ASTM D2397-12

(Specification)Standard Specification for Cationic Emulsified Asphalt

Standard Specification for Cationic Emulsified Asphalt

ABSTRACT

This specification covers the seven grades of cationic emulsified asphalt for use in pavement construction. The asphalt shall be homogeneous after thorough mixing provided separation has not been caused by freezing and shall conform to the requirements set for viscosity, storage stability, demulsibility, coating ability and water resistance, particle charge, and distillation.

SCOPE

1.1 This specification covers seven grades of cationic emulsified asphalt for use in pavement construction in the manner designated.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2397 −12

StandardSpecification for

1

Cationic Emulsified Asphalt

This standard is issued under the fixed designation D2397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Requirements

1.1 This specification covers seven grades of cationic emul- 3.1 The emulsified asphalt shall be tested within 14 days of

delivery. The emulsified asphalt shall be homogeneous after

sified asphalt for use in pavement construction in the manner

designated. thorough mixing provided separation has not been caused by

freezing. Emulsions separated by freezing shall not be tested.

2. Referenced Documents

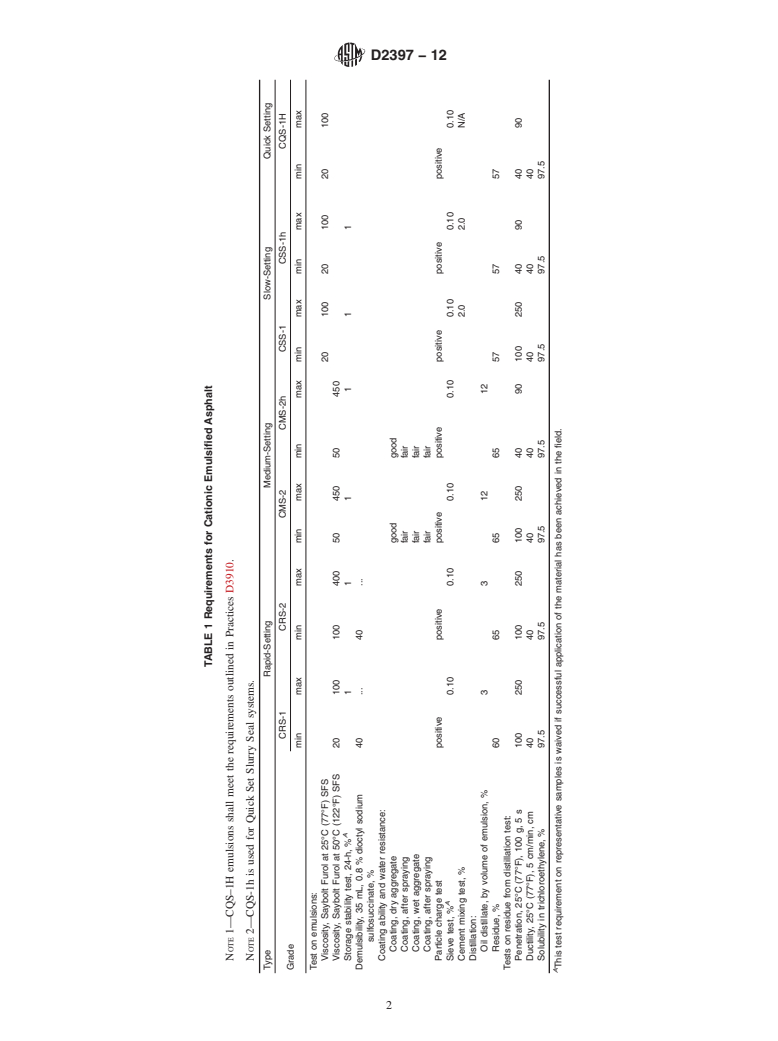

3.2 Emulsified asphalt shall conform to the requirements

2

prescribed in Table 1.

2.1 ASTM Standards:

D140 Practice for Sampling Bituminous Materials

4. Sampling

D244 Test Methods and Practices for Emulsified Asphalts

D3910 Practices for Design, Testing, and Construction of

4.1 Samples of emulsified asphalt shall be taken in accor-

Slurry Seal

dance with Practice D140.

D6930 Test Method for Settlement and Storage Stability of

4.2 Samples shall be stored in clean, airtight sealed contain-

Emulsified Asphalts

ers at a temperature of not less than 4°C (39.2°F) until tested.

D6933 Test Method for Oversized Particles in Emulsified

Asphalts (Sieve Test)

5. Test Methods

D6935 Test Method for Determining Cement Mixing of

Emulsified Asphalt

5.1 The properties of the emulsified asphalts given in Table

D6936 Test Method for Determining Demulsibility of Emul-

1 shall be determined in accordance with the followingASTM

sified Asphalt

test methods:

D6997 Test Method for Distillation of Emulsified Asphalt

5.1.1 Viscosity—Test Method D7496.

D7402 Practice for Identifying Cationic EmulsifiedAsphalts

5.1.2 Storage Stability—Test Method D6930.

D7496 Test Method for Viscosity of Emulsified Asphalt by

5.1.3 Demulsibility—Test Method D6936.

Saybolt Furol Viscometer

5.1.4 Coating Ability and Water Resistance—Test Methods

D244.

5.1.5 Particle Charge—Test Method D7402.

1

This specification is under the jurisdiction of ASTM Committee D04 on Road

5.1.6 Sieve Test—Test Method D6933, except use distilled

and Paving Materials and is the direct responsibility of Subcommittee D04.41 on

Emulsified Asphalt Specifications.

water in all wetting and washing operations in place of the

Current edition approved July 1, 2012. Published July 2012. Originally approved

nonionic surfactant solution (1 %).

in 1965. Last previous edition approved in 2005 as D2397–05. DOI: 10.1520/

5.1.7 Cement Mixing—Test Method D6935.

D2397-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1.8 Distillation—Test Method D6997.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.9 Tests on Residue from Distillation—Test Methods

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. D244.

Copyrigh

...

Designation: D2397 − 05 D2397 − 12

Standard Specification for

1

Cationic Emulsified Asphalt

This standard is issued under the fixed designation D2397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers seven grades of cationic emulsified asphalt for use in pavement construction in the manner

designated.

2. Referenced Documents

2

2.1 ASTM Standards:

D140 Practice for Sampling Bituminous Materials

D244 Test Methods and Practices for Emulsified Asphalts

D3910 Practices for Design, Testing, and Construction of Slurry Seal

D6930 Test Method for Settlement and Storage Stability of Emulsified Asphalts

D6933 Test Method for Oversized Particles in Emulsified Asphalts (Sieve Test)

D6935 Test Method for Determining Cement Mixing of Emulsified Asphalt

D6936 Test Method for Determining Demulsibility of Emulsified Asphalt

D6997 Test Method for Distillation of Emulsified Asphalt

D7402 Practice for Identifying Cationic Emulsified Asphalts

D7496 Test Method for Viscosity of Emulsified Asphalt by Saybolt Furol Viscometer

3. Requirements

3.1 The emulsified asphalt shall be tested within 14 days of delivery. The emulsified asphalt shall be homogeneous after

thorough mixing provided separation has not been caused by freezing. Emulsions separated by freezing shall not be tested.

3.2 Emulsified asphalt shall conform to the requirements prescribed in Table 1.

4. Sampling

4.1 Samples of emulsified asphalt shall be taken in accordance with Practice D140.

4.2 Samples shall be stored in clean, airtight sealed containers at a temperature of not less than 4°C (39.2°F) until tested.

5. Test Methods

5.1 The properties of the emulsified asphalts given in Table 1 shall be determined in accordance with the following ASTM test

methods:

5.1.1 Viscosity—Test MethodsMethod D244D7496.

5.1.2 Storage Stability—Test Method D6930.

5.1.3 Demulsibility—Test Method D6936.

5.1.4 Coating Ability and Water Resistance—Test Methods D244.

5.1.5 Particle Charge—Test MethodsMethod D244D7402.

5.1.6 Sieve Test—Test Method D6933, except use distilled water in all wetting and washing operations in place of the nonionic

surfactant solution (1 %).

5.1.7 Cement Mixing—Test Method D6935.

5.1.8 Distillation—Test Method D6997.

5.1.9 Tests on Residue from Distillation—Test Methods D244.

6. Keywords

6.1 cationic; emulsified asphalt; emulsion; medium setting; rapid setting; slow setting

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2397 − 12

2

TABLE 1 Requirements for Cationic Emulsified Asphalt

NOTE 1—CQS–1H emulsions shall meet the requirements outlined in Practices D3910.

NOTE 2—CQS-1h is used for Quick Set Slurry Seal systems.

Type Rapid-Setting Medium-Setting Slow-Setting Quick Setting

CRS-1 CRS-2 CMS-2 CMS-2h CSS-1 CSS-1h CQS-1H

Grade

min max min max min max min max min max min max min max

Test on emulsions:

Viscosit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.