ASTM D4061-13

(Test Method)Standard Test Method for Retroreflectance of Horizontal Coatings

Standard Test Method for Retroreflectance of Horizontal Coatings

SIGNIFICANCE AND USE

5.1 The quantity coefficient of retroreflected luminance is a measure of the reflected luminance in the direction of the observer. This is the light returned by the retroreflective surface to the observer from the source, which in practice is the vehicle headlamp.

5.2 This test method may be used as a measure of the nighttime performance of horizontally applied surfacing materials used on highway surfaces for lane markings and other traffic control purposes.

5.3 Since this test method is a laboratory procedure, test specimens must be prepared so that they can be mounted on the specimen holder. Specimens measured by this laboratory method may be used as transfer standards for the calibration of portable instrumentation.

5.4 Specimen selection and preparation may significantly influence the results of this test method.

SCOPE

1.1 This test method describes the instrumental measurement of the retroreflective properties of horizontal surfacing materials, such as traffic stripe paint systems, traffic tapes, and traffic surface symbols.

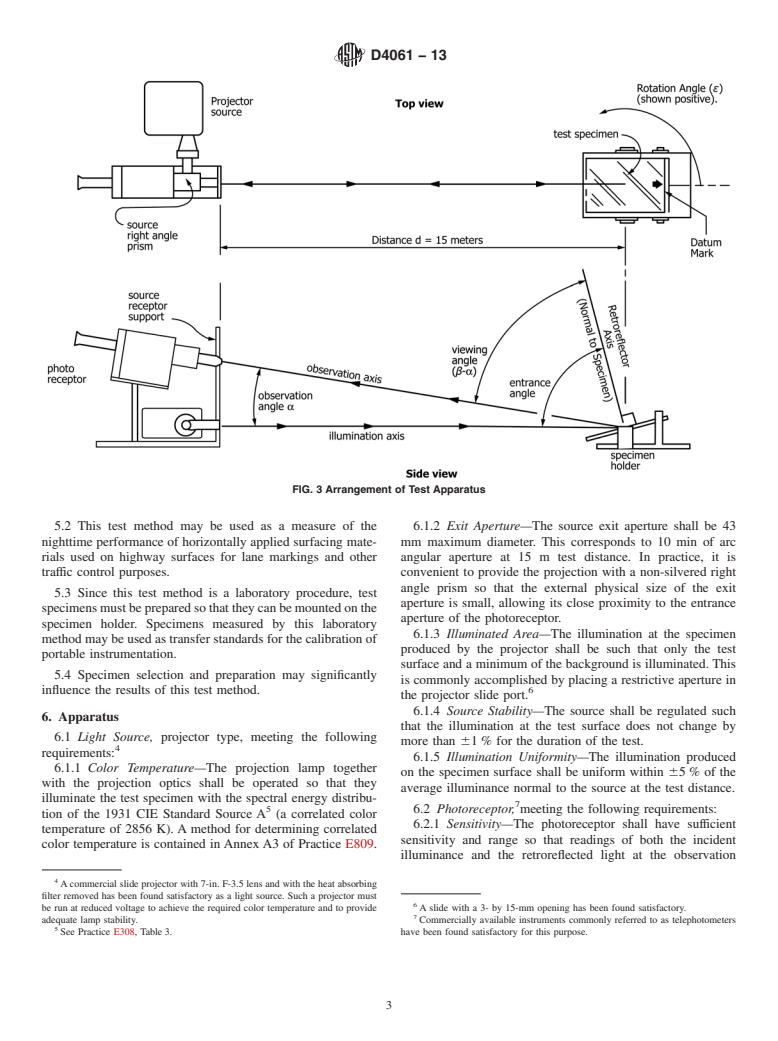

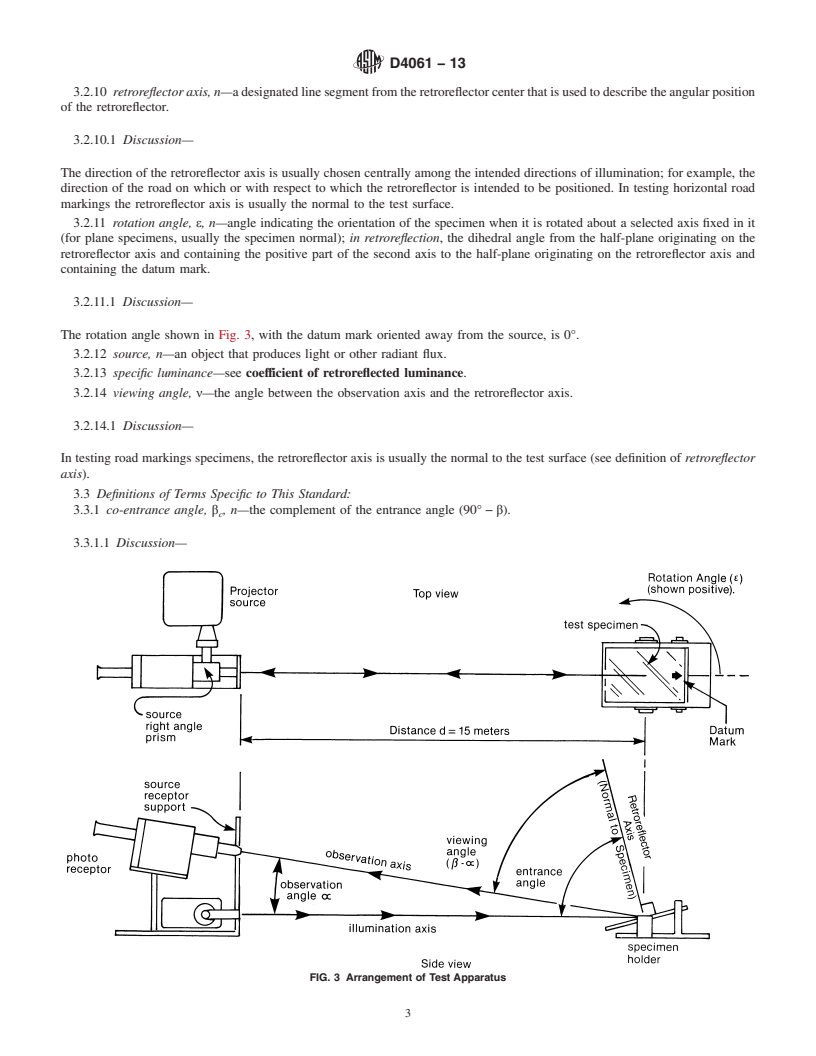

1.2 Specimen preparation, size, and shape must be determined and specified by the user of this test method. Likewise, the user must specify the observation and entrance angles to be used (see Fig. 1).

1.3 The geometric requirements of this test method are based on materials for which the relative retroreflectance changes less than approximately 50 % over the observation angle range from 0.2 to 0.5°. This is illustrated in Fig. 2.

1.4 This test method is a laboratory test and requires a facility that can be darkened sufficiently so that stray light does not affect the test results. This facility must be capable of housing the required 15-m test distance.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4061 −13

Standard Test Method for

1

Retroreflectance of Horizontal Coatings

This standard is issued under the fixed designation D4061; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Determine the Precision of a Test Method

E808Practice for Describing Retroreflection

1.1 This test method describes the instrumental measure-

E809Practice for Measuring Photometric Characteristics of

ment of the retroreflective properties of horizontal surfacing

Retroreflectors

materials, such as traffic stripe paint systems, traffic tapes, and

3

traffic surface symbols. 2.2 CIE Publication:

No. 54Retroreflection Definition and Measurement

1.2 Specimen preparation, size, and shape must be deter-

mined and specified by the user of this test method. Likewise,

3. Terminology

theusermustspecifytheobservationandentranceanglestobe

used (see Fig. 1). 3.1 The terms and definitions inTerminology E284 apply to

this test method.

1.3 The geometric requirements of this test method are

based on materials for which the relative retroreflectance 3.2 Definitions:

changes less than approximately 50% over the observation 3.2.1 coeffıcient of retroreflected luminance, R ,n—ratio of

L

the luminance, L, of a projected surface to the normal

angle range from 0.2 to 0.5°. This is illustrated in Fig. 2.

illuminance, E , at the surface on a plane normal to the

'

1.4 This test method is a laboratory test and requires a

incident light, expressed in candelas per square metre per lux

facilitythatcanbedarkenedsufficientlysothatstraylightdoes

−2 −1

(cd·m ·lx ).

not affect the test results. This facility must be capable of

R 5 L/E (1)

housing the required 15-m test distance. ~ !

L '

3.2.2 datum mark, n—in retroreflection,anindicationonthe

1.5 The values stated in SI units are to be regarded as

retroreflector that is used to define the orientation of the

standard. No other units of measurement are included in this

retroreflector with respect to rotation about the retroreflector

standard.

axis.

1.6 This standard does not purport to address all of the

3.2.2.1 Discussion—The datum mark must not lie on the

safety concerns, if any, associated with its use. It is the

retroreflector axis.

responsibility of the user of this standard to establish appro-

3.2.3 entrance angle, β, n—in retroreflection,anglebetween

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. the illumination axis and the retroreflector axis.

3.2.3.1 Discussion—For plane retroreflective surfaces, the

2. Referenced Documents entrance angle is no larger than 90°.

2 3.2.3.2 Discussion—Theentranceanglemaybedividedinto

2.1 ASTM Standards:

components β and β . This is described in Practice E808.In

1 2

E284Terminology of Appearance

this test method only the component β is used. Therefore,

1

E308PracticeforComputingtheColorsofObjectsbyUsing

where only the entrance angle β is specified the convention

the CIE System

used is β =0 and β =β.

2 1

E691Practice for Conducting an Interlaboratory Study to

3.2.4 illumination axis, n—in retroreflection, a line from the

effective center of the source aperture to the retroreflector

1

center.

This test method is under the jurisdiction of ASTM Committee E12 on Color

and Appearance and is the direct responsibility of Subcommittee E12.10 on

3.2.5 normal illuminance, E —theilluminanceonaretrore-

'

Retroreflection.

flective surface measured in the plane that passes through the

Current edition approved July 1, 2013. Published August 2013. Originally

approved in 1989. Last previous edition approved in 2006 as D4061–94(2006).

DOI: 10.1520/D4061-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.NationalCommitteeoftheCIE(InternationalCommission

Standards volume information, refer to the standard’s Document Summary page on on Illumination), C/o Thomas M. Lemons, TLA-Lighting Consultants, Inc., 7 Pond

the ASTM website. St., Salem, MA 01970, http://www.cie-usnc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4061−13

3.2.10 retroreflector axis, n—a designated line segment

from the retroreflector center that is used to describe the

angular position of the retroreflector.

3.2.10.1 Discussion—Thedirectionoftheretroreflectoraxis

is usually chosen centrally among the intended directions of

illumination;forexample,thedirectionoftheroadonwhichor

with respect to which the retroreflector is

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4061 − 94 (Reapproved 2006) D4061 − 13

Standard Test Method for

1

Retroreflectance of Horizontal Coatings

This standard is issued under the fixed designation D4061; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describes the instrumental measurement of the retroreflective properties of horizontal surfacing materials,

such as traffic stripe paint systems, traffic tapes, and traffic surface symbols.

1.2 Specimen preparation, size, and shape must be determined and specified by the user of this test method. Likewise, the user

must specify the observation and entrance angles to be used (see Fig. 1).

1.3 The geometric requirements of this test method are based on materials for which the relative retroreflectance changes less

than approximately 50 % over the observation angle range from 0.2 to 0.5°. This is illustrated in Fig. 2.

1.4 This test method is a laboratory test and requires a facility that can be darkened sufficiently so that stray light does not affect

the test results. This facility must be capable of housing the required 15-m test distance.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E284 Terminology of Appearance

E308 Practice for Computing the Colors of Objects by Using the CIE System

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E808 Practice for Describing Retroreflection

E809 Practice for Measuring Photometric Characteristics of Retroreflectors

3

2.2 CIE Publication:

No. 54 Retroreflection Definition and Measurement

3. Terminology

3.1 The terms and definitions in Terminology E284 apply to this test method.

3.2 Definitions:

3.2.1 coeffıcient of retroreflected luminance, R , n—ratio of the luminance, L, of a projected surface to the normal illuminance,

L

−2 −1

E , at the surface on a plane normal to the incident light, expressed in candelas per square metre per lux (cd·m ·lx ).

'

R 5 L/E (1)

~ !

L '

3.2.2 datum mark, n—in retroreflection, an indication on the retroreflector that is used to define the orientation of the

retroreflector with respect to rotation about the retroreflector axis.

1

This test method is under the jurisdiction of ASTM Committee E12 on Color and Appearance and is the direct responsibility of Subcommittee E12.10 on Retroreflection.

Current edition approved July 1, 2006July 1, 2013. Published July 2006August 2013. Originally approved in 1989. Last previous edition approved in 20002006 as

D4061 – 94 (2000).(2006). DOI: 10.1520/D4061-94R06.10.1520/D4061-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from U.S. National Committee of the CIE (International Commission on Illumination), C/o Thomas M. Lemons, TLA-Lighting Consultants, Inc., 7 Pond St.,

Salem, MA 01970.01970, http://www.cie-usnc.org.

3.2.2.1 Discussion—

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4061 − 13

NOTE 1—Includes observation angle α, entrance angle β, viewing angle ν , co-viewing angle ν , and co-entrance angle β . The retroreflector axis,

a c c

illumination axis, and observation axis all lie in the same plane.

FIG. 1 Diagram Illustrating Geometry for Measurement of Horizontal Coatings Specimens

FIG. 2 Illustration of Typical Rate of Change of Retroreflectance Versus Observation Angle for Horizontal Retroreflective Material Mea-

sured at 86° Entrance Angle

The datum mark must not lie on the retroreflector axis.

3.2.3 entrance angle, β, n—in retroreflection, angle between the illumination axis and the retroreflector axis.

3.2.3.1 Discussi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.