable Hand-Operated Instruments

surface symbols, using a mobile retroreflectometer unit that E284Terminology of Appearance

can be operated at traffic speed, mounted on a vehicle to E808Practice for Describing Retroreflection

measure the retroreflection at a prescribed geometry. E1710Test Method for Measurement of Retroreflective

Pavement Marking Materials with CEN-Prescribed Ge-

1.2 The entrance and observation angles of the MRU affect

ometry Using a Portable Retroreflectometer

the readings. As specified by the European Committee for

2.2 Other Standards:

Standardization(CEN)andinTestMethodE1710,theentrance

CEN EN 1436Road Marking Materials—Road Marking

and observation angles shall be 88.76° and 1.05°, respectively.

3

Performance for Road Users and Test Methods

1.3 This test method is intended to be used for field

CIE publication No. 54.2Retroreflection – Definition and

4

measurement of pavement markings at traffic speed.

Measurement

5

1.4 This test method is intended to be used for retroreflec- ISO 10526CIE standard illuminants for colorimetry

tivity measurement of dry pavement markings.

3. Terminology

1.5 The values stated in SI units are to be regarded as

3.1 The terminology used in this test method generally

standard. The values given in parentheses after SI units are

agrees with that used in Terminology E284.

provided for information only and are not considered standard.

3.2 Definitions—The delimiting phrase “in retroreflection”

1.6 Thisstandarddoesnotpurporttoaddressregulatoryand

applies to each of the following definitions when used outside

safety regulations of the MRU and its use. It is the responsi-

the context of this or other retroreflection test methods:

bility of the manufacturer to fulfill regulatory standards. It is

3.2.1 actual measuring distance, D, n—theactualhorizontal

the responsibility of the user of this standard to establish

distance from the MRU to the center of the measuring areas of

appropriate safety and health practices and determine the

the pavement marking.

applicability of regulatory limitations prior to use.

3.2.2 coeffıcient of retroreflected luminance, R ,n—theratio

L

1.7 This international standard was developed in accor-

of the luminance, L, of a projected surface to the normal

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Development of International Standards, Guides and Recom-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mendations issued by the World Trade Organization Technical

Standards volume information, refer to the standard’s Document Summary page on

Barriers to Trade (TBT) Committee.

the ASTM website.

3

Available from European Committee for Standardization (CEN), Avenue

Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

4

AvailablefromU.S.NationalCommitteeoftheCIE(InternationalCommission

1

This test method is under the jurisdiction of ASTM Committee E12 on Color on Illumination), C/o Alan Laird Lewis, 282 E. Riding, Carlisle, MA 01741,

and Appearance and is the direct responsibility of Subcommittee E12.10 on http://www.cie-usnc.org.

5

Retroreflection. Available from International Organization for Standardization (ISO), ISO

Current edition approved Oct. 1, 2021. Published June 2022. DOI: 10.1520/ Central Secretariat, Chemin de Blandonnet 8, CP 401, 1214 Vernier, Geneva,

E3320-21. Switzerland, https://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E3320 − 21

illuminance, E',atthesurfaceonaplanenormaltotheincident 4.3 The observation angle is fixed at 1.05°. See Fig. 1.

light expressed in candelas per square meter per lux

4.4 The entrance angle compon

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.