ASTM F1264-03(2007)e1

(Specification)Standard Specification and Test Methods for Intramedullary Fixation Devices

Standard Specification and Test Methods for Intramedullary Fixation Devices

SIGNIFICANCE AND USE

A2.4.1 This test method describes a static torsional test to determine the torsional stiffness of the central and uniform portion of an intramedullary fixation device.

A2.4.2 This test method may not be appropriate for all types of implant applications. The user is cautioned to consider the appropriateness of the method in view of the devices being tested and their potential application.

SCOPE

1.1 This specification is intended to provide a characterization of the design and mechanical function of intramedullary fixation devices (IMFDs), specify labeling and material requirements, provide test methods for characterization of IMFD mechanical properties, and identify needs for further development of test methods and performance criteria. The ultimate goal is to develop a standard which defines performance criteria and methods for measurement of performance-related mechanical characteristics of IMFDs and their fixation to bone. It is not the intention of this specification to define levels of performance or case-specific clinical performance of these devices, as insufficient knowledge to predict the consequences of the use of any of these devices in individual patients for specific activities of daily living is available. It is not the intention of this specification to describe or specify specific designs for IMFDs.

1.2 This specification describes IMFDs for surgical fixation of the skeletal system. It provides basic IMFD geometrical definitions, dimensions, classification, and terminology; labeling and material specifications; performance definitions; test methods and characteristics determined to be important to in-vivo performance of the device.

1.3 This specification includes four standard test methods:

1.3.1 Static Four-Point Bend Test Method—Annex A1 and

1.3.2 Static Torsion Test Method—Annex A2.

1.3.3 Bending Fatigue Test Method—Annex A3.

1.3.4 Test Method for Bending Fatigue of IMFD Locking Screws—Annex A4.

1.4 A rationale is given in Appendix X1.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

A1.1.1 This test method describes methods for static four-point bend testing of intrinsic, structural properties of intramedullary fixation devices (IMFDs) for surgical fixation of the skeletal system. This test method includes bend testing in a variety of planes relative to the major anatomic planes. The purpose is to measure bending strength and bending stiffness intrinsic to the design and materials of IMFDs.

A1.1.2 This test method is designed specifically to test IMFD designs that have a well-defined working length (WL) of uniform open or closed cross section throughout the majority of its length (WL ≥ 10× diameter) and is to be applied to the full length of the diaphysis of a femur, tibia, humerus, radius, or ulna. This is not applicable to IMFDs that are used to fix only a short portion of the diaphysis of any of the long bones or the diaphysis of small bones such as the metacarpals, metatarsals, phalanges, and so forth.

A1.1.3 This test method is not intended to test the extrinsic properties of any IMFD, that is, the interaction of the device with bone or other biologic materials.

A1.1.4 This test method is not intended to define case-specific clinical performance of these devices, as insufficient knowledge to predict the consequences of the use of any of these devices in individual patients is available.

A1.1.5 This test method is not intended to serve as a quality assurance document, and thus, statistical sampling techniques for batches from production of IMFDs are not addressed.

A1.1.6 This test method may not be appropriate for all types of implant applications. The user is cautioned to consider the appropriateness of the method in view of the devices being tested, the material of the...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F 1264 – 03 (Reapproved 2007)

Standard Specification and Test Methods for

Intramedullary Fixation Devices

This standard is issued under the fixed designation F 1264; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made throughout in December 2008.

1. Scope 2. Referenced Documents

1.1 This specification is intended to provide a characteriza- 2.1 ASTM Standards:

tion of the design and mechanical function of intramedullary A 214/A 214M Specification for Electric-Resistance-

fixation devices (IMFDs), specify labeling and material re- Welded Carbon Steel Heat-Exchanger and Condenser

quirements, provide test methods for characterization of IMFD Tubes

mechanical properties, and identify needs for further develop- A 450/A 450M Specification for General Requirements for

ment of test methods and performance criteria. The ultimate Carbon and Low Alloy Steel Tubes

goal is to develop a standard which defines performance D 790 TestMethodsforFlexuralPropertiesofUnreinforced

criteria and methods for measurement of performance-related and Reinforced Plastics and Electrical Insulating Materials

mechanicalcharacteristicsofIMFDsandtheirfixationtobone. E4 Practices for Force Verification of Testing Machines

It is not the intention of this specification to define levels of E 691 Practice for Conducting an Interlaboratory Study to

performance or case-specific clinical performance of these Determine the Precision of a Test Method

devices, as insufficient knowledge to predict the consequences F86 Practice for Surface Preparation and Marking of Me-

of the use of any of these devices in individual patients for tallic Surgical Implants

specific activities of daily living is available. It is not the F 138 Specification for Wrought 18Chromium-14Nickel-

intention of this specification to describe or specify specific 2.5Molybdenum Stainless Steel Bar and Wire for Surgical

designs for IMFDs. Implants (UNS S31673)

1.2 This specification describes IMFDs for surgical fixation F 339 Specification for Cloverleaf Intramedullary Pins

of the skeletal system. It provides basic IMFD geometrical F 383 Practice for Static Bend and Torsion Testing of

definitions, dimensions, classification, and terminology; label- Intramedullary Rods

ing and material specifications; performance definitions; test F 565 Practice for Care and Handling of Orthopedic Im-

methods and characteristics determined to be important to plants and Instruments

in-vivo performance of the device. F 1611 Specification for Intramedullary Reamers

1.3 This specification includes four standard test methods: 2.2 AMS Standard:

1.3.1 Static Four-Point Bend Test Method—Annex A1 and AMS5050 SteelTubing,Seamless,0.15Carbon,Maximum

1.3.2 Static Torsion Test Method—Annex A2. Annealed

1.3.3 Bending Fatigue Test Method—Annex A3. 2.3 SAE Standard:

1.3.4 Test Method for Bending Fatigue of IMFD Locking SAEJ524 SeamlessLow-CarbonSteelTubingAnnealedfor

Screws—Annex A4. Bending and Flaring

1.4 A rationale is given in Appendix X1.

3. Terminology

1.5 The values stated in SI units are to be regarded as

3.1 Definitions for Geometric:

standard. The values given in parentheses are mathematical

conversions to inch-pound units that are provided for informa-

tion only and are not considered standard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This specification is under the jurisdiction of ASTM Committee F04 on Standards volume information, refer to the standard’s Document Summary page on

Medical and Surgical Materials and Devices and is the direct responsibility of the ASTM website.

Subcommittee F04.21 on Osteosynthesis. Withdrawn.

Current edition approved Oct. 1, 2007. Published October 2007. Originally Available from Society of Automotive Engineers (SAE), 400 Commonwealth

approved in 1989. Last previous edition approved in 2003 as F 1264 – 03. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

F 1264 – 03 (2007)

3.1.1 closed section, n—any cross section perpendicular to 3.2.4 yield strength, n—the force parameter (for example,

thelongitudinalaxisofasolidIMFDorhollowIMFDinwhich load, moment, torque, stress, and so forth) which initiates

there is no discontinuity of the outer wall. permanent deformation as defined and measured according to

the test conducted.

3.1.1.1 Discussion—To orient the IMFD for testing and for

3.2.5 no load motion—relative motion between the IMFD

insertion, the desired relationship of any irregularities, asyme-

and the bone that occurs with no elastic strain in the device and

tries, and so forth, to the sagittal and coronal planes should be

no (or minimal) change in load. (See Note 1.)

described for the intended applications.

3.2.6 structural stiffness, n—the maximum slope of the

3.1.2 IMFD curvature, n—dimensions of size and locations

elastic portion of the load-displacement curve as defined and

of arcs of the curvature, or mathematical description of the

measured according to the test conducted.

curvature, or other quantitative descriptions to which the

3.2.6.1 Discussion—For bending in a specified plane, this

curvature is manufactured along with tolerances.

termisdefinedanddeterminedinthestaticfour-pointbendtest

3.1.2.1 Discussion—To orient the IMFD for testing and for

described in Annex A1.

insertion, the desired relationship of the curvature to the

3.2.7 ultimate strength, n—maximum force parameter (for

sagittalandcoronalplanesshouldbedescribedfortheintended

example, load, moment, torque, stress, and so forth) which the

applications.

structure can support, defined and measured according to the

3.1.3 IMFD diameter, n—diameter of the circumscribed

test conducted.

circle that envelops the IMFDs’ cross section when measured

3.2.8 N—a variable representing a specified number of

along the IMFDs’ working length. If the diameter is not

cycles.

constant along the working length, then the site of measure-

ment should be indicated. 4. Classification

3.1.4 IMFD length, n—length of a straight line between the

4.1 The following IMFDs may be used singly, multiply, and

most proximal and distal ends of the IMFD.

with or without attached supplemental fixation.

3.1.5 open section, n—any cross section perpendicular to 4.2 Types of IMFDs: solid cross section, hollow cross

section (open, closed, combination).

the longitudinal axis of a hollow IMFD in which there is a

discontinuity of the outer wall. 4.3 IntendedapplicationoruseforparticularIMFDdesigns:

4.3.1 Preferred Orientation:

3.1.5.1 Discussion—To orient the IMFD for testing and

4.3.1.1 Right versus left,

insertion, the desired relationship of the discontinuity to the

4.3.1.2 Sagittal versus coronal plane,

sagittalandcoronalplanesshouldbedescribedfortheintended

4.3.1.3 Proximal versus distal, and

applications.

4.3.1.4 Universal or multiple options.

3.1.6 potential critical stress concentrator (CSC), n—any

4.3.2 Preferred Anatomic Location:

change in section modulus, material property, discontinuity, or

4.3.2.1 Specific bone,

other feature of a design expected to cause a concentration of

4.3.2.2 Proximal versus distal versus midshaft, and

stress in a region of the IMFD expected to be highly stressed

4.3.2.3 Universal or multiple options.

under the normal anticipated loading conditions.

4.3.3 Preferred Use Limited to Specific Procedures:

3.1.7 working length, n—length of uniform cross section of

4.3.3.1 Acute care of fractures,

the IMFD intended to obtain some type of fit to the medullary

(a) Specific types,

canal in the area of the diaphysis.

(b) Specific locations,

3.1.8 tolerance, n—acceptable deviations from the nominal

4.3.3.2 Reconstructive procedures, and

size of any dimension describing the IMFD.

4.3.3.3 Universal or multiple options.

3.2 Definitions—Mechanical/Structural:

5. Material

3.2.1 bending compliance, n—reciprocal of the stiffness of

5.1 All IMFDs are made of materials that have an ASTM

the IMFD under a bending load in a specified plane as defined

standard shall meet those requirements given in the ASTM

and determined in the static four-point bend test described in

standards (2.1).

Annex A1.

3.2.2 fatigue strength at N cycles, n—the maximum cyclic

6. Performance Considerations and Test Methods

forceparameter(forexample,load,moment,torque,stress,and

6.1 Cross Section Dimensional Tolerances affect matching

so forth) for a given load ratio, which produces device

thebonepreparationinstruments(thatis,reamers)totheIMFD

structural damage or meets some other failure criterion in no

diameter, and fit the fixation of IMFDs in the bone.

lessthanNcyclesasdefinedandmeasuredaccordingtothetest

6.1.1 Terminology related to sizing of IMFD devices and

conducted.

instruments is provided in Terminology F 1611.

3.2.3 failure strength, n—the force parameter (for example,

6.2 Longitudinal Contour Tolerances (along with bending

load, moment, torque, stress, and so forth) required to meet the

compliance) affect the fit and fixation of IMFDs in the bone.

failure criteria, as defined and measured according to the test

6.3 FatigueStrengthaffectsthechoiceofimplantincasesin

conducted. (See Note 1.)

which delayed healing is anticipated (that is, infected non-

unions, allografts, segmental loss, multiple trauma, and so

NOTE 1—No present testing standard exists related to this term for

IMFDs. forth).

´1

F 1264 – 03 (2007)

6.3.1 ThefatiguestrengthorfatiguelivesorbothforIMFDs 7.5.3 Lot or serial number,

subjected to cycle bending forces shall be determined using the 7.5.4 IMFD diameter (3.1.3), and

cyclic bending fatigue test method described in Annex A3. 7.5.5 IMFD length (3.1.4).

6.3.2 The fatigue strength or fatigue lives or both for IMFD 7.6 Care for and handle IMFDs in accordance with Practice

locking screws subjected to cyclic bending forces shall be F 565.

determined using the cyclic bending fatigue test method for

8. Means for Insertion and Extraction

locking screws described in Annex A4.

8.1 For IMFDs that are to be extracted using a hook device,

6.4 Bending Strength affects the choice of implant in which

the following requirements apply:

load sharing is minimized or loading is severe or both (that is,

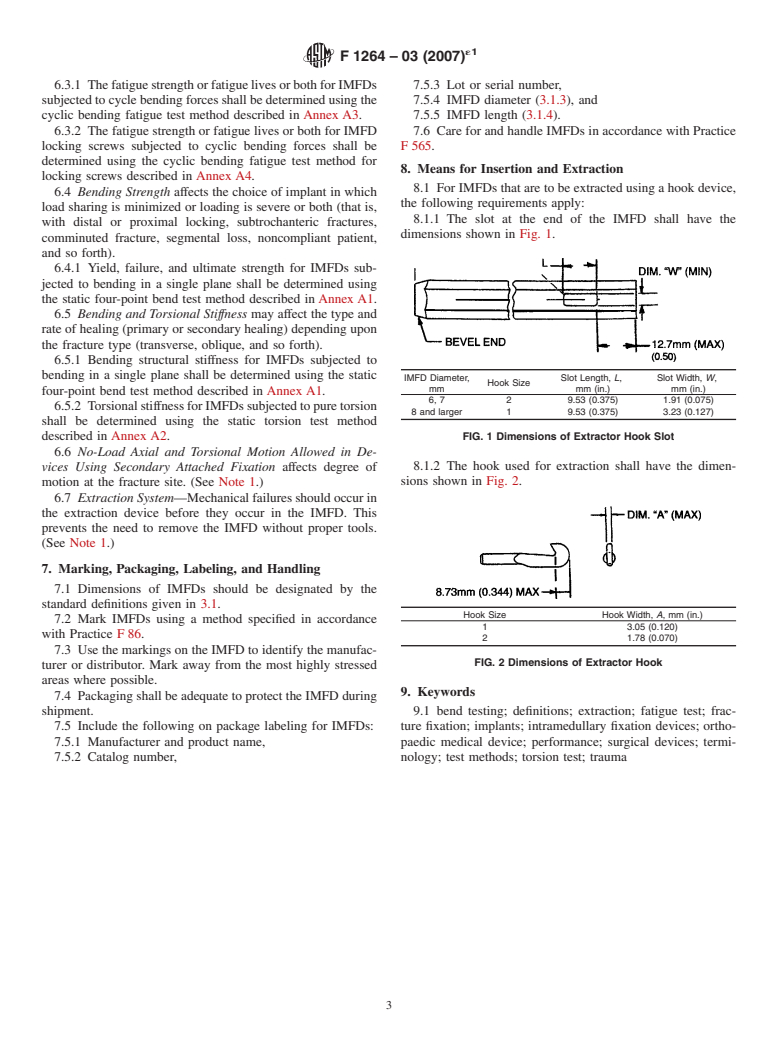

8.1.1 The slot at the end of the IMFD shall have the

with distal or proximal locking, subtrochanteric fractures,

dimensions shown in Fig. 1.

comminuted fracture, segmental loss, noncompliant patient,

and so forth).

6.4.1 Yield, failure, and ultimate strength for IMFDs sub-

jected to bending in a single plane shall be determined using

the static four-point bend test method described in Annex A1.

6.5 Bending and Torsional Stiffness may affect the type and

rate of healing (primary or secondary healing) depending upon

the fracture type (transverse, oblique, and so forth).

6.5.1 Bending structural stiffness for IMFDs subjected to

bending in a single plane shall be determined using the static

IMFD Diameter, Slot Length, L, Slot Width, W,

Hook Size

mm mm (in.) mm (in.)

four-point bend test method described in Annex A1.

6, 7 2 9.53 (0.375) 1.91 (0.075)

6.5.2 TorsionalstiffnessforIMFDssubjectedtopuretorsion

8 and larger 1 9.53 (0.375) 3.23 (0.127)

shall be determined using the static torsion test method

described in Annex A2. FIG. 1 Dimensions of Extractor Hook Slot

6.6 No-Load Axial and Torsional Motion Allowed in De-

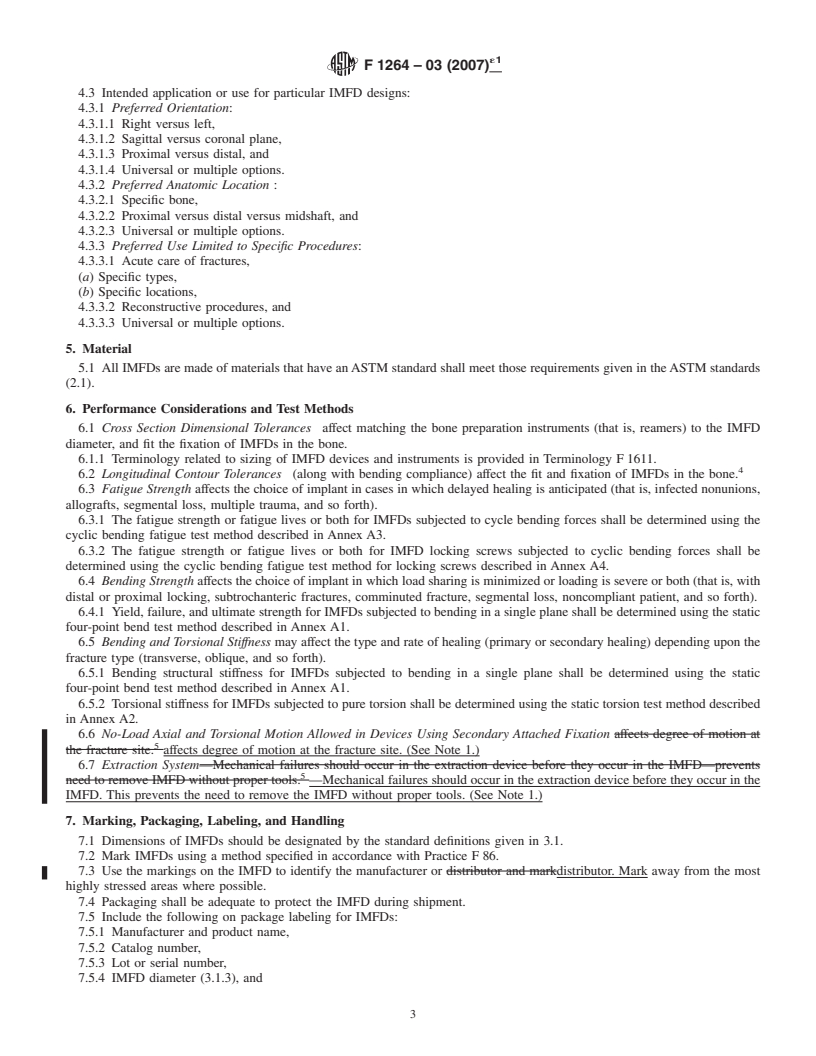

8.1.2 The hook used for extraction shall have the dimen-

vices Using Secondary Attached Fixation affects degree of

sions shown in Fig. 2.

motion at the fracture site. (See Note 1.)

6.7 Extraction System—Mechanicalfailuresshouldoccurin

the extraction device before they occur in the IMFD. This

prevents the need to remove the IMFD without proper tools.

(See Note 1.)

7. Marking, Packaging, Labeling, and Handling

7.1 Dimensions of IMFDs should be designated by the

standard definitions given in 3.1.

Hook Size Hook Width, A, mm (in.)

7.2 Mark IMFDs using a method specified in accordance

1 3.05 (0.120)

with PracticeF86.

2 1.78 (0.070)

7.3 Use the markings on the IMFD to identify the manufac-

FIG. 2 Dimensions of Extractor Hook

turer or distributor. Mark away from the most highly stressed

areas where possible.

9. Keywords

7.4 Packaging shall be adequate to protect the IMFD during

shipment. 9.1 bend testing; definitions; extraction; fatigue test; frac-

7.5 Include the following on package labeling for IMFDs: ture fixation; implants; intramedullary fixation devices; ortho-

7.5.1 Manufacturer and product name, paedic medical device; performance; surgical devices; termi-

7.5.2 Catalog number, nology; test methods; torsion test; trauma

´1

F 1264 – 03 (2007)

ANNEXES

(Mandatory Information)

A1. TEST METHOD FOR STATIC FOUR-POINT BEND TEST METHOD

A1.1 Scope A1.2.1.2.1 Discussion—Failure may be defined by perma-

nent deformation, breakages, or buckling.

A1.1.1 This test method describes methods for static four-

A1.2.1.3 bending moment to yield, n—moment which pro-

point bend testing of intrinsic, structural properties of in-

duces plastic deformation as defined by the 0.2 % strain off-set

tramedullary fixation devices (IMFDs) for surgical fixation of

method from the load-displacement curve.

the skeletal system. This test method includes bend testing in a

A1.2.1.4 bending structural stiffness, n—resistance to bend-

variety of planes relative to the major anatomic planes. The

ing of an IMFD tested in accordance with the procedures of

purpose is to measure bending strength and bending stiffness

A1.5.1, normalized to the cross-sectional properties of the

intrinsic to the design and materials of IMFDs.

workinglengthwithoutregardtothelengthofIMFDtested,by

A1.1.2 This test method is designed specifically to test

the calculations described inA1.5.1.8 (the effective EI for the

e

IMFD designs that have a well-defined working length (WL)of

region tested).

uniform open or closed cross section throughout the majority

A1.2.1.5 fixture/device compliance, n—measurement of the

of its length (WL$ 103 diameter) and is to be applied to the

combined compliance of the IMFD on the test fixture with

full length of the diaphysis of a femur, tibia, humerus, radius,

co-aligned load-support points (such as A1.6.2). This value is

or ulna. This is not applicable to IMFDs that are used to fix

dependent upon IMFD orientation, load direction and load and

only a short portion of the diaphysis of any of

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F 1264 – 03 (Reapproved 2007)

Standard Specification and Test Methods for

Intramedullary Fixation Devices

This standard is issued under the fixed designation F 1264; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made throughout in December 2008.

1. Scope

1.1 This specification is intended to provide a characterization of the design and mechanical function of intramedullary fixation

devices (IMFDs), specify labeling and material requirements, provide test methods for characterization of IMFD mechanical

properties, and identify needs for further development of test methods and performance criteria. The ultimate goal is to develop

a standard which defines performance criteria and methods for measurement of performance-related mechanical characteristics of

IMFDs and their fixation to bone. It is not the intention of this specification to define levels of performance or case-specific clinical

performance of these devices, as insufficient knowledge is available to predict the consequences of the use of any of these devices

in individual patients for specific activities of daily living is available. It is not the intention of this specification to describe or

specify specific designs for IMFDs.

1.2 This specification describes IMFDs for surgical fixation of the skeletal system. It provides basic IFMDIMFD geometrical

definitions,dimensions,classification,andterminology;labelingandmaterialspecifications;performancedefinitions;testmethods

and characteristics determined to be important to in-vivo performance of the device.

1.3 This specification includes four standard test methods:

1.3.1 Static Four-Point Bend Test Method—Annex A1 and

1.3.2 Static Torsion Test Method—Annex A2.

1.3.3 Bending Fatigue Test Method—Annex A3.

1.3.4 Test Method for Bending Fatigue of IMFD Locking Screws—Annex A4.

1.4 A rationale is given in Appendix X1.

1.5The values stated in SI units are to be regarded as the standard.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions

to inch-pound units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 ASTM Standards:

A 214/A 214M Specification for Electric-Resistance-Welded Carbon Steel Heat-Exchanger and Condenser Tubes

A 450/A 450M Specification for General Requirements for Carbon and Low Alloy Steel Tubes

D 790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

E4 Practices for Force Verification of Testing Machines

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

F86 Practice for Surface Preparation and Marking of Metallic Surgical Implants

F 138 Specification for Wrought 18Chromium-14Nickel-2.5Molybdenum Stainless Steel Bar and Wire for Surgical Implants

(UNS S31673)

F 339 Specification for Cloverleaf Intramedullary Pins

F 383 Practice for Static Bend and Torsion Testing of Intramedullary Rods

F 565 Practice for Care and Handling of Orthopedic Implants and Instruments

F 1611 Specification for Intramedullary Reamers

2.2 AMS Standard:

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.21 on Osteosynthesis.

Current edition approved Oct. 1, 2007. Published October 2007. Originally approved in 1989. Last previous edition approved in 2003 as F 1264 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

F 1264 – 03 (2007)

AMS 5050 Steel Tubing, Seamless, 0.15 Carbon, Maximum Annealed

2.3 SAE Standard:

SAE J524 Seamless Low-Carbon Steel Tubing Annealed for Bending and Flaring

3. Terminology

3.1 Definitions for Geometric:

3.1.1 closedsection,n—anycrosssectionperpendiculartothelongitudinalaxisofasolidIMFDorhollowIMFDinwhichthere

is no discontinuity of the outer wall.

3.1.1.1 Discussion—To orient the IMFD for testing and for insertion, the desired relationship of any irregularities, asymetries,

and so forth, to the sagittal and coronal planes should be described for the intended applications.

3.1.2 IMFD curvature, n—dimensions of size and locations of arcs of the curvature, or mathematical description of the

curvature, or other quantitative descriptions to which the curvature is manufactured along with tolerances.

3.1.2.1 Discussion—To orient the IMFD for testing and for insertion, the desired relationship of the curvature to the sagittal and

coronal planes should be described for the intended applications.

3.1.3 IMFD diameter, n—The diameter —diameter of the circumscribed circle, whichcircle that envelops the IMFDs’IMFDs’

cross section when measured along the IMFDs’IMFDs’working length. If the diameter is not constant along the working length,

then the site of measurement should be indicated.

3.1.4 IMFD length, n—the length—length of a straight line between the most proximal and distal ends of the IMFD.

3.1.5 open section, n—any cross section perpendicular to the longitudinal axis of a hollow IMFD in which there is a

discontinuity of the outer wall.

3.1.5.1 Discussion—ToorienttheIMFDfortestingandinsertion,thedesiredrelationshipofthediscontinuitytothesagittaland

coronal planes should be described for the intended applications.

3.1.6 potential critical stress concentrator (CSC), n—any change in section modulus, material property, discontinuity, or other

featureofadesignexpectedtocauseaconcentrationofstressthatislocatedinaregionoftheIMFDexpectedtobehighlystressed

under the normal anticipated loading conditions.

3.1.7 working length, n—a length—length of uniform cross section of the IMFD intended to obtain some type of fit to the

medullary canal in the area of the diaphysis.

3.1.8 tolerance—the acceptable, n—acceptable deviations from the nominal size of any dimension describing the IMFD.

3.2 Definitions—Mechanical/Structural:

3.2.1 bending compliance, n—the reciprocal—reciprocal of the stiffness of the IMFD under a bending load in a specified plane

as defined and determined in the static four-point bend test described in Annex A1.

3.2.2 fatigue strength at N cycles, n—the maximum cyclic force parameter (for example, load, moment, torque, stress, and so

forth)foragivenloadratio,whichproducesdevicestructuraldamageormeetssomeotherfailurecriterioninnolessthan Ncycles

as defined and measured according to the test conducted.

3.2.3 failure strength, n—the force parameter (for example, load, moment, torque, stress, and so forth) required to meet the

failure criteria defined and measured according to the test conducted. —the force parameter (for example, load, moment, torque,

stress, and so forth) required to meet the failure criteria, as defined and measured according to the test conducted. (See Note 1.)

NOTE 1—No present testing standard exists related to this term for IMFDs.

3.2.4 yield strength, n—the force parameter (for example, load, moment, torque, stress, and so forth) which initiates permanent

deformation as defined and measured according to the test conducted.

3.2.5 no load motion—some devices have a degree of free motion at fixation points which allows relative motion to occur

between the device and the bone with no elastic strain in the device and no (or minimal) change in load. This is termed “no load

motion.” —relative motion between the IMFD and the bone that occurs with no elastic strain in the device and no (or minimal)

change in load. (See Note 1.)

3.2.6 structural stiffness, n—the maximum slope of the elastic portion of the load-displacement curve as defined and measured

according to the test conducted.

3.2.6.1 Discussion—For bending in a specified plane, this term is defined and determined in the static four-point bend test

described in Annex A1.

3.2.7 ultimate strength, n—themaximum—maximumforceparameter(forexample,load,moment,torque,stress,andsoforth)

which the structure can support, defined and measured according to the test conducted.

3.2.8 N—a variable representing a specified number of cycles.

4. Classification

4.1 The following IMFDs may be used singly, multiply, and with or without attached supplemental fixation.

4.2 Types of IMFDs: solid cross section, hollow cross section (open, closed, combination).

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

´1

F 1264 – 03 (2007)

4.3 Intended application or use for particular IMFD designs:

4.3.1 Preferred Orientation:

4.3.1.1 Right versus left,

4.3.1.2 Sagittal versus coronal plane,

4.3.1.3 Proximal versus distal, and

4.3.1.4 Universal or multiple options.

4.3.2 Preferred Anatomic Location :

4.3.2.1 Specific bone,

4.3.2.2 Proximal versus distal versus midshaft, and

4.3.2.3 Universal or multiple options.

4.3.3 Preferred Use Limited to Specific Procedures:

4.3.3.1 Acute care of fractures,

(a) Specific types,

(b) Specific locations,

4.3.3.2 Reconstructive procedures, and

4.3.3.3 Universal or multiple options.

5. Material

5.1 All IMFDs are made of materials that have anASTM standard shall meet those requirements given in theASTM standards

(2.1).

6. Performance Considerations and Test Methods

6.1 Cross Section Dimensional Tolerances affect matching the bone preparation instruments (that is, reamers) to the IMFD

diameter, and fit the fixation of IMFDs in the bone.

6.1.1 Terminology related to sizing of IMFD devices and instruments is provided in Terminology F 1611.

6.2 Longitudinal Contour Tolerances (along with bending compliance) affect the fit and fixation of IMFDs in the bone.

6.3 Fatigue Strength affects the choice of implant in cases in which delayed healing is anticipated (that is, infected nonunions,

allografts, segmental loss, multiple trauma, and so forth).

6.3.1 The fatigue strength or fatigue lives or both for IMFDs subjected to cycle bending forces shall be determined using the

cyclic bending fatigue test method described in Annex A3.

6.3.2 The fatigue strength or fatigue lives or both for IMFD locking screws subjected to cyclic bending forces shall be

determined using the cyclic bending fatigue test method for locking screws described in Annex A4.

6.4 Bending Strength affects the choice of implant in which load sharing is minimized or loading is severe or both (that is, with

distal or proximal locking, subtrochanteric fractures, comminuted fracture, segmental loss, noncompliant patient, and so forth).

6.4.1 Yield, failure, and ultimate strength for IMFDs subjected to bending in a single plane shall be determined using the static

four-point bend test method described in Annex A1.

6.5 Bending and Torsional Stiffness may affect the type and rate of healing (primary or secondary healing) depending upon the

fracture type (transverse, oblique, and so forth).

6.5.1 Bending structural stiffness for IMFDs subjected to bending in a single plane shall be determined using the static

four-point bend test method described in Annex A1.

6.5.2 Torsional stiffness for IMFDs subjected to pure torsion shall be determined using the static torsion test method described

in Annex A2.

6.6 No-Load Axial and Torsional Motion Allowed in Devices Using Secondary Attached Fixation affects degree of motion at

the fracture site. affects degree of motion at the fracture site. (See Note 1.)

6.7 Extraction System—Mechanical failures should occur in the extraction device before they occur in the IMFD—prevents

need to remove IMFD without proper tools. —Mechanical failures should occur in the extraction device before they occur in the

IMFD. This prevents the need to remove the IMFD without proper tools. (See Note 1.)

7. Marking, Packaging, Labeling, and Handling

7.1 Dimensions of IMFDs should be designated by the standard definitions given in 3.1.

7.2 Mark IMFDs using a method specified in accordance with Practice F 86.

7.3 Use the markings on the IMFD to identify the manufacturer or distributor and markdistributor. Mark away from the most

highly stressed areas where possible.

7.4 Packaging shall be adequate to protect the IMFD during shipment.

7.5 Include the following on package labeling for IMFDs:

7.5.1 Manufacturer and product name,

7.5.2 Catalog number,

7.5.3 Lot or serial number,

7.5.4 IMFD diameter (3.1.3), and

´1

F 1264 – 03 (2007)

7.5.5 IMFD length (3.1.4).

7.6 Care for and handle IMFDs in accordance with Practice F 565.

8. Means for Insertion and Extraction

8.1 For IMFDs that are to be extracted using a hook device, the following requirements apply:

8.1.1 The slot at the end of the IMFD shall have the dimensions shown in Fig. 1.

IMFD Diameter, Slot Length, L, Slot Width, W,

Hook Size

mm mm (in.) mm (in.)

6, 7 2 9.53 (0.375) 1.91 (0.075)

8 and larger 1 9.53 (0.375) 3.23 (0.127)

FIG. 1 Dimensions of Extractor Hook Slot

8.1.2 The hook used for extraction shall have the dimensions shown in Fig. 2.

Hook Size Hook Width, A, mm (in.)

1 3.05 (0.120)

2 1.78 (0.070)

FIG. 2 Dimensions of Extractor Hook

9. Keywords

9.1 bend testing; definitions; extraction; fatigue test; fracture fixation; implants; intramedullary fixation devices; orthopaedic

medical device; performance; surgical devices; terminology; test methods; torsion test; trauma

´1

F 1264 – 03 (2007)

ANNEXES

(Mandatory Information)

A1. TEST METHOD FOR STATIC FOUR-POINT BEND TEST METHOD

A1.1 Scope

A1.1.1 This test method describes methods for static four-point bend testing of intrinsic, structural properties of intramedullary

fixation devices (IMFDs) for surgical fixation of the skeletal system. This test method includes bend testing in a variety of planes

defined relative to the major anatomic planes. The purpose is to measure bending strength and bending stiffness intrinsic to the

design and materials of IMFDs.

A1.1.2 This test method is designed specifical

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:F1264–01 Designation: F 1264 – 03 (Reapproved 2007)

Standard Specification and Test Methods for

Intramedullary Fixation Devices

This standard is issued under the fixed designation F 1264; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made throughout in December 2008.

1. Scope

1.1 This specification is intended to provide a characterization of the design and mechanical function of intramedullary fixation

devices (IMFDs), specify labeling and material requirements, provide test methods for characterization of IMFD mechanical

properties, and identify needs for further development of test methods and performance criteria. The ultimate goal is to develop

a standard which defines performance criteria and methods for measurement of performance-related mechanical characteristics of

IMFDs and their fixation to bone. It is not the intention of this specification to define levels of performance or case-specific clinical

performance of these devices, as insufficient knowledge is available to predict the consequences of the use of any of these devices

in individual patients for specific activities of daily living is available. It is not the intention of this specification to describe or

specify specific designs for IMFDs.

1.2 This specification describes IMFDs for surgical fixation of the skeletal system. It provides basic IFMDIMFD geometrical

definitions,dimensions,classification,andterminology;labelingandmaterialspecifications;performancedefinitions;testmethods

and characteristics determined to be important to in-vivo performance of the device.

1.3 This specification includes four standard test methods:

1.3.1 Static Four-Point Bend Test Method—Annex A1 and

1.3.2 Static Torsion Test Method—Annex A2.

1.3.3 Bending Fatigue Test Method—Annex A3.

1.3.4 Test Method for Bending Fatigue of IMFD Locking Screws—Annex A4.

1.4 A rationale is given in Appendix X1.

1.5The values stated in SI units are to be regarded as the standard.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions

to inch-pound units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 ASTM Standards:

A 214/A 214M Specification for Electric-Resistance-Welded Carbon Steel Heat-Exchanger and Condenser Tubes

A 450/A 450M SpecificationforGeneralRequirementsforCarbon,FerriticAlloy,CarbonandAusteniticLowAlloySteelTubes

D 790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

E 4 Practices for Force Verification of Testing Machines

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

F 86 Practice for Surface Preparation and Marking of Metallic Surgical Implants

F 138 Specification for Wrought 18Chromium-14Nickel-2.5Molybdenum Stainless Steel Bar and Wire for Surgical Implants

(UNS S31673)

F 339 Specification for Cloverleaf Intramedullary Pins

F 383 Practice for Static Bend and Torsion Testing of Intramedullary Rods

F 565 Practice for Care and Handling of Orthopaedic Implants and Instruments

F 1611 Specification for Intramedullary Reamers

2.2 AMS Standard:

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.21 on Osteosynthesis.

Current edition approved Dec. 10, 2001. Published April 2002. Originally published as F1264–89. Last previous edition F1264–00.

Current edition approved Oct. 1, 2007. Published October 2007. Originally approved in 1989. Last previous edition approved in 2003 as F 1264 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 08.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

F 1264 – 03 (2007)

AMS 5050 Steel Tubing, Seamless, 0.15 Carbon, Maximum Annealed

2.3 SAE Standard:

SAE J524 Seamless Low-Carbon Steel Tubing Annealed for Bending and Flaring

3. Terminology

3.1 Definitions for Geometric:

3.1.1 closedsection,n—anycrosssectionperpendiculartothelongitudinalaxisofasolidIMFDorhollowIMFDinwhichthere

is no discontinuity of the outer wall.

3.1.1.1 Discussion—To orient the IMFD for testing and for insertion, the desired relationship of any irregularities, asymetries,

and so forth, to the sagittal and coronal planes should be described for the intended applications.

3.1.2 IMFD curvature, n—dimensions of size and locations of arcs of the curvature, or mathematical description of the

curvature, or other quantitative descriptions to which the curvature is manufactured along with tolerances.

3.1.2.1 Discussion—To orient the IMFD for testing and for insertion, the desired relationship of the curvature to the sagittal and

coronal planes should be described for the intended applications.

3.1.3 IMFD diameter, n—The diameter —diameter of the circumscribed circle, whichcircle that envelops the IMFDs’IMFDs’

cross section when measured along the IMFDs’IMFDs’working length. If the diameter is not constant along the working length,

then the site of measurement should be indicated.

3.1.4 IMFD length, n—the length—length of a straight line between the most proximal and distal ends of the IMFD.

3.1.5 open section, n—any cross section perpendicular to the longitudinal axis of a hollow IMFD in which there is a

discontinuity of the outer wall.

3.1.5.1 Discussion—ToorienttheIMFDfortestingandinsertion,thedesiredrelationshipofthediscontinuitytothesagittaland

coronal planes should be described for the intended applications.

3.1.6 potential critical stress concentrator (CSC), n—any change in section modulus, material property, discontinuity, or other

featureofadesignexpectedtocauseaconcentrationofstressthatislocatedinaregionoftheIMFDexpectedtobehighlystressed

under the normal anticipated loading conditions.

3.1.7 working length, n—a length—length of uniform cross section of the IMFD intended to obtain some type of fit to the

medullary canal in the area of the diaphysis.

3.1.8 tolerance—the acceptable, n—acceptable deviations from the nominal size of any dimension describing the IMFD.

3.2 Definitions—Mechanical/Structural:

3.2.1 bending compliance, n—the reciprocal—reciprocal of the stiffness of the IMFD under a bending load in a specified plane

as defined and determined in the static four-point bend test described in Annex A1.

3.2.2 fatigue strength at N cycles, n—the maximum cyclic force parameter (for example, load, moment, torque, stress, and so

forth)foragivenloadratio,whichproducesdevicestructuraldamageormeetssomeotherfailurecriterioninnolessthan Ncycles

as defined and measured according to the test conducted.

3.2.3 failure strength, n—the force parameter (for example, load, moment, torque, stress, and so forth) required to meet the

failure criteria defined and measured according to the test conducted. —the force parameter (for example, load, moment, torque,

stress, and so forth) required to meet the failure criteria, as defined and measured according to the test conducted. (See Note 1.)

NOTE 1—No present testing standard exists related to this term for IMFDs.

3.2.4 yield strength, n—the force parameter (for example, load, moment, torque, stress, and so forth) which initiates permanent

deformation as defined and measured according to the test conducted.

3.2.5 no load motion—some devices have a degree of free motion at fixation points which allows relative motion to occur

between the device and the bone with no elastic strain in the device and no (or minimal) change in load. This is termed “no load

motion.” —relative motion between the IMFD and the bone that occurs with no elastic strain in the device and no (or minimal)

change in load. (See Note 1.)

3.2.6 structural stiffness, n—the maximum slope of the elastic portion of the load-displacement curve as defined and measured

according to the test conducted.

3.2.6.1 Discussion—For bending in a specified plane, this term is defined and determined in the static four-point bend test

described in Annex A1.

3.2.7 ultimate strength, n—themaximum—maximumforceparameter(forexample,load,moment,torque,stress,andsoforth)

which the structure can support, defined and measured according to the test conducted.

3.2.8 N—a variable representing a specified number of cycles.

4. Classification

4.1 The following IMFDs may be used singly, multiply, and with or without attached supplemental fixation.

Annual Book of ASTM Standards, Vol 14.02.

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

´1

F 1264 – 03 (2007)

4.2 Types of IMFDs: solid cross section, hollow cross section (open, closed, combination).

4.3 Intended application or use for particular IMFD designs:

4.3.1 Preferred Orientation:

4.3.1.1 Right versus left,

4.3.1.2 Sagittal versus coronal plane,

4.3.1.3 Proximal versus distal, and

4.3.1.4 Universal or multiple options.

4.3.2 Preferred Anatomic Location :

4.3.2.1 Specific bone,

4.3.2.2 Proximal versus distal versus midshaft, and

4.3.2.3 Universal or multiple options.

4.3.3 Preferred Use Limited to Specific Procedures:

4.3.3.1 Acute care of fractures,

(a) Specific types,

(b) Specific locations,

4.3.3.2 Reconstructive procedures, and

4.3.3.3 Universal or multiple options.

5. Material

5.1 All IMFDs are made of materials that have an ASTM International standard shall meet those requirements given in the

ASTM International standards (2.1).

6. Performance Considerations and Test Methods

6.1 Cross Section Dimensional Tolerances affect matching the bone preparation instruments (that is, reamers) to the IMFD

diameter, and fit the fixation of IMFDs in the bone.

6.1.1 Terminology related to sizing of IMFD devices and instruments is provided in Terminology F 1611.

6.2 Longitudinal Contour Tolerances (along with bending compliance) affect the fit and fixation of IMFDs in the bone.

6.3 Fatigue Strength affects the choice of implant in cases in which delayed healing is anticipated (that is, infected nonunions,

allografts, segmental loss, multiple trauma, and so forth).

6.3.1 The fatigue strength or fatigue lives or both for IMFDs subjected to cycle bending forces shall be determined using the

cyclic bending fatigue test method described in Annex A3.

6.3.2 The fatigue strength or fatigue lives or both for IMFD locking screws subjected to cyclic bending forces shall be

determined using the cyclic bending fatigue test method for locking screws described in Annex A4.

6.4 Bending Strength affects the choice of implant in which load sharing is minimized or loading is severe or both (that is, with

distal or proximal locking, subtrochanteric fractures, comminuted fracture, segmental loss, noncompliant patient, and so forth).

6.4.1 Yield, failure, and ultimate strength for IMFDs subjected to bending in a single plane shall be determined using the static

four-point bend test method described in Annex A1.

6.5 Bending and Torsional Stiffness may affect the type and rate of healing (primary or secondary healing) depending upon the

fracture type (transverse, oblique, and so forth).

6.5.1 Bending structural stiffness for IMFDs subjected to bending in a single plane shall be determined using the static

four-point bend test method described in Annex A1.

6.5.2 Torsional stiffness for IMFDs subjected to pure torsion shall be determined using the static torsion test method described

in Annex A2.

6.6 No-Load Axial and Torsional Motion Allowed in Devices Using Secondary Attached Fixation affects degree of motion at

the fracture site. affects degree of motion at the fracture site. (See Note 1.)

6.7 Extraction System—Mechanical failures should occur in the extraction device before they occur in the IMFD—prevents

need to remove IMFD without proper tools. —Mechanical failures should occur in the extraction device before they occur in the

IMFD. This prevents the need to remove the IMFD without proper tools. (See Note 1.)

7. Marking, Packaging, Labeling, and Handling

7.1 Dimensions of IMFDs should be designated by the standard definitions given in 3.1.

7.2 Mark IMFDs using a method specified in accordance with Practice F 86.

7.3 Use the markings on the IMFD to identify the manufacturer or distributor and markdistributor. Mark away from the most

highly stressed areas where possible.

7.4 Packaging shall be adequate to protect the IMFD during shipment.

7.5 Include the following on package labeling for IMFDs:

7.5.1 Manufacturer and product name,

7.5.2 Catalog number,

7.5.3 Lot or serial number,

´1

F 1264 – 03 (2007)

7.5.4 IMFD diameter (3.1.3), and

7.5.5 IMFD length (3.1.4).

7.6 Care for and handle IMFDs in accordance with Practice F 565.

8. Means for Insertion and Extraction

8.1 For IMFDs that are to be extracted using a hook device, the following requirements apply:

8.1.1 The slot at the end of the IMFD shall have the dimensions shown in Fig. 1.

IMFD Diameter, Slot Length, L, Slot Width, W,

Hook Size

mm mm (in.) mm (in.)

6, 7 2 9.53 (0.375) 1.91 (0.075)

8 and larger 1 9.53 (0.375) 3.23 (0.127)

FIG. 1 Dimensions of Extractor Hook Slot

8.1.2 The hook used for extraction shall have the dimensions shown in Fig. 2.

Hook Size Hook Width, A, mm (in.)

1 3.05 (0.120)

2 1.78 (0.070)

FIG. 2 Dimensions of Extractor Hook

9. Keywords

9.1 bend testing; definitions; extraction; fatigue test; fracture fixation; implants; intramedullary fixation devices; orthopaedic

medical device; performance; surgical devices; terminology; test methods; torsion test; trauma

´1

F 1264 – 03 (2007)

ANNEXES

(Mandatory Information)

A1. TEST METHOD FOR STATIC FOUR-POINT BEND TEST METHOD

A1.1 Scope

A1.1.1 This test method describes methods for static four-point bend testing of intrinsic, structural properties of intramedullary

fixation devices (IMFDs) for surgical fixation of the skeletal system. This te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.