ASTM F1511-09

(Specification)Standard Specification for Mechanical Seals for Shipboard Pump Applications

Standard Specification for Mechanical Seals for Shipboard Pump Applications

ABSTRACT

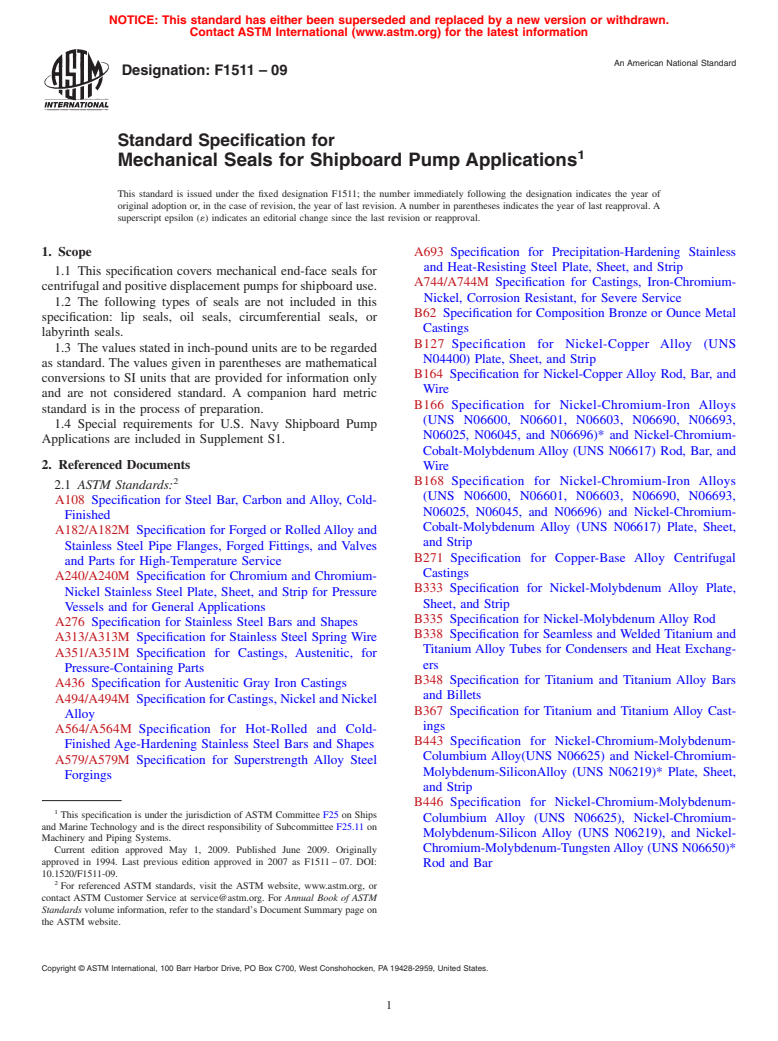

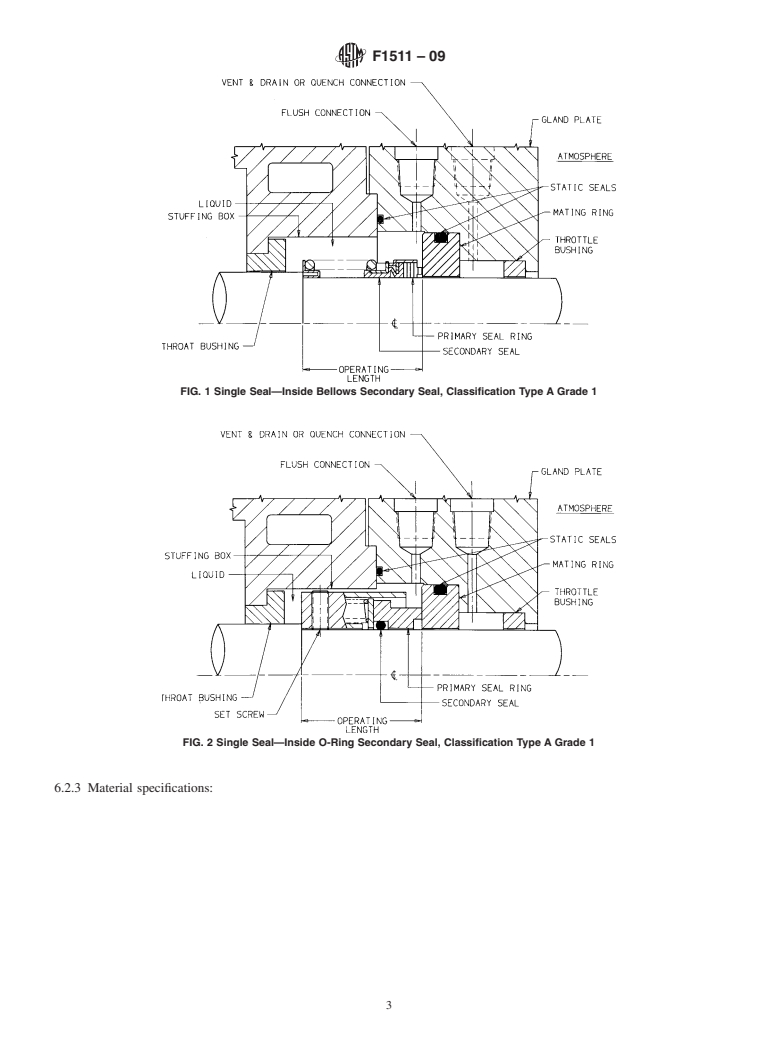

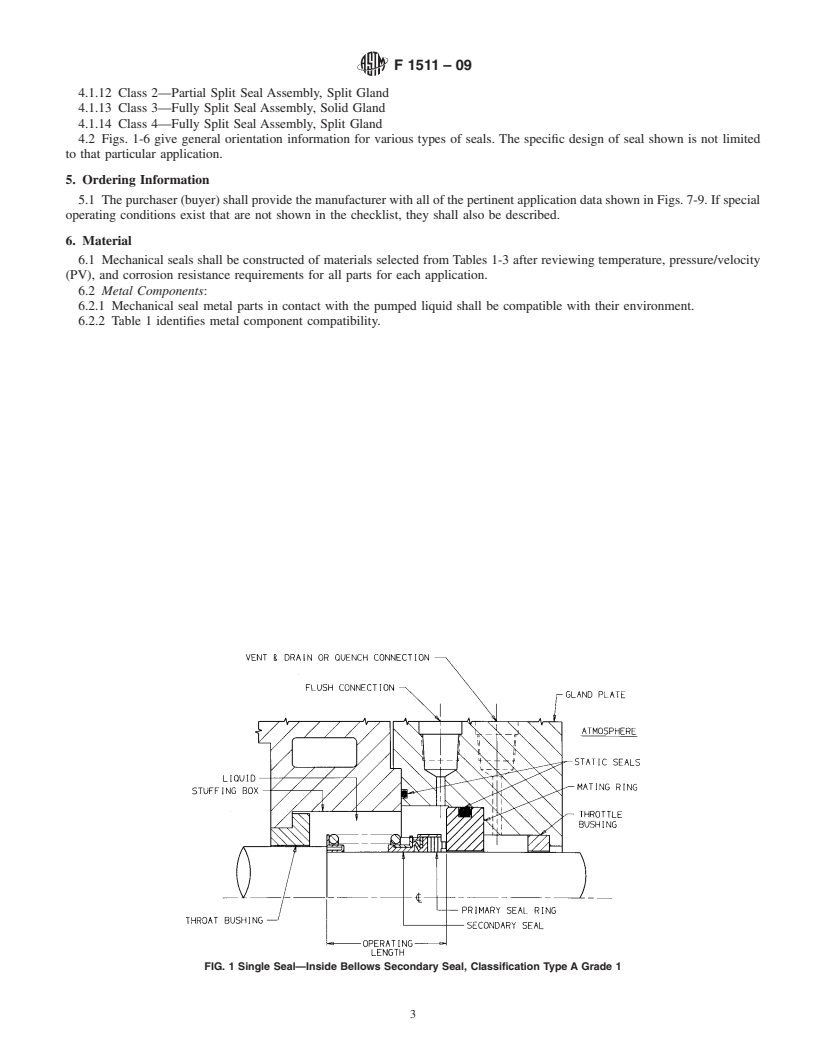

This specification covers mechanical end-face seals for centrifugal and positive displacement pumps for shipboard use. Mechanical seals shall be classified by type, grade, and class. Types: type A - inside single mounted seals, type B - outside single mounted seals, type C - double seals, type D - tandem seals, type E - gas seal, and type F - special arrangement/applications vacuum or gas seal. Grades: grade 1 - basic end face seal, grade 2 - cartridge seal, and grade 3 - split seal. Classes: class 0 - nonsplit seal assembly, class 1 - partial split seal assembly, solid gland, class 2 - partial split seal assembly, split gland, class 3 - fully split seal assembly, solid gland, and class 4 - fully split seal assembly, split gland. Seal life shall be defined in terms of the time period in which the mechanical seal functions properly under its specified service.

SCOPE

1.1 This specification covers mechanical end-face seals for centrifugal and positive displacement pumps for shipboard use.

1.2 The following types of seals are not included in this specification: lip seals, oil seals, circumferential seals, or labyrinth seals.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. A companion hard metric standard is in the process of preparation.

1.4 Special requirements for U.S. Navy Shipboard Pump Applications are included in Supplement S1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F1511 – 09

Standard Specification for

1

Mechanical Seals for Shipboard Pump Applications

This standard is issued under the fixed designation F1511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A693 Specification for Precipitation-Hardening Stainless

and Heat-Resisting Steel Plate, Sheet, and Strip

1.1 This specification covers mechanical end-face seals for

A744/A744M Specification for Castings, Iron-Chromium-

centrifugalandpositivedisplacementpumpsforshipboarduse.

Nickel, Corrosion Resistant, for Severe Service

1.2 The following types of seals are not included in this

B62 Specification for Composition Bronze or Ounce Metal

specification: lip seals, oil seals, circumferential seals, or

Castings

labyrinth seals.

B127 Specification for Nickel-Copper Alloy (UNS

1.3 The values stated in inch-pound units are to be regarded

N04400) Plate, Sheet, and Strip

as standard. The values given in parentheses are mathematical

B164 Specification for Nickel-Copper Alloy Rod, Bar, and

conversions to SI units that are provided for information only

Wire

and are not considered standard. A companion hard metric

B166 Specification for Nickel-Chromium-Iron Alloys

standard is in the process of preparation.

(UNS N06600, N06601, N06603, N06690, N06693,

1.4 Special requirements for U.S. Navy Shipboard Pump

N06025, N06045, and N06696)* and Nickel-Chromium-

Applications are included in Supplement S1.

Cobalt-Molybdenum Alloy (UNS N06617) Rod, Bar, and

2. Referenced Documents Wire

2

B168 Specification for Nickel-Chromium-Iron Alloys

2.1 ASTM Standards:

(UNS N06600, N06601, N06603, N06690, N06693,

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

N06025, N06045, and N06696) and Nickel-Chromium-

Finished

Cobalt-Molybdenum Alloy (UNS N06617) Plate, Sheet,

A182/A182M Specification for Forged or RolledAlloy and

and Strip

Stainless Steel Pipe Flanges, Forged Fittings, and Valves

B271 Specification for Copper-Base Alloy Centrifugal

and Parts for High-Temperature Service

Castings

A240/A240M Specification for Chromium and Chromium-

B333 Specification for Nickel-Molybdenum Alloy Plate,

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

Sheet, and Strip

Vessels and for General Applications

B335 Specification for Nickel-Molybdenum Alloy Rod

A276 Specification for Stainless Steel Bars and Shapes

B338 Specification for Seamless and Welded Titanium and

A313/A313M Specification for Stainless Steel Spring Wire

Titanium Alloy Tubes for Condensers and Heat Exchang-

A351/A351M Specification for Castings, Austenitic, for

ers

Pressure-Containing Parts

B348 Specification for Titanium and Titanium Alloy Bars

A436 Specification for Austenitic Gray Iron Castings

and Billets

A494/A494M Specification for Castings, Nickel and Nickel

B367 Specification for Titanium and Titanium Alloy Cast-

Alloy

ings

A564/A564M Specification for Hot-Rolled and Cold-

B443 Specification for Nickel-Chromium-Molybdenum-

Finished Age-Hardening Stainless Steel Bars and Shapes

Columbium Alloy(UNS N06625) and Nickel-Chromium-

A579/A579M Specification for Superstrength Alloy Steel

Molybdenum-SiliconAlloy (UNS N06219)* Plate, Sheet,

Forgings

and Strip

B446 Specification for Nickel-Chromium-Molybdenum-

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships

Columbium Alloy (UNS N06625), Nickel-Chromium-

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Molybdenum-Silicon Alloy (UNS N06219), and Nickel-

Machinery and Piping Systems.

Chromium-Molybdenum-TungstenAlloy (UNS N06650)*

Current edition approved May 1, 2009. Published June 2009. Originally

approved in 1994. Last previous edition approved in 2007 as F1511 – 07. DOI:

Rod and Bar

10.1520/F1511-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1511 – 09

B472 Specification for Nickel Alloy Billets and Bars for AMS 7276 Rings, Sealing, Fluorocarbon (FKM) Rubber

Reforging High-Temperature—Fluid Resistant Low Compression

B473 Specification for UNS N08020, UNS N08024, and Set 70 to 80

UNS N08026 Nickel Alloy Bar and Wire AMS 3216 Fluorocarbon (FKM) Rubber, High-

B505/B505M Specification for Copper Alloy Continuous Temperature—Fluid Resistant, Low Compression, Set 70

Castings to

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F 1511–07 Designation: F 1511 – 09

Standard Specification for

1

Mechanical Seals for Shipboard Pump Applications

This standard is issued under the fixed designation F 1511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers mechanical end-face seals for centrifugal and positive displacement pumps for shipboard use.

1.2 Thefollowingtypesofsealsarenotincludedinthisspecification:lipseals,oilseals,circumferentialseals,orlabyrinthseals.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.Acompanion hard metric standard

is in the process of preparation.

1.4 Special requirements for U.S. Navy Shipboard Pump Applications are included in Supplement S1.

2. Referenced Documents

2

2.1 ASTM Standards:

A 108 Specification for Steel Bar, Carbon and Alloy, Cold-Finished

A 182/A 182M SpecificationforForgedorRolledAlloyandStainlessSteelPipeFlanges,ForgedFittings,andValvesandParts

for High-Temperature Service

A 240/A 240M Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels

and for General Applications

A 276 Specification for Stainless Steel Bars and Shapes

A 313/A 313M Specification for Stainless Steel Spring Wire

A 351/A 351M Specification for Castings, Austenitic, for Pressure-Containing Parts

A 436 Specification for Austenitic Gray Iron Castings

A 494/A 494M Specification for Castings, Nickel and Nickel Alloy

A 564/A 564M Specification for Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes

A 579/A 579M Specification for Superstrength Alloy Steel Forgings

A 693 Specification for Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and Strip

A 744/A 744M Specification for Castings, Iron-Chromium-Nickel, Corrosion Resistant, for Severe Service

B62 Specification for Composition Bronze or Ounce Metal Castings

B 127 Specification for Nickel-Copper Alloy (UNS N04400) Plate, Sheet, and Strip

B 164 Specification for Nickel-Copper Alloy Rod, Bar, and Wire

B 166 Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045,

and N06696) and Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617) Rod, Bar, and Wire

B 168 Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045,

and N06696) and Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617) Plate, Sheet, and Strip

B 271 Specification for Copper-Base Alloy Centrifugal Castings

B 333 Specification for Nickel-Molybdenum Alloy Plate, Sheet, and Strip

B 335 Specification for Nickel-Molybdenum Alloy Rod

B 338 Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers

B 348 Specification for Titanium and Titanium Alloy Bars and Billets

B 367 Specification for Titanium and Titanium Alloy Castings

B 443 Specification for Nickel-Chromium-Molybdenum-Columbium Alloy (UNSN06625) and Nickel-Chromium-

Molybdenum-Silicon Alloy (UNS N06219) Plate, Sheet, and Strip

B 446 Specification for Nickel-Chromium-Molybdenum-Columbium Alloy (UNS N06625), Nickel-Chromium-Molybdenum-

Silicon Alloy (UNS N06219), and Nickel-Chromium-Molybdenum-Tungsten Alloy (UNS N06650) Rod and Bar

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

Current edition approved May 1, 2007.2009. Published June 2007.2009. Originally approved in 1994. Last previous edition approved in 20062007 as F 1511 – 067.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1511 – 09

B 472 Specification for Nickel Alloy Billets and Bars for Reforging

B 473 Specification for UNS N08020, UNS N08024, and UNS N08026 Nickel Alloy B

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.