ASTM D6373-15

(Specification)Standard Specification for Performance Graded Asphalt Binder

Standard Specification for Performance Graded Asphalt Binder

ABSTRACT

This specification covers asphalt binders graded by performance. Grading designations are related to the average seven-day maximum pavement design temperature, and minimum pavement design temperature. Asphalt binder shall be prepared by the refining of crude petroleum by suitable methods, with or without the addition of modifiers, which may be any organic material of suitable manufacture that is used in virgin or recycled condition, and that is dissolved, dispersed or reacted in asphalt cement to enhance its performance. This specification incorporates an aid for determining the critical low cracking temperature using a combination of test procedures.

SCOPE

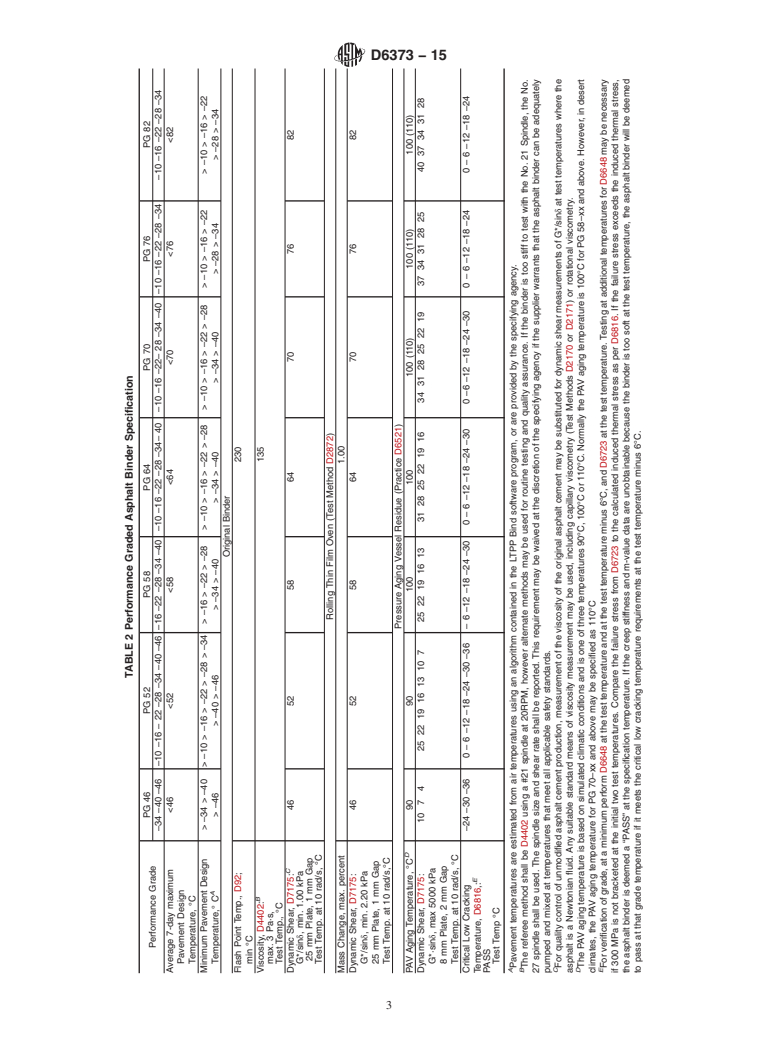

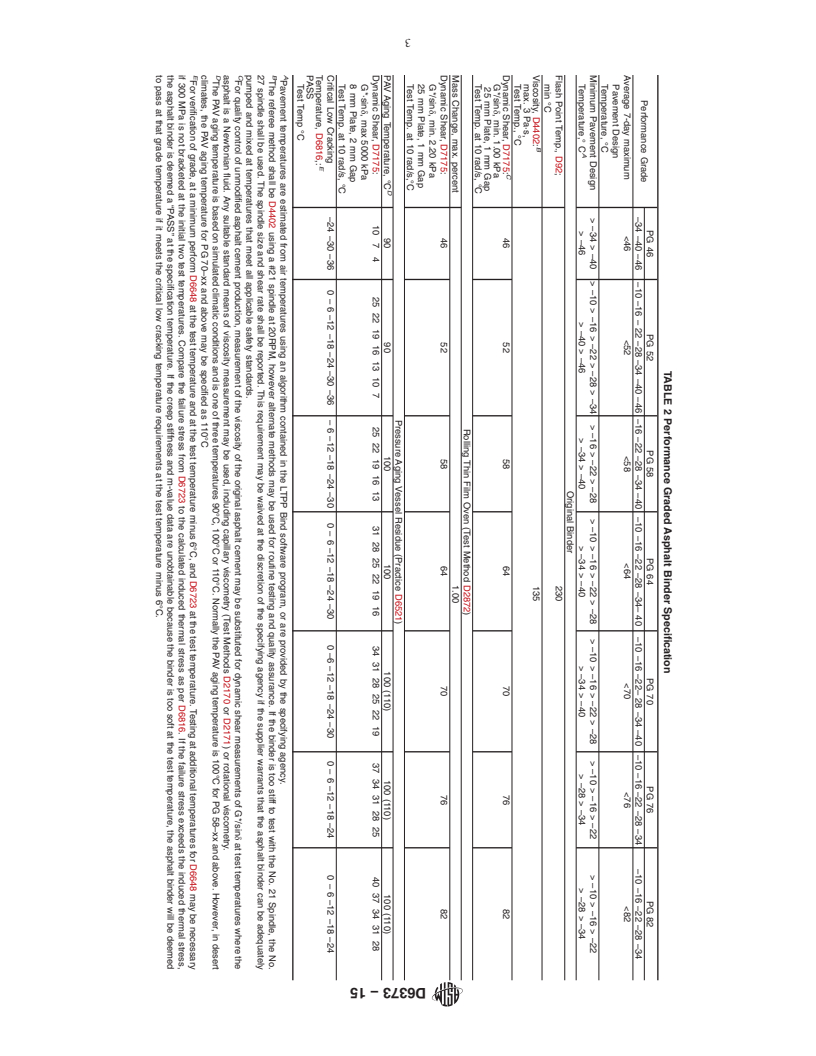

1.1 This specification2 covers asphalt binders graded by performance. Grading designations are related to the average seven-day maximum pavement design temperature, and minimum pavement design temperature. This specification contains Table 1 and Table 2. Table 2 incorporates Practice D6816 for determining the critical low cracking temperature using a combination of Test Method D6648 and Test Method D6723 test procedures. If no table is specified, the default is Table 1. (A) Pavement temperatures are estimated from air temperatures using an algorithm contained in the LTPP Bind software program, or are provided by the specifying agency.(B) The referee method shall be D4402 using a #21 spindle at 20RPM, however alternate methods may be used for routine testing and quality assurance. If the binder is too stiff to test with the No. 21 Spindle, the No. 27 spindle shall be used. The spindle size and shear rate shall be reported. This requirement may be waived at the discretion of the specifying agency if the supplier warrants that the asphalt binder can be adequately pumped and mixed at temperatures that meet all applicable safety standards.(C) For quality control of unmodified asphalt cement production, measurement of the viscosity of the original asphalt cement may be substituted for dynamic shear measurements of G*/sinδ at test temperatures where the asphalt is a Newtonian fluid. Any suitable standard means of viscosity measurement may be used, including capillary viscometry (Test Methods D2170 or D2171) or rotational viscometry.(D) The PAV aging temperature is based on simulated climatic conditions and is one of three temperatures 90°C, 100°C or 110°C. Normally the PAV aging temperature is 100°C for PG 58–xx and above. However, in desert climates, the PAV aging temperature for PG 70–xx and above may be specified as 110°C(E) If the creep stiffness is below 300 MPa, the direct tension test is not required. If the creep stiffness is between 300 and 600 MPa the direct tension failure strain requirement can be used in lieu of the creep stiffness requirement. The m-value requirement must be satisfied in both cases. If the creep stiffness and m-value data are unobtainable because the binder is too soft at the test temperature, the asphalt binder will be deemed to pass at that grade temperature if it meets the creep stiffness and m-value requirements at the test temperature minus 6°C. (A) Pavement temperatures are estimated from air temperatures using an algorithm contained in the LTPP Bind software program, or are provided by the specifying agency.(B) The referee method shall be D4402 using a #21 spindle at 20RPM, however alternate methods may be used for routine testing and quality assurance. If the binder is too stiff to test with the No. 21 Spindle, the No. 27 spindle shall be used. The spindle size and shear rate shall be reported. This requirement may be waived at the discretion of the specifying agency if the supplier warrants that the asphalt binder can be adequately pumped and mixed at temperatures that meet all applicable safety standards.(C) For quality control of unmodified asphalt cement production, measurement of the viscosity of the original asphalt cement may be substituted for dynamic shear measurements of G*/sinδ at test temperatures where th...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6373 −15

StandardSpecification for

1

Performance Graded Asphalt Binder

This standard is issued under the fixed designation D6373; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2171 Test Method for Viscosity of Asphalts by Vacuum

2

Capillary Viscometer

1.1 This specification covers asphalt binders graded by

D2872 Test Method for Effect of Heat andAir on a Moving

performance. Grading designations are related to the average

Film of Asphalt (Rolling Thin-Film Oven Test)

seven-day maximum pavement design temperature, and mini-

D3381 Specification for Viscosity-Graded Asphalt Cement

mum pavement design temperature.This specification contains

for Use in Pavement Construction

Table 1 and Table 2. Table 2 incorporates Practice D6816 for

D4402 Test Method for Viscosity Determination of Asphalt

determining the critical low cracking temperature using a

at Elevated Temperatures Using a Rotational Viscometer

combination of Test Method D6648 and Test Method D6723

D5546 Test Method for Solubility of Asphalt Binders in

test procedures. If no table is specified, the default is Table 1.

Toluene by Centrifuge

NOTE 1—For asphalt cements graded by penetration at 25°C, see

D6521 Practice for Accelerated Aging of Asphalt Binder

Specification D946. For asphalt cements graded by viscosity at 60°C see

Using a Pressurized Aging Vessel (PAV)

Specification D3381.

D6648 Test Method for Determining the Flexural Creep

NOTE 2—AASHTO R 29 provides non-mandatory information for

Stiffness of Asphalt Binder Using the Bending Beam

determining the performance grade of an asphalt binder.

Rheometer (BBR)

1.2 The values stated in SI units are to be regarded as

D6723 Test Method for Determining the Fracture Properties

standard. No other units of measurement are included in this

of Asphalt Binder in Direct Tension (DT)

standard.

D6816 Practice for Determining Low-Temperature Perfor-

mance Grade (PG) of Asphalt Binders

2. Referenced Documents

D7175 Test Method for Determining the Rheological Prop-

3

2.1 ASTM Standards:

erties of Asphalt Binder Using a Dynamic Shear Rheom-

D8 Terminology Relating to Materials for Roads and Pave-

eter

ments

D7553 Test Method for Solubility of Asphalt Materials in

D92 Test Method for Flash and Fire Points by Cleveland

N-Propyl Bromide

Open Cup Tester

4

2.2 AASHTO Standards:

D95 Test Method for Water in Petroleum Products and

AASHTOR 29 GradingorVerifyingthePerformanceGrade

Bituminous Materials by Distillation

of an Asphalt Binder

D140 Practice for Sampling Bituminous Materials

AASHTO M 320 Standard Specification for Performance-

D946 Specification for Penetration-Graded Asphalt Cement

Graded Asphalt Binder

for Use in Pavement Construction

D2042 Test Method for Solubility of Asphalt Materials in

3. Terminology

Trichloroethylene

D2170 Test Method for Kinematic Viscosity of Asphalts

3.1 Definitions:

(Bitumens)

3.1.1 Definitions for many terms common to asphalt binder

are found in Terminology Standard D8.

1 3.2 Definitions of Terms Specific to This Standard:

This specification is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.40 on

3.2.1 asphalt binder, n—an asphalt-based cement that is

Asphalt Specifications.

produced from petroleum residue either with or without the

Current edition approved Jan. 1, 2015. Published January 2015. Originally

addition of modifiers.

approved in 1999. Last previous edition approved in 2013 as D6373 – 13. DOI:

10.1520/D6373-15.

2

This specification is based on SHRP Product 1001 and AASHTO MP1.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Association of State Highway and Transportation

Standards volume information, refer to the standard’s Document Summary page on Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

the ASTM website. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6373−15

2

TABLE 1 Performance Graded Asphalt Binder Specification

PG 46 PG 52 PG 58 PG 64 PG 70 PG 76 PG 82

Performance Grade

–34 –40 –46 –10 –16 – 22 –28 –34 –40 –46 –16 –22 –28 –34 –40 –10 –16 –22 –28 –34– 40 –10 –16 –22– 28 –34 –40 –10 –16 –22 –28 –34 –10 –16 –22 –28 –34

Average 7-day maximum <46 <52 <58 <64 <70 <76 <82

Pavement Design

Temperature, °C

Minimum Pavement Design > –34 > –40 > –10 > –16 > –22 > –28 > –34 >

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6373 − 13 D6373 − 15

Standard Specification for

1

Performance Graded Asphalt Binder

This standard is issued under the fixed designation D6373; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

2

1.1 This specification covers asphalt binders graded by performance. Grading designations are related to the average seven-day

maximum pavement design temperature, and minimum pavement design temperature. This specification contains Table 1 and

Table 2. Table 2 incorporates Practice D6816 for determining the critical low cracking temperature using a combination of Test

Method D6648 and Test Method D6723 test procedures. If no table is specified, the default is Table 1.

NOTE 1—For asphalt cements graded by penetration at 25°C, see Specification D946. For asphalt cements graded by viscosity at 60°C see Specification

D3381.

NOTE 2—AASHTO R 29 provides non-mandatory information for determining the performance grade of an asphalt binder.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

2. Referenced Documents

3

2.1 ASTM Standards:

D8 Terminology Relating to Materials for Roads and Pavements

D92 Test Method for Flash and Fire Points by Cleveland Open Cup Tester

D95 Test Method for Water in Petroleum Products and Bituminous Materials by Distillation

D140 Practice for Sampling Bituminous Materials

D946 Specification for Penetration-Graded Asphalt Cement for Use in Pavement Construction

D2042 Test Method for Solubility of Asphalt Materials in Trichloroethylene

D2170 Test Method for Kinematic Viscosity of Asphalts (Bitumens)

D2171 Test Method for Viscosity of Asphalts by Vacuum Capillary Viscometer

D2872 Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test)

D3381 Specification for Viscosity-Graded Asphalt Cement for Use in Pavement Construction

D4402 Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer

D5546 Test Method for Solubility of Asphalt Binders in Toluene by Centrifuge

D6521 Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV)

D6648 Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR)

D6723 Test Method for Determining the Fracture Properties of Asphalt Binder in Direct Tension (DT)

D6816 Practice for Determining Low-Temperature Performance Grade (PG) of Asphalt Binders

D7175 Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer

D7553 Test Method for Solubility of Asphalt Materials in N-Propyl Bromide

4

2.2 AASHTO Standards:

AASHTO R 29 Grading or Verifying the Performance Grade of an Asphalt Binder

AASHTO M 320 Standard Specification for Performance-Graded Asphalt Binder

3. Terminology

3.1 Definitions:

3.1.1 Definitions for many terms common to asphalt binder are found in Terminology Standard D8.

1

This specification is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.40 on Asphalt

Specifications.

Current edition approved June 1, 2013Jan. 1, 2015. Published July 2013January 2015. Originally approved in 1999. Last previous edition approved in 20072013 as

e1

D6373 – 07D6373 – 13. . DOI: 10.1520/D6373-13.10.1520/D6373-15.

2

This specification is based on SHRP Product 1001 and AASHTO MP1.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from American Association of State Highway and Transportation Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6373 − 15

2

TABLE 1 Performance Graded Asphalt Binder Specification

PG 46 PG 52 PG 58 PG 64 PG 70 PG 76 PG 82

Performance Grade

–34 –40 –46 –10 –16 – 22 –28 –34 –40 –46 –16 –22 –28 –34 –40 –10 –16 –22 –28 –34– 40 –10 –16 –22– 28 –34 –40 –10 –16 –22 –28 –34 –10 –16

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.