ASTM D5430-07(2011)

(Test Method)Standard Test Methods for Visually Inspecting and Grading Fabrics

Standard Test Methods for Visually Inspecting and Grading Fabrics

SIGNIFICANCE AND USE

Test Method D5430 is considered satisfactory for acceptance testing a commercial shipments since the method has been used extensively in the trade for grading of fabric and fabric acceptance determination.

The penalty points obtained in grading the same rolls or bolts of fabric may vary considerably when using each of the three options listed herein. For this reason, the same point assignment option should be used in cases of disagreement arising from differences of values reported by the purchaser and the supplier.

If there are differences of practical significance between reported test results for two laboratories (or more), comparative test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, ensure the test samples to be used are as homogeneous as possible, are drawn from the material from which the disparate test results ere obtained, and are randomly assigned in equal numbers to each laboratory for testing. The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

SCOPE

1.1 These test methods describe a procedure to establish a numerical designation for grading of fabrics from a visual inspection.

1.2 These test methods may be used for the delivery and acceptance of fabrics with requirements mutually agreed upon by the purchaser and the supplier.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5430 − 07(Reapproved 2011)

Standard Test Methods for

Visually Inspecting and Grading Fabrics

This standard is issued under the fixed designation D5430; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 For all terminology related to Fabric Defects, refer to

Terminology D3990.

1.1 These test methods describe a procedure to establish a

numerical designation for grading of fabrics from a visual 3.3 For all other terms related to textiles, refer to Terminol-

inspection. ogy D123

1.2 These test methods may be used for the delivery and

4. Summary of Test Method

acceptance of fabrics with requirements mutually agreed upon

4.1 Rolls or bolts of fabric are visually inspected and

by the purchaser and the supplier.

individually graded at an examination station using an agreed

1.3 This standard does not purport to address all of the

upon point system.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.2 Fabric is normally inspected and graded on one side

priate safety and health practices and determine the applica- only. Certain types of end use fabrics may be inspected and

bility of regulatory limitations prior to use.

gradedonbothsidesasagreeduponbetweenthepurchaserand

supplier.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

5.1 Test Method D5430 is considered satisfactory for ac-

D3990 Terminology Relating to Fabric Defects

ceptance testing a commercial shipments since the method has

D4850 Terminology Relating to Fabrics and Fabric Test

been used extensively in the trade for grading of fabric and

Methods

fabric acceptance determination.

2.2 ANSI Standards:

5.2 The penalty points obtained in grading the same rolls or

ANSI/ASQC Standard A1-1978 Definitions, Symbols,

bolts of fabric may vary considerably when using each of the

Formulas, and Tables for Control Charts

three options listed herein. For this reason, the same point

ANSI/ASQC Standard Z1.4-1981 Sampling Procedures and

assignment option should be used in cases of disagreement

Tables for Inspection by Attributes.

arising from differences of values reported by the purchaser

and the supplier.

3. Terminology

5.3 If there are differences of practical significance between

3.1 For all terminology relating to D13.59, Fabric Test

reported test results for two laboratories (or more), compara-

Methods, General, refer to Terminology D4850.

tive test should be performed to determine if there is a

3.1.1 The following terms are relevant to this standard:

statistical bias between them, using competent statistical assis-

critical defect, defect, in inspection and grading, grade,

tance.As a minimum, ensure the test samples to be used are as

inspection, major defect, minor defect.

homogeneous as possible, are drawn from the material from

which the disparate test results ere obtained, and are randomly

assigned in equal numbers to each laboratory for testing. The

These test methods are under the jurisdiction of ASTM Committee D13 on

testresultsfromthetwolaboratoriesshouldbecomparedusing

Textiles and is the direct responsibility of Subcommittee D13.59 on Fabric Test

a statistical test for unpaired data, at a probability level chosen

Methods, General.

CurrenteditionapprovedMay1,2011.PublishedJuly2011.Originallyapproved prior to the testing series. If a bias is found, either its cause

in 1993. Last previous edition approved in 2007 as D5430–07. DOI: 10.1520/

must be found and corrected, or future test results for that

D5430-07R11.

material must be adjusted in consideration of the known bias.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 6. Apparatus

the ASTM website.

6.1 A suitable fabric inspection machine providing a flat

AmericanSocietyforQualityControl,310W.WisconsinAve.,Milwaukee,WS

53203. viewing area and an interruptible speed controlled fabric

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

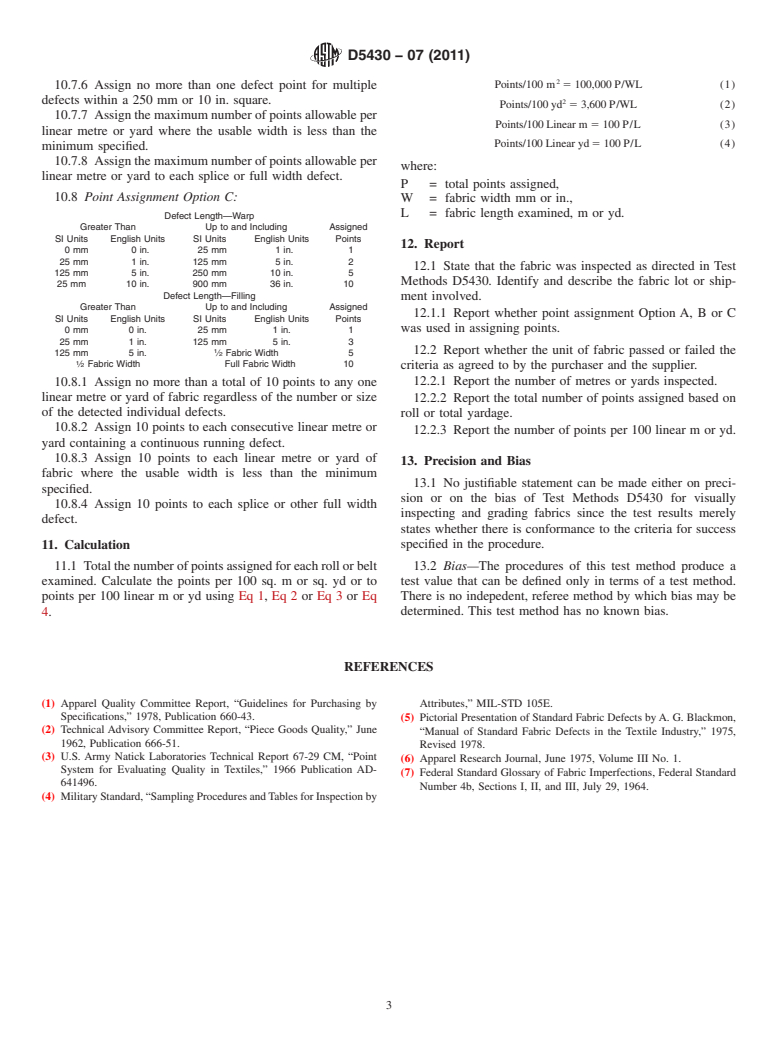

D5430 − 07 (2011)

rewind. Examination and grading are usually done with over- stoppedtogradewhennecessarytoaffirmmarginaldefectsand

head direct lighting. The inspection machine may be equipped defects may be flagged.

with the option of back lighting (transmitted) light providing

10.3 Inspect and grade the total length of each roll or bolt

the choice by prior agreement depending on the fabric end use.

sampled.

The overhead direct lighting source shall be mounted parallel

10.4 Detect and assign points to defects observed as agreed

to the viewing surface so as to illuminate with direct perpen-

upon in 9.1-9.4 using options A (10.6),B(10.7), or C (10.8).

dicular impinging light rays. The surface illumination level

shall be a minimum of 1075 lux (100 foot candles).

10.5 Assign points to the defects based upon their length

within the plane of the fabric according to one of the following

6.2 The lighting source should be cool white preheat rapid

options of assigning points, as agreed upon between the

startfluorescentlampshavingacorrelatedcolortemperatureof

purchaser and the supplier.

4100 to 4500 K with white reflectors and without baffles or

glues, or by agreement between the purchaser and supplier.

10.6 Point Assignment Option A:

Defect Length

7. Sampling

Greater Than Up to and Including Assigned

SI Units English Units SI Units English Units Points

7.1 Withshipmentswhichtotal1000morydorless,inspect

0mm 0 in. 75mm 3 in. 1

and grade the total number of rolls or bolts.

75 mm 3 in. 150 mm 6 in. 2

150 mm 6 in. 230 mm 9 in. 3

7.2 For shipments exceeding 1000 m or yd, select samples

230 mm 9 in. 4

as agreed upon by the purchaser and supplier. In the absence of

10.6.1 Assign no more than a total of 4 points to any one

such a specification, a reliable statistical sampling plan such as

linear metre or yard of fabric, regardless of the number or size

Practice D2903 or MIL-STD 105E may be used.

of the detected individual defects.

10.6.2 Assign 4 points to each consecutive linear metre or

8. Conditioning

yard in which a continuous running defect exceeds 230

8.1 No conditioning is required.

millimetres or 9 inches.

10.6.3 Assign 4 points to each linear metre or yard of fabric

9. Defects and Tolerances

where the useable width is less than the minimum specified.

9.1 The purchaser and the supplier shall agree on a list of

10.6.4 Assign 4 points to each seam or other full width

defects to be used in grading fabric. See 2.1 and 2.2 and Refs.

defect or seam if applicable.

1-7forpublicationsofvariouslistsoffabricdefectswhichmay

10.7 Point Assignment Option B:

be used.

Defect Length

9.1.1 The fabric defects listed shall be classified as either a

Greater Than Up to and Including Assigned

critical defect, major defect, or minor defect.

SI Units English Units SI Units English U

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.