ASTM C802-96(2008)e1

(Practice)Standard Practice for Conducting an Interlaboratory Test Program to Determine the Precision of Test Methods for Construction Materials

Standard Practice for Conducting an Interlaboratory Test Program to Determine the Precision of Test Methods for Construction Materials

SIGNIFICANCE AND USE

Certain criteria need to be met before undertaking an interlaboratory study to determine the precision of a test method. It is not necessary that all of the following conditions described be completely fulfilled in every case; however, if some conditions are not met or are met incompletely, the program will become more complicated and require more work and expense, or may result in impaired information. The recommendations outlined in this section are intended to ensure that the test method is free of technical difficulties to the greatest extent possible before an expensive and time-consuming interlaboratory study is undertaken.

The first requirement is the existence of a valid and well-written test method that has been developed in one competent laboratory (or by cooperative work in a small number of laboratories), and has been subjected to a screening procedure, or to ruggedness testing as described in Practice C 1067. As a result of the screening procedure and some experience with the test method in the sponsoring laboratory and one or two others, a written version of the test method has been developed (but not necessarily published as a standard method) that describes the test procedure in terms that can easily be followed in any properly equipped laboratory. Conditions that affect the test results should be identified and the proper degree of control of those conditions should be specified in the description of the test procedure (see Note 1).

Note 1—The desired degree of control of conditions that affect test results may not always be practically achievable, and tolerances in the test method should recognize this fact. Variations in test results due to variations in such conditions contribute to the total variation which determines the precision of the test method. If the resulting variation is so great that uncertainties in average values obtained by the test method are unacceptably high, then the test method itself is at fault, and efforts should be ma...

SCOPE

1.1 This practice describes techniques for planning, conducting, and analyzing the results of an interlaboratory study of a test method. It is designed to be used in conjunction with Practice C 670. Thus, the procedures recommended in this practice have the limited purpose of providing reliable information on which precision statements of the type described in Practice C 670 can be based. It is not appropriate for use in programs whose purpose is to develop a test method or to assess the relative merits of two or more test methods.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation:C802–96 (Reapproved 2008)

Standard Practice for

Conducting an Interlaboratory Test Program to Determine

the Precision of Test Methods for Construction Materials

This standard is issued under the fixed designation C802; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—A units statement was added editorially as paragraph 1.2 in December 2008.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This practice describes techniques for planning, con-

E178 Practice for Dealing With Outlying Observations

ducting,andanalyzingtheresultsofaninterlaboratorystudyof

a test method. It is designed to be used in conjunction with

3. Significance and Use

Practice C670. Thus, the procedures recommended in this

3.1 Certain criteria need to be met before undertaking an

practice have the limited purpose of providing reliable infor-

interlaboratory study to determine the precision of a test

mation on which precision statements of the type described in

method. It is not necessary that all of the following conditions

Practice C670 can be based. It is not appropriate for use in

described be completely fulfilled in every case; however, if

programs whose purpose is to develop a test method or to

some conditions are not met or are met incompletely, the

assess the relative merits of two or more test methods.

programwillbecomemorecomplicatedandrequiremorework

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

and expense, or may result in impaired information. The

as standard. The values given in parentheses are mathematical

recommendations outlined in this section are intended to

conversions to SI units that are provided for information only

ensurethatthetestmethodisfreeoftechnicaldifficultiestothe

and are not considered standard.

greatest extent possible before an expensive and time-

2. Referenced Documents consuming interlaboratory study is undertaken.

3.1.1 The first requirement is the existence of a valid and

2.1 ASTM Standards:

well-written test method that has been developed in one

C109/C109M Test Method for Compressive Strength of

competent laboratory (or by cooperative work in a small

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

number of laboratories), and has been subjected to a screening

Specimens)

procedure, or to ruggedness testing as described in Practice

C136 Test Method for Sieve Analysis of Fine and Coarse

C1067. As a result of the screening procedure and some

Aggregates

experience with the test method in the sponsoring laboratory

C670 Practice for Preparing Precision and Bias Statements

and one or two others, a written version of the test method has

for Test Methods for Construction Materials

been developed (but not necessarily published as a standard

C1067 Practice for ConductingARuggedness or Screening

method) that describes the test procedure in terms that can

Program for Test Methods for Construction Materials

easily be followed in any properly equipped laboratory. Con-

E105 Practice for Probability Sampling Of Materials

ditions that affect the test results should be identified and the

properdegreeofcontrolofthoseconditionsshouldbespecified

This practice is under the jurisdiction of ASTM Committee C09 on Concrete

in the description of the test procedure (see Note 1).

andConcreteAggregates.ThispracticewasdevelopedjointlybyASTMCommittee

C01, C09, D04, and D18, and is endorsed by all four committees.

NOTE 1—The desired degree of control of conditions that affect test

Current edition approved Dec. 1, 2008. Published February 2009. Originally

resultsmaynotalwaysbepracticallyachievable,andtolerancesinthetest

approvedin1974.Lastpreviouseditionapprovedin2002asC802–96(2002).DOI:

method should recognize this fact. Variations in test results due to

10.1520/C0802-96R08E01.

variations in such conditions contribute to the total variation which

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

determines the precision of the test method. If the resulting variation is so

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

great that uncertainties in average values obtained by the test method are

Standards volume information, refer to the standard’s Document Summary page on

unacceptablyhigh,thenthetestmethoditselfisatfault,andeffortsshould

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

C802–96 (2008)

be made to improve it or to replace it by a better one. An expensive and

difficult ones connected with the process. The number of

time-consuming interlaboratory study should not be undertaken on such a

laboratoriesavailableisseldomasextensiveasonewouldlike,

test method.

and if the test method is new, complicated, or expensive and

3.1.2 Any apparatus required for performing the test should

time-consuming to run, the problem is further complicated.

be appropriately designed and available at reasonable cost. The problem usually becomes one of finding and obtaining the

3.1.3 Personnel in participating laboratories should have

cooperation of enough qualified laboratories to obtain mean-

enough experience with the test method so that they are ingful estimates of precision, rather than that of selection

competent to run the test. The importance of this requirement

among a group of available laboratories. If there is great

will vary with the complexity of the method and the degree to difficulty in obtaining a sufficient number of competent and

which it departs from familiar procedures.

willing laboratories, then the possibility exists that the test

3.1.4 Preliminary knowledge should exist about how method should not be subjected to a formal interlaboratory

changes in materials and conditions affect the test results.

study.

There should be a reasonable degree of certainty that the 4.2 For the purposes of programs using this recommended

within-laboratory variances are the same in different laborato-

practice, it is recommended that at least ten participating

ries, and that troublesome interactions do not exist. These laboratoriesbeincluded (1, 2). Incaseswhereitisimpossible

conditions are investigated in the analysis of the data of an to obtain ten laboratories, the effect of an increased number

interlaboratory study, and are discussed further in 8.2.2, 8.2.3, maybeobtainedbyrepeatingtheprogramwiththesamegroup

and Appendix X1. of laboratories six months later. Usually, results obtained from

3.1.5 Facilities and procedures for procurement, prepara-

the same laboratory after a time lapse of approximately six

tion, and distribution of samples must be available and should months display most of the characteristics of results from a

be as simple and free of difficulties as practicable.

different laboratory, especially if a different operator and

3.1.6 Selectionofsamplesmustbedonebyarandomization apparatus can be used. If this procedure is followed, it is

process, and one person who is familiar with randomization

necessary to be sure that the same materials are used, and that

procedures should be responsible for seeing that the procedure their characteristics have not changed in the interim.

is carried out. Refer to Recommended Practice E105.

4.3 In general, it is recommended that any laboratory that is

3.1.7 Adequate numbers of participating laboratories, op- considered qualified to run the test in routine testing situations

erators,andmaterialsmustbeavailable.Requirementsinthese

should be permitted and encouraged to participate. “Qualified”

areas are specified in Sections 4 and 5. implies proper laboratory facilities and testing equipment,

3.1.8 The entire interlaboratory test program should be

competentoperatorsfamiliarwiththetestmethod,areputation

developed from the beginning with the help and advice of for reliable testing work, and sufficient time and interest to do

persons familiar with statistical procedures and with the

agoodjob.Itdoesnotmean,however,thatonlyaselectgroup

materials involved (see Note 2).The same persons who design oflaboratoriesthatareconsideredtobethosebestqualifiedfor

the experiment should also carry out, or at least have control

the interlaboratory study should be picked. Precision estimates

over, the process of analysis of the data. for inclusion in a test method must be obtained under condi-

tions and through the efforts of laboratories and personnel that

NOTE 2—It may not always be possible to obtain people who are

are representative of the situations in which the test method

familiar with the materials involved who have a sufficient knowledge of

will be used in practice (3). If a laboratory has all the other

the proper statistical techniques and their proper use. In this case, the

committee should obtain the services of a competent statistician who has requirements, but its personnel has had insufficient experience

experienceinpracticalworkwithdatafrommaterialstesting,andprovide

with the method, the operators in that laboratory should be

him with an opportunity for learning something about the particular

givenanopportunitytofamiliarizethemselveswiththemethod

materials and test method involved. Planners of an interlaboratory study

and to practice its application before the interlaboratory study

should also be warned to avoid the pitfall of assuming that the use of a

starts.

large computer necessarily results in special expertise in the handling of

data or the interpretation of results.

5. Materials

3.2 It is important to bear in mind that estimates of the

5.1 The number and type of materials to be included in an

precision of a test method are always based on a particular set

interlaboratory study will depend on the following:

of data obtained at a particular time and they need to be kept

5.1.1 The range of the values of the property being mea-

up-to-date.Asmaterials,apparatus,andconditionschange,and

sured on a given material and how the precision varies over

operators change or gain more experience, the characteristic

that range,

precision of the results obtained may change, especially if the

5.1.2 The number of different materials to which the test

test method is new. In some cases, it may even be desirable to

method is to be applied,

conduct more tests at a later date (though not necessarily a

5.1.3 The difficulty and expense involved in obtaining,

repetition of the complete interlaboratory study) in order to

processing, and distributing samples,

provide a check on estimates previously obtained and either

5.1.4 The difficulty of, length of time required for, and

verify them or introduce revisions.

expense of performing the tests, and

4. Laboratories

4.1 The problem of obtaining competent participating labo-

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

ratories for an interlaboratory study is often one of the most this practice.

´1

C802–96 (2008)

5.1.5 The uncertainty of prior information on any of these reported. Whenever a test result is defined, either in the test

points. For example, if it is already known that the precision is method or in the instructions to laboratories participating in an

relativelyconstantorproportionaltotheaverageleveloverthe interlaboratory test program, as the average of a particular

range of values of interest, a smaller number of materials will number of determinations, the individual determinations

be needed than if it is known that the precision changes should be reported, in addition to the averages. When two or

erratically at different levels. A preliminary pilot or screening more measurements are averaged to obtain a test result, the

program may help to settle some of these questions, and may data from the interlaboratory test program may be used to

often result in the saving of considerable time and expense in develop an estimate of the precision of these individual

the full interlaboratory study (4). measurements. See 3.3.3 of Practice C670.

5.2 In general, a minimum of three materials should be 7.2.2 Rounding of Data:

considered acceptable.

7.2.2.1 Generally, laboratories should be required to report

all figures obtained in making the measurements, rather than

6. Estimates of Precision

rounding the results before recording them. In some cases, this

6.1 In accordance with Recommended Practice C670, the may result in recording of more digits than is customary or

procedure described in this practice is designed to provide two even more than the test method calls for in the section on

basic estimates of the precision of a test method: (a) single- Reporting(seeX1.3.1).Thisisnecessarybecausethevariation

operator precision, and (b) multilaboratory precision. If other from which information about the precision of the test method

estimates of precision are desired, other references should be comes is contained in the least significant digits, which are

often discarded in reporting the results of routine testing (6).

consulted (see Practice E177) (5).

6.2 Single-operator precision provides an estimate of the For example, Method C136 calls for reporting of percentages

to the nearest whole number. This is adequate for the usual

difference that may be expected between duplicate measure-

mentsmadeonthesamematerialinthesamelaboratorybythe reporting purposes, but for purposes of determining precision,

same operator using the same apparatus within a time span of at least one decimal place is needed. It is better to require the

a few days. reporting of too many decimal places than too few, since a

6.3 Multilaboratory precision provides an estimate of the decisionaboutroundingalldatacanbemadewhentheanalysis

difference that may be expected between measurements made is done. If too few places are reported, however, valuable

on the same material in two different laboratories. informationmaybeirretrievablylost,andtheresultmightwell

be the impairment of the entire program.

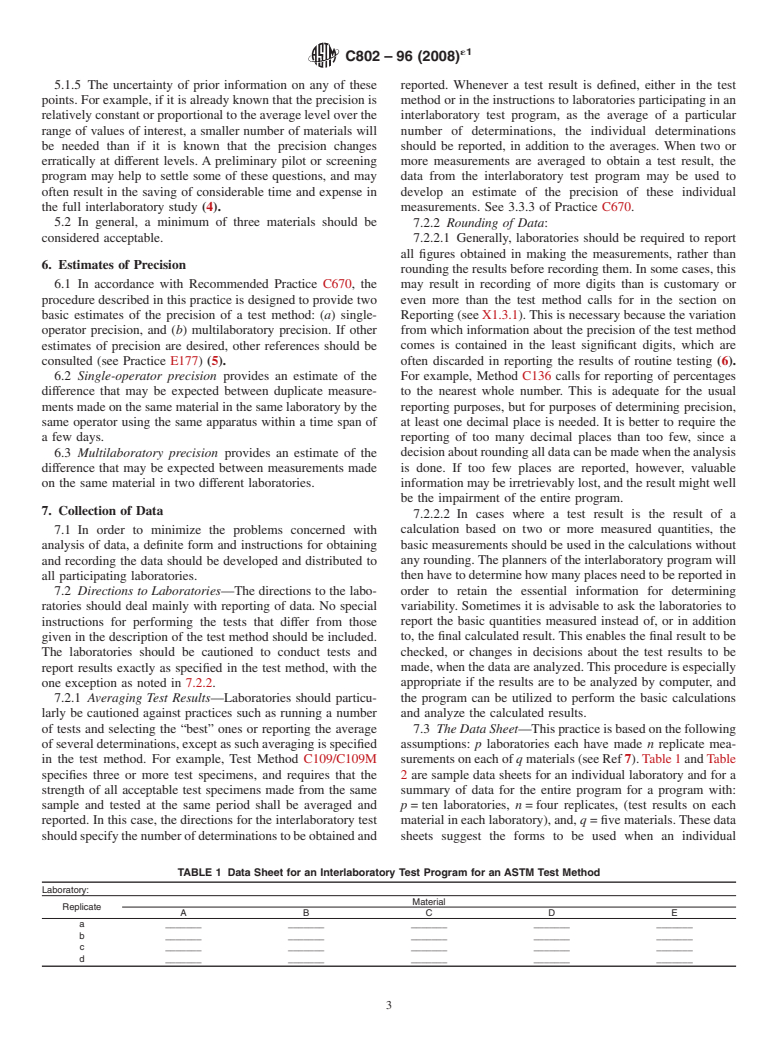

7. Collection of Data

7.2.2.2 In cases where a test result is the result of a

7.1 In order to minimize the problems concerned with calculation based on two or more measured quantities, the

analysis of data, a definite form and instructions for obtaining basic measurements should be used in the calculations without

and recording the data should be developed and distributed to anyrounding.Theplannersoftheinterlaboratoryprogramwill

all participating laboratories. thenhavetodeterminehowmanyplacesneedtobereportedin

7.2 Directions to Laboratories—The directions to the labo- order to retain the essentia

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.