ASTM D1424-09(2013)e1

(Test Method)Standard Test Method for Tearing Strength of Fabrics by Falling-Pendulum (Elmendorf-Type) Apparatus

Standard Test Method for Tearing Strength of Fabrics by Falling-Pendulum (Elmendorf-Type) Apparatus

SIGNIFICANCE AND USE

5.1 This test method for the determination of tearing strength by the falling pendulum type apparatus is used in the trade for the acceptance testing of commercial shipments of fabrics, but caution is advised since technicians may fail to get good agreement between results on certain fabrics. Comparative tests as directed in 5.1.1 may be needed.

5.1.1 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of fabric of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using appropriate statistical analysis and an acceptable probability level chosen by the two parties before the testing began. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results with consideration to the known bias.

5.2 Microprocessor systems for automatic collection of data can provide economical and reliable results when properly calibrated. See Test Methods D2261 and D5587.

SCOPE

1.1 This test method covers the determination of the force required to propagate a single-rip tear starting from a cut in a fabric and using a falling-pendulum (Elmendorf-Type) apparatus.

1.2 This test method applies to most fabrics including woven, layered blankets, napped pile, blanket, and air bag fabrics, provided the fabric does not tear in the direction crosswise to the direction of the force application during the test. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated. Instructions are provided for testing specimens with, or without, wetting.

1.3 This test method is suitable only for the warp direction tests of warp-knit fabrics. It is not suited for the course direction of warp knit fabrics or either direction of most other knitted fabrics.

1.4 The values stated in either SI units or U.S. customary units are to be regarded as standard, but must be used independently of each other. The U.S. customary units may be approximate.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D1424 − 09 (Reapproved 2013)

Standard Test Method for

Tearing Strength of Fabrics by Falling-Pendulum

(Elmendorf-Type) Apparatus

This standard is issued under the fixed designation D1424; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—In Table A3.1, typographical errors in the Useable Test Ranges were corrected editorially in January 2015.

1. Scope D629 Test Methods for Quantitative Analysis of Textiles

D1776 Practice for Conditioning and Testing Textiles

1.1 This test method covers the determination of the force

D2261 Test Method for Tearing Strength of Fabrics by the

required to propagate a single-rip tear starting from a cut in a

Tongue (Single Rip) Procedure (Constant-Rate-of-

fabric and using a falling-pendulum (Elmendorf-Type) appa-

Extension Tensile Testing Machine)

ratus.

D2904 Practice for Interlaboratory Testing of a Textile Test

1.2 This test method applies to most fabrics including

Method that Produces Normally Distributed Data (With-

woven, layered blankets, napped pile, blanket, and air bag

drawn 2008)

fabrics, provided the fabric does not tear in the direction

D2906 Practice for Statements on Precision and Bias for

crosswise to the direction of the force application during the

Textiles (Withdrawn 2008)

test. The fabrics may be untreated, heavily sized, coated,

D4848 Terminology Related to Force, Deformation and

resin-treated,orotherwisetreated.Instructionsareprovidedfor

Related Properties of Textiles

testing specimens with, or without, wetting.

D4850 Terminology Relating to Fabrics and Fabric Test

Methods

1.3 This test method is suitable only for the warp direction

tests of warp-knit fabrics. It is not suited for the course D5587 Test Method for Tearing Strength of Fabrics by

Trapezoid Procedure

direction of warp knit fabrics or either direction of most other

knitted fabrics.

3. Terminology

1.4 The values stated in either SI units or U.S. customary

3.1 For all terminology relating to D13.59, Fabric Test

units are to be regarded as standard, but must be used

Methods, General, refer to Terminology D4850.

independently of each other. The U.S. customary units may be

approximate.

3.2 For all terminology relating to Force, Deformation and

1.5 This standard does not purport to address all of the Related Properties in Textiles, refer to Terminology D4848.

3.2.1 The following terms are relevant to this standard:

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- cross-machine direction, CD, length of tear, machine direction,

MD, tearing energy, tearing force, tear resistance, tearing

priate safety and health practices and determine the applica-

strength, fabric.

bility of regulatory limitations prior to use.

3.3 For all other terminology related to textiles, refer to

2. Referenced Documents

Terminology D123.

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

4. Summary of Test Method

4.1 Aslit is centrally precut in a test specimen held between

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

two clamps and the specimen is torn through a fixed distance.

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

The resistance to tearing is in part factored into the scale

Specific.

Current edition approved July 1, 2013. Published September 2013. Originally reading of the instrument and is computed from this reading

approved in 1956. Last previous edition approved in 2009 as D1424 – 09. DOI:

and the pendulum capacity.

10.1520/D1424-09R13E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D1424 − 09 (2013)

5. Significance and Use substituted by means of calculating and displaying the required

results without the use of a pointer, such as digital display and

5.1 This test method for the determination of tearing

computer driven systems. Preferably the clamps may be air

strength by the falling pendulum type apparatus is used in the

actuated, but manual clamping is permitted.

trade for the acceptance testing of commercial shipments of

6.1.4 The test instrument should be equipped to provide

fabrics, but caution is advised since technicians may fail to get

interchangeable full scale force ranges. Typical full scale

good agreement between results on certain fabrics. Compara-

ranges are shown in Table A3.1.

tive tests as directed in 5.1.1 may be needed.

5.1.1 In case of a dispute arising from differences in 6.2 Calibration Weight(s) for graduation of 50 % of the full

reported test results when using this test method for acceptance scale force range, or other means as described by the manu-

testing of commercial shipments, the purchaser and the sup- facturer of the test apparatus.

plier should conduct comparative tests to determine if there is

6.3 Cutting Diehavingessentiallytheshapeanddimensions

a statistical bias between their laboratories. Statistical assis-

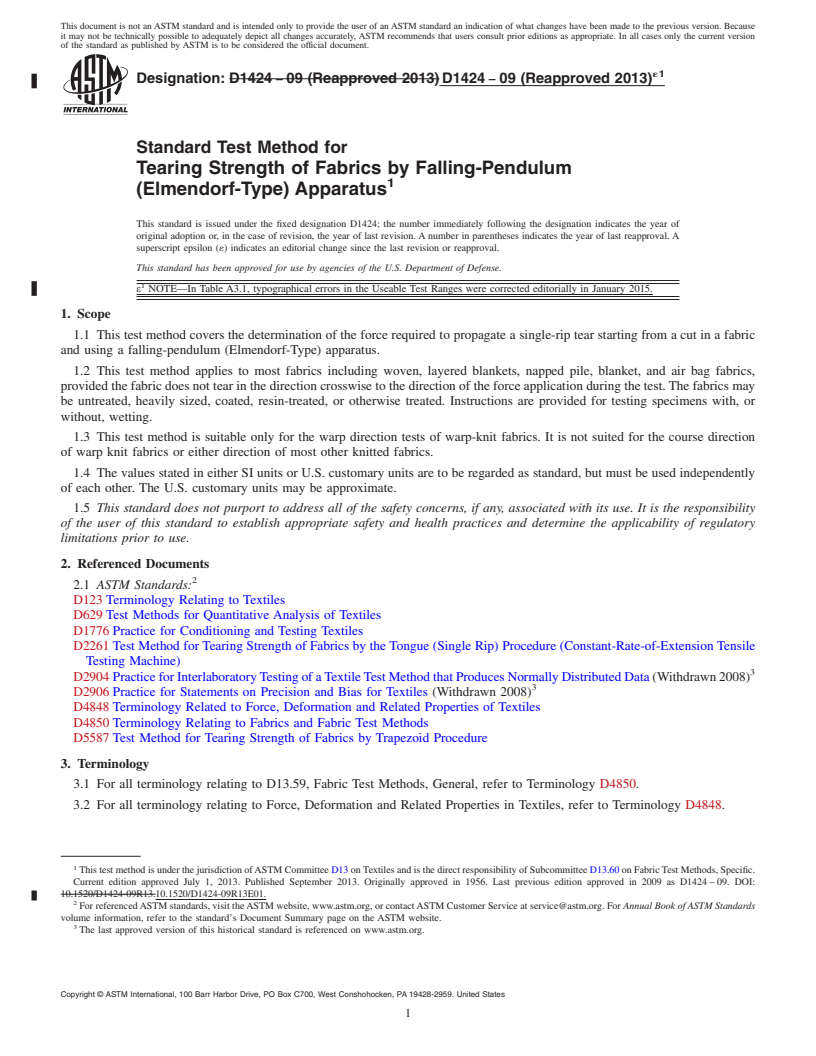

shown in Fig. 1(a) or (b). Either die provides the basic

tance is recommended for the investigation of bias. As a

rectangular test specimen 100 62mm(4 6 0.05 in.) long by

minimum, the two parties should take a group of test speci-

63 6 0.15 mm (2.5 6 0.005 in.) wide, along with additional

mens that are as homogeneous as possible and that are from a

fabricatthetopedgeofthespecimentohelpensurethebottom

lot of fabric of the type in question. The test specimens should

portion of specimen will be torn during the test. The critical

then be randomly assigned in equal numbers to each laboratory

dimension of the test specimen is the distance 43.0 6 0.15 mm

for testing. The average results from the two laboratories

(1.696 0.005 in.) which is to be torn during the test.

should be compared using appropriate statistical analysis and

NOTE 1—The improved die model shown in Fig. 1(a) has two new

anacceptableprobabilitylevelchosenbythetwopartiesbefore

features not found in the original model, Fig. 1(b), namely a cutout for the

the testing began. If a bias is found, either its cause must be

bottom of the specimen to aid in centering it in the clamps, and (optional)

found and corrected or the purchaser and the supplier must

provision for cutting the 20.0 mm (0.75 in.) slit prior to inserting the

agree to interpret future test results with consideration to the

specimen in the tester. These dies can be made to order by most die

manufacturers.

known bias.

6.4 Air Pressure Regulator, capable of controlling gage air

5.2 Microprocessor systems for automatic collection of data

pressure between 410 kPa and 620 kPa (60 psi and 90 psi),

can provide economical and reliable results when properly

when applicable, for air clamps.

calibrated. See Test Methods D2261 and D5587.

6.5 Setting Gage for Cutting Blade that will provide a cut

6. Apparatus

slit that leaves a 43 6 0.15 mm (1.69 6 0.005 in.) specimen

6.1 Falling-Pendulum (Elmendorf-Type) Tester —Thetester

tearing distance for a 63 6 0.15 mm (2.5 6 0.005 in.) wide

includes: a stationary clamp, a clamp carried on a pendulum

specimen, or equivalent.

that is free to swing on a bearing, means for leveling as

6.6 Jaw Spacing Gage 2.5 6 0.25 mm (0.1 6 0.01 in.)

applicable, means for holding the pendulum in a raised

width, or equivalent.

position, means for instantly releasing the pendulum, and

6.7 Oil, light weight, non-gumming clock type.

means for measuring the force to tear the test specimen.

6.1.1 Aknife can be mounted on a stationary post for initial

6.8 Silicone Grease, when applicable, for air clamp lubri-

slitting of the specimens centered between the clamps and

cation.

adjusted in height to give a tearing distance of 43.0 6 0.15 mm

6.9 Vacuum Cleaner, when applicable, for cleaning dust and

(1.69 6 0.005 in.); that is, the distance between the end of the

fiber from sensor, or equivalent.

slit made by the knife and the upper edge of the specimen is

43.0 6 0.15 mm (1.69 6 0.005 in.) when the lower edge of the

7. Sampling and Test Specimens

63.0-mm (2.5 6 0.005 in.) wide specimen rests against the

7.1 Lot Sample—As a lot sample for acceptance testing,

bottom of the clamp.

randomly select the number of rolls or pieces of fabric directed

6.1.2 With the pendulum in its initial position ready for a

in an applicable material specification or other agreement

test, the two clamps are separated by a distance of 2.5 6 0.25

mm (0.1 6 0.01 in.) and are aligned such that the clamped

specimen lies in a plane parallel to the axis of the pendulum,

the plane making an angle of 0.480 rad (27.5 6 0.5°) with the

perpendicular line joining the axis and the horizontal line

formed by the top edges of the clamping jaws. The distance

between the axis and the top edges of the clamping jaws is

1036 0.1 mm (4.055 6 0.004 in.). The clamping surface in

each jaw is at least 25 mm (1.0 in.) wide and 15.9 6 0.1 mm

(0.625 6 0.004 in.) deep.

6.1.3 The tester may have a pointer mounted on the same

axis as the pendulum to register the tearing force, or it may be

Apparatus is commercially available. FIG. 1 Die Diagram for Cutting Notched Specimens

´1

D1424 − 09 (2013)

NOTE 4—For standard test apparatus, the useable portion of the full

between the purchaser and the supplier. Consider the rolls or

scale force range is 20 to 80 %. For the high capacity test instrument, the

pieces of fabric to be the primary sampling units. In the

useable portion of the full scale force range is 20 to 60 %.

absence of such an agreement, take the number of fabric rolls

8.2 When equipped with a registering sensor, examine the

or pieces specified in Table 1.

scale and the complementary sensor, as applicable. Using care

NOTE 2—An adequate specification or other agreement between the

and without touching the sensor, vacuum away any loose fibers

purchaserandsupplierrequirestakingintoaccountthevariabilitybetween

and dust.

rolls or pieces of fabric and between specimens from a swatch from a roll

orpieceoffabrictoprovideasamplingplanwithameaningfulproducer’s

8.3 Examine the knife edge for sharpness, wear, and central

risk, consumer’s risk, acceptable quality level, and limiting quality level.

alignment as directed in A1.5 – A1.7.

7.2 Laboratory Sample—For acceptance testing, take a

8.4 For air clamps, set the air gage pressure to the clamps to

swatch extending the width of the fabric and approximately 1

about 550 kPa (80 psi).

m (1 yd) along the machine direction from each roll or piece in

8.4.1 Maximum gage pressure should be no more than 620

the lot sample. For rolls of fabric, take a sample that will

kPa (90 psi) and minimum gage pressure no less than 410 kPa

exclude fabric from the outer wrap of the roll or the inner wrap

(60 psi).

around the core of the roll of fabric.

8.5 When using microprocessor automatic data gathering

7.3 Test Specimens—From each laboratory sampling unit,

systems, set the appropriate parameters as defined in the

take five specimens from the machine direction and five

manufacturer’s instructions.

specimens from the cross-machine direction, for each test

8.6 Verifythecalibrationoftheselectedpendulumfullscale

condition described in 9.1 and 9.2, as applicable to a material

force range using the procedure described in AnnexA2, unless

specification or contract order.

otherwise specified.

7.3.1 Direction of Test—Consider the long direction of the

specimen as the direction of test.

9. Conditioning

7.3.2 Cutting Test Specimens—Take the specimens to be

used for the measurement of machine direction with the longer

9.1 Condition 1, Standard Testing Conditioning:

dimension parallel to the machine direction. Take the speci-

9.1.1 Precondition the specimens by bringing them to ap-

menstobeusedforthemeasurementofthecross-machinewith

proximate moisture equilibrium in the standard atmosphere for

the longer dimension parallel to the cross-machine direction.

preconditioning textiles as directed in Practice D1776, unless

Use the cutting die described in 6.3 and shown in Fig. 1(a) or

otherwise directed in a material specification or contract order.

(b), as applicable. When specimens are to be tested wet, cut

9.1.2 After preconditioning, bring the test specimens to

from areas adjacent to the dry test specimens. Label to

moisture equilibrium for testing in the standard atmosphere for

maintain specimen identity.

testing textiles as directed in Practice D1776 or, if applicable,

7.3.2.1 In cutting the woven fabric specimens, take care to

in the specified atmosphere in which the testing is to be

align the yarns running in the short direction parallel with the

performed,unlessotherwisedirectedinamaterialspecification

die such that when the slit is cut, the subsequent tear will take

or contract order.

placebetweentheseyarnsandnotacrossthem.Thisprecaution

9.2 Condition 2, Wet Specimen Testing Conditioning:

is most important when testing bowed fabrics.

9.2.1 When desizing treatments are specified prior to wet

7.3.2.2 Cut specimens representing a broad distribution

testing, use desizing treatments that will not affect the normal

across the width and length, and preferably along the diagonal

physical property of the fabric as directed in Test Method

of the laboratory sample, and no nearer the edge than one-tenth

D629.

its width. Ensure specimens are free of folds, creases, or

9.2.2 Submerge the specimens in a container of distilled or

wrinkles.Avoidgettingoil,water,grease,etc.onthespecimens

deionized water at ambient temperature until thoroughly

when handling.

soaked (see 8.2.1.1).

NOTE 3—The reading obtained is directly proportional to the length of

9.2.2.1 The time of immersion must be sufficient to wet out

the material torn, therefore, it is essential that the specimen be prepared to

the specimens, as indicated by no significant change in tearing

the exact size specified.

force followed by longer periods of immersion. For most

8. Preparation of Apparatus and Calibration

fabrics this time period will be about 1 h. For fabrics not

readily wet out with water, such as those treated with water-

8.1 Select test instrument force range, such that the tear

repelle

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D1424 − 09 (Reapproved 2013) D1424 − 09 (Reapproved 2013)

Standard Test Method for

Tearing Strength of Fabrics by Falling-Pendulum

(Elmendorf-Type) Apparatus

This standard is issued under the fixed designation D1424; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—In Table A3.1, typographical errors in the Useable Test Ranges were corrected editorially in January 2015.

1. Scope

1.1 This test method covers the determination of the force required to propagate a single-rip tear starting from a cut in a fabric

and using a falling-pendulum (Elmendorf-Type) apparatus.

1.2 This test method applies to most fabrics including woven, layered blankets, napped pile, blanket, and air bag fabrics,

provided the fabric does not tear in the direction crosswise to the direction of the force application during the test. The fabrics may

be untreated, heavily sized, coated, resin-treated, or otherwise treated. Instructions are provided for testing specimens with, or

without, wetting.

1.3 This test method is suitable only for the warp direction tests of warp-knit fabrics. It is not suited for the course direction

of warp knit fabrics or either direction of most other knitted fabrics.

1.4 The values stated in either SI units or U.S. customary units are to be regarded as standard, but must be used independently

of each other. The U.S. customary units may be approximate.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D629 Test Methods for Quantitative Analysis of Textiles

D1776 Practice for Conditioning and Testing Textiles

D2261 Test Method for Tearing Strength of Fabrics by the Tongue (Single Rip) Procedure (Constant-Rate-of-Extension Tensile

Testing Machine)

D2904 Practice for Interlaboratory Testing of a Textile Test Method that Produces Normally Distributed Data (Withdrawn 2008)

D2906 Practice for Statements on Precision and Bias for Textiles (Withdrawn 2008)

D4848 Terminology Related to Force, Deformation and Related Properties of Textiles

D4850 Terminology Relating to Fabrics and Fabric Test Methods

D5587 Test Method for Tearing Strength of Fabrics by Trapezoid Procedure

3. Terminology

3.1 For all terminology relating to D13.59, Fabric Test Methods, General, refer to Terminology D4850.

3.2 For all terminology relating to Force, Deformation and Related Properties in Textiles, refer to Terminology D4848.

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods, Specific.

Current edition approved July 1, 2013. Published September 2013. Originally approved in 1956. Last previous edition approved in 2009 as D1424 – 09. DOI:

10.1520/D1424-09R13.10.1520/D1424-09R13E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D1424 − 09 (2013)

3.2.1 The following terms are relevant to this standard: cross-machine direction, CD, length of tear, machine direction, MD,

tearing energy, tearing force, tear resistance, tearing strength, fabric.

3.3 For all other terminology related to textiles, refer to Terminology D123.

4. Summary of Test Method

4.1 A slit is centrally precut in a test specimen held between two clamps and the specimen is torn through a fixed distance. The

resistance to tearing is in part factored into the scale reading of the instrument and is computed from this reading and the pendulum

capacity.

5. Significance and Use

5.1 This test method for the determination of tearing strength by the falling pendulum type apparatus is used in the trade for

the acceptance testing of commercial shipments of fabrics, but caution is advised since technicians may fail to get good agreement

between results on certain fabrics. Comparative tests as directed in 5.1.1 may be needed.

5.1.1 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of

commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias

between their laboratories. Statistical assistance is recommended for the investigation of bias. As a minimum, the two parties

should take a group of test specimens that are as homogeneous as possible and that are from a lot of fabric of the type in question.

The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from

the two laboratories should be compared using appropriate statistical analysis and an acceptable probability level chosen by the

two parties before the testing began. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier

must agree to interpret future test results with consideration to the known bias.

5.2 Microprocessor systems for automatic collection of data can provide economical and reliable results when properly

calibrated. See Test Methods D2261 and D5587.

6. Apparatus

6.1 Falling-Pendulum (Elmendorf-Type) Tester —The tester includes: a stationary clamp, a clamp carried on a pendulum that

is free to swing on a bearing, means for leveling as applicable, means for holding the pendulum in a raised position, means for

instantly releasing the pendulum, and means for measuring the force to tear the test specimen.

6.1.1 A knife can be mounted on a stationary post for initial slitting of the specimens centered between the clamps and adjusted

in height to give a tearing distance of 43.0 6 0.15 mm (1.69 6 0.005 in.); that is, the distance between the end of the slit made

by the knife and the upper edge of the specimen is 43.0 6 0.15 mm (1.69 6 0.005 in.) when the lower edge of the 63.0-mm (2.5

6 0.005 in.) wide specimen rests against the bottom of the clamp.

6.1.2 With the pendulum in its initial position ready for a test, the two clamps are separated by a distance of 2.5 6 0.25 mm

(0.1 6 0.01 in.) and are aligned such that the clamped specimen lies in a plane parallel to the axis of the pendulum, the plane

making an angle of 0.480 rad (27.5 6 0.5°) with the perpendicular line joining the axis and the horizontal line formed by the top

edges of the clamping jaws. The distance between the axis and the top edges of the clamping jaws is 1036 0.1 mm (4.055 6 0.004

in.). The clamping surface in each jaw is at least 25 mm (1.0 in.) wide and 15.9 6 0.1 mm (0.625 6 0.004 in.) deep.

6.1.3 The tester may have a pointer mounted on the same axis as the pendulum to register the tearing force, or it may be

substituted by means of calculating and displaying the required results without the use of a pointer, such as digital display and

computer driven systems. Preferably the clamps may be air actuated, but manual clamping is permitted.

6.1.4 The test instrument should be equipped to provide interchangeable full scale force ranges. Typical full scale ranges are

shown in Table A3.1.

6.2 Calibration Weight(s) for graduation of 50 % of the full scale force range, or other means as described by the manufacturer

of the test apparatus.

6.3 Cutting Die having essentially the shape and dimensions shown in Fig. 1(a) or (b). Either die provides the basic rectangular

test specimen 100 6 2 mm (4 6 0.05 in.) long by 63 6 0.15 mm (2.5 6 0.005 in.) wide, along with additional fabric at the top

edge of the specimen to help ensure the bottom portion of specimen will be torn during the test. The critical dimension of the test

specimen is the distance 43.0 6 0.15 mm (1.696 0.005 in.) which is to be torn during the test.

NOTE 1—The improved die model shown in Fig. 1(a) has two new features not found in the original model, Fig. 1(b), namely a cutout for the bottom

of the specimen to aid in centering it in the clamps, and (optional) provision for cutting the 20.0 mm (0.75 in.) slit prior to inserting the specimen in the

tester. These dies can be made to order by most die manufacturers.

6.4 Air Pressure Regulator, capable of controlling gage air pressure between 410 kPa and 620 kPa (60 psi and 90 psi), when

applicable, for air clamps.

Apparatus is commercially available.

´1

D1424 − 09 (2013)

FIG. 1 Die Diagram for Cutting Notched Specimens

6.5 Setting Gage for Cutting Blade that will provide a cut slit that leaves a 43 6 0.15 mm (1.69 6 0.005 in.) specimen tearing

distance for a 63 6 0.15 mm (2.5 6 0.005 in.) wide specimen, or equivalent.

6.6 Jaw Spacing Gage 2.5 6 0.25 mm (0.1 6 0.01 in.) width, or equivalent.

6.7 Oil, light weight, non-gumming clock type.

6.8 Silicone Grease, when applicable, for air clamp lubrication.

6.9 Vacuum Cleaner, when applicable, for cleaning dust and fiber from sensor, or equivalent.

7. Sampling and Test Specimens

7.1 Lot Sample—As a lot sample for acceptance testing, randomly select the number of rolls or pieces of fabric directed in an

applicable material specification or other agreement between the purchaser and the supplier. Consider the rolls or pieces of fabric

to be the primary sampling units. In the absence of such an agreement, take the number of fabric rolls or pieces specified in Table

1.

NOTE 2—An adequate specification or other agreement between the purchaser and supplier requires taking into account the variability between rolls

or pieces of fabric and between specimens from a swatch from a roll or piece of fabric to provide a sampling plan with a meaningful producer’s risk,

consumer’s risk, acceptable quality level, and limiting quality level.

7.2 Laboratory Sample—For acceptance testing, take a swatch extending the width of the fabric and approximately 1 m (1 yd)

along the machine direction from each roll or piece in the lot sample. For rolls of fabric, take a sample that will exclude fabric

from the outer wrap of the roll or the inner wrap around the core of the roll of fabric.

7.3 Test Specimens—From each laboratory sampling unit, take five specimens from the machine direction and five specimens

from the cross-machine direction, for each test condition described in 9.1 and 9.2, as applicable to a material specification or

contract order.

7.3.1 Direction of Test—Consider the long direction of the specimen as the direction of test.

7.3.2 Cutting Test Specimens—Take the specimens to be used for the measurement of machine direction with the longer

dimension parallel to the machine direction. Take the specimens to be used for the measurement of the cross-machine with the

longer dimension parallel to the cross-machine direction. Use the cutting die described in 6.3 and shown in Fig. 1(a) or (b), as

applicable. When specimens are to be tested wet, cut from areas adjacent to the dry test specimens. Label to maintain specimen

identity.

7.3.2.1 In cutting the woven fabric specimens, take care to align the yarns running in the short direction parallel with the die

such that when the slit is cut, the subsequent tear will take place between these yarns and not across them. This precaution is most

important when testing bowed fabrics.

7.3.2.2 Cut specimens representing a broad distribution across the width and length, and preferably along the diagonal of the

laboratory sample, and no nearer the edge than one-tenth its width. Ensure specimens are free of folds, creases, or wrinkles. Avoid

getting oil, water, grease, etc. on the specimens when handling.

NOTE 3—The reading obtained is directly proportional to the length of the material torn, therefore, it is essential that the specimen be prepared to the

exact size specified.

TABLE 1 Number of Rolls or Pieces of Fabric in the Lot Sample

Number of Rolls or Pieces Number of Rolls or Pieces in Lot

in Lot, Inclusive Sample

1 to 3 all

4 to 24 4

25 to 50 5

over 50 10 % to a max of 10 rolls or pieces

´1

D1424 − 09 (2013)

8. Preparation of Apparatus and Calibration

8.1 Select test instrument force range, such that the tear occurs between 20 and 80 % or 20 and 60 % of the full-scale range

as applicable. Ensure the clamps are spaced as directed in A1.4.

NOTE 4—For standard test apparatus, the useable portion of the full scale force range is 20 to 80 %. For the high capacity test instrument, the useable

portion of the full scale force range is 20 to 60 %.

8.2 When equipped with a registering sensor, examine the scale and the complementary sensor, as applicable. Using care and

without touching the sensor, vacuum away any loose fibers and dust.

8.3 Examine the knife edge for sharpness, wear, and central alignment as directed in A1.5 – A1.7.

8.4 For air clamps, set the air gage pressure to the clamps to about 550 kPa (80 psi).

8.4.1 Maximum gage pressure should be no more than 620 kPa (90 psi) and minimum gage pressure no less than 410 kPa (60

psi).

8.5 When using microprocessor automatic data gathering systems, set the appropriate parameters as defined in the

manufacturer’s instructions.

8.6 Verify the calibration of the selected pendulum full scale force range using the procedure described in Annex A2, unless

otherwise specified.

9. Conditioning

9.1 Condition 1, Standard Testing Conditioning:

9.1.1 Precondition the specimens by bringing them to approximate moisture equilibrium in the standard atmosphere for

preconditioning textiles as directed in Practice D1776, unless otherwise directed in a material specification or contract order.

9.1.2 After preconditioning, bring the test specimens to moisture equilibrium for testing in the standard atmosphere for testing

textiles as directed in Practice D1776 o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.