ASTM D6441-99ae1

(Test Method)Standard Test Methods for Measuring the Hiding Power of Powder Coatings

Standard Test Methods for Measuring the Hiding Power of Powder Coatings

SCOPE

1.1 These test methods determine and report the hiding power of a powder coating with respect to two parameters:

1.1.1 Test Method A-Contrast Ratio at a given film thickness

1.1.2 Test Method B-Film thickness at 0.98 (98%) contrast ratio.

Note 1-The measured parameters conform to powder coating industry practice by measuring hiding power in relation to film thickness, rather than the more conventional "Spreading Rate" function employed in Test Methods D 344 and D 2805 and other hiding power test methods.

Note 2-Hiding power is photometrically defined as the spreading rate at 0.98 contrast ratio. See definitions of spreading rate and hiding power in Terminology D 16, D 2805, and the Paint and Coatings Testing Manual.

Note 3-The contrast ratio of 0.98 is conventionally accepted in the coatings industry as representing "complete" hiding for reflectometric hiding power measurements. But visually, as well as photometrically, it is slightly less than complete.

1.2 These test methods cover the determination of the hiding power of powder coatings applied by electrostatic spraying.

1.3 These test methods determine hiding power by means of reflectometric and thickness gage measurements. They are limited to coatings having a minimum CIE-Y reflectance of 15 %.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D6441–99a

Standard Test Methods for

Measuring the Hiding Power of Powder Coatings

This standard is issued under the fixed designation D 6441; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Last line of Table 1 editorially corrected in February 2000.

1. Scope D 16 Terminology for Paint, and Related Coatings, Materi-

als, and Applications

1.1 These test methods determine and report the hiding

D 344 Test Method for Relative Hiding Power of Paints by

power of a powder coating with respect to two parameters:

the Visual Evaluation of Brushouts

1.1.1 Test Method A—Contrast Ratio at a given film thick-

D 2805 Test Method for Hiding Power of Paints by Reflec-

ness

tometry

1.1.2 Test Method B—Film thickness at 0.98 (98 %) con-

D 3451 Practices for Testing Polymeric Powders and Pow-

trast ratio.

der Coatings

NOTE 1—The measured parameters conform to powder coating indus- 2

E 284 Terminology Relating to Appearance

trypracticebymeasuringhidingpowerinrelationtofilmthickness,rather

E 1331 Test Method for Reflectance Factor and Color by

than the more conventional “Spreading Rate” function employed in Test

Spectrophotometry Using Hemispherical Geometry

Methods D 344 and D 2805 and other hiding power test methods.

E 1347 Test Method for Color and Color Difference Mea-

NOTE 2—Hiding power is photometrically defined as the spreading rate

at 0.98 contrast ratio. See definitions of spreading rate and hiding power surement by Tristimulus (Filter) Colorimetry

in Terminology D 16, D 2805, and the Paint and Coatings Testing

E 1349 Test Method for Reflectance Factor and Color by

Manual.

Spectophotometry Using Bidirectional Geometry

NOTE 3—The contrast ratio 0.98 is conventionally accepted in the

2.2 Other Standard:

coatings industry as representing “complete” hiding for reflectometric

1-GP-71, Method 14.7, Hiding Power, Contrast Ratio

hiding power measurements. But visually, as well as photometrically, it is

Method, October 1982

slightly less than complete.

2.3 Paint & Coatings Testing Manual (Gardner-Sward

1.2 These test methods cover the determination of the

Handbook), 14th Edition, Chapter 42, Hiding Power

hiding power of powder coatings applied by electrostatic

spraying.

1.3 Thesetestmethodsdeterminehidingpowerbymeansof

3. Terminology

reflectometric and thickness gage measurements. They are

3.1 Definitions of Terms Specific to This Standard:

limited to coatings having a minimum CIE-Y reflectance of

3.1.1 reflectance—term of wide applicability, referring

15 %.

herein to the luminous reflectance factor as defined in Termi-

1.4 The values stated in SI units are to be regarded as the

nology E 284, and equivalent to the CIE Tristimulus value Y

standard. The values given in parentheses are for information

measured in accordance with Test Methods E 1331, E 1347 or

only.

Test Method E 1349 with specular reflection excluded. It is

1.5 This standard does not purport to address all of the

expressed as a percentage in this standard.

safety concerns, if any, associated with its use. It is the

3.1.2 white substrate—For purposes of this test, a substrate

responsibility of the user of this standard to establish appro-

of neutral shade with a minimum reflectance of 78 %.

priate safety and health practices, and to determine in advance

3.1.3 black substrate—A substrate with a maximum reflec-

the applicability of regulatory limitations prior to use.

tance of 1 %, which is effectively zero for the purpose of

measuring hiding power.

2. Referenced Documents

3.1.4 white reflectance (R )—Reflectance of the applied

W

2.1 ASTM Standards:

test film over a white substrate of reflectance W.

1 2

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD-1onPaint Annual Book of ASTM Standards, Vol 06.01.

and Related Coatings, Materials, and Applications and the direct responsibility of Annual Book of ASTM Standards, Vol 06.02.

Subcommittee D01.51 on Powder Coatings. Canadian General Standards Board, (CGSB), 222 Queen St., Ottawa, Ont.,

Current edition approved Dec. 10, 1999. Published February 2000. Originally Canada K1A 1G6.

published as D 6441 – 99. Last previous edition D 6441 – 99. Paint & Coatings Testing Manual, MNL 17, ASTM, 1995.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D6441–99a

NOTE 1—Shows black and white substrate areas exposed after removal of masking tape.

FIG. 1 “Wedge” Film Application

3.1.5 black reflectance (R )—Reflectance of the applied test 3.2.1 T—the specified or measured thickness of the test

o

film over a black substrate. coating on the substrate.

3.2.2 t —the amount by which the black substrate exceeds

3.1.6 reflectivity (R )—The reflectance of a coating applied

o

`

the white substrate in thickness.

thicklyenoughtobecompletelyopaque,asevidencedbyequal

reflectance over the black and a white test substrate. 3.2.3 T8—T + t ; the thickness reading corresponding to T

o

over the black substrate when measured with the gage cali-

3.1.7 contrast ratio (C )—(1) The ratio of the reflectance

W

brated to the white substrate as zero.

of a film applied on a black substrate to a film of equal

3.3 For additional definitions applicable to these test meth-

thickness applied on a white substrate. (2) An instrumental

ods see Terminology E 284.

measure of film opacity.

3.1.7.1 Discussion—Contrast ratio can be expressed as a

4. Summary of Test Method

decimal fraction (R /R ) or as a percentage (100R /R ), the

O W O W

latter being preferred for the general concept of hiding or

4.1 Test MethodA—Contrast Ratio (C ) at a Specified Film

W

opacity, and employed in these test methods.

Thickness:

3.1.8 opacity—The degree to which a coating film hides a

4.1.1 The coating is applied as a “wedge” on a specified test

black and white substrate, as perceived visually or as measured

panel.

instrumentally, (see contrast ratio defined in 3.1.7).

4.1.2 Severalpairsofpointsareencircledovertheblackand

3.1.9 wedge of coating—Afilmofcoatinghavingarangeof white substrate at the specified coating thickness, their reflec-

film thickness giving a corresponding range of opacities on a

tances R and R are measured, and their contrast ratios (C

O W W

black and white substrate. (see Fig. 1). = 100 R /R ) calculated.

O W

3.2 Symbols: 4.1.3 The mean contrast ratio for the panel is calculated.

e1

D6441–99a

FIG. 2 Examples of Commercially Available Test Panels

NOTE 5—Some test panels require a pre-bake before using, to expell

4.2 Test Method B—Film Thickness (T ) at a Contrast

residual volatiles that can create pinholes in the subsequently applied

Ratio of 98 %:

powder coating.When necessary pre-bake for 10 min at 180°C (350°F) to

4.2.1 The coating is applied as a “wedge” on the specified

eliminate this problem.

test panel.

6.3 Suitable equipment for applying and baking the test

4.2.2 Several equal thickness pairs of black and white

coatings.

substrate points, at varying thicknesses, are located and their

6.4 Electronic Gage, adequately sensitive for measuring

contrast ratios determined.

coating film thickness.

4.2.3 Contrast ratio versus film thickness is plotted on

6.5 Heat-Resistant Tape, 20-mm ( ⁄4-in.) wide, easily re-

suitable graph paper, and the thickness at T determined from

moved after baking, leaving no discoloration or adhesive

the graph.

residue.

5. Significance and Use

6.6 Permanent Marker, extra fine point.

6.7 Suitable Graph Paper.

5.1 Contrast ratio at a specified film thickness is a useful

hiding power parameter for production control and purchasing

specifications. 7. Measurements—General Rules

5.2 Thegreaterthehidingpower,thelesscoatingisrequired

7.1 For each powder and test method, fill out an individual

per unit area to obtain adequate hiding. Knowledge of hiding

work sheet in the form of a table (see Fig. 3 for Test Method

power is therefore important in regard to coating costs and for

A, Fig. 4 for Test Method B), into which all test data and

comparing coating value.

calculated values are entered in the indicated locations.

7.2 Measure reflectance as a percentage to two decimal

6. Apparatus and Material

places. Calculate (or measure) contrast ratio (C ) as a percent-

W

6.1 Reflectometer, that measures the luminous reflectance

age (100R /R ) to two decimal places, and report final results

B W

factor, (specular reflection excluded) using CIE standard illu-

to one decimal place.

minant C and the CIE 1931 (2°) standard observer, in accor-

7.3 The circles drawn to locate measurement points must be

dance with Test Method E 1331, E 1347 or E 1349. The

at least larger than the measurement opening of the reflecto-

instrument shall be capable of viewing a diameter of at least 3

meter.

1 3

to5mm( ⁄8 to ⁄16in.).

7.4 Measurethicknessasaccuratelyaspossible,reportingto

nearest 1.3 µm (0.05 mils), or closer if possible.

NOTE 4—Otherobserver-illuminantcombinationsandaperturesmaybe

used by agreement.

8. Calibration and Panel Preparation

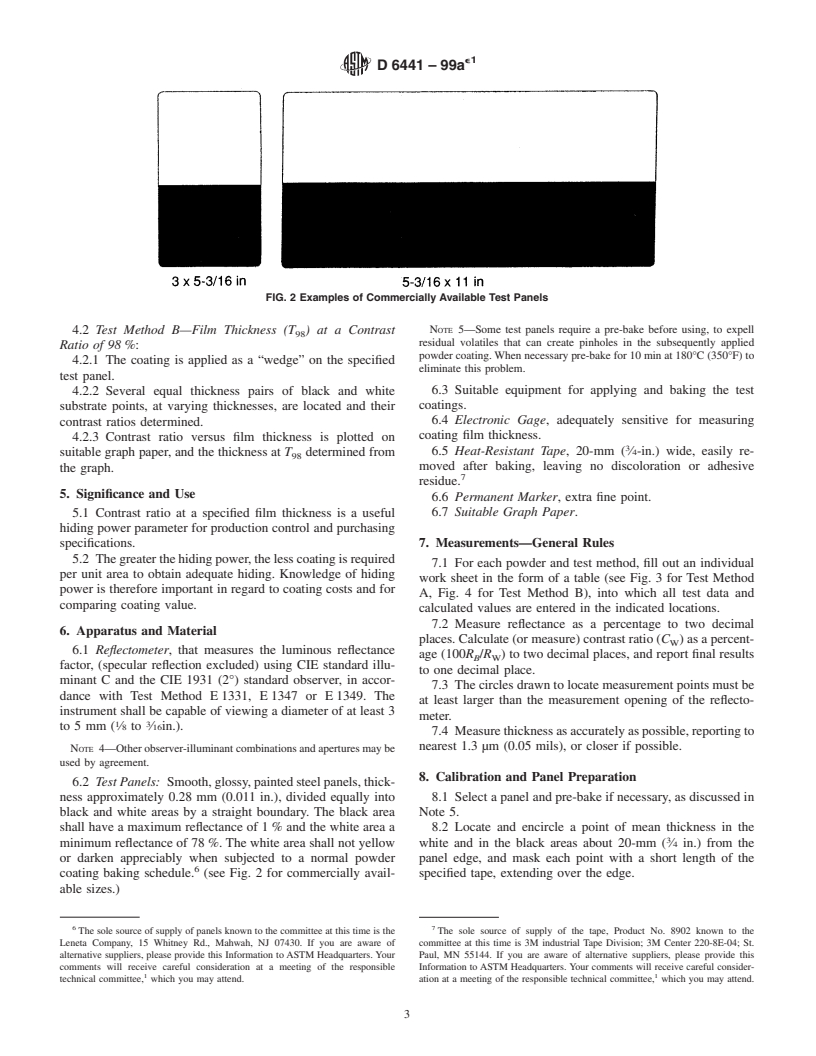

6.2 TestPanels: Smooth,glossy,paintedsteelpanels,thick-

ness approximately 0.28 mm (0.011 in.), divided equally into 8.1 Select a panel and pre-bake if necessary, as discussed in

Note 5.

black and white areas by a straight boundary. The black area

shall have a maximum reflectance of 1 % and the white area a 8.2 Locate and encircle a point of mean thickness in the

white and in the black areas about 20-mm ( ⁄4 in.) from the

minimum reflectance of 78 %. The white area shall not yellow

or darken appreciably when subjected to a normal powder panel edge, and mask each point with a short length of the

specified tape, extending over the edge.

coating baking schedule. (see Fig. 2 for commercially avail-

able sizes.)

6 7

The sole source of supply of panels known to the committee at this time is the The sole source of supply of the tape, Product No. 8902 known to the

Leneta Company, 15 Whitney Rd., Mahwah, NJ 07430. If you are aware of committee at this time is 3M industrial Tape Division; 3M Center 220-8E-04; St.

alternative suppliers, please provide this Information to ASTM Headquarters. Your Paul, MN 55144. If you are aware of alternative suppliers, please provide this

comments will receive careful consideration at a meeting of the responsible Information to ASTM Headquarters. Your comments will receive careful consider-

1 1

technical committee, which you may attend. ation at a meeting of the responsible techni

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.