ASTM D7489-09(2013)

(Practice)Standard Practice for Evaluating Touch-Up Properties of Architectural Coatings under Various Environmental Conditions

Standard Practice for Evaluating Touch-Up Properties of Architectural Coatings under Various Environmental Conditions

SIGNIFICANCE AND USE

5.1 During construction of a home, paints are subjected to a wide variety of drying conditions, and this may exhibit differences between the original coat and the touched-up area in appearance after its full cure. Therefore, it it essential for the paint to be able to perform under a wide variety of drying conditions. A paint that does this is very advantageous to the contractor.

5.2 It is possible for a paint to have excellent color touch-up, but poor sheen touch-up, or vice-versa. The ideal paint will have both excellent color and sheen touch-up under testing conditions.

5.3 Color, gloss and base choice can have a major impact on touch-up of the paint.

SCOPE

1.1 This practice determines the ability of a paint to be recoated or “touched up” in small areas. Variations in color, gloss, and sheen that result in a different appearance from the original paint can be evaluated visually.

1.2 This practice describes evaluation of touch-up characteristics in a laboratory-scale controlled environment as opposed to a full-scale field environment.

1.3 Evaluation of touch-up properties under constant drying conditions is described. Environmental conditions can be adjusted to incorporate high or low temperature drying , or both. The changes in application temperature can lead to larger differences in touch-up than applying both coats under the same environmental conditions.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7489 − 09 (Reapproved 2013)

Standard Practice for

Evaluating Touch-Up Properties of Architectural Coatings

under Various Environmental Conditions

This standard is issued under the fixed designation D7489; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D5069 Practice for Preparation of Paint-Roller Covers for

Evaluation of Architectural Coatings

1.1 This practice determines the ability of a paint to be

D6762 Test Method for Determining the Hiding Power of

recoated or “touched up” in small areas. Variations in color,

Paint by Visual Evaluation of Spray Applied Coatings

gloss, and sheen that result in a different appearance from the

E1347 Test Method for Color and Color-Difference Mea-

original paint can be evaluated visually.

surement by Tristimulus Colorimetry

1.2 This practice describes evaluation of touch-up charac-

teristics in a laboratory-scale controlled environment as op-

3. Terminology

posed to a full-scale field environment.

3.1 Definitions:

1.3 Evaluation of touch-up properties under constant drying

3.1.1 touch-up, n—to repair visual differences in a painted

conditions is described. Environmental conditions can be

surface by recoating small areas with the same paint that was

adjusted to incorporate high or low temperature drying , or

used for the original coat.

both.The changes in application temperature can lead to larger

3.1.1.1 Discussion—This includes color and sheen differ-

differences in touch-up than applying both coats under the

ences in the dry film.

same environmental conditions.

1.4 This standard does not purport to address all of the

4. Summary of Practice

safety concerns, if any, associated with its use. It is the

4.1 Paints, application tools, and drying conditions are

responsibility of the user of this standard to establish appro-

selected before starting this practice. Relevant color(s) for

priate safety and health practices and determine the applica-

testing and any specific primers should also be selected at this

bility of regulatory limitations prior to use.

time.

2. Referenced Documents

4.2 Multiple coats of the test paint are applied to a specified

substrate in a prescribed manner to simulate touch-up condi-

2.1 ASTM Standards:

tions. The results are visually evaluated for variations in color,

D344 Test Method for Relative Hiding Power of Paints by

gloss, and sheen between the touch-up coating and the first and

the Visual Evaluation of Brushouts

second coat.

D523 Test Method for Specular Gloss

D1475 Test Method For Density of Liquid Coatings, Inks,

4.3 A qualitative rating scale for the touch-up result is

and Related Products

described.

D1729 Practice for Visual Appraisal of Colors and Color

Differences of Diffusely-Illuminated Opaque Materials

5. Significance and Use

D5068 Practice for Preparation of Paint Brushes for Evalu-

5.1 During construction of a home, paints are subjected to a

ation

wide variety of drying conditions, and this may exhibit

differences between the original coat and the touched-up area

in appearance after its full cure.Therefore, it it essential for the

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

paint to be able to perform under a wide variety of drying

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.42 on Architectural Coatings.

conditions. A paint that does this is very advantageous to the

Current edition approved July 1, 2013. Published July 2013. Originally approved

contractor.

in 2009. Last previous edition approved in 2009 as D7489 – 09. DOI: 10.1520/

D7489-09R13.

5.2 Itispossibleforapainttohaveexcellentcolortouch-up,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

but poor sheen touch-up, or vice-versa. The ideal paint will

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

have both excellent color and sheen touch-up under testing

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. conditions.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7489 − 09 (2013)

5.3 Color,glossandbasechoicecanhaveamajorimpacton 7.2 Select a convenient and suitable spreading rate, mutu-

touch-up of the paint. ally agreeable to all parties involved in the testing program,

and preferably in the range from 8.6 to 11.0 m /L (350 to

6. Apparatus and Materials

450 ft /gal). See Appendix X1 for examples of typical

touch-up applicator and drying conditions.

6.1 Tinted Test Paint.

7.2.1 Results may be highly dependent on film thickness;

6.2 Dry Wall Panels, Upson Board , or other accepted

therefore, it is essential that the test paints be weighed on

material. Minimum size 30 by 30 cm (1 ft by 1 ft).

accurately, particularly for small test areas. The amount of

6.3 Primary Applicator, which could be:

paint in grams required for a specific spread rate can be

6.3.1 Good quality paint roller with ⁄8 in. nap.

determined from the following equation:

6.3.2 Airless spray unit capable of 1000 to 3000 psi and

g 5 ~~Am*D!/Sm!*1000 (1)

appropriate spray tip.

where:

NOTE 1—If using an airless spray unit, typically a larger test panel is

Am = area, square metres,

required.

D = density, g/mL or kg/L, and

6.3.3 Other applicators, as agreed upon.

Sm = spreading rate, square metres/L.

6.4 Secondary Applicator, which could be:

or the following imperial units equation:

6.4.1 Good quality paint roller with 1 cm ( ⁄8 in.) nap.

g 5 A*W /S *3.15 (2)

~~ ! !

6.4.2 Good quality polyester/nylon paint brush.

6.4.3 A natural or synthetic sponge.

where:

6.4.4 Other applicators, as agreed upon.

A = area, sq. in.,

W = weight per gal. (Test Method D1475), lb./gal, and

6.5 Controlled Temperature Drying Area/Cabinet, such as:

S = spreading rate, square ft/gal.

6.5.1 Cold cabinet (refrigerator), maintaining 4 6 2°C (40

NOTE 2—The gallon unit here and throughout this test method is the U.

6 5°F ).

S. gallon (3.78 L).

6.5.2 Constanttemperatureroom,maintaining25 62°C(77

NOTE 3—To avoid variations in initial gloss, the substrate may require

6 5°F).

priming.

6.5.3 May be done in a cabinet maintained at other tem-

7.3 Application of First Coat:

peratures or humidities, or both, as agreed.

7.3.1 The test substrate, applicator for the first coat (appli-

6.6 Gloss Meter (optional), to read gloss differences on test

cator A) and paint are placed in an area (oven, refrigerator, or

panel.

constant temperature room) that corresponds with drying

conditions for first coat (drying conditions A), and allowed to

6.7 Spectrophotometer (optional), to read color differences

equilibrate for at least 4 h.

on test panel.

7.3.2 Applicator is broken in or conditioned for use (for

6.8 Bench Scale (optional), to measure weight of paint

example, Practice D5068 for paint brushes and Practice D5069

applied to test.

for paint rollers).

6.9 Ruler (optional), or other measuring device to measure

7.3.3 Then, one coat of the test paint is applied to the test

area of paint application.

substrate using the applicator A at drying conditions A. An

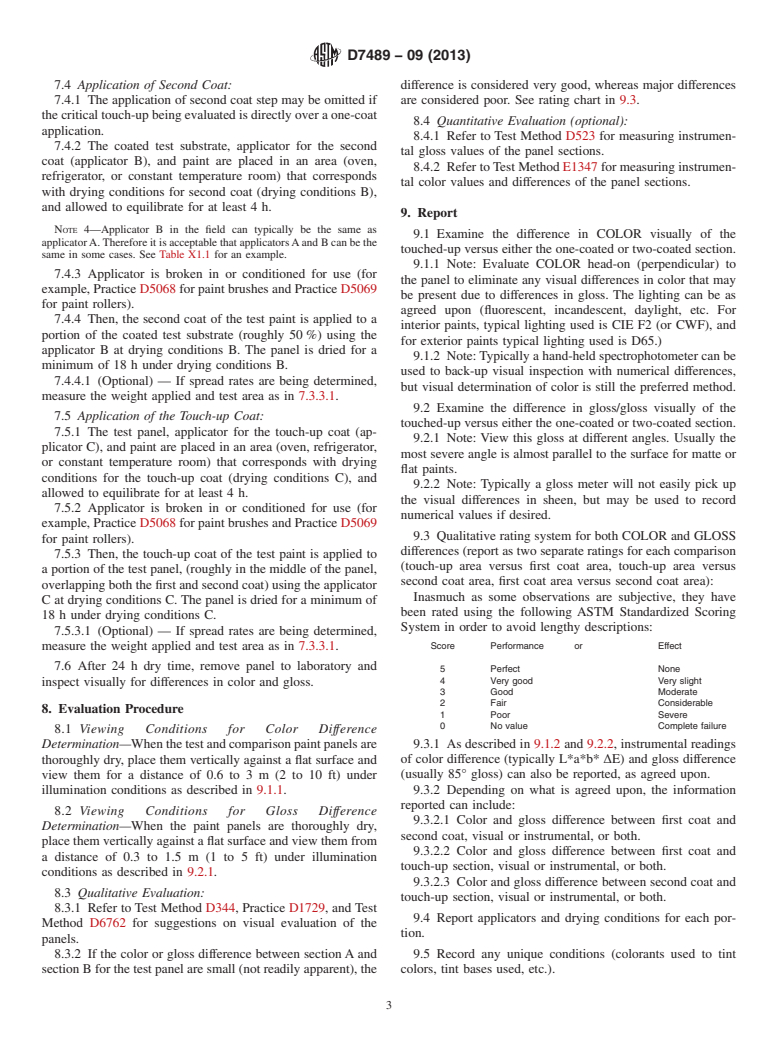

illustration of the series of three application steps is found in

7. Procedure

Fig. 1. The panel is dried for a minimum of 18 h under drying

7.1 Before starting this method, agree upon paints, tinted conditions A.

color, applicator types for first coat, second coat and touch-up 7.3.3.1 (Optional) — If spread rates are being determined,

area(s), as well as temperature under which each will be measure the weight applied to the test panel using a bench

applied and dried. scale, and measure the length and width of the test area.

FIG. 1 Graphic Representation of First and Second Coats and Touch-up Areas

D7489 − 09 (2013)

7.4 Application of Second Coat: difference is considered very good, whereas major differences

7.4.1 The application of second coat step may be omitted if are considered poor. See rating chart in 9.3.

the critical touch-up being evaluated is directly over a one-coat

8.4 Quantitative Evaluation (optional):

application.

8.4.1 Refer to Test Method D523 for measuring instrumen-

7.4.2 The coated test substrate, applicator for the second

tal gloss values of the panel sections.

coat (applicator B), and paint are placed in an area (oven,

8.4.2 Refer toTest Method E1347 for measuring instrumen-

refrigerator, or constant temperature r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.