ASTM B745/B745M-97(2005)

(Specification)Standard Specification for Corrugated Aluminum Pipe for Sewers and Drains

Standard Specification for Corrugated Aluminum Pipe for Sewers and Drains

ABSTRACT

This specification covers corrugated aluminum pipe intended for use for storm water drainage, underdrains, the construction of culverts, and similar uses. Pipe covered by this specification is not normally used for the conveyance of sanitary or industrial wastes. All pipe fabricated under this specification shall be formed from aluminum-alloy sheet conforming to the requirements specified. The sheet used in fabricating coupling bands shall conform to the requirements specified. The material used for rivets in riveted pipe shall conform to the requirements specified. Bolts and nuts for coupling bands shall conform to the required specification. If gaskets are used in couplings, they shall be a band of expanded rubber meeting the specified requirements. The fabrication requirements for type I, type II, type IA, and type IR pipe are presented. The corrugations shall be either annular or helical as provided. The different pipe requirements like pipe dimensions, sheet thickness, pipe-arch dimensions, longitudinal seams, and perforations are presented in details. Field joints for each type of corrugated aluminum pipe shall maintain pipe alignment during construction and prevent infiltration of fill material during the life of the installation.

SCOPE

1.1 This specification covers corrugated aluminum pipe intended for use for storm water drainage, underdrains, the construction of culverts, and similar uses. Pipe covered by this specification is not normally used for the conveyance of sanitary or industrial wastes.

1.2 This specification does not include requirements for bedding, backfill, or the relationship between earth-cover load and sheet thickness of the pipe. Experience has shown that the successful performance of this product depends upon the proper selection of sheet thickness, type of bedding and backfill, controlled manufacture in the plant, and care in the installation. The purchaser must correlate the above factors and also the corrosion and abrasion requirements of the field installation with the sheet thickness. The structural design of corrugated aluminum pipe and the proper installation procedures are given in Practices B 790/B 790M and B 788/B 788M, respectively. A procedure for using life-cycle cost analysis techniques to evaluate alternative drainage system designs using corrugated metal pipe is given in Practice A 930.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B745/B745M −97(Reapproved 2005)

Standard Specification for

Corrugated Aluminum Pipe for Sewers and Drains

This standard is issued under the fixed designation B745/B745M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers corrugated aluminum pipe

A153/A153M Specification for Zinc Coating (Hot-Dip) on

intended for use for storm water drainage, underdrains, the

Iron and Steel Hardware

construction of culverts, and similar uses. Pipe covered by this

A307 Specification for Carbon Steel Bolts and Studs, 60 000

specification is not normally used for the conveyance of

PSI Tensile Strength

sanitary or industrial wastes.

A563 Specification for Carbon and Alloy Steel Nuts

1.2 This specification does not include requirements for

A563M Specification for Carbon andAlloy Steel Nuts (Met-

bedding, backfill, or the relationship between earth-cover load

ric)

and sheet thickness of the pipe. Experience has shown that the

A930 Practice for Life-Cycle Cost Analysis of Corrugated

successful performance of this product depends upon the

Metal Pipe Used for Culverts, Storm Sewers, and Other

proper selection of sheet thickness, type of bedding and

Buried Conduits

backfill, controlled manufacture in the plant, and care in the

B209 Specification for Aluminum and Aluminum-Alloy

installation.Thepurchasermustcorrelatetheabovefactorsand

Sheet and Plate

also the corrosion and abrasion requirements of the field

B209M Specification for Aluminum and Aluminum-Alloy

installation with the sheet thickness. The structural design of

Sheet and Plate (Metric)

corrugated aluminum pipe and the proper installation proce-

B221 Specification forAluminum andAluminum-Alloy Ex-

dures are given in Practices B790/B790M and B788/B788M,

truded Bars, Rods, Wire, Profiles, and Tubes

respectively. A procedure for using life-cycle cost analysis

B221M Specification for Aluminum and Aluminum-Alloy

techniques to evaluate alternative drainage system designs

Extruded Bars, Rods, Wire, Profiles, and Tubes (Metric)

using corrugated metal pipe is given in Practice A930.

B316/B316M Specification for Aluminum and Aluminum-

1.3 The values stated in either SI units or inch-pound units

Alloy Rivet and Cold-Heading Wire and Rods

are to be regarded separately as standard. The values stated in

B633 Specification for Electrodeposited Coatings of Zinc on

each system may not be exact equivalents; therefore, each

Iron and Steel

system shall be used independently of the other. Combining

B666/B666M Practice for Identification Marking of Alumi-

values from the two systems may result in non-conformance

num and Magnesium Products

with the standard.

B695 Specification for Coatings of Zinc Mechanically De-

1.4 This standard does not purport to address all of the posited on Iron and Steel

B744/B744M Specification for Aluminum Alloy Sheet for

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- Corrugated Aluminum Pipe

B788/B788M Practice for Installing Factory-Made Corru-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. gated Aluminum Culverts and Storm Sewer Pipe

B790/B790M Practice for Structural Design of Corrugated

Aluminum Pipe, Pipe-Arches, and Arches for Culverts,

Storm Sewers, and Other Buried Conduits

This specification is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.08 on

Corrugated Aluminum Pipe and Corrugated Aluminum Structural Plate. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2005. Published September 2005. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1985. Last previous edition approved in 1997 as B745/B745M – 97. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/B0745_B0745M-97R05. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B745/B745M−97 (2005)

C443 Specification for Joints for Concrete Pipe and 4.1.8 Type IIIR—This pipe, intended for the underground

Manholes, Using Rubber Gaskets disposal of water or for subsurface drainage, shall be aType IR

D1056 Specification for Flexible Cellular Materials—

pipe which has been perforated to permit the outflow or inflow

Sponge or Expanded Rubber

of water.

F467 Specification for Nonferrous Nuts for General Use

4.2 Perforations in Type III pipe are classified as Class 1 or

F467M Specification for Nonferrous Nuts for General Use

Class 2 and perforations in Type IIIR pipe are classified as

(Metric)

Class 4, as described in 8.3.2.

F468 Specification for Nonferrous Bolts, Hex Cap Screws,

and Studs for General Use

5. Ordering Information

F468M SpecificationforNonferrousBolts,HexCapScrews,

and Studs for General Use (Metric)

5.1 Orders for material to this specification shall include the

F568M Specification for Carbon and Alloy Steel Externally

following information as necessary, to adequately describe the

Threaded Metric Fasteners (Metric) (Withdrawn 2012)

desired product:

F593 Specification for Stainless Steel Bolts, Hex Cap

5.1.1 Name of material (corrugated aluminum pipe),

Screws, and Studs

F594 Specification for Stainless Steel Nuts

5.1.2 ASTM designation and year of issue, as B745-_ for

F738M Specification for Stainless Steel Metric Bolts,

inch-pound units or B745M-_ for SI units,

Screws, and Studs

5.1.3 Type of pipe (4.1),

F836M Specification for Style 1 Stainless Steel Metric Nuts

5.1.4 Method of fabrication for Type I and Type II pipe

(Metric)

(7.1),

2.2 AASHTO Standard:

5.1.5 Diameter of circular pipe (8.1.1), or span and rise of

T 249 Test for Helical Lock Seam Corrugated Pipe

pipe-arch section (8.2.1),

3. Terminology

5.1.6 Length, either total length or length of each piece and

3.1 Definitions of Terms Specific to This Standard:

number of pieces,

3.1.1 fabricator—the producer of the pipe.

5.1.7 Description of corrugations (7.2),

3.1.2 manufacturer—the producer of the sheet.

5.1.8 Sheet thickness (8.1.2),

3.1.3 purchaser—the purchaser of the finished product.

5.1.9 Coupling bands, number, and type (9.1) if special type

is required,

4. Classification

5.1.10 Gaskets for coupling bands, if required (9.3),

4.1 The corrugated aluminum pipe covered by this specifi-

cation is classified as follows: 5.1.11 For perforated pipe, the class of perforations. If no

4.1.1 Type I—This pipe shall have a full circular cross- class is specified for Type III pipe, Class 1 perforations will be

section, with a single thickness of corrugated sheet, fabricated

furnished.TypeIIIRpipeisfurnishedwithClass4perforations

with annular (circumferential) or helical corrugations.

only (8.3.2.1 and 8.3.2.3),

4.1.2 Type IA—This pipe shall have a full circular cross-

5.1.12 Certification, if required (13.1), and

section, with an outer shell of corrugated sheet and an inner

5.1.13 Special requirements.

liner of smooth (uncorrugated) sheet, fabricated with helical

corrugations and lock seams.

6. Materials

4.1.3 Type IR—This pipe shall have a full circular cross-

section, with a single thickness of smooth sheet, fabricated

6.1 Aluminum Sheet for Pipe—Allpipefabricatedunderthis

with helical ribs projecting outwardly.

specification shall be formed from aluminum-alloy sheet con-

4.1.4 Type II—This pipe shall be a Type I pipe which has

forming to Specification B744/B744M.

been reformed into a pipe-arch, having an approximately flat

6.2 Aluminum Sheet for Coupling Bands—The sheet used in

bottom.

fabricating coupling bands shall conform to Specification

4.1.5 Type IIA—This pipe shall be aType IApipe which has

B744/B744M.

been reformed into a pipe-arch, having an approximately flat

bottom.

6.3 Rivets—The material used for rivets in riveted pipe shall

4.1.6 Type IIR—This pipe shall be aType IR pipe which has

conform to the requirements of Specification B316/B316M for

been reformed into a pipe-arch, having an approximately flat

alloy 6053-T4, with the following mechanical properties:

bottom.

Tensile Strength, min, ksi [MPa] 25 [170]

4.1.7 Type III—This pipe, intended for use as underdrains or

Yield Strength, min, ksi [MPa] 14 [95]

for underground disposal of water, shall be aType I pipe which

Shear Strength, min, ksi [MPa] 15 [105]

has been perforated to permit the in-flow or out-flow of water. Elongation in 2 in., 50 mm, or 4x dia., min, % 16

If bolts and nuts are substituted for rivets (see 7.3.1), they

The last approved version of this historical standard is referenced on

shall meet the following requirements for either steel bolts and

www.astm.org.

4 nuts, stainless steel bolts and nuts, or aluminum alloy bolts and

Available from American Association of State Highway and Transportation

Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001. nuts:

B745/B745M−97 (2005)

mm], and not less than 45° from the axis for pipe diameters of

Bolts Nuts

21 in. [525 mm] and smaller.

For B745 pipe

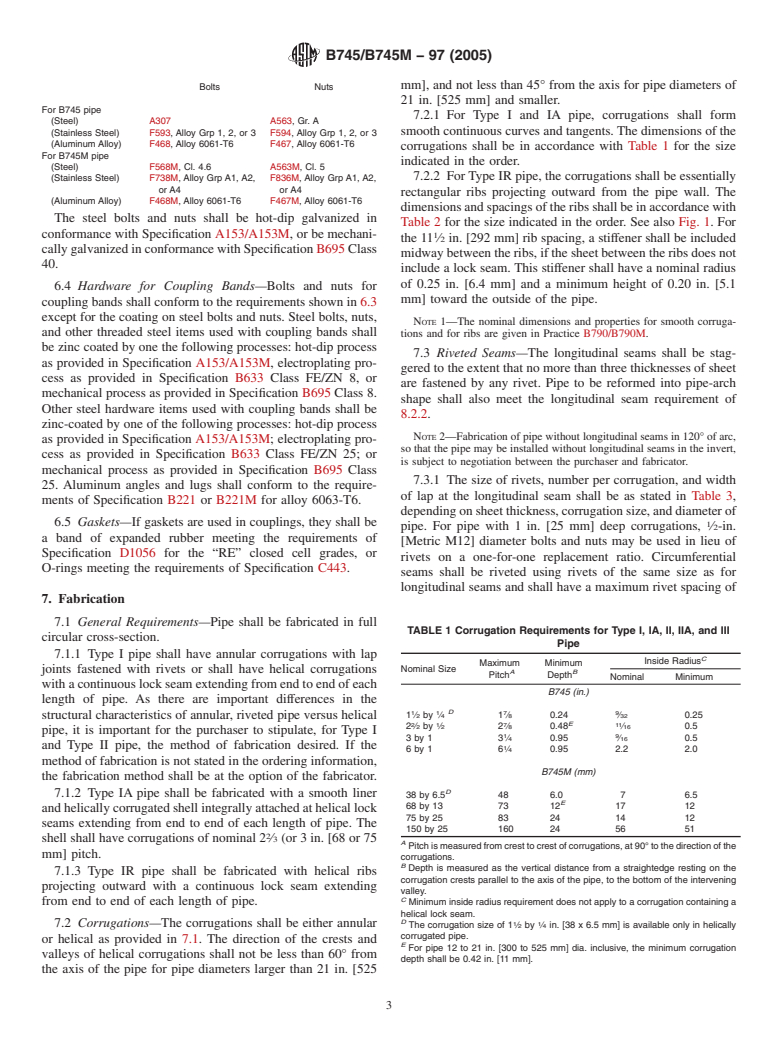

7.2.1 For Type I and IA pipe, corrugations shall form

(Steel) A307 A563,Gr.A

smooth continuous curves and tangents. The dimensions of the

(Stainless Steel) F593, Alloy Grp 1, 2, or 3 F594, Alloy Grp 1, 2, or 3

(Aluminum Alloy) F468, Alloy 6061-T6 F467, Alloy 6061-T6

corrugations shall be in accordance with Table 1 for the size

For B745M pipe

indicated in the order.

(Steel) F568M, Cl. 4.6 A563M, Cl. 5

7.2.2 For Type IR pipe, the corrugations shall be essentially

(Stainless Steel) F738M, Alloy Grp A1, A2, F836M, Alloy Grp A1, A2,

or A4 or A4

rectangular ribs projecting outward from the pipe wall. The

(Aluminum Alloy) F468M, Alloy 6061-T6 F467M, Alloy 6061-T6

dimensionsandspacingsoftheribsshallbeinaccordancewith

The steel bolts and nuts shall be hot-dip galvanized in

Table 2 for the size indicated in the order. See also Fig. 1. For

conformance with Specification A153/A153M, or be mechani- 1

the 11 ⁄2 in. [292 mm] rib spacing, a stiffener shall be included

callygalvanizedinconformancewithSpecificationB695Class

midway between the ribs, if the sheet between the ribs does not

40.

include a lock seam. This stiffener shall have a nominal radius

of 0.25 in. [6.4 mm] and a minimum height of 0.20 in. [5.1

6.4 Hardware for Coupling Bands—Bolts and nuts for

mm] toward the outside of the pipe.

coupling bands shall conform to the requirements shown in 6.3

except for the coating on steel bolts and nuts. Steel bolts, nuts,

NOTE 1—The nominal dimensions and properties for smooth corruga-

and other threaded steel items used with coupling bands shall

tions and for ribs are given in Practice B790/B790M.

be zinc coated by one the following processes: hot-dip process

7.3 Riveted Seams—The longitudinal seams shall be stag-

as provided in Specification A153/A153M, electroplating pro-

gered to the extent that no more than three thicknesses of sheet

cess as provided in Specification B633 Class FE/ZN 8, or

are fastened by any rivet. Pipe to be reformed into pipe-arch

mechanical process as provided in Specification B695 Class 8.

shape shall also meet the longitudinal seam requirement of

Other steel hardware items used with coupling bands shall be

8.2.2.

zinc-coated by one of the following processes: hot-dip process

NOTE 2—Fabrication of pipe without longitudinal seams in 120° of arc,

as provided in Specification A153/A153M; electroplating pro-

so that the pipe may be installed without longitudinal seams in the invert,

cess as provided in Specification B633 Class FE/ZN 25; or

is subject to negotiation between the purchaser and fabricator.

mechanical process as provided in Specification B695 Class

7.3.1 The size of rivets, number per corrugation, and width

25. Aluminum angles and lugs shall conform to the require-

of lap at the longitudinal seam shall be as stated in Table 3,

ments of Specification B221 or B221M for alloy 6063-T6.

dependingonsheetthickness,corrugationsize,anddiameterof

6.5 Gaskets—If gaskets are used in couplings, they shall be 1

pipe. For pipe with 1 in. [25 mm] deep corrugations, ⁄2-in.

a band of expanded rubber meeting the requirements of

[Metric M12] diameter bolts and nuts may be used in lieu of

Specification D1056 for the “RE” closed cell grades, or

rivets on a one-for-one replacement ratio. Circumferential

O-rings meeting the requirements of Specification C443.

seams shall be riveted using rivets of the same size as for

longitudinal seams and shall have a maximum rivet spacing of

7. Fabrication

7.1 General Requirements—Pipe shall be fabricated in full

TABLE 1 Corrugation Requirements for Type I, IA, II, IIA, and III

circular cross-section.

Pipe

7.1.1 Type I pipe shall have annular corrugations with lap

C

Inside Radius

Maximum Minimum

Nominal Size

joints fastened with rivets or shall have helical corrugations

A B

Pitch Depth

Nominal Minimum

with a continuous lock seam extending from end to end of each

B745 (in.)

length of pipe. As there are important differences in the

D

1 1 7 9

structural characteristics of annular, riveted pipe versus helical 1 ⁄2 by ⁄4 1 ⁄8 0.24 ⁄32 0.25

E

2 1 7 11

2 ⁄2 by ⁄2 2 ⁄8 0.48 ⁄16 0.5

pipe, it is important for the purchaser to stipulate, for Type I

1 9

3by1 3 ⁄4 0.95 ⁄16 0.5

and Type II pipe, the method of fabrication desired. If the 1

6by1 6 ⁄4 0.95 2.2 2.0

method of fabrication is not stated in the ordering information,

B745M (mm)

the fabrication method shall be at the option of the fabricator.

D

7.1.2 Type IA pipe shall be fabricated with a smooth liner 38 by 6.5 48 6.0 7 6.5

E

68 by 13 73 12 17 12

andhelicallycorrugatedshellintegrallyattachedathelicallock

75 by 25 83 24 14 12

seams extending from end to end of each length of pipe. The

150 by 25 160 24 56 51

shell shall have corrugations of nominal 2 ⁄3 (or 3 in. [68 or 75

A

Pitchismeasuredfromcresttocrestofcorrugations,at90°tothedirectionofthe

mm] pitch.

corrugations.

B

Depth is measured as the vertical distance from a straightedge resting on the

7.1.3 Type IR pipe shall be fabricated with helical ribs

corrugation crests parallel to the axis of the pipe, to the bottom of the intervening

projecting outward with a continuous lock seam extending

valley.

C

from end to end of each length of pipe. Minimum inside radius requirement does not apply to a corrugation containing a

helical lock seam.

D

1 1

7.2 Corrugations—The corrugations shall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.