ASTM F1359-99a(2004)

(Test Method)Standard Test Method for Liquid Penetration Resistance of Protective Clothing or Protective Ensembles Under a Shower Spray While on a Mannequin

Standard Test Method for Liquid Penetration Resistance of Protective Clothing or Protective Ensembles Under a Shower Spray While on a Mannequin

SCOPE

1.1 This test method measures the ability of protective clothing or protective ensembles to resist liquid penetration in the form of a shower spray with surfactant-treated water.

1.2 This test method measures the liquid penetration resistance of the construction and configuration of the overall protective clothing or protective ensemble, but especially of seams, closures, and interfaces with other components such as gloves, boots, hoods, and respiratory protective equipment. It is intended that this test method be used to assess the liquid penetration resistance of protective clothing and protective ensembles as received from the manufacturer and worn in accordance with their instructions.

1.3 Resistance of materials used in protective clothing to permeation or penetration can be determined in accordance with Test Methods F 739 and F 903, respectively.

1.4 The integrity of vapor protective ensembles is measured by its ability to maintain positive internal pressure with Test Method F 1052.

1.5 The values in SI units or in other units shall be regarded separately as standard. The values stated in each system must be used independently of the other, without combining values in any way.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1359 – 99a (Reapproved 2004)

Standard Test Method for

Liquid Penetration Resistance of Protective Clothing or

Protective Ensembles Under a Shower Spray While on a

Mannequin

This standard is issued under the fixed designation F 1359; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Personnel in industry and emergency response can be exposed to numerous chemicals capable of

causing harm upon contact with the human body. The deleterious effects of these chemicals can range

from acute trauma such as skin irritation and burn, to chronic degenerative disease such as cancer.

Since engineering controls cannot eliminate all possible exposures, attention is often placed on

reducing the potential for direct skin contact through the use of protective clothing.

Protective clothing is available in a variety of constructions, configurations and materials, and is

designed to provide various levels of protection against many hazards. Protective clothing offering the

highest level of chemical protection is constructed to prevent any contact of solid, liquid, or gaseous

chemicals with the wearer. Test Method F 1052 evaluates the integrity and construction of the vapor

protective ensembles by way of an internal pressure test. In some applications, chemical protective

clothing need only isolate the wearer from splashes of liquids.This test method evaluates the integrity

of the construction and configuration of liquid-penetration-resistant protective clothing or protective

ensembles with a shower-spray test.

Resistance of materials used in protective clothing to chemical permeation should be evaluated by

Test Method F 739 for continuous contact and Test Method F 1383 for intermittent contact (that is,

splash), or byTest Method F 1407 using the permeation cup method. Resistance of protective clothing

materials to liquid penetration should be determined by Test Method F 903.

Physical properties of materials used in the construction of protective clothing can be determined

using a variety of test methods including, Test Methods D 751 for dimensions, weight, breaking

strength, elongation, burst, tear resistance, and hydrostatic resistance; Test Method D 2582 for

puncture propagation tear resistance; Test Method D 4157 for abrasion resistance; Test Method F 392

for flexural fatigue; Test Method F 1358 for flammability, as well as many others.

1. Scope intended that this test method be used to assess the liquid

penetration resistance of protective clothing and protective

1.1 This test method measures the ability of protective

ensembles as received from the manufacturer and worn in

clothing or protective ensembles to resist liquid penetration in

accordance with their instructions.

the form of a shower spray with surfactant-treated water.

1.3 Resistance of materials used in protective clothing to

1.2 This test method measures the liquid penetration resis-

permeation or penetration can be determined in accordance

tance of the construction and configuration of the overall

with Test Methods F 739 and F 903, respectively.

protective clothing or protective ensemble, but especially of

1.4 The integrity of vapor protective ensembles is measured

seams, closures, and interfaces with other components such as

by its ability to maintain positive internal pressure with Test

gloves,boots,hoods,andrespiratoryprotectiveequipment.Itis

Method F 1052.

1.5 The values in SI units or in other units shall be regarded

This test method is under the jurisdiction of ASTM Committee F23 on separately as standard. The values stated in each system must

Protective Clothing and is the direct responsibility of Subcommittee F23.30 on

be used independently of the other, without combining values

Chemicals.

in any way.

CurrenteditionapprovedJune1,2004.PublishedJuly2004.Originallyapproved

in 1991. Last previous edition approved in 1999 as F 1359 - 99a.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1359 – 99a (2004)

1.6 This standard does not purport to address all of the 3.1.5 protective clothing, n—apparelusedforthepurposeof

safety concerns, if any, associated with its use. It is the isolatingpartsofthebodyfromcontactwithapotentialhazard.

responsibility of the user of this standard to establish appro- 3.1.6 protective ensemble, n—the combination of protective

priate safety and health practices and determine the applica- clothingwithrespiratoryprotectiveequipment,hoods,helmets,

bility of regulatory limitations prior to use. gloves, boots, communication systems, cooling devices, and

other accessories intended to protect the wearer from a

2. Referenced Documents

potential hazard when worn together.

3.1.6.1 Discussion—For evaluating liquid penetration resis-

2.1 ASTM Standards:

tance, the protective ensemble includes only those clothing

D 751 Test Methods for Coated Fabrics

items or accessories which are necessary to provide resistance

D 2582 Test Method for Puncture-Propagation Tear Resis-

to liquid penetration.

tance of Plastic Film and Thin Sheeting

3.1.7 vapor protective ensemble, n—a chemical protective

D 4157 Test Method for Abrasion Resistance of Textile

ensemble used to protect the wearer from chemical liquids,

Fabrics (Oscillatory Cylinder Method)

vapors, and gases.

F 392 Test Method for Flex Durability of Flexible Barrier

Materials

4. Summary of Test Method

F 739 Test Method for Resistance of Protective Clothing

4.1 A test specimen (protective clothing or protective en-

Materials to Permeation by Liquids or Gases Under Con-

semble) is placed on a mannequin that is already dressed in a

ditions of Continuous Contact

liquid-absorptive garment covering portions of the mannequin

F 903 Test Method for Resistance of Materials Used in

form that are of interest.

Protective Clothing to Penetration by Liquids

4.2 Water, treated to achieve a surface tension of

F 1052 Practice for Pressure Testing of Gas-Tight Totally

0.032 6 0.002 N/m (32 6 2 dynes/cm) is sprayed at the test

Encapsulating Chemical Protective Suits

specimen from five nozzles positioned in a specific configura-

F 1358 Test Method for Effects of Flame Impingement on

tion with respect to the specimen. The specimen is exposed to

Materials Used in Protective Clothing Not Designated

theliquidsprayforaperiodof15minineachoffourspecimen

Primarily for Flame Resistance

orientations.

F 1383 Test Method for Resistance of Protective Clothing

4.3 Liquid penetration resistance is determined by the ab-

Materials to Permeation by Liquids or Gases Under Con-

sence of liquid inside the specimen or on the inner liquid-

ditions of Intermittent Contact

absorptive garment.

F 1407 Test Method for Resistance of Chemical Protective

4.4 The test specimen is rated as passing if liquid does not

ClothingMaterialstoLiquidPermeation—PermeationCup

penetrate and as failing if liquid does penetrate.

Method

5. Significance and Use

3. Terminology

5.1 Thistestmethodevaluatestheabilityoftheconstruction

3.1 Definitions:

and configuration of protective clothing or protective en-

3.1.1 liquid splash protective clothing, n—protective cloth-

sembles to resist liquid penetration. In most cases, the condi-

ing used to protect the wearer from liquid splashes of chemi-

tions used in this test method will not represent actual end-use

cals.

conditions.

3.1.2 liquid splash protective ensemble, n—protective en-

5.2 The one-hour duration of the test is not intended to

semble used to protect the wearer from liquid splashes of

simulateuserexposuretosplashesofliquidchemicalbutrather

chemicals.

to provide sufficient time for enough liquid to penetrate to

3.1.3 penetration, n—for chemical-resistant clothing, in a

make visual detection easier.

protective clothing material or item, the process by which a

5.3 A nontoxic, non-foaming surfactant is added to water

solid, liquid, or gas moves through closures, seams, interstices,

for this test method to simulate liquids of lower surface

and pinholes or other imperfections on a non-molecular level.

tensions. Liquids of specific interest can be simulated by

3.1.4 permeation, n—the process by which a chemical

treating water to achieve an equivalent surface tension.

moves through a protective clothing material on a molecular

5.4 For protective clothing with water-repellent surfaces,

level.

thelowersurfacetensionliquidwillaidintheevaluationofthe

3.1.4.1 Discussion—Permeation involves the following: (1)

construction and configuration of the garment because it is not

sorption of molecules of the chemical into the contacted

repelled but wets the protective clothing. This is especially

(challenge side) surface of the material, (2) diffusion of the

useful for reusable garments whose water-repellent surface

sorbed molecules in the material, and (3) desorption of the

interferes with the evaluation of their construction and con-

molecules from the opposite (collection side) surface of the

figuration when new, but is diminished after wearing and

material.

washing.

5.5 Fluorescent or colored dyes may be added to the water

to enhance detection of liquid penetration into the protective

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

clothing or protective ensemble.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.6 This test method can be used by both manufacturers and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. enduserstoassessliquidpenetrationresistance.Manufacturers

F 1359 – 99a (2004)

can use this test method to evaluate quality of construction and

effectiveness of clothing and ensemble configurations.

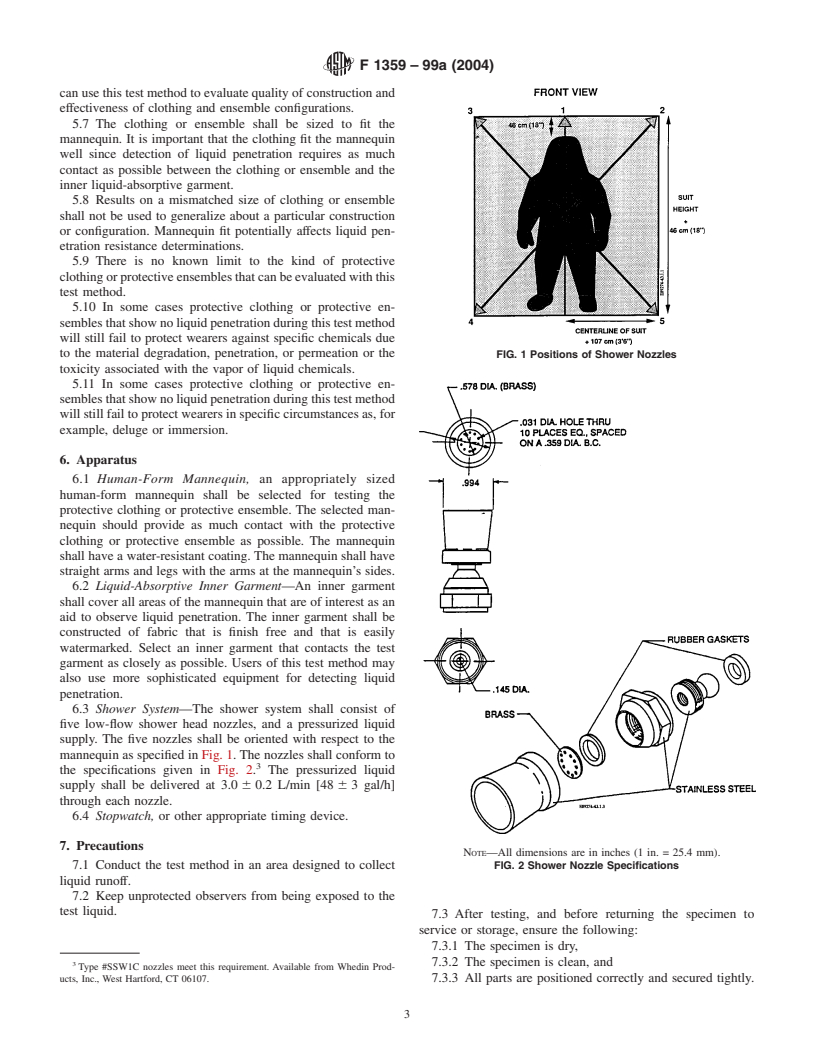

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.